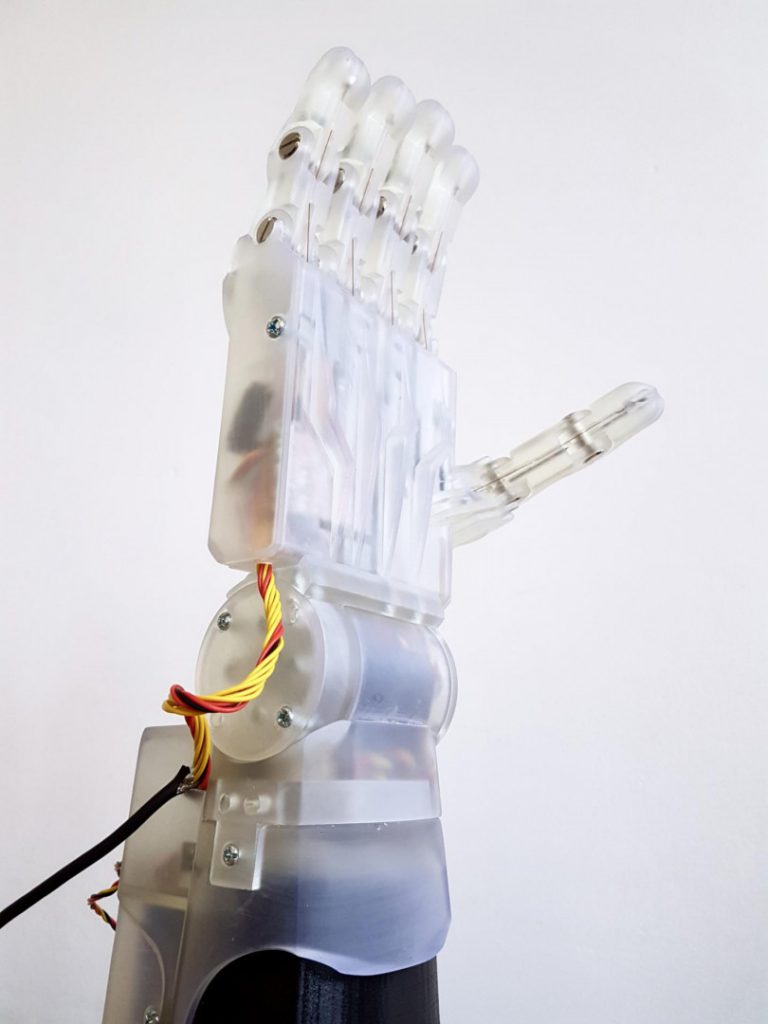

Robot hand 3d print

Build your own 3D printed robotic hand in under an hour — Open Bionics

Today Open Bionics announced the release of their first open source 3D printed robotic hand kit. The ‘Ada hand’.

The team, based in the UK’s Bristol Robotics Lab, have released their first robotic hand called ‘Ada’ complete with tutorials, detailed build instructions, and bill of materials. Check it out on their website or on Instructables, Thingiverse, and Youmagine.

The project is currently featured by editors on Instructables.

Open Bionics said they wanted to offer the robotics, maker, and 3D printing community the easiest to make open source robotic hand, and this release can be built within an hour.

Instead of spending tens of thousands on robotic hands for research robots like Baxter, Open Bionics says build your own for £500.

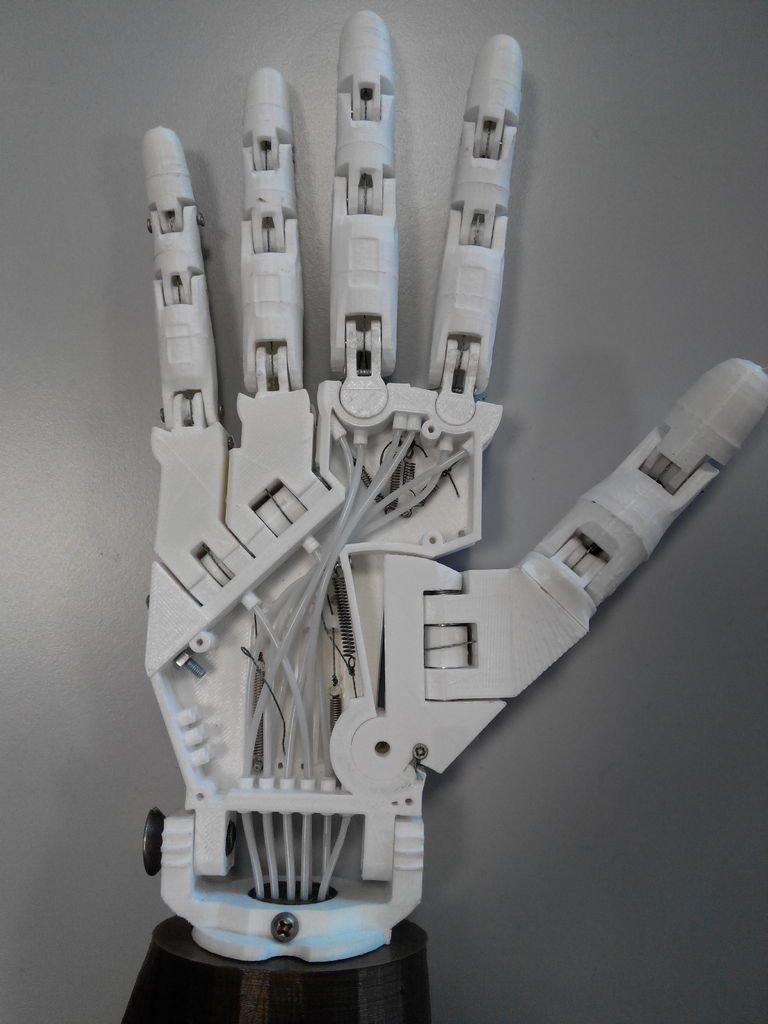

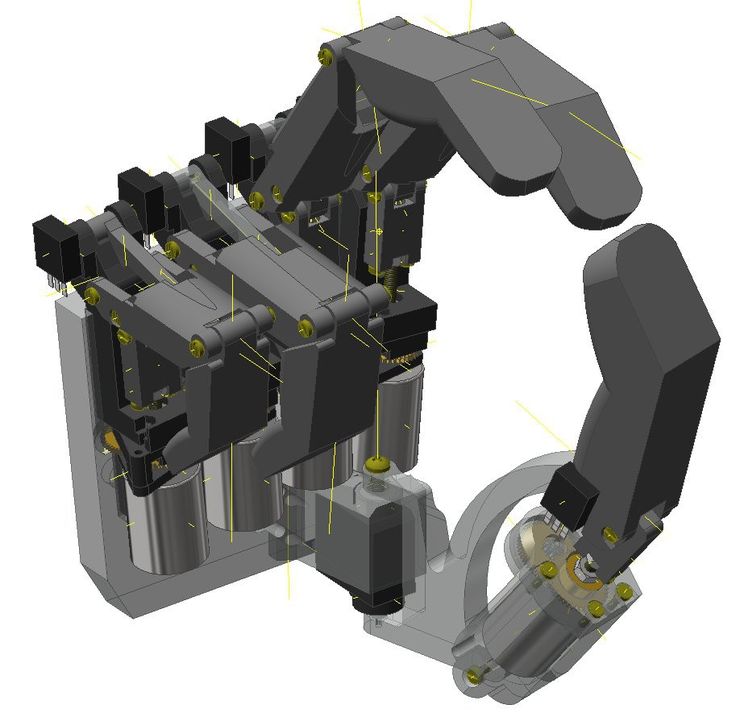

The Ada Hand is a fully articulated robotic hand from Open Bionics. It is a kit of parts and can be assembled in around 1 hour using standard tools. The hand has 5 degrees of freedom (DOF) and can be controlled from a PC or MAC over USB connection. The Ada hand houses all of the actuators required to move the fingers as well as its own custom control printed circuit board (PCB). The PCB is based around the ATMEGA2560 microcontroller and can be programmed using the Arduino programming environment which will be familiar to many developers.

The Ada hand is perfect for anyone that is doing a project with robotic hands or wants a neat, light, and functional robotic hand for use with a humanoid robot.

Open Bionics’ ‘Ada’ hand is very different to the original ‘Dextrus’ hand. The print and assembly time has been made radically faster and easier.

Joel Gibbard, Open Bionics’ CEO, said the team wanted to make robot hand building easy.

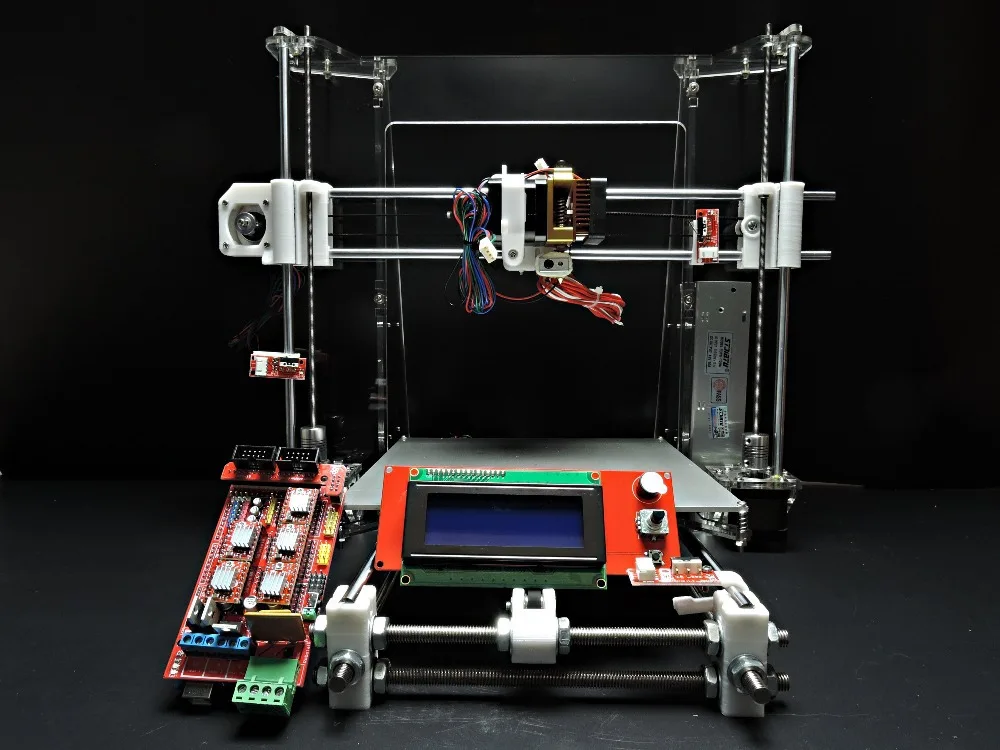

“We know there are hundreds of people around the world that really want to contribute to designing a fantastic robotic hand, both for applications in robotics and in prosthetics. At the moment there is a large barrier to entry to getting involved in this project and contributing to developments. With the Ada hand we want to remove that barrier. The hand is 3D printable on an FDM desktop home printer and can be assembled in an hour, we’ve also created a developer community so people can sign up and post their developments in our forums. We’ll constantly be suggesting bite-sized projects for developers to take on and taking feedback from them about what else they need."

With the Ada hand we want to remove that barrier. The hand is 3D printable on an FDM desktop home printer and can be assembled in an hour, we’ve also created a developer community so people can sign up and post their developments in our forums. We’ll constantly be suggesting bite-sized projects for developers to take on and taking feedback from them about what else they need."

“I think one of the big barriers to people making and starting projects is a daunting magnitude of the build and a lack of documentation, instruction, and guidance. We are trying really hard to make sure we have detailed and easy to follow assembly instructions, comprehensive data sheets, and lots of tutorials to suit all levels of ability.

“We’re trying to make this as easy as we can for people with any level of technical ability. For example, if a researcher is studying robot interaction and needs a robot hand, but building a robot hand from scratch isn’t part of her/his project and they’re looking at affordable options, we want this build available to them and for it to be quick and easy. ”

”

Part of this move is to encourage developers to post their research in the newly opened Open Bionics’ developer forum.

Joel added: “We receive a lot of emails from researchers who want to buy or make our hands. But we receive more emails from researchers and makers who want to contribute to our goal of making low-cost 3D printed bionic hands readily available for amputees. We’ve had a handful of researchers who have used our hands to contribute to award-winning medical research and prosthetic testing. We’re hoping that by making our robotic hands easier to make, we’re opening up the possibility for more researchers to get involved and contribute.”

Open Bionics named their robotic hand after Ada Lovelace, celebrating Lovelace’s contribution to programming.

Olly McBride, Open Bionics’ Software Engineer said: “Ada's vision was to develop the capability of computers to go beyond mere calculating and number crunching, our robotic hands are an embodiment of this development as embedded programming has enabled us to programme multiple grip modes for this hand. ”

”

This was a big release for Open Bionics. In the week since the developer forum opened they’ve had 109 makers, engineers, and amputees sign up to contribute to our research and development.

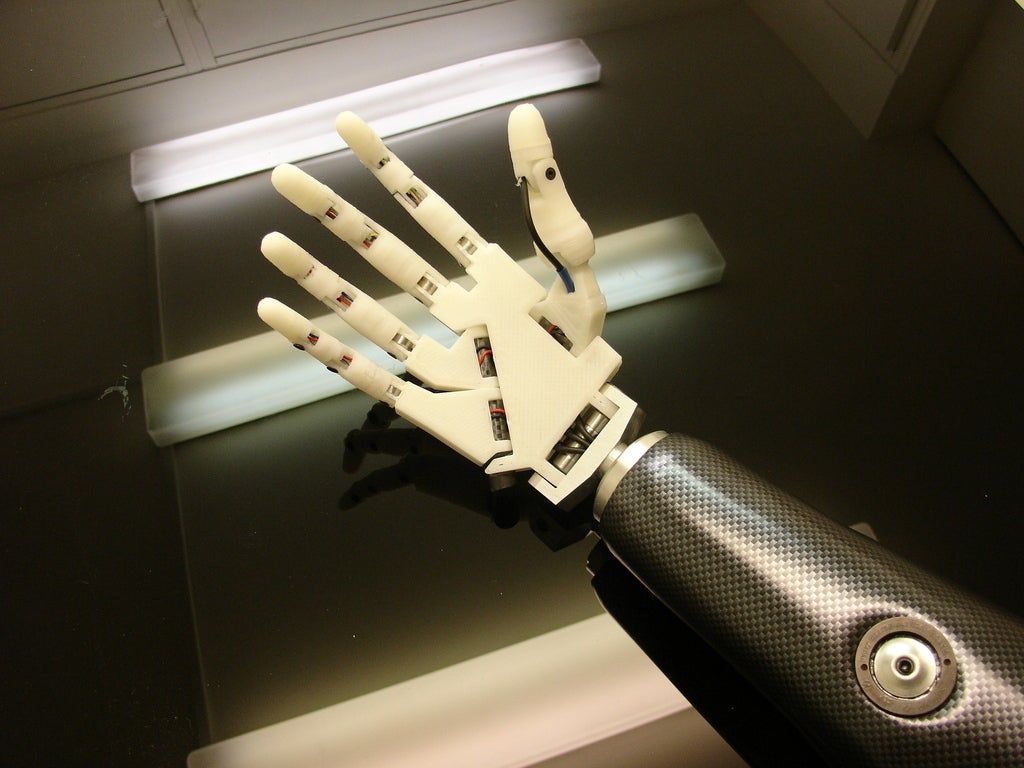

Open Bionics is an award-winning robotics company creating affordable 3D printed bionic hands for amputees. Last year they announced a deal with Disney to create official Iron Man, Star Wars, and Frozen hands for amputees.

Join the Open Bionics developer community! 3D print your own hand with a print time of 24 hours or buy an assembly kit with all components here.

Build Your Own 3D Printed Robotic Hand in Less than an Hour

0Shares

Open Bionics has been making significant progress in the world of 3D printed prosthetic hands, outfitting young and old alike with their bionic limbs. And, after joining the Disney Accelerator program, they were able to transform their robotic hands so that they could transform a handful of kids into super heroes and princesses with Iron Man, Frozen, and Star Wars-themed prosthetics. Now, the UK-based Open Bionics is ready to bring their designs to the masses with their first open source 3D printed robotic hand kit.

Now, the UK-based Open Bionics is ready to bring their designs to the masses with their first open source 3D printed robotic hand kit.

With the .STLs uploaded to Instructables, Thingiverse, Youmagine, and their own site, along with tutorials, instructions, and a bill of materials, the ‘Ada Hand’ is a completely open source kit that allows anyone to 3D print and build their own robotic hand. In total, the parts to build the device cost around £500, a fraction of the tens of thousands of dollars required to purchase a robotic hand from a manufacturer. While it may take about 24 hours to print, Open Bionics says that it should take less than an hour to build it!

The Ada Hand is a fully articulated robotic hand with five degress of freedom and that can be controlled via PC or Mac with a USB connection. Powered by a custom PCB designed around the ATMEGA2560 microcontroller, the hand itself stores all of the actuators to move the fingers and can be programmed with the Arduino programming language. In this way, the hand is ideal for those hoping to research robotics or are even thinking about building a hand for their own robot project.

In this way, the hand is ideal for those hoping to research robotics or are even thinking about building a hand for their own robot project.

Unlike Open Bionics’ original Dextrus hand, the Ada hand is mean to be faster and easier to build. Joel Gibbard, Open Bionics’ CEO, says of the new design, “We know there are hundreds of people around the world that really want to contribute to designing a fantastic robotic hand, both for applications in robotics and in prosthetics. At the moment there is a large barrier to entry to getting involved in this project and contributing to developments. With the Ada hand we want to remove that barrier. The hand is 3D printable on an FDM desktop home printer and can be assembled in an hour, we’ve also created a developer community so people can sign up and post their developments in our forums. We’ll constantly be suggesting bite-sized projects for developers to take on and taking feedback from them about what else they need. ”

”

He continues, “I think one of the big barriers to people making and starting projects is a daunting magnitude of the build and a lack of documentation, instruction, and guidance. We are trying really hard to make sure we have detailed and easy to follow assembly instructions, comprehensive data sheets, and lots of tutorials to suit all levels of ability. We’re trying to make this as easy as we can for people with any level of technical ability. For example, if a researcher is studying robot interaction and needs a robot hand, but building a robot hand from scratch isn’t part of her/his project and they’re looking at affordable options, we want this build available to them and for it to be quick and easy.”

At the same time, Open Bionics has opened a developers forum to meet the increasing demand for their designs and a place to share research around those designs. Since the forum opened, they’ve already had 109 members join. Gibbard says, “We receive a lot of emails from researchers who want to buy or make our hands. But we receive more emails from researchers and makers who want to contribute to our goal of making low-cost 3D printed bionic hands readily available for amputees. We’ve had a handful of researchers who have used our hands to contribute to award-winning medical research and prosthetic testing. We’re hoping that by making our robotic hands easier to make, we’re opening up the possibility for more researchers to get involved and contribute.”

But we receive more emails from researchers and makers who want to contribute to our goal of making low-cost 3D printed bionic hands readily available for amputees. We’ve had a handful of researchers who have used our hands to contribute to award-winning medical research and prosthetic testing. We’re hoping that by making our robotic hands easier to make, we’re opening up the possibility for more researchers to get involved and contribute.”

Olly McBride, Open Bionics’ Software Engineer, describes the inspiration for this new hand, Ada Lovelace, often considered the world’s first computer programmer. “Ada’s vision was to develop the capability of computers to go beyond mere calculating and number crunching,” McBride says. “Our robotic hands are an embodiment of this development as embedded programming has enabled us to programme multiple grip modes for this hand.”

The Ada Hand can be found on various locations throughout the web, as mentioned previously. Or you can purchase the complete kit, including 3D printed parts, at the Open Bionics shop.

Or you can purchase the complete kit, including 3D printed parts, at the Open Bionics shop.

Michael Molitch-Hou

Michael Molitch-Hou previously served as Editor-in-Chief of 3D Printing Industry, he is now the Editor of Engineering . com's 3D printing section. He has covered additive manufacturing technology day in and day out since 2012 and has hundreds of article to his credit. He is the founder of The Reality Institute.

Free STL file Perfect Robot Arm・3D printing design to download・Cults

Fishing boat

Free

Red firefighter helmet

Free

Motorcycle helmet

Free

Real 3D head

Free

Real toilet

Free

Iron Man 3D

Free

3D Lego Man

Free

Speedboat

Free

Best 3D Printer Files in the Gadget Category

ISS and LEO satellite tracker

Free

CHARGE/EUROCENT HOLDER

0,90 €

IKEA GLIS CABLE BOX

3,59 €

Multibox (closed 180x370 mm) construction Contenitore multipla trasportabile Multibox

2,99 €

dragon on crystal ball

free

Phone Holder - Porta Celular

1 €

Hygienic can lid

Free

Bestsellers in the Gadget category

Working steam engine, printed on site, fully assembled, without supports

3. 38 €

38 €

Dice box with mechanical rotating top

4.05 €

CYLINDER WALL/PISTON 2-STROKE

0,91 €

ENGINE BLOCK - WALL KEY HANGER

1,83 €

Writing Machine V2.0 - 2D pen plotter

6.82 €

Keychain "Fussy Cauldron" - Halloween

1.89 €

Double text illusion application

3.72 €

Karambit keychain spinner tiktok keyrambit NO BEARING

€1.71 -ten% 1.54 €

Brush rinse

2.25 €

Case for PIXEL 7 (two designs)

0,96 €

Case for PIXEL 7 PRO (two designs)

0,96 €

Duck with pumpkin

1. 25 €

25 €

App to turn your photo into 10 types of jewelry

3.72 €

G17- DD17 Frame with rails

7.50 €

Bumper DJI Avata

5 €

wall key holder (dragon ball)

1.25 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Top 10 DIY 3D Printing Arms

3DPrintStory Reviews 10 Best DIY 3D Printing Manipulators

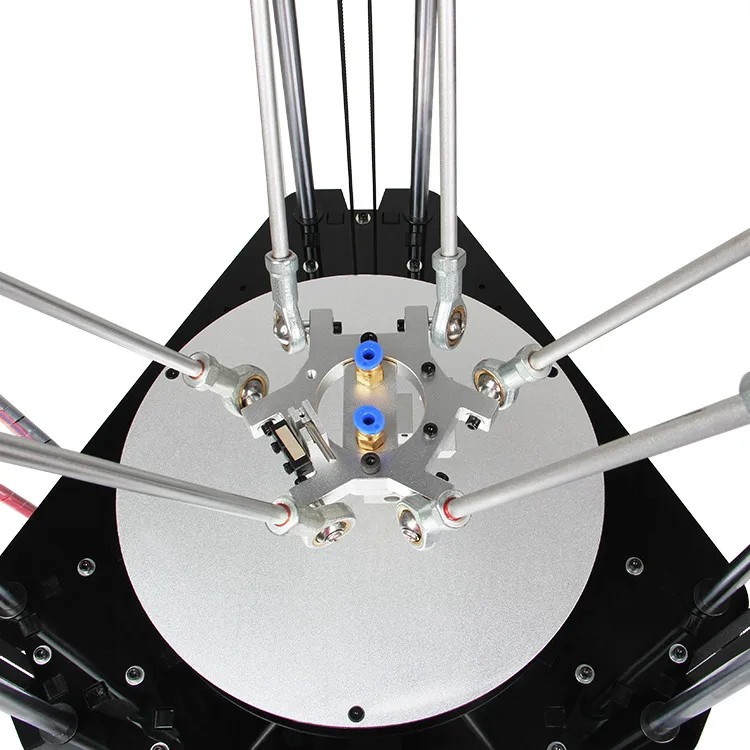

There are many different configurations of robotic arms, but most of them work on the same general principles of movement. Unlike mechanisms that work in the Cartesian coordinate system, such as, for example, 3D printers, manipulators mostly use the polar coordinate system for movement and have an arc-shaped work area. Robotic arms are unique in that they are not limited by footprint and take up very little space compared to other machines with similar functions.

In robotics there is such a definition as degrees of freedom (DOF). The term is used to refer to the number of rotating joints or axles on a particular arm, for example a 4DOF arm can be rotated by four separate joints.

Robotic arms are used in a variety of ways, but most are capable of picking up and moving, while some are designed to work in tandem with CNC machines, laser engraving, and even 3D printing.

Since there are hundreds of great designs and designs to consider when choosing a good arm to buy or 3D print, we've narrowed it down to 10 of the best and most popular arms that you can find and reproduce designs using your 3D printer's capabilities as well. .

UFactory uArm

UArm is probably one of the most versatile of all the robot arms on this list. At the moment, this design already has the third release version - uArm Swift and more functional Swift Pro.

This open source robot arm is fully compatible with Arduino, Raspberry Pi and Seeed Studio Grove kits. It's unique in that the Swift Pro can do laser engraving and 3D printing - provided it's equipped with the right heads - and can "learn" the movements without the need for a computer.

It's unique in that the Swift Pro can do laser engraving and 3D printing - provided it's equipped with the right heads - and can "learn" the movements without the need for a computer.

This is a 4DOF manipulator with an accuracy of 0.2 millimeters.

You can find more information and where to buy it on the UFactory product page.

Thor

This manipulator developed by Hackaday AngelLM is completely open source and can be used for 3D printing. This is a 6DOF paddle with a maximum payload of 750 grams and a unique design for great flexibility.

You can find all the 3D printing files for this robot on the Thor project page.

EEZYbotARM MK2

The EEZYbotARM MK2 is a 4DOF reference arm, fully 3D printed with excellent building instructions. This robotic arm has won several competitions and is probably one of the easiest robotic arms to make. An MK3 version is also being developed.

You can find complete assembly instructions on the EEZYbotARM webpage.

Roboteurs RBX1

This is another great fully 3D printed robot arm that has amazing flexibility and aesthetics. In addition to purchasing the components yourself, Roboteurs offers a complete parts kit with a proprietary stepper motor driver to run the RBX1. All you need is a Raspberry Pi and a 3D printer. This manipulator is a 6DOF type design and has a beautiful appearance.

You can find the complete specification and parts kit on the Roboteurs product page.

LittleArm

LittleArm, designed by Slant Concepts on Hackaday.io, is the simplest robotic arm on this list. With only 3DOF, this arm can be a great introduction to Arduino programming for students and opens exciting doors of new technologies for newcomers to the world of 3D printing and robotics.

This fully 3D printed arm is very easy to assemble. The creators even developed an application with a simple interface for computers that can be used with this robot.

You can find full documentation on the LittleArm project page.

3D Printable Robot Arm

Created by Andreas Helldorfer on Hackaday.io. It's a large arm, fully 3D printed, with many uses. The creator developed it for 4 iterations before making a really worthy industrial design that is available to everyone. With a 6DOF design and a maximum payload of up to 2kg, this arm can really be used in many applications.

To find the 3D printable files for this arm and the full specification, visit the project page.

MeArm

MeArm is one of the most popular manipulators and for good reason. It consists of simple parts that can be laser cut or 3D printed and features a simple yet robust 4DOF construction.

This design is so popular that two others on this list copy it. This is a manipulator equipped with four servos and either an Arduino or a Raspberry Pi. It is available in several different colors as a kit, or you can make all the parts yourself.

For pre-assembled kits, check out the MeArm product page.

For 3D printing files, take a look at MeArm on Thingiverse.

Zortrax Robotic Arm

The Zortrax 5DOF robotic arm is not the strongest for its size, with a maximum payload of only 100 grams, but it has a very impressive design. And it's a fully 3D printed arm, making it worthy of a mention on the current list. Its uniqueness lies in the fact that only three axles are driven, while the rest are set manually.

This manipulator is primarily used for supplying a set of interchangeable tool heads.

For a complete list of part files, including those for 3D printing, visit the project page.

BCN3D Moveo

BCN3D Moveo is an impressive Arduino controlled 4DOF robot arm. It is fully 3D printed, open source, and has been well tested as a mockup for educational purposes and is already in active use in educational institutions.

Being open source, this manipulator is not limited to its intended use and as such can be modified to perform all kinds of tasks and can be used as a dedicated household apprentice or used on an industrial scale.