3D printer print electronics

3D printing electronics: Transforming the electronic industry

3D Learning Hub

See all categories

Contents:

- Introduction

- What are the advantages of 3D printing for electronics?

- 3D printing with electrostatic discharging properties

- Conductive 3D printing offering new opportunities

- 3D printed electronics: What is possible?

- What about the future of 3D printing in the electronics industry?

Introduction

What are the advantages of 3D printing for electronics?

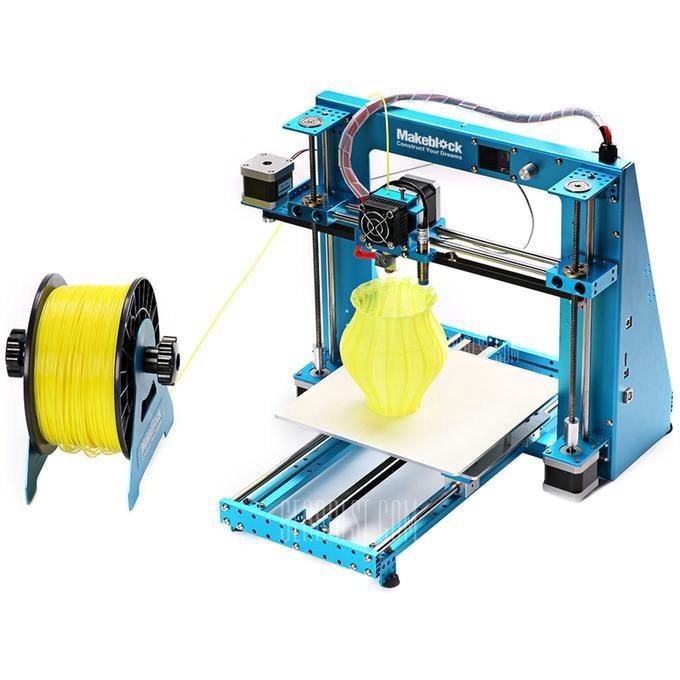

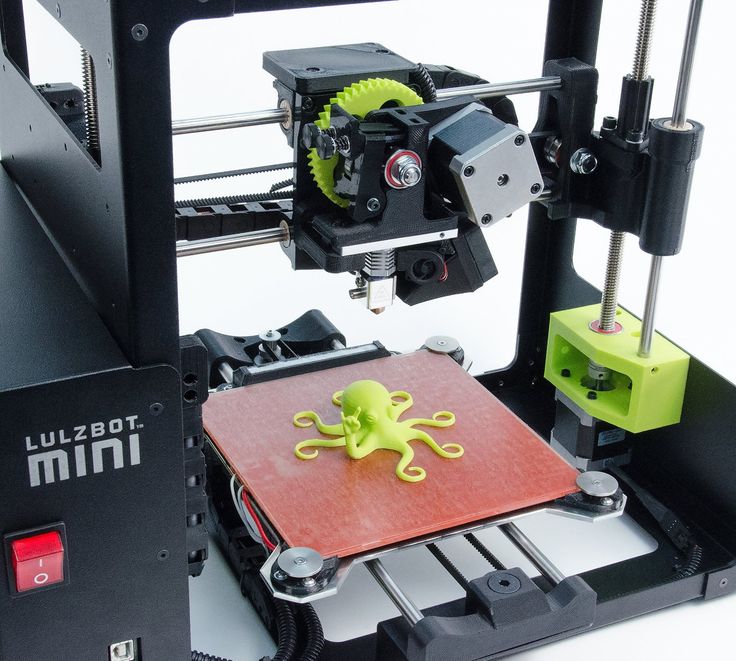

3D print the perfect prototype

3D printing helps you get from the idea to the product in a matter of days.Launch your first series

Moreover, the electronics industry can truly benefit from additive manufacturing. No stock, no minimum number of units and short turnaround are the key upsides of using Sculpteo’s 3D printing service for your electronic devices, regardless of where they are in product life cycle management. Electronic production is made easy thanks to our 3D printing technology and will improve and simplify your whole supply chain management! 3D printing and electronics are strongly linked. Online 3D printing allows you to create a new kind of relationship with your clients. You can easily produce small series, limited editions and spare parts in a small batch. Whether you’re looking for just a prototype or a thousand units, your 3D printing product will benefit from our experience and know-how to achieve the best quality.

You can easily produce small series, limited editions and spare parts in a small batch. Whether you’re looking for just a prototype or a thousand units, your 3D printing product will benefit from our experience and know-how to achieve the best quality. Design freedom

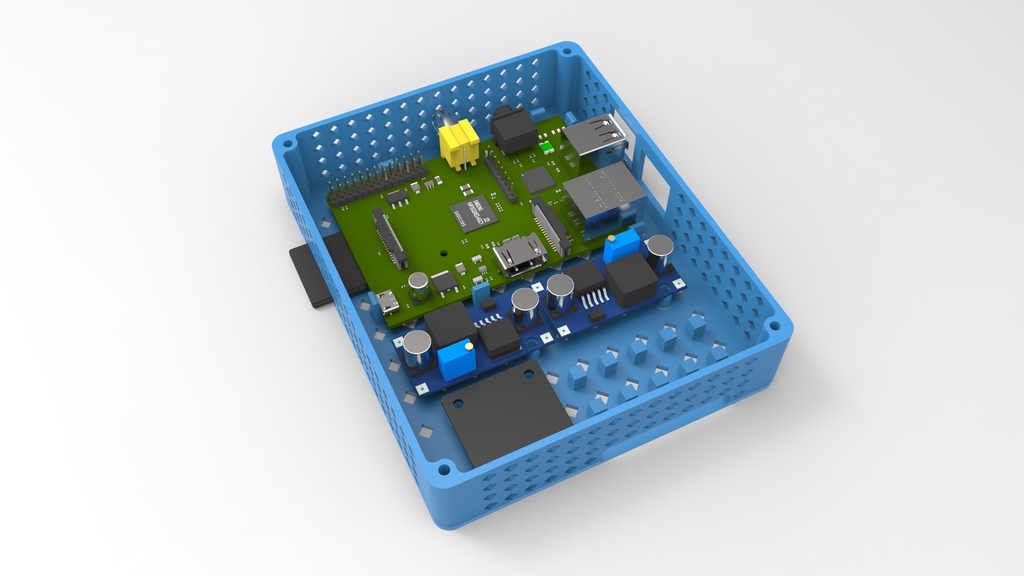

Electronic components production can now be thought in terms of 3D design and not only 2D, with new ways of stacking the circuits. It opens new possibilities to design for electronics, that are new to explore! Customization is becoming a big asset while using additive manufacturing for the creation of your products: you can create parts perfectly adapted to a circuit board or any electronic device. 3D printing can be used to create personalized electronic enclosures, USB stick cases, and keyboards, for example. Using additive manufacturing also offers you flexibility in the creation of your design. More than a perfectly adapted device, you can also elaborate complex geometries impossible to make with other traditional manufacturing techniques. With 3D printing, you can also make the most of parts that don’t require any assembly process!

With 3D printing, you can also make the most of parts that don’t require any assembly process! 3D printing with electrostatic discharging properties

What is an electrostatic discharge?

What is called “electrostatic discharge” (ESD) is the flow of electricity between two electrically charged parts causes by contact. Static electricity often causes ESD through a process known as tribocharging. This static electricity can arise when surfaces rub together and this results in an excess of electrons on one surface and a deficiency on the other. The ESD occurs when differently-charged objects are brought close together or when the dielectric between them breaks down, often creating a visible spark. Electrostatic Discharges are a real problem and can damage sensitive electronic components. It can also lead to the alteration of magnetic media and set off fires, explosions in flammable environments! ESD is a big concern for the electronic industry, and being able to manufacture ESD-safe part is a real advantage to avoid any problem.

Focus on: Ultrasint PA 11 ESD

At Sculpteo, we are now offering you the possibility to manufacture your ESD-safe parts. If you are prototyping or producing a project where electrostatic discharging safety is critical, our Ultrasint® PA11 ESD material will be a perfect choice. Ultrasint® PA11 ESD is a bio-derived material, appearing to be a perfect choicel for increased process safety in advanced applications. With its interesting mechanical properties, this material offers new possibilities for a wide range of new applications, especially for the electronics sector. Indeed, with its low resistivity, Ultrasint® PA11 ESD is reducing the risk of electrostatically induced damage or failures, the material does not accumulate static electricity and can come in contact with electronic components without running any risk. The surface resistivity of Ultrasint® PA11 ESD is lower than traditional electrostatic dissipating materials. You can now make the most of the advantages of both additive manufacturing and electrostatic discharge properties. For electronic housing, electronic jigs and fixtures, this material is perfectly adapted. PA 11 ESD also as other advantages and interesting mechanical properties such as high tensile strength and elasticity, which could help you create efficient tools. What are you waiting for? With this material, you can create parts combining superior mechanical and thermal characteristics with outstanding electrostatic discharging properties. Get your parts 3D printed with Ultrasint® PA11 ESD by uploading your 3D file on our 3D printing service right now. It will only take a few clicks and you will get an instant quote.

For electronic housing, electronic jigs and fixtures, this material is perfectly adapted. PA 11 ESD also as other advantages and interesting mechanical properties such as high tensile strength and elasticity, which could help you create efficient tools. What are you waiting for? With this material, you can create parts combining superior mechanical and thermal characteristics with outstanding electrostatic discharging properties. Get your parts 3D printed with Ultrasint® PA11 ESD by uploading your 3D file on our 3D printing service right now. It will only take a few clicks and you will get an instant quote.

Conductive 3D printing offering new opportunities

3D printing complex electronic components could go even further with conductive 3D printing. The creation of electronic devices with conductive features using 3D printing can particularly be useful to develop IoT (Internet of Things) projects. This innovative technology could allow creating 3D printed devices like LED, or touch sensors. But this ability to 3D print conductive devices could be involved in bigger projects, in soft robotics, 3D electronics, and also for communication devices such as 3D printed Near Field Communication (NFC) antennas.

But this ability to 3D print conductive devices could be involved in bigger projects, in soft robotics, 3D electronics, and also for communication devices such as 3D printed Near Field Communication (NFC) antennas.

3D printed electronics: What is possible?

As you will see, this 3D technology can be used for various applications in the electronics industry. Get inspired by these innovative electronic devices made using additive manufacturing!

3D printed circuit board by Nano Dimension and Harris Corp: 3D Printed Circuit Boards

Nano Dimension is known to work actively on 3D printed electronic devices The Nano Dimension’s DragonFly™ system is used to 3D print functional electronics prototypes and complex multi-layer Printed Circuit Boards (PCBs). But that is not all.

Nano Dimension and Harris Corp partnered to develop 3D printed electronic devices to create a radio frequency (RF) amplifier. They now work to go further and create hardware for the International Space Station. Their goal is to optimize the 3D printing process for RF components for flight studies aboard the ISS. Using additive manufacturing is a solution for them to find new ways to create radio frequency and circuit boards to find new innovative techniques.

Their goal is to optimize the 3D printing process for RF components for flight studies aboard the ISS. Using additive manufacturing is a solution for them to find new ways to create radio frequency and circuit boards to find new innovative techniques.

The Simusolar project

At Sculpteo, some of our customers are working on solar energy using 3D printing. On the blog, we already told you about Simusolar, a company created in 2014 and looking to bring solar energy to the rural population of Tanzania. They develop and implement small-scale sustainable solutions to help local people in their everyday life.

They decided to use 3D printing because they needed a lot of custom made parts, for a low price. Their clients are farmers, fishers, or rural residents looking for various equipment powered by solar energy.

Optomec developing the Aerosol Jet Technology

Optomec announced that their Aerosol Jet Technology will be printing embedded electronics at the micron scale. The innovative process relies on both local deposition and local curing. This way, electronics parts are more affordable and require less waste of materials, and all of this with a superior resolution.

The innovative process relies on both local deposition and local curing. This way, electronics parts are more affordable and require less waste of materials, and all of this with a superior resolution.

Start 3D printing enclosures!

3D printing enclosures are one of the most common uses of 3D printing for the electronic industry. Solidity, quality, customization, and accuracy, this is what you will make the most of while 3D printing your electronics enclosures.

If you are interested in 3D printing your own enclosure, you can follow our 3D printed enclosure design guide!

What about the future of 3D printing in the electronics industry?

What if in a few years, we could be able to create fully-functional smartphones or multi-material products using additive manufacturing? If these ideas are still dreams today, the innovations related to conductive 3D printing and electronic devices are now showing new opportunities. It might be time to rethink the way we conceive enclosures, circuit boards, and electronic components. From your prototyping process to the production and the management of your supply-chain, additive manufacturing could help you go through new challenges.

From your prototyping process to the production and the management of your supply-chain, additive manufacturing could help you go through new challenges.

As you can see additive manufacturing has a lot to offer for electronics. It could become quite common to 3D print electrical elements. If you have an electronic project, but you don’t know what software you could use to start it: here is our selection of the best CAD software for electronics. Then, don’t hesitate to try out our online 3D printing service. You will just have to upload your 3D file, we will take care of it and send you your 3D printed objects in a few days.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

What are 3D Printed Electronics? Let us tell you.

..

..Design

The complexity of electronics combined with the capabilities of 3D printing. Heard of 3D printed electronics but want to know more?The ability to 3D print electronics is making waves in an industry plagued by long stints of R&D and a never ending cycle of prototypes and new releases.

But what exactly does this process entail? And how, as a designer, architect, or artist, can it help you? Is it sustainable? What are the dangers? And what should you know about it?

This guide is a useful starting point for you to find out…

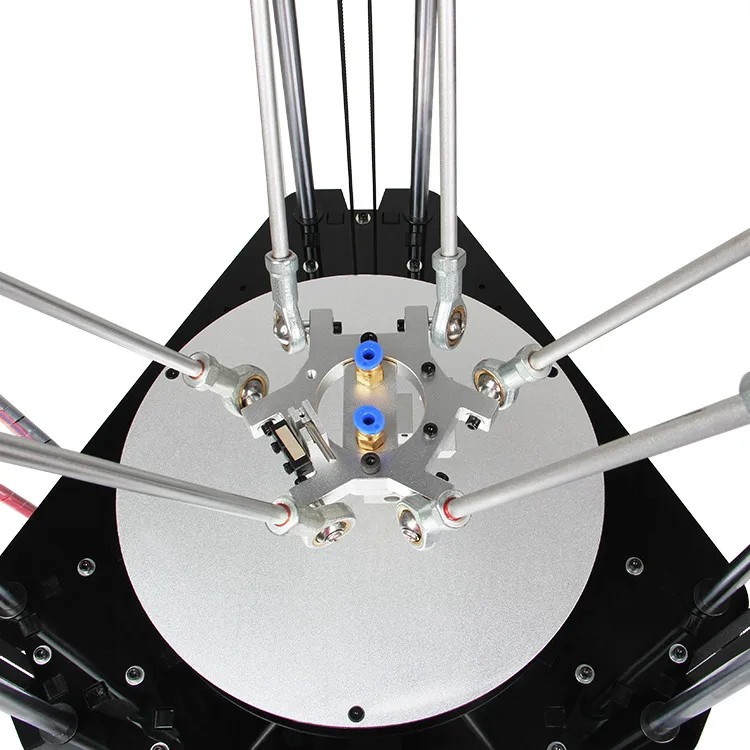

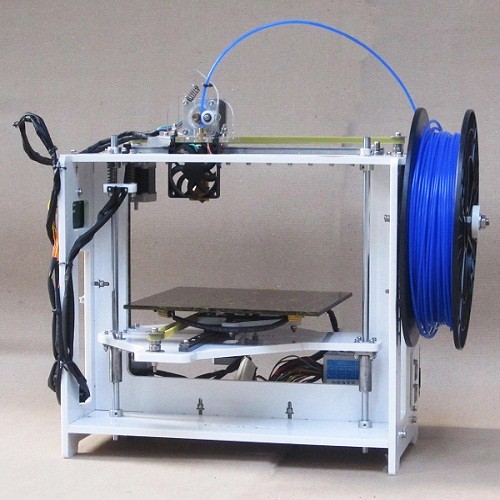

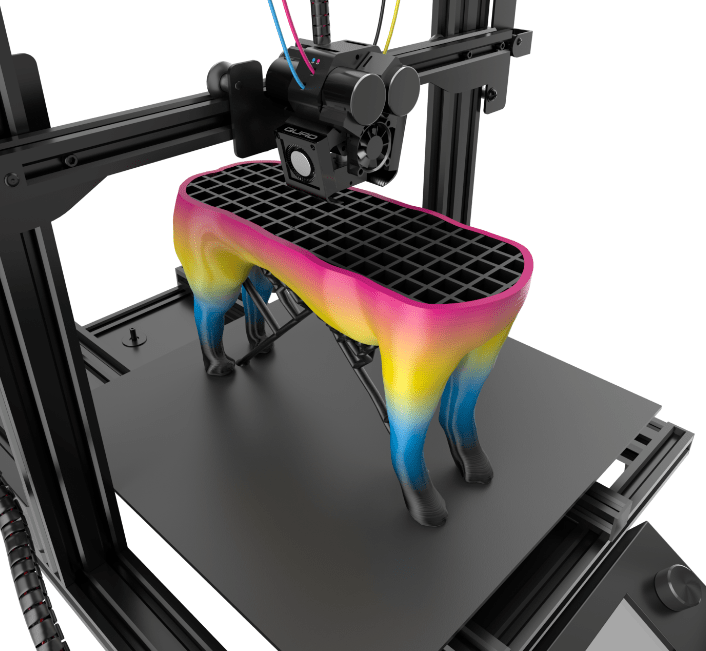

With 3D printing electronics it is possible to make various types of boards that can be programmed and connected to prototypes – ©iakovenko123/Depositphotos. com – Cover image – ©iprescott10/Depositphotos.comWhat is it?

com – Cover image – ©iprescott10/Depositphotos.comWhat is it?3D Printing objects with electronic functionality is a relatively new concept.

It involves the use of material jetting technology, which is used to jet conductive and insulating inks onto the printing surface.

These inks are applied in lines as thin as a few microns before UV light is used to solidify the inks.

The use of material jetting facilitates multi-material 3D printing, which is particularly useful for the electronics industry.

This means that the different elements necessary in electronics, such as functional circuitry and enclosures, can be manufactured in a single print run.

3D printing electronics involves the use of material jetting technology, which is used to jet conductive and insulating inks onto the printing surface – ©IgorVetushko/Depositphotos.comWhat materials are used when 3D printing electronics?Where systems could typically use just one material in the 3D printing process, recent advancements have enabled the involvement of multiple materials.

This allows manufacturers to merge conductive materials with non-conductive materials.

The thermoplastics used in the 3D printing process are often made with copper, carbon and graphene.

Meanwhile, proprietary conductive and dielectric inks are used simultaneously to build functional circuits and antennas. This expands the range of functions in 3D printed electronics.

Because the process combines multiple materials into the same 3D object it also requires a solvent to ensure their compatibility. The particular solvent used is known as an orthogonal solvent, which is specifically designed not to cause damage to the different components.

The thermoplastics used in the 3D printing process are often made with copper, carbon and graphene – © Julian Pagliaccio, via Wikimedia CommonsWhat can 3D printing electronics produce?With 3D printing electronics, it is possible to make various types of boards that can be programmed and connected to prototypes.

A very wide range of inks can be utilized enabling a full range of printed electronics functionality: conductors, semiconductors, dielectrics, resistors and more.

The process can be used to manufacture electronic components such as resistors, capacitors, antennas, sensors, and thin film transistors.

Using the 3D printing process, it is also possible to rapidly 3D print fully functional electronic circuits that contain electrically-conductive metallic inks and insulating polymeric inks, which could be useful for medical devices, radio frequency shielding surfaces and novel structures for harvesting solar energy.

Today, however, it’s main applications include printing electronics for use in prototypes for upcoming products, prosthetics and more complexly shaped electronic products.

Give me a step-by-stepWhile several methods exist for 3D printing electronic components, they typically mirror the various steps utilised in regular 3D printing. The main difference is the use of a dual-material fused filament process with conductive thermoplastic filaments.

The main difference is the use of a dual-material fused filament process with conductive thermoplastic filaments.

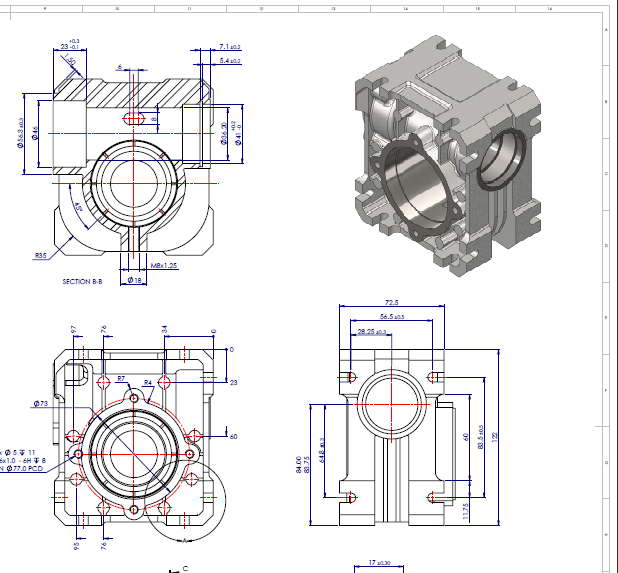

As with all 3D printing, a digital CAD model of the desired part is designed, which serves as the printer’s instruction model.

When the printing process begins, a trace or “fingerprint” is created, and then the requisite materials needed for that specific part are added in layers.

The process flow of the 3D systemWhat machinery is used when 3D printing electronics?Specialised machinery is required which integrates a precise inkjet deposition printer with dedicated nano-inks and software capable of printing electronic circuits such as printed circuit boards (PCBs), antennas, capacitors and sensors.

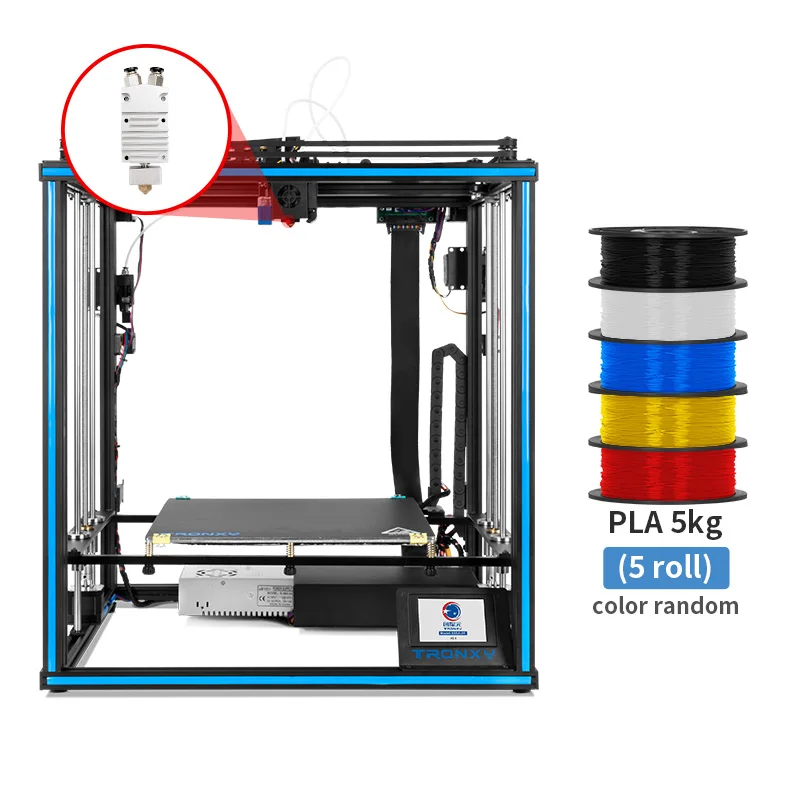

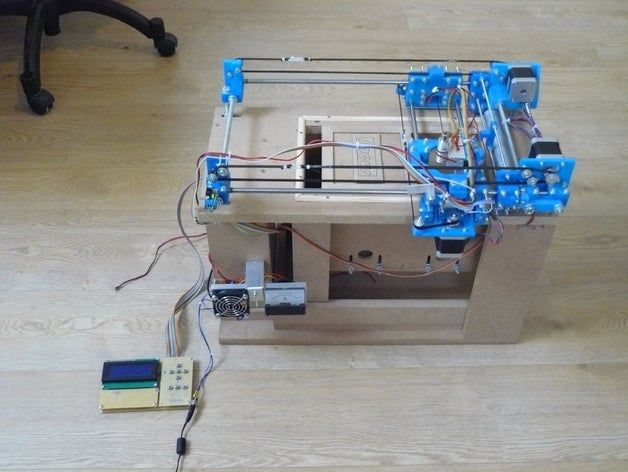

Can I do it at home?Due to the complexity of the process, it is not possible to replicate it at home unless you have the capability of manufacturing your own 3D printer.

With the relevant machinery, it is possible to 3D print electronics at home.

Find out more about manufacturing processes, don’t miss What is Explosive Forming? Let us tell you…

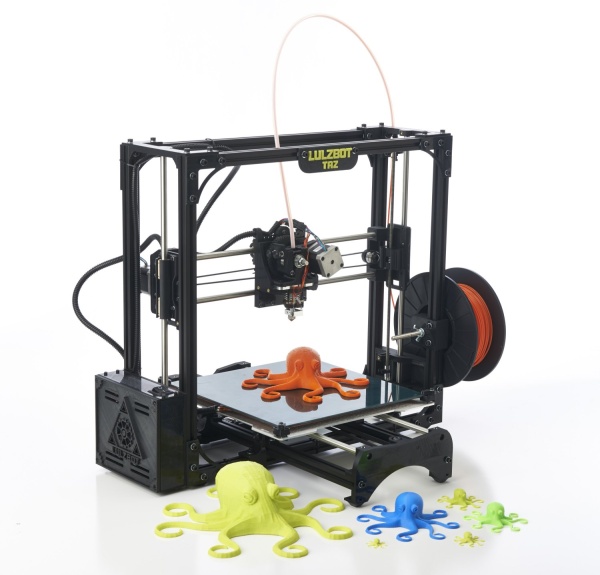

The benefits of 3D printing electronics range from faster time-to-market, greater freedom of design and customizationWhat are the pros & cons of 3D printed electronics?At the core of every electronic device is a Printed Circuit Board (PCB) which is difficult to produce. Luckily, with the advent of 3D printing, manufacturing these circuit boards is less challenging.

The benefits of 3D printing electronics range from faster time-to-market, greater freedom of design and customisation.

This is because with the advent of 3D printing electronics manufacturers can create prototypes of circuits and circuit birds in-house, reducing procurement expenses and eliminating concerns about IP infringement.

3D printing also opens up opportunities to design complex shapes and components. For example, multilayer circuits can now be 3D printed on non-flat, flexible surfaces, which would not be possible with traditional manufacturing techniques.

Components can also be printed onto 3D surfaces eliminating the need for a separate substrate and reducing the size, thickness and weight of the end product.

However, there are several limitations when it comes to 3D printing electronics, not only because it is limited in the types of parts it can produce.

Whilst the recyclability of 3D printed electronics is an area being explored by various researchers, it remains a con due to what is currently possible.

Another downside to 3D printed electronics, and in fact, all 3D printed products is their structural integrity.

Whilst printed layers adhere together in some cases, and under certain stresses or conditions, they can delaminate.

Another major downside to 3D printing as a whole is its increasing popularity and accessibility. On one hand, it democratises the manufacturing processes but it also makes it easier to fake and counterfeit products.

I want to know if it’s sustainable…Whilst 3D printing electronics can minimise the manufacturing footprint by localising production, the difficulty in recycling the various components means it can’t be considered a sustainable process.

There are several resources that are useful when it comes to building your knowledge around 3D printed electronics.

If you want to learn more check these out:

- A visual demonstration of the 3D printing process used to manufacture electronics.

- An explanation of the various capabilities of 3D printing electronics.

- A paper detailing the evolution of 3D printing electronics.

- A breakdown of the various benefits and current systems employed when 3D printing electronics

- A detailed research into the future of 3D printing electronics and its benefits when used for prototyping.

Fascinated by 3d printing? Don’t miss 3D printing ceramics: Interview with Hilda Nilsson.

Printed electronics - foreign experience. DragonFly Multilayer PCB 3D Printer

The market for 3D printing of body parts is rapidly moving from product prototyping to part production. Equipment and technologies for printed electronics began to develop not so long ago compared to conventional 3D printers, but they already have a number of significant achievements.

A few years ago, the first 3D printer manufactured by NanoDimension, Israel, appeared on the market, which made it possible to print a multilayer printed circuit board and revolutionized the field of printed circuit board prototyping (Fig. 1). Moreover, it turned out that its capabilities are much wider than the manufacturer intended, and users were able to solve many other problems with it. The article discusses the new capabilities of this equipment and presents foreign experience in its operation.

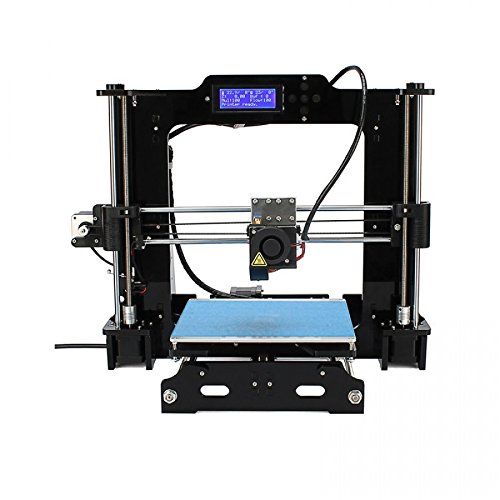

Let's take a quick look at the main features of the hardware. The DragonFly 3D printer prints with two materials: dielectric and conductive paste. In fact, it allows you to print the entire board from scratch, including all layers, microvias from any to any layer, masking, marking (Fig. 2). No pre- and post-operations are required. Previously, to prototype boards, you needed a small PCB shop with chemical, mechanical, photochemical and other operations, which needed water supply, exhaust, drains and compressed air. Instead, you can now put one 3D printer in the designer's office (Figure 3), start printing in the evening and in the morning already have a finished PCB sample with impressive characteristics (57 layers, conductor/gap: 110/110 µm, microvia diameter 200 µm and etc.).

In fact, it allows you to print the entire board from scratch, including all layers, microvias from any to any layer, masking, marking (Fig. 2). No pre- and post-operations are required. Previously, to prototype boards, you needed a small PCB shop with chemical, mechanical, photochemical and other operations, which needed water supply, exhaust, drains and compressed air. Instead, you can now put one 3D printer in the designer's office (Figure 3), start printing in the evening and in the morning already have a finished PCB sample with impressive characteristics (57 layers, conductor/gap: 110/110 µm, microvia diameter 200 µm and etc.).

The technology is relevant:

- For companies that want to keep design and technological solutions secret when developing and prototyping products.

- For technology parks and universities that are engaged in research activities.

- For enterprises that want to speed up the prototyping process and make it more efficient to get products that have a serious competitive advantage in the market.

- For developers of various non-standard micromechanical products with an electrical circuit.

The technology allows you to perform standard PCB prototyping tasks, but it also has a number of capabilities that are superior to traditional technology (Table 1).

Table 1. Applications of DragonFly

*NanoDimension provides a base of standard capacitors of various capacities by creating a multi-layer structure with up to 57 layers.

**Example: previously it was required to order 3 parts (PC, antenna, battery holder) and assemble them. During operation, there were problems with the reliability of the connection of parts, and the DragonFly 3D printer allows you to print and integrate all three functions in one part in one go, increasing the reliability of the product.

Experience of foreign users

HARRIS COOPERATION (USA)

Antennas printed on a printer are close in their characteristics to antennas manufactured using traditional technology, as evidenced by the graphs of loss and noise versus frequency shown in Figure 4.

A 3D printer, unlike traditional technology, where the slightest inaccuracies in the manufacturing process change the parameters of the antenna, has a higher repeatability in manufacturing. That is why 3D printed antennas (Figure 5) designed to operate at 5.2 GHz and an RF amplifier operating up to 6 GHz (designed by Harris) were chosen for organizing the flight to the ISS.

HENSOLDT (FORMER AIRBUS / EADS) (Germany)

Hensoldt develops responsible products. The introduction of the DragonFly 3D printer (Fig. 6) made it possible to significantly speed up the process of obtaining prototypes compared to ordering boards from a third-party manufacturer.

HENSOLDT Director Thomas Müller said: “Sensors for special applications require reliability and performance much higher than those for consumer applications. The ability to quickly prototype in multiple iterations gives us a competitive edge when designing these products.”

In the photographs of Figure 7, you can see the same board made in the traditional way and on a 3D printer.

The DragonFly 3D printer has expanded the range of Hensoldt's capabilities, so now the company prints not only boards, but also non-standard products that the market needs, for example, waveguides (Fig. 8):

PHYTEC (Germany)

PHYTEC is a manufacturer of products based on microprocessors. In some of its boards, it uses a non-standard solution: one or more chips are installed on a board made on a DragonFly printer, and then the board with the chip is soldered to the main board at a temperature of 240 ° C. We do not know exactly the reasons for this course of action, but the following options are possible:

- know-how retention in the manufacture of components through cooperation;

- completion of electrical circuits of products.

ITALIAN INSTIT UTE OF TEC HNOLOGY IIT (Italy)

A study by a leading biological institute that deals with wearable electronics aims to read the parameters of the human body. One of the difficult tasks is the sensor packaging (Fig. 10). The old construct did not ensure the reliability of the electrical connection - cracks formed on the sensor, leading to the failure of the product during operation. Printing the case on a 3D printer made it possible to avoid casting processes, reduce the influence of the human factor in the manufacture of the sensor, eliminate wires, soldering and installing a connector.

One of the difficult tasks is the sensor packaging (Fig. 10). The old construct did not ensure the reliability of the electrical connection - cracks formed on the sensor, leading to the failure of the product during operation. Printing the case on a 3D printer made it possible to avoid casting processes, reduce the influence of the human factor in the manufacture of the sensor, eliminate wires, soldering and installing a connector.

Professor Massimo De Vittorio: “The DragonFly system is suitable for fast and low cost prototyping. Its capabilities make the printer an ideal choice for our team and allow us to achieve the best results - fast development and printing of complex forms that are not possible with traditional technology.

A distinctive feature of the company's activities is a three-stage work process: printing the base, installing the sensor, printing the upper part of the mount along with electrical switching. In fact, this is the printing of a board with a component (sensor) built into it, which has significantly increased the reliability of the product.

REHAU (Germany)

REHAU is a manufacturer of consumer products. Dr. Ansgar Niehoff, Head of Department at REHAU: “We want to make our products smarter and thus add value to our customers by seamlessly integrating electronics into products. With the help of this technology, prototypes can be made within days without the help of third-party manufacturers, and the company saves time and effort. 3D printing is especially interesting in products where there is little space for top-mounted components. Creating smart products is no longer the future, but the present. REHAU develops smart home and IoT products, and NanoDimension provides critical technologies to accelerate new product time to market” (Figure 11).

CADLOG (Italy)

CADLOG is one of the leading software and electronics developers. She recently opened a prototyping center in Italy, where there is a DragonFly installation. Video about the center: https://youtu.be/HtZnLUJUyWs.

Despite the recent opening of the center, DragonFly already plays a significant role in the work of CADLOG.

Conclusion

The promise of this technology is huge, and those companies that start using the DragonFly 3D printer now will be one step ahead of the rest. Enterprises have already appeared in Russia that have become pioneers of this technology.

New opportunities for design, prototyping and manufacturing will allow our designers to more fully develop their talents and capabilities and create unique consumer products for society.

Koreans have created a wearable 3D printer for printing electronics on the skin

Korean engineers have created a small wearable 3D printer for printing flexible electronics on the skin. It is attached to the arm, back or any desired part of the body and prints conductive electronic tracks on it. They can be used to track body movements, touch, or other purposes. The developers plan to talk in detail about the printer at the fall UIST 2020 conference, but for now, they have published a video with examples of its operation and a brief description.

In the field of wearable electronics, there is a concept according to which electronics should be directly integrated with the body: sticking sensors on the skin or, in the long term, implanting electrodes. There are also separate studies in which simple electronic components, for example, stretch or pressure sensors, are offered to be printed directly on the skin using a 3D printer. This is a potentially convenient method, but since printing takes some time, and the person moves during this time, the printing is inaccurate. In 2018, American engineers solved this problem technologically: they supplemented the printer with cameras that track hand movements and compensate for it by moving the print head.

A group of engineers from the Korea Institute of Advanced Technology led by Andrea Bianchi took a different, simpler approach in their new development. They created a compact printer that can be mounted directly above the print site on the body so that the print quality is almost independent of human movements.

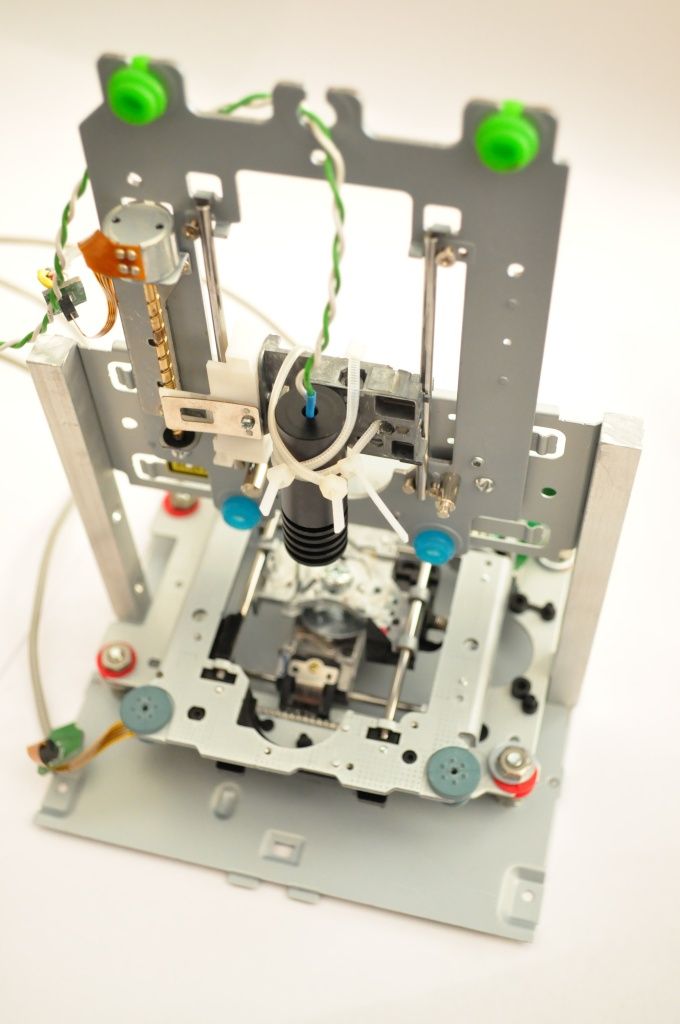

The printer has a simple design. It consists of a frame that is placed on the skin and pressed tightly against the body with two straps, and above the frame there is a mechanism that moves the print head in two directions. The print head itself is also simple: it is a syringe with a conductive flexible material, and a linear motor on top that squeezes the substance out of the syringe.

Before printing, the layout of the printed tracks can be changed in the program. Also, before starting the process, the printer calibrates, lowering the head to the level of the skin in different places in order to understand its relief. Immediately before printing, an insulating transparent layer must be smeared onto the skin, after which the printer will draw tracks on it in a few minutes, which can then be connected to electrodes leading to the readout electronics. In addition, while the print substance is still wet, small rigid components, such as an LED, can be inserted into it.