3D printed static mixer

This 3D Printed Syringe Static Mixer Does It All

- by: Steven Dufresne

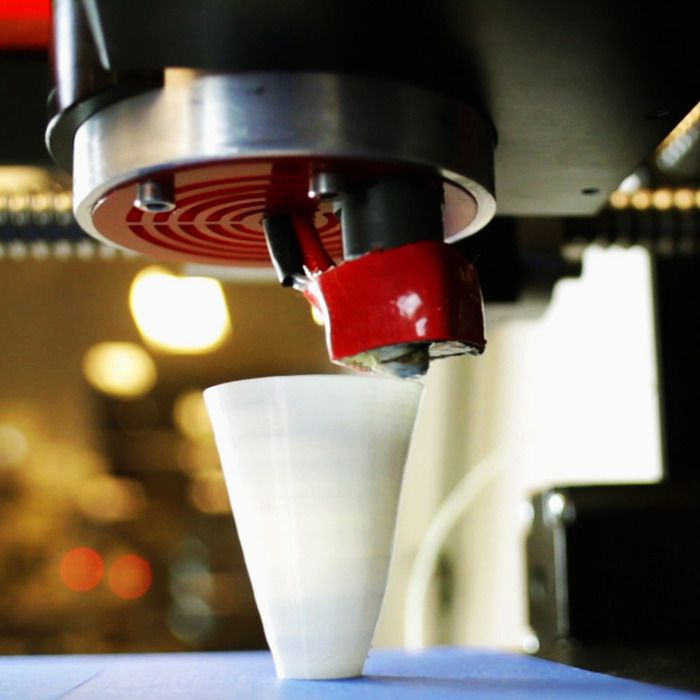

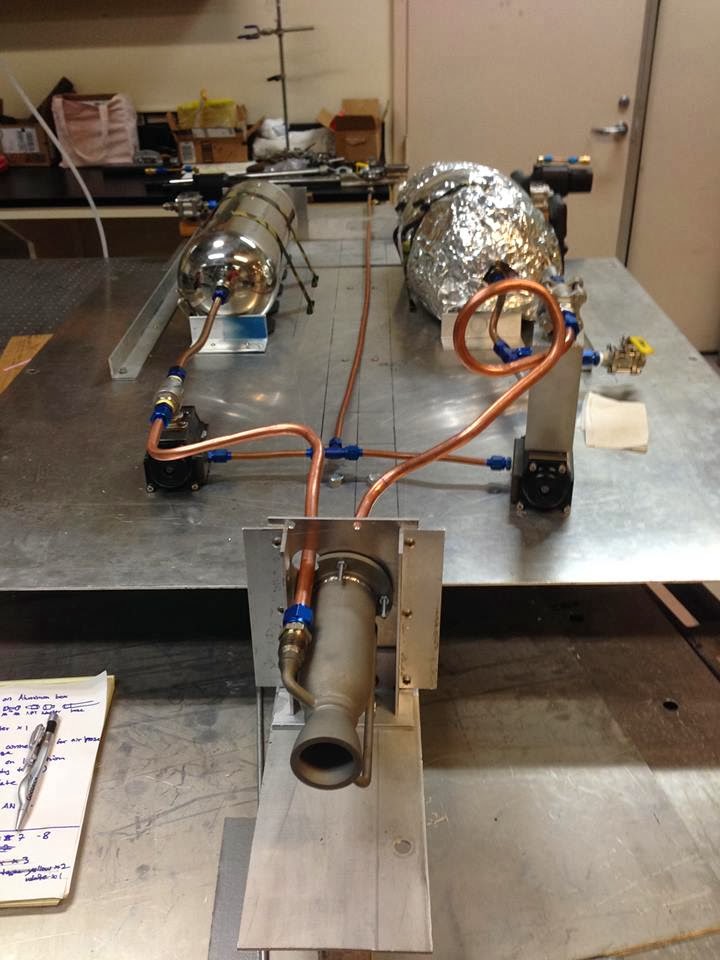

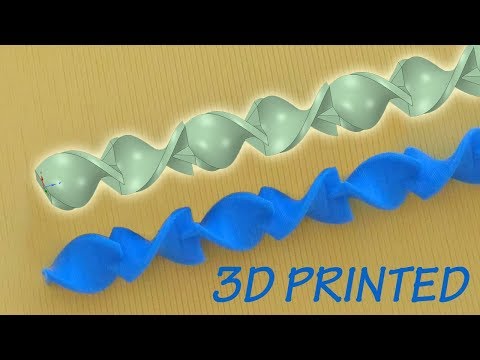

One trick for getting the bubbles out of freshly mixed 2-part epoxy, aka degassing, is to go over it gently with the flame from a propane torch. But both the mixing and degassing take time. [Gianteye] came up with a 3D printed dual-syringe static mixing system which speeds up the process. He used it with silicone to get the difficult steps out of the way quickly for his hands-on soft robotics class, allowing the students to focus more on the matter at hand. But we figure most readers might use it for epoxy.

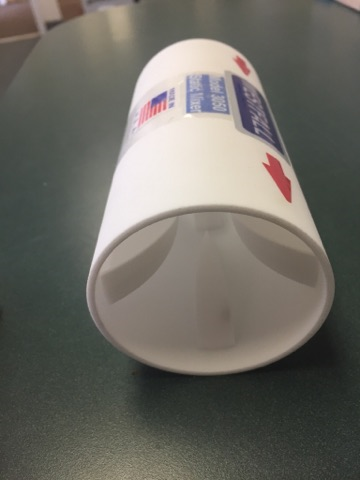

Mixing tube interiorIf you’ve bought those 2-part epoxy syringes available in stores before then you’ll know that they usually come with two syringes, each filled with one of the two parts to be mixed. Depressing the syringes causes each part to come out of its own tube. It’s then your job to mix them together and degas the result.

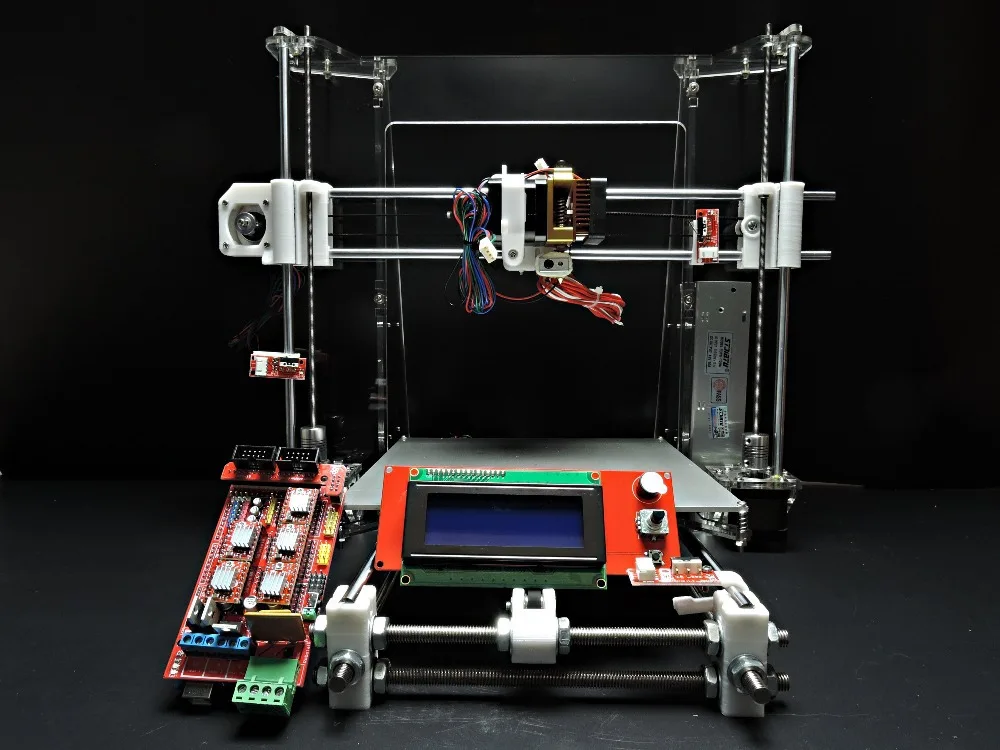

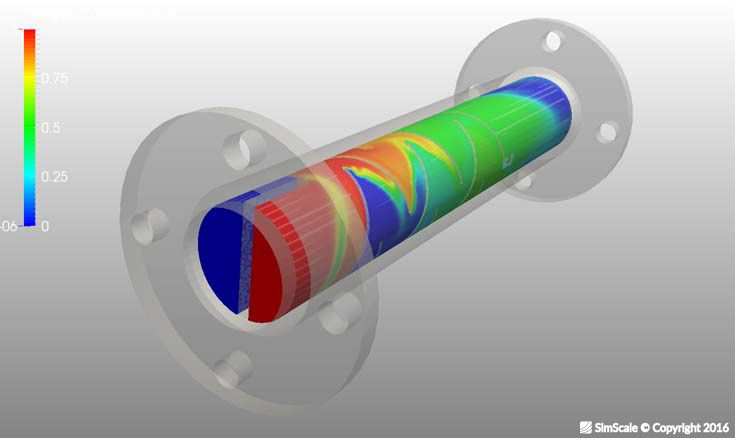

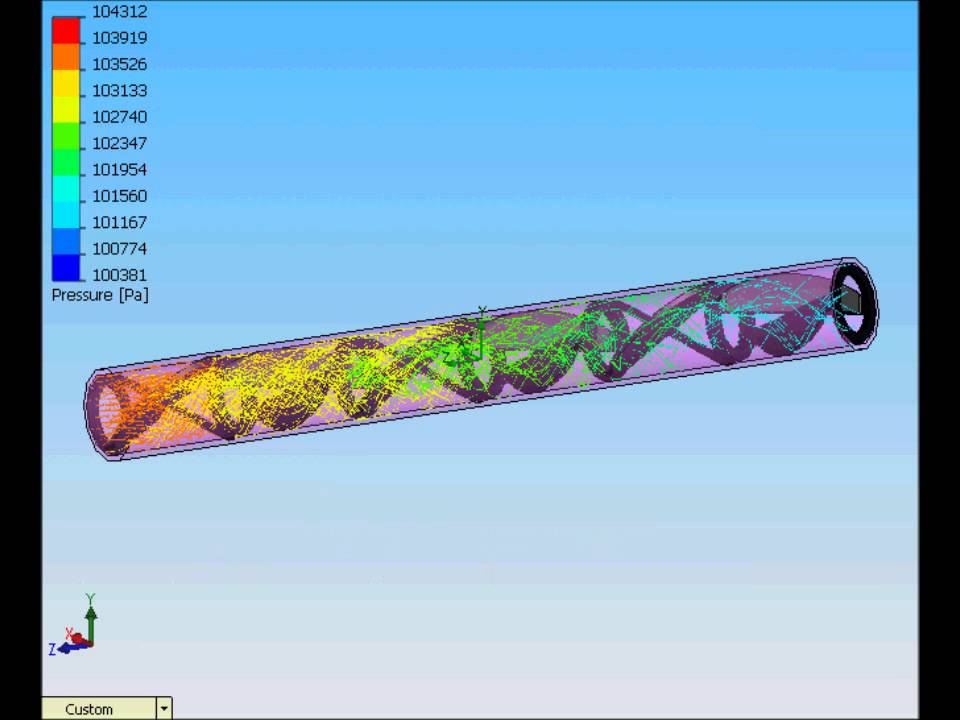

[Gianteye’s] system consists of 3D printed parts and two syringes. Models for the 3D printing are available on his Thingiverse page and the syringes can be found online. Some of the 3D printed parts help you first fill and degas the syringes. You then attach a 3D printed mixing tube to the ends of the syringes. This tube serves two purposes. When the syringe’s plungers are depressed, both parts of the material are forced through the tube and extruded out. But on their way through, both parts pass through eight helices which form 180° turns and mix the parts together. Out comes the portioned, mixed and degassed material which can go straight into a mold or to wherever you need it.

The mixing tube was designed for one-time use but [Gianteye] discovered during an evaluation that it can be reused if you pull out any cured material and purge it. The evaluation involved silicone though. With hardened epoxy, you’ll probably have to use a new tube each time.

Check out the full details of his system in the video below, including both assembly and usage.

If you’re looking for a metallic look for something without wanting to cast metal than have a look at our own [Gerrit Coetzee’s] article about cold casting wherein he makes some very nice looking parts.

Static Mixer with 3D Printed Nylon Inserts Saves Industry Customers Time and Money - 3DPrint.

com

comUsually when I think about mixers, I start dreaming about baking brownies and cakes for birthday parties and holidays. 3D printing technology has been used to make hand mixers, both electric and manual. In 2016, a handheld Thor3D Scanner and a ceramic composite mold were used to help a large bakery, which operates several professional-grade dough mixers, come up with a less time-consuming and costly way to replace the spiral screw that actually mixes the dough.

But there are other types of mixers out there – cement mixers, for one, and 3D printing technology was also used to create a unique mixer that can mix together multiple materials in zero gravity conditions.

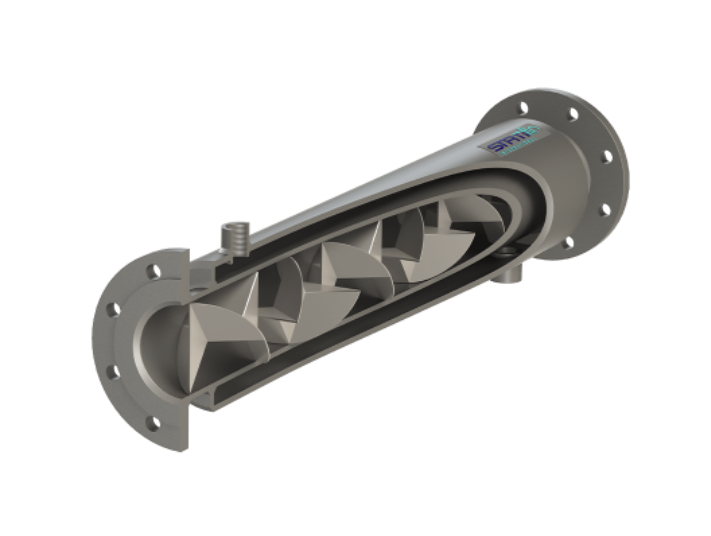

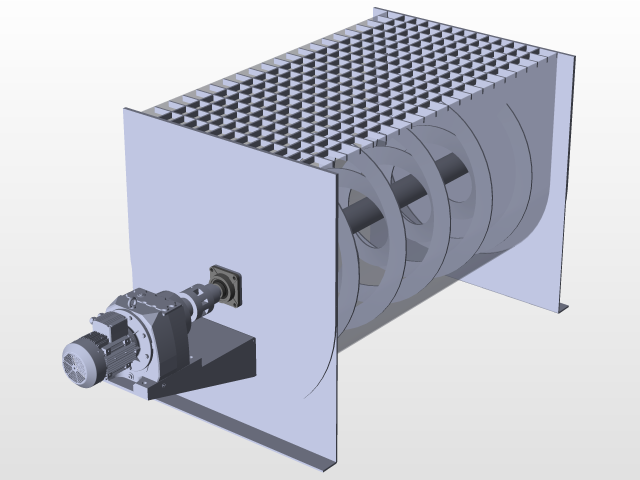

Located near the Port of Providence, Rhode Island, Westfall Manufacturing specializes in high-performance drop-in motionless (static) mixers, which are used in pipeline and blending systems for multiple industries, such as aerospace, water and wastewater treatment, oil, gas and biofuels, chemical, food and beverage, and insulation.

Each of the company’s many static mixers, which provide energy-efficient, high performance mixing for decades, is designed and custom manufactured to solve a specific customer problem, such as retrofits and infrastructure upgrades. Westfall specializes in oversize mixers, but as the company recently added 3D printing technology to its workflow, it can now fabricate smaller static mixers.

The company had been receiving requests from customers, asking for its patented Low Headloss Mixer 3050 in a smaller size, specifically in the 3/8″ to 5″ range – far too small to cost-effectively fabricate using custom stainless steel or fiberglass.

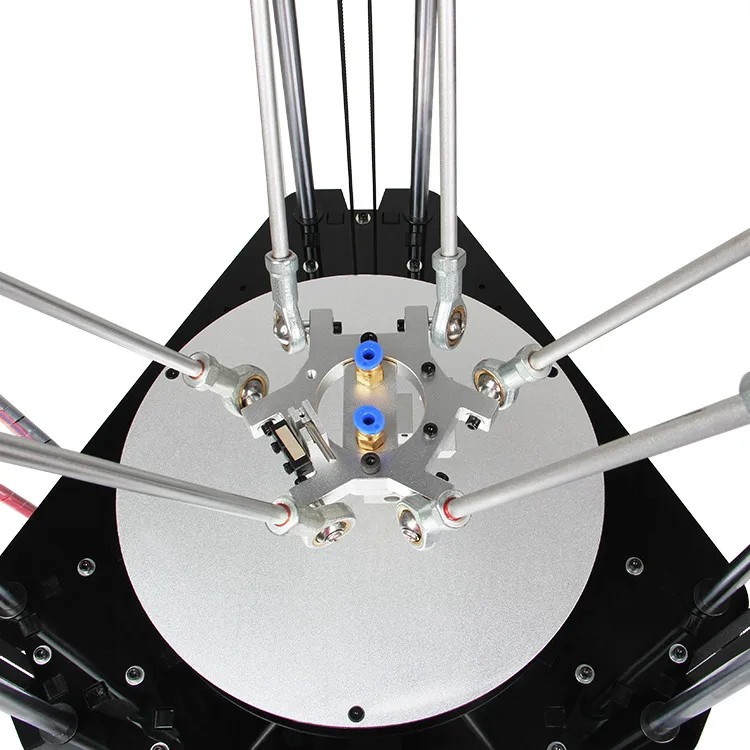

The company has patented mixing vanes, and four of these tapered and curved vanes are welded around the interior of the mixer’s pipe. Each vane is angled 45° to resist fouling, which gives the Low Headloss Mixer 3050 series the ability to provide precise mixing, with two to four times less headloss than other static mixers provide and no maintenance.

While trying to figure out how to make the mixer smaller, engineers at Westfall knew that the material choice didn’t matter as much as the geometry – so long as the hydrodynamics stayed the same, fiberglass, metal, or even 3D printed nylon could be used. So the company decided to apply 3D printing technology to the manufacturing process for its Low Headloss Mixer 3050.

Engineers manufactured a smaller version of the mixer by 3D printing vanes and inserts out of durable nylon material, which were then attached to the inside of a PVC pipe with glue.

The 3D printed inserts can be made from multiple materials, such as stainless steel and Kynar, but the durable nylon used in this smaller, pre-assembled Static Mixer is able to hold up better under steady exposure to harsh chemicals like oil, gas, and caustics.

“For mixing low velocity, low viscosity water and gases, durable 3D printed nylon inserts are the wave of the future.

For mixing high velocity and high viscosity fluids, durable 3D printed stainless steel inserts are the wave of the future,” said Westfall CEO Bob Glanville. “Either way, 3D printing makes our high performance Static Mixers more affordable to customers around the world.”

By using 3D printing technology to make the mixer in a smaller size, Westfall’s many customers can save on both time and money.

Let us know your thoughts; join the discussion of this and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

[Sources: Westfall, PR Newswire / Images: Westfall]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed inserts • 3d printed mixer • 3D printing nylon • Nylon • pipe mixer • Westfall

Please enable JavaScript to view the comments powered by Disqus.

The German company Grohe prints faucets on a 3D printer / Habr

Leonid_R

Design 3D printers

Futuristic metal faucets joined the Grohe lineup in the summer of 2019. However, you can buy them so far only in offline stores in Europe.

Source: Grohe

Grohe explains that the Atrio Icon 3D faucet component consists of 4,700 metal layers, each 0.06 millimeters thick. Faucets are printed from metal powder. After printing, the component is ground first on a milling machine and then manually. Grohe clarifies that the Atrio Icon 3D will not be mass-produced – each faucet will be made individually to order.

A total of four printed faucets are available in the range. The price of all four copies is decent - the mixer will cost 11,998 euros per set.

Seum added that in the final design, Grohe managed to create an ambivalent impression on the buyers. When a person looks at the Atrio Icon 3D in profile, he sees more of a crane in a traditional design.

“That's the impression you get until you look sideways and see his silhouette. From this vantage point, a person sometimes does not believe that the faucet is so thin and does not understand where the water comes from in the end,” adds Seum.

3D printed metal faucets are not new to the plumbing market. Back in 2016, American Standard introduced an exclusive series of its faucets, which differ from Grohe in smoother lines. American cranes manufactured by contractor DXV by order of American Standard cost decently: from 12 thousand to 20 thousand dollars - and are also made only to order.

Source: DXV

In addition to filling bathrooms, the rooms themselves are already being printed on 3D printers. A research team from Nanyang Technological University has developed a special concrete mix infused with geopolymers. During the printing process, the concrete remains watery enough to properly distribute through the 3D printer's hoses and nozzle, but is able to harden quickly enough for the machine to apply another layer on top of it shortly thereafter. The final design does not let water through and allows you to equip a real bathroom inside. However, mixers, like other stuffing, it uses ordinary ones.

A research team from Nanyang Technological University has developed a special concrete mix infused with geopolymers. During the printing process, the concrete remains watery enough to properly distribute through the 3D printer's hoses and nozzle, but is able to harden quickly enough for the machine to apply another layer on top of it shortly thereafter. The final design does not let water through and allows you to equip a real bathroom inside. However, mixers, like other stuffing, it uses ordinary ones.

Tags:

- Design

- 3D -ip

- 3D printer

Habs:

- Design

- 3D printers

TALKER 15: ↑ 14 and ↓ 1 +13

6.9 K

Comments 5

Leonid Romashchenko @Leonid_R

User

Comments Comments 5

Shocks in the bathroom: causes and what to do

Contents of article

- 1 The essence and the reasons for the phenomenon

- 1.

1 devices malfunction

1 devices malfunction - 1.2 damage or wiring dilapidation

- 1.3 Unauthorized grounding

- 1.4 Loss of contact

- 1.5 Warm 3 Apartment solutions

- 3.1 Old housing stock

- 3.1.1 Protective earthing

- 3.1.2 Grounding

- 3.1.3 Protective shutdown

- 3.1.4 Potential equalization

- 3.1.5 Separation of circuits, Super -short voltage

- 3.2 New building

- 3.2.1 DSUP

- 3.1 Old housing stock

- 4 Private house

- 4.1 TT system 900.2

- 4.3 TN Systems

- 5 Reliability

The situation when the water in the bathroom is surging requires immediate action. Until the cause is clarified, prohibit loved ones from using the bathroom in order to avoid mortal danger!

The essence and causes of the phenomenon

There are two sources of discomfort:

- static electricity;

- exposure to mains voltage: water, plumbing, pipes, equipment cases.

The first one causes only tingling. Synthetic, woolen clothing accumulates a charge flowing down when touching metal objects. The potential reaches thousands of volts, but the current is negligible. You can remove static less sensitively by touching the steel pipe or mixer with the back of your hand. A static discharge does not repeat itself twice in a row.

A strong blow indicates a second source that threatens health and life. The reasons why the equipment of the shower room is energized are various, the main ones are: Scale causes local overheating, tube rupture, ceramic cracks, through which water penetrates to the spiral. The process progresses from microcurrent leaks to a full circuit through the liquid.

- 1.

- Water seeps through the permeable gaskets to the heating element clamps, which can short-circuit. A powerful machine, with a margin “so as not to knock out”, will not turn off the power; with a two-wire network, you will not envy the owners.

- Violation of the insulation of the electric motor of the washing machine, control unit.

Often these are the consequences of vibration, the “jumping” unit simply tears the cord.

Often these are the consequences of vibration, the “jumping” unit simply tears the cord.

Damaged or dilapidated wiring

Unauthorized grounding

Loss of contact

- Loss of contact of the potential equalization circuit with the PE bus of the shield causes the possibility of widespread electric shocks. Soviet dwellings are not equipped with such a tire, connection with PEN increases the risk many times over (see 3.1.2).

Manipulation in the panel is the prerogative of professionals, call the service organization, call an electrician to troubleshoot.

Underfloor heating

Electric underfloor heating breakdown, laid without observing electrical safety measures: no metal ground mesh, poor waterproofing, non-rigid floor covering.

Incorrect location of sockets

Insufficient degree of protection of electrical installation devices, electrical appliances leads to leakage currents, breakdown:

Contacting with the above, a person closes the circuit between the phase and the ground, a current passes through the body, the strength of which is inversely proportional to the resistance of the section.

Reference: the bathroom is classified as a particularly dangerous room, the requirements for electrical installations are contained in chapter 7.1 of the PUE; GOST R 50571.11-96.

In detail: How to make the wiring in the bathroom.

Troubleshooting

You will need an indicator screwdriver or multimeter. A device with a resistor and a neon lamp will work at a voltage above 60 V, an LED one is more sensitive, models with an LCD display will show a value of 12 V or more. Accurate measurements are taken with a multimeter, setting the limits one by one from the highest.

For safety reasons, do not touch the tested equipment with your hands, put on dry slippers, put on household rubber gloves. The algorithm of actions is as follows:

- Turn on the water heater, washing machine, electric floor heating.

- Touch the indicator tip successively to plumbing fixtures, pipes, instrument cases, walls, floors.

An illuminated light, an audible signal, or a display indicates voltage.

An illuminated light, an audible signal, or a display indicates voltage. - Turn off the automatic boiler, repeat the test. If the indication is gone, the source of the problem has been found, otherwise we continue to turn off the power consumers, lighting one by one, de-energize the adjacent rooms, controlling the result.

- The absence of changes indicates problems with the neighbors: the riser is energized due to a faulty tank, washing machine, damage to the phase wire during repair.

Measurements with a multimeter are identical, one probe is applied to the controlled surface, the second - to the "ground".

Solutions for an apartment

Old housing stock

The problems discussed above are typical for a two-wire network of the TN-C earthing system of Soviet-built buildings. The zero working conductor (N), grounded at the substation, also serves as a protective conductor (PE), designated PEN. The automata of the apartment shield open the circuit in case of a short circuit (short circuit), heating from prolonged overload.

In the event of an insulation breakdown, for example, a heating element, there is a high risk of falling under 220V voltage by opening a tap. If you are "lucky", the electromagnetic release will work from a short circuit, but it will shake pretty well. From leakage currents, "neighborly greetings" - residents are defenseless.

The situation needs to be corrected comprehensively. Electrical safety is provided by:

- protective grounding;

- zeroing;

- safety shutdown;

- potential equalization;

- chain separation;

- low voltage.

Protective earth

It is forbidden to use pipelines as a charger! Grounding behind wall reinforcement is a little better: in emergency mode, the neighbors may not be affected, but the resistance of the grid is high, unstable - the functionality is doubtful.

The 1986 edition of the PUE prescribed the connection of metal cases of shower trays, bathtubs with metal water pipes (clause 7.

1.55). In the latest edition, the requirement was removed due to the mass replacement of steel pipes with non-conductive plastic ones. Attempts to ground the gas pipeline may end in an explosion!

Zeroing

PUE-7 does not allow the combination of working and protective zero in single-phase circuits. The TN-C system of old buildings should be upgraded to TN-C-S by dividing a single PEN conductor into two separate ones: PE, N in the input switchgear (ASU). It is recommended to re-ground PE, PEN conductors at the input, from experience - a mandatory event.

Gross violation - separation of PEN in the floor board: in the event of a break, burnout of the working zero, voltage will appear on the ground terminals of the sockets connected to the supposedly “protective” wire, which means that voltage will appear on the cases of zeroed electrical appliances!

Residual current

Residual current device (RCD), together with other measures, provides a high level of electrical safety. Paragraph 1.7.80 of the PUE is interpreted as a ban on the installation of RCDs in single-phase lines of the TN-C system:

Paragraph 1.7.80 of the PUE is interpreted as a ban on the installation of RCDs in single-phase lines of the TN-C system:

Differential protection in the network without a dedicated protective zero will not work on the leakage current, but will open the circuit during a short circuit between the phase and the ground through the human body for 0.04 s (GOST R IEC 60755-2012). Thanks to the speed, the accident is likely to end without harm to health, but remember:

Before the reconstruction of the house's electricity supply, RCD is an acceptable solution. Types allowed: A, AC, electromechanical models are preferred. On group lines supplying sockets, an RCD of a maximum of 30 mA is required. It is recommended to power the outlet of the washing machine, the water heater from the shield with separate cables, after the circuit breaker, a 30 mA RCD is mounted. When buying, choose products for a current rating higher than the machine.

Potential equalization

Equalization of electrical potentials in the TN-C circuit using an additional system (DSUP) - you can not do it! This is explained by the need to connect the DSUP with the PE bus (7. 1.88 PUE), which does not exist. Connection to the PEN conductor will result in the appearance of 220 V on the mating conductive elements in case of an accident.

1.88 PUE), which does not exist. Connection to the PEN conductor will result in the appearance of 220 V on the mating conductive elements in case of an accident.

Advice of "experts" to connect a bathroom, metal risers, equipment cases with a conductor without connecting to the PEN terminals - dangerous! The statement that if two of them accidentally touch, there will be no electric shock, since the potential is the same - an error.

There will be a potential difference between the person and the non-insulating floor. The result depends on the total resistance: body, slippers, rug, tiles, but deaths have been recorded. Replacing a steel water pipe with a plastic one, even partial, excludes grounding such a self-made "SUP" for it.

The actual option for the lower floors of creating a DCS connected to an individual storage device, for example, in the basement, causes discussion. Unfortunately, the regulations do not provide for this case.

Separation of circuits, extra low voltage

Separation of circuits is carried out using an isolating transformer, consisting of two mutually insulated windings. The neutral wire behind the transformer is insulated from earth, unlike the zero from the substation. The reverse current to the ground electrode through your body, in case of accidental direct or indirect contact with the phase, does not occur. Electrical appliances are not grounded. Limiting factors: power, dimensions, security, reliability, price of the unit.

The neutral wire behind the transformer is insulated from earth, unlike the zero from the substation. The reverse current to the ground electrode through your body, in case of accidental direct or indirect contact with the phase, does not occur. Electrical appliances are not grounded. Limiting factors: power, dimensions, security, reliability, price of the unit.

The safety extra-low voltage (SELV) value must not exceed 50V, for 0-12V zone. In fact, the method is only suitable for lighting.

Khrushchev residents have little choice: wait for the reconstruction of the power supply, collectively carry it out at their own expense or hope for an RCD. It is important to properly operate household appliances, carry out preventive maintenance in time: cleaning tanks, adjusting the legs of machines, replacing gaskets.

New building

Residents of relatively new houses are lucky: the power supply was originally made according to the TN-C-S system, at least. Electrical safety is ensured by the protection of RCD lines, the DSUP device in the bathroom.

Electrical safety is ensured by the protection of RCD lines, the DSUP device in the bathroom.

The functional requirement of the PUE for RCDs (clause 7.1.83) limits the background leakage current of the network to a third of the rated current of the device. Otherwise, false positives are likely. Conventionally, the value of natural leakage is taken as 0.4 mA per 1A load, 10 μA per meter of cable. Worn wiring, loads above 40A require an input RCD of 100 mA. In this case, the bathroom lines are protected by separate 30 mA devices (see 3.1.3).

DSUP

Do not confuse the main (OSUP) and additional electrical potential equalization system (DSUP). The first one is equipped by the developer at the entrance to the building by combining conductive parts:

The second one provides additional electrical safety, which is mandatory for bathrooms, shower rooms:

DSUP includes:

- potential equalization conductors;

- potential equalization box (KUP).

Step-by-step process of organizing DSUP:

Protective conductors are connected to standard grounding parts (brackets, lugs, lugs), if they are not provided, a bolt hole is drilled in non-removable parts of the structure. It is not allowed to fasten stamped bathtubs to false legs; for acrylic inserts, the supporting frame is grounded. Use stainless or chrome fasteners. Pipes are grounded through special clamps. The attachment points are covered with Vaseline.

Private house

Electricity supply to the private sector is implemented through the TN-C, TN-C-S, TT systems. The TT option is used for old overhead lines with bare wires; TN-C is the best choice if a modern power line is laid with SIP wire. Owners can upgrade their existing TN-C to TN-C-S on their own; make a ground loop, OSUP, DSUP.

CT system

A phase-to-earth fault in a CT system causes a potential to appear on the housings of electrical appliances. The installation of an RCD is mandatory (clause 1.7.59PUE)! When the neutral is broken, 380 V comes to consumers, so it is recommended to use a voltage monitoring relay.

The installation of an RCD is mandatory (clause 1.7.59PUE)! When the neutral is broken, 380 V comes to consumers, so it is recommended to use a voltage monitoring relay.

Features:

- All group lines are equipped with a 30 mA RCD. At the input, a device is mounted with a setting of 100 - 300 mA.

- It is not allowed to connect the operating zero N to the PE bus, local memory.

- Surge protection required.

Mandatory condition:

Theoretically condition of clause 1.7.59guarantees a single vertical ground electrode from a corner 50 × 50 × 5 mm with a length of 2 - 2.5 m. In fact, three profiles are buried in the ground at the vertices of an equilateral triangle with a side of 1.5 - 3 m, combined by welding a steel strip 40 × 4 mm.

Grounding from profiles

The strip is bolted to the ground conductor connected to the main protective busbar (MSB) of the shield. The section is limited:

The video tells about the technology of arranging progressive modular pin grounding:

TN systems

Electrical safety requirements for bathrooms in multi-apartment buildings remain valid for individual housing construction (see 3.1, 3.2). If there is no grounding, does not meet the standards, organize a new one similar to the TN-C-S system.

Cottage grounding TN-C-S.A triangular loop is also used for additional grounding, as shown in the previous paragraph.

Reliability

Corrosion, loose connections, mechanical damage - increase the resistance of conductors. Insulation resistance, on the other hand, decreases with time. The probability of failures increases, therefore, periodic monitoring of the condition of the components is carried out.

Independently visually inspect the integrity of the ground loops, potential equalization. Check the tightness of the connections, tighten the released ones. Any work is done by turning off the power. The performance of the RCD is checked by pressing the "TEST" button monthly.

Any work is done by turning off the power. The performance of the RCD is checked by pressing the "TEST" button monthly.

Measurements of the grounding resistance of a private house are carried out at least once every 12 years, preferably in summer in dry weather. The operation is performed by ETL employees, upon completion, a measurement protocol is drawn up.

Specialists perform an instrumental check of the RCD, measure the insulation resistance of the wiring with a megaohmmeter, and determine the value of leakage currents. Based on the results, a conclusion is made about the safety of further operation.

Tip! If you need a bathroom remodeler, there is a very convenient service for the selection of specialists from PROFI.RU. Just fill in the details of the order, the masters themselves will respond and you can choose with whom to cooperate. Each specialist in the system has a rating, reviews and examples of work that will help with the choice.

Learn more