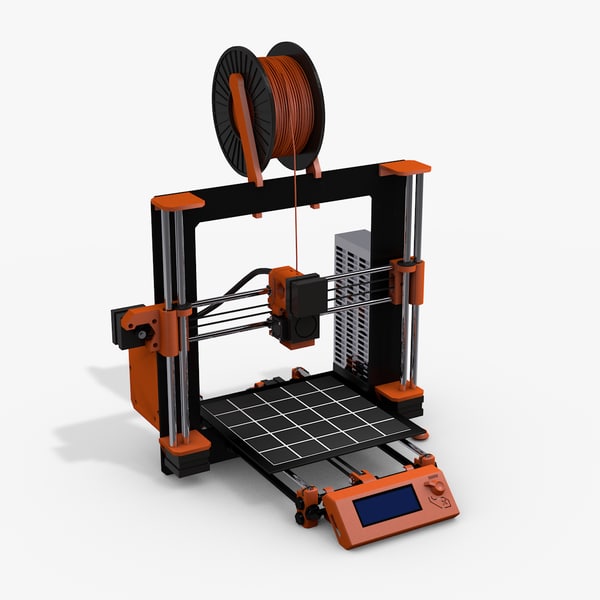

Replica 3d printer

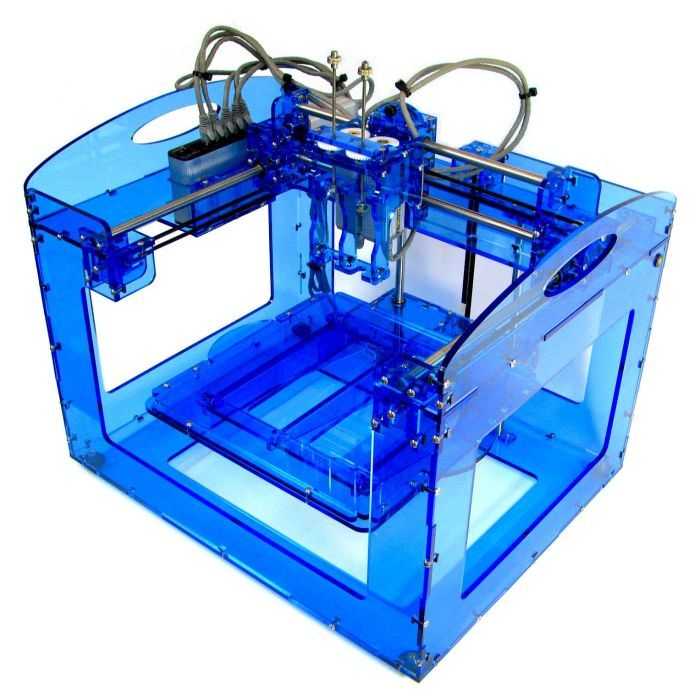

Professional 3D Printer Comparison | MakerBot

METHOD | REPLICATOR+ | REPLICATOR Z18 | |

|---|---|---|---|

CATEGORY | Performance | Desktop | Desktop Large Volume |

USES | Prototypes, manufacturing aids, and other parts that require complex assemblies, extreme geometries, and commercial precision. | Classroom lesson plans, STEM projects, design thinking exercises, and facilitation of 21st-century career skills. | Oversized models, housings, and structures that require a massive build volume. |

PRICE | $4,999 | $2,799 | $5,499 |

LAYER HEIGHTThe range of thicknesses of each printed layer measured in microns. | 20 - 400 microns Print Modes: | 100 - 400 microns Print Modes: | 100 - 400 microns Print Modes: |

COMPATIBLE EXTRUDERSMakerBot 3D printers utilize swappable extruders for flexibility of print options and convenience of maintainance. | Model 1 Performance Extruder, Model 2 Performance Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder | Smart Extruder+ Tough Smart Extruder+ Experimental Extruder |

BUILD SPEEDMax Material Flow rate is the maximum speed material can be extruded. Print Head Travel Speed is the speed that extruder moves on the xy axis. | Max Material Flow Rate: ~50mm3/sec Print Head Travel Speed: 500 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec | Max Material Flow Rate: ~15mm3/sec Print Head Travel Speed: Up to 175 mm/sec |

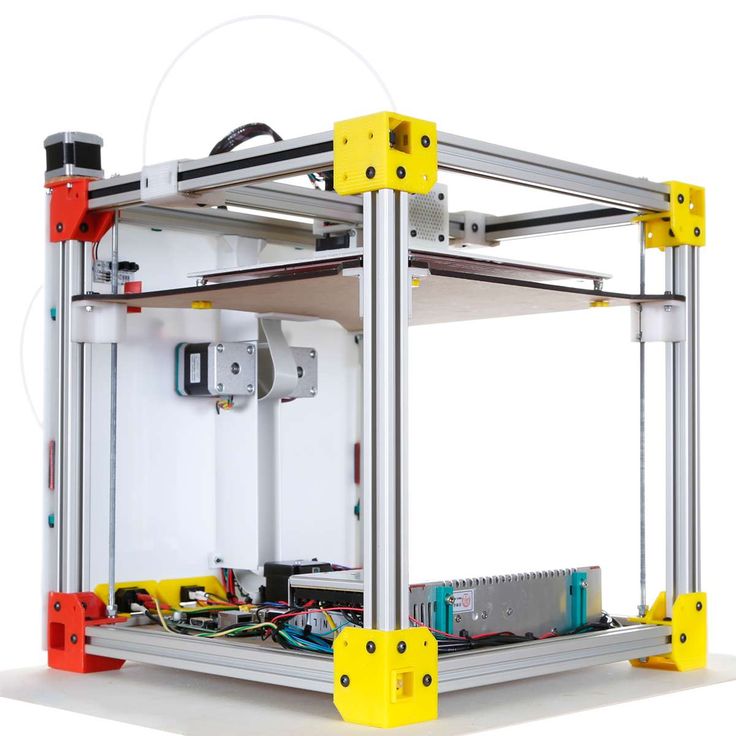

PRINTER FRAME CONSTRUCTIONThe printer's frame connects the xy gantry to the z stage making it the essential structural component of the printer. | Ultra-Rigid Metal Frame | Injection Molded ABS with aluminum gantry-reinforcement | Injection Molded ABS with aluminum gantry-reinforcement |

BUILD VOLUMEThe maximum space available for 3D printing either your complete object or a component of your final, assembled object. | 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in single extrusion 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in dual extrusion | 29.5 L x 19.5 W x 16.0 H cm / 11.6 L x 7.  6 W x 6.5 H in 6 W x 6.5 H in | 30.0 L x 30.5 W x 45.7 H cm / 11.8 L x 12.0 W x 18.0 H in |

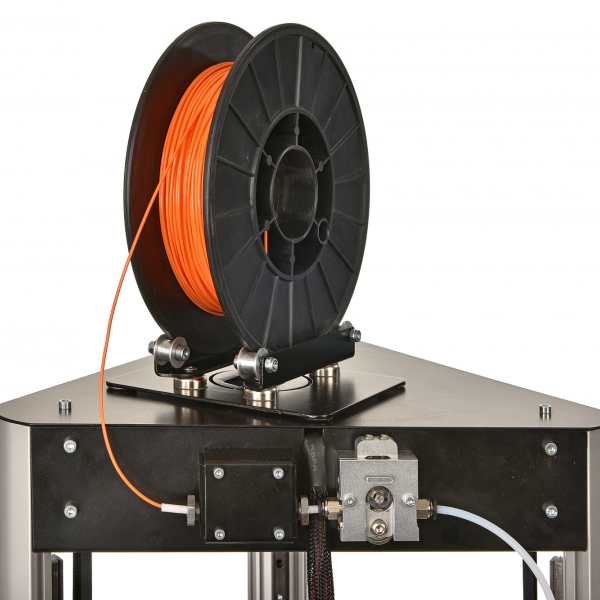

MATERIAL STORAGEMaterial storage location can improve the user experience, and a sealed storage compartment can significantly increase the "pristine" lifetime of material allowing for high print accuracy. | Dry-Sealed Material Bay | Open back loaded material drawer | Open bottom loaded material drawer |

COMPATIBLE MATERIALDifferent materials can be used for different applications. | MakerBot Precision PLA, MakerBot Precision Tough, MakerBot Precision PVA, MakerBot Specialty PETG | MakerBot PLA, Smart Extruder+. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. | MakerBot PLA, Smart Extruder+. MakerBot Tough, Tough Smart Extruder+. Additional materials such as bronzeFill, copperFill, and woodFill, Experimental Extruder. |

BUILD PLATFORMBuild surface and platform type | Factory-Leveled Spring Steel Build Plate with Reusable Grip Surface | Factory-Leveled Flex Build Plate with Reusable Grip Surface | Factory-Leveled ABS Build Plate with Reusable Grip Surface |

MEASURABLE DIMENSIONAL ACCURACY3D printed parts that consistently match CAD dimensions to within a published tolerance. | |||

DUAL EXTRUSIONTwo extruders provide the added ability to print with soluble support material alongside model material. | |||

ENCLOSED HEATED BUILD CHAMBERAn elevated 3D printing environmental temperature improves layer adhesion, reduces warping, and improves dimensional accuracy. | |||

SMART ASSIST MATERIAL LOADINGAn extra sensor and drive motor designed to automate the loading process from spool to extruder. | |||

SMART SPOOL COMPATIBILITYRFID Tag equipped spool providing real-time information on material type, color, and amount remaining. | |||

CAMERAOnboard camera for monitoring your print jobs and sharing pictures of your 3D prints. | |||

INTERFACEProvides easy, computer-free access to printing menus, commands, and your cloud storage library. | 5" Capacitive Touch Screen | 3.5" LCD Screen | 3.5" LCD Screen |

CONNECTIVITYOptions for connecting directly or remotely to the printer for from launching and monitoring prints, to adjusting settings and updating firmware. | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable | WI-FI Ethernet USB Stick USB Cable |

| Shop Method | Shop Replicator+ | Shop Replicator Z18 |

Replica best 3D printer models・Cults

Sandman Helm Printable Assembly

€9

Panzerfaust 250

Free

Hogwart's Legacy Collectors edition wand! :Replica

€5

Pistol Walther P99 Prop practice fake training gun

€4

HAND GRENADE M52

€3

Ninja Girl v1

€9. 99

99

Wednesday Addams v2

€12.99

Adidas Messi 10.4 FxG - Non-Wearable replica soccer shoes

€35 -50% €17.50

Funko Pop Pea Plants Vs Zombies

€3.50

The City Gargantuar Plants VS Zombies 2

€2.50

Chamber Sniper

€5

SLIPKNOT Mick Thomson Mask V1

€4.68

M4 Stock

€5

Nerf DinoSquad Stego Smash Toy gun 3D Print 3D print model

€14.30

Lancia Delta Integrale Evo 2 replica Scale 1/10 for 3d Printing

€6. 25

25

The Avengers Loki Crown for Cosplay

€14.90

9mm Bullet replica for jewelry

€0.94

Wednesday Addams

€10.99

M64 US BOMB for aeromodelling

€4.80

Atomic heart AXE Swede

€12.50

Battinson 2022 | Epinephrine Autoinjector | STL | UPDATED

€5.53

M240D Conversion Kit

€6.91

Foldable Avenger M8 Model Mass Effect Fan art It auto unfold

€23.40

Wednesday Addams Family Hand for Cosplay 3D print model

€8.90

Cyberpunk 2077 Kongou Pistol Prop Cosplay

€4

Star Wars Death Trooper Backplate

€9

Pistol CZ Shadow 2 Prop practice fake training gun

€4

PDR-D Aep by BENen3D - 250mm Printer Version

€15 -15% €12. 75

75

Vaadwaur Pulsewave Pistol STO

€17.45

Walther PPK Silencer Gun Display Stand

€5

PDR-C AEP BY BENEN3D - 250mm PRINTER VERSION

€15 -15% €12.75

Chainsaw Man head printable assembly

€12

Chainsaw Man arm blade printable assembly

€8

Cyberpunk 2077 Apparition Pistol Prop Cosplay

€4

Ayus Bow - Genshin Impact 3d Print Model

€14.30 -15% €12.16

Mjolnir - Thor hammer

€4. 99

99

Star Guardian Miss Fortune League of Legends Weapon - STL File

€2.66 -40% €1.60

Star Guardian Miss Fortune League of Legends Familiar - STL File

€0.89

Star Guardian Miss Fortune League of Legends Acessories - STL File

€1.77 -40% €1.06

AN/PVS-2 Night Vision Scope style Dummy

€13.89

Airsoft MP5 HOP UP CHAMBER PARTS

€0.64

Mag spacer AK DBOYI DBOYS BOYI hop up mounting part

€0.64

Star Guardian Lux League of Legends Acessories - STL File

€1. -40% €1.06 77

77

Star Guardian Kai'sa League of Legends Acessories - STL File

€1.77 -40% €1.06

Star Guardian Kai'sa League of Legends Boosters - STL File

€2.66 -40% €1.60

Star Guardian Kai'sa League of Legends Familiars - STL File

€0.89

Xayah Brave Phoenix League of Legends - STL file

€2.66 -40% €1.60

Star Guardian Soraka League of Legends Weapon - STL File

€2. -40% €1.60 66

66

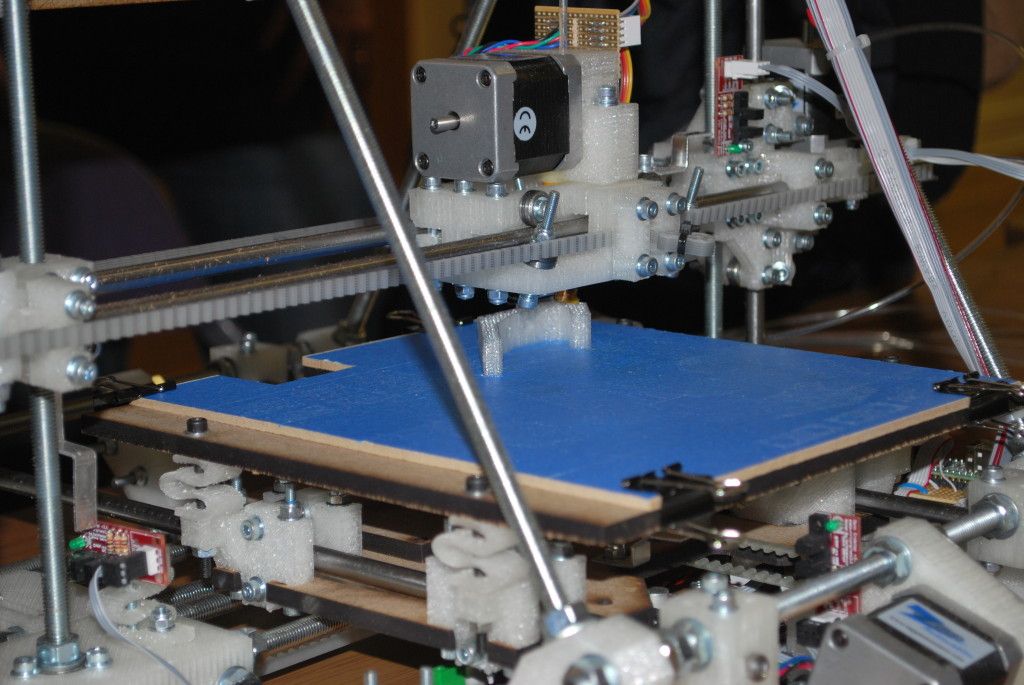

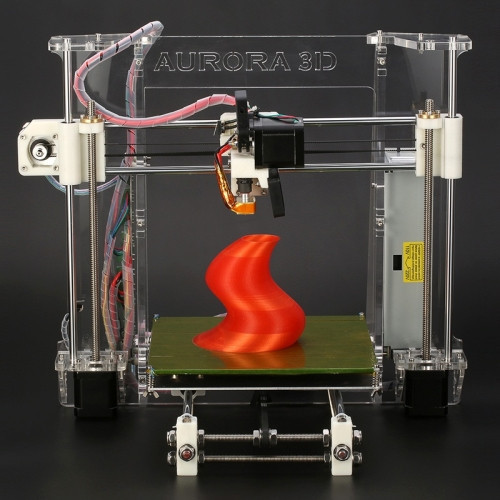

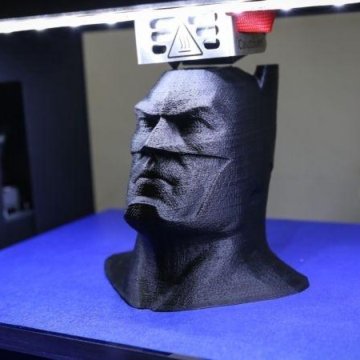

3D printers are able to "print" copies of objects and people

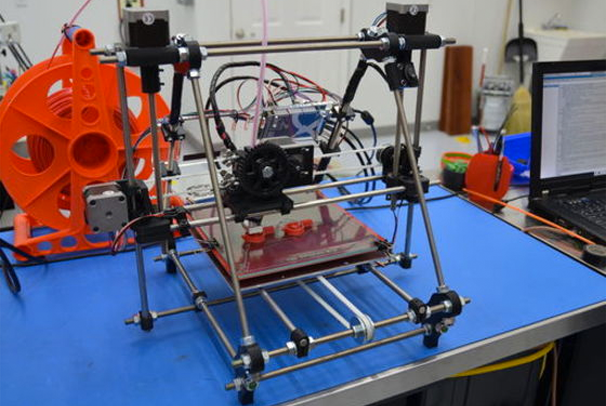

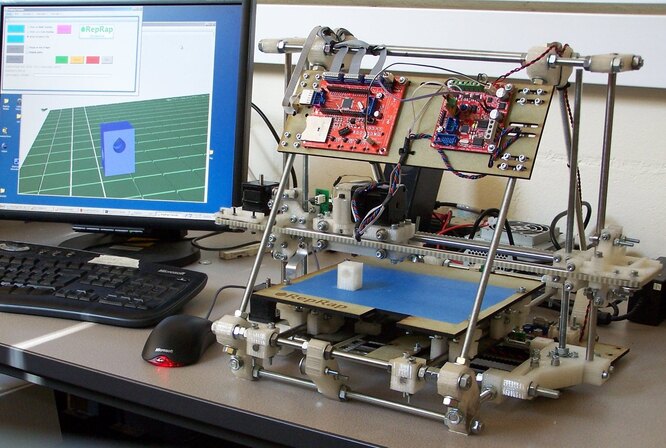

Computer technology is increasingly intertwined with real life. A real industrial revolution was made by 3D printers, capable of "printing" copies of any object and even a person. New technologies, in the development of which they began to actively invest in China, make it easier to realize their creative potential and allow dreams to materialize literally.

Unlike traditional printing methods, 3D printing is the process of creating three-dimensional solid objects with a dedicated digital printer. You can make a copy of not only any object, but also a person.

Shahirezada Eralieva, CCTV Correspondent-Russian:

"The digital model created by the scanner is edited in a special computer program. Then this model is reproduced by the printer. Printing is based on the layer-by-layer principle."

Printing is based on the layer-by-layer principle."

Shao Moyu, Director of 3D Printing Center:

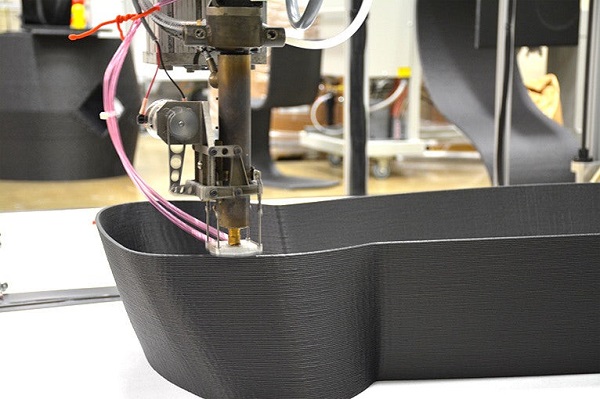

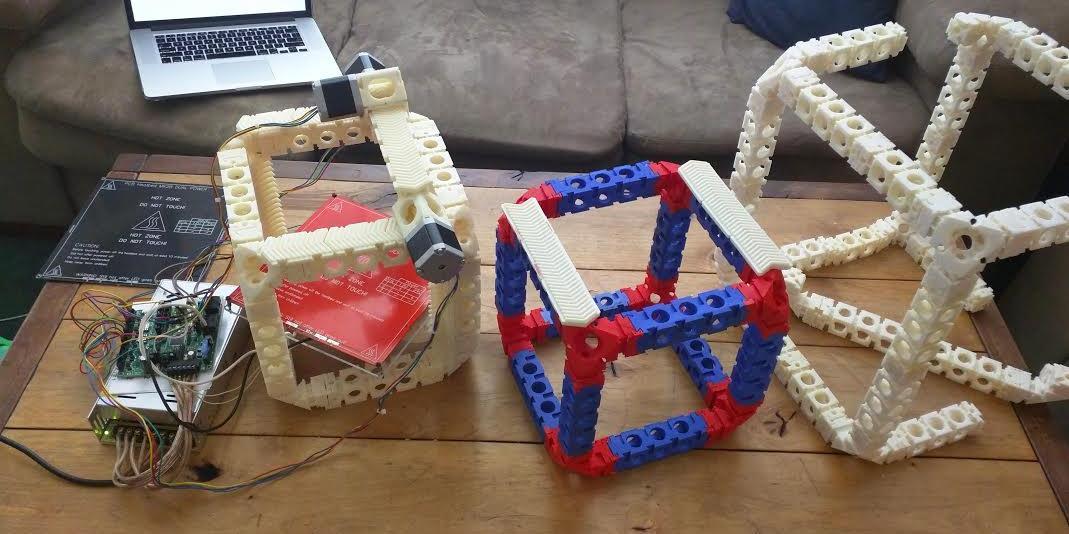

"3D printing can be used in areas such as mechanical engineering, aviation, electrical engineering, medicine and construction, as well as innovative design. Printing materials are very different: gypsum, nylon, metal, plastic, resin and others.

After a few hours, the copy is ready. Its quality depends on how accurately the scan was made. Copy sizes can be set to a variety of sizes, printing is also done by different types of printers, depending on the complexity of the job.

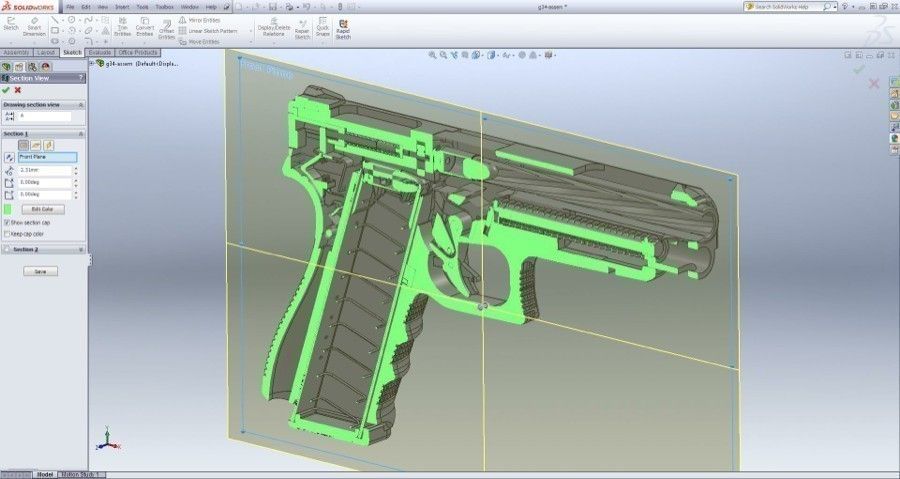

This innovation is called the industrial revolution, the prerequisites for which have been outlined for a long time. But since that time, 3D printing has greatly pushed the boundaries of possibilities, the number of components suitable as raw materials is growing, as well as the quality of the objects created is improving. The new technology has been tried in the creation of clothing, medical items, weapons, and in the near future, 3D printing will be used in the construction of houses.

Shao Moyu, Director of the 3D Printing Center:

"This technology is not the latest, it appeared in the late 80s of the last century, and is more used in the industrial sector, so little is known about it in wide circles. By Compared with traditional manufacturing, 3D printing has the advantage of greater efficiency and lower costs.It cannot completely replace traditional manufacturing, but it has great development potential."

You can print not only a scanned object, but also an object drawn or copied on the Internet. This is how design studios began to work with 3D printing. Everything that they create in their head, and then on paper or in a computer, then the printer puts it into a solid form. With the advent of home 3D printers, it will be possible to purchase any item without leaving home.

Experts predict great prospects for a new type of industry, whose performance is growing even in the stock markets. Shares of companies engaged in 3D printing are growing at the fastest pace (diagram). Some players have already realized the scale of the upcoming changes and have stopped investing in "traditional production".

Shares of companies engaged in 3D printing are growing at the fastest pace (diagram). Some players have already realized the scale of the upcoming changes and have stopped investing in "traditional production".

Liu Jing, Designer:

"I work as a designer myself, I have a small studio. In order to continue developing our company, increase our competitiveness, occupy more market place. We are following the development of 3D printing very closely."

China has been actively investing in 3D technology to increase its manufacturing capacity. This year, Hunan province has introduced 3D printing for the first time in the government's report, which will be heard during the March sessions. In the capital of the country, employees of companies united by the Beijing Industrial and Innovation Base are working on the development of this technology. It was here that the first 3D printing salon in China was opened. --0--

3d printing of a person - 3d printing of figures of people on a 3d printer in Moscow

Masterpieces of fine art always amaze with filigree and liveliness of human images. It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

Opportunities and benefits of the masterpiece technology

Every person on the planet is unique, therefore, any copy of a person, whether it be a statuette, a model or a portrait on paper, will also have a uniqueness. 3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

And, let it sound a little cynical, but 3D printing of a person opens up incredible opportunities in various areas of our lives. Just imagine, the creation of sculptural copies of a person takes months, and sometimes years. The cost of such a sculpture is often simply beyond the reach of an ordinary person. And the chances of becoming a model of a talented sculptor are negligible.

On the other hand, getting your own exact copy a few centimeters in size is now absolutely not difficult and not expensive. Moreover, a real boom in the popularity of 3D printing is brewing in the world, which will soon create a significant alternative to photo printing and video chronicles. And it's not just about private ambitions and fun!

Spheres of demand for 3D printing technology of people

3D printing of figurines is already widespread today in:

● advertising;

● decoration of wedding celebrations;

● souvenir industry;

● prototyping of industrial and commercial facilities;

● design;

● medicine.

Noble missions of innovative technology

Moreover, the circle of people who are professionally interested in the service in order to develop their business is constantly growing. In addition to the persistent interest in technology, its profitability and spectacularity, 3D printing of people also serves noble purposes, for example:

● allows blind people to tactilely get acquainted with the external images of their relatives and friends, communication with which is limited to virtual space;

● allows future parents to admire their baby in the womb, not only with the help of ultrasound pictures. 3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

● Printing figurines on a 3D printer helps people with mental trauma and disorders to adapt to a certain social environment;

● in psychology and educational disciplines, three-dimensional models of people are involved in methods of working with children.

Steps for creating 3D copies of a person

High-quality and high-quality 3D printing of people actually requires several preparatory steps.

● In the first one, a full-length 3D scan of a person is performed

● In the second, a copy of the 3D model is carefully processed

● In the third, the figure is scaled down and printed.

The technology also includes a number of post-press processing steps. Figures may require surface grinding, painting or tinting, freeing them from auxiliary elements - clamps, additional details, coating with protective varnishes, finishing agents.

Consumables and features of technological processes

Different materials are used for 3D printing of human figures and

even different equipment, technically and technologically different from each other. So, the result can be presented in plastic, gypsum, polymer mixtures. It can be single color or multicolor. Realistic or only in general terms reminiscent of the original.

Human 3D printing technologies are also different. The most popular and frequently used are two:

● layer-by-layer reconstruction of the model on an inkjet 3D printer;

● Laser baking, stereolithography on a laser printer.

For the best and most accurate reproduction of the image of a person, it is advisable to use the method of layer-by-layer gluing of a cellulose-starch mixture.

The use of 3D printed human figures in the advertising industry

Of course, the advertising industry has traditionally been at the forefront of bringing innovation to its service. 3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

But the scope of advertising use of this technology is much wider:

● Figures of real company employees in company uniforms can make up a static installation.

● May be part of a believable animated advertisement.

● Given as souvenirs, they will be a powerful motivation for a common cause and common success.

● 3D printing of human figures in addition to the presentation of 3D models of industrial, construction, social facilities can bring liveliness and dynamics to the presentation of projects.

● Using a 3D printer, you can create not only mini copies of real people, but also transform familiar replicated images of famous sculptures. For example, dress the Venus de Milo in the costume of a stewardess of the advertised airline, and use a mini copy of Rodin's sculpture in an advertisement for ladies' accessories.

The position of 3D copies of a person in souvenir production

A treasure trove of invaluable prospects 3D printer and human printing will bring to souvenir production. With the help of technology, you can make:

● popular interior figurines;

● intricate paperweights;

● gift personalized figurines;

● wedding souvenirs of the bride and groom;

● commemorative figurines of anniversaries and heroes of the occasion.

Variants of representation of the image in a three-dimensional miniature

When creating souvenir miniatures of people, you can most often find three directions for recreating the image:

● realistic or ordinary, the one that can be found in an amateur photo or in life;

● staged, when models are presented in fantasy, stylized images, for example, superheroes or characters from famous fairy tales, movies, literary works, comics;

● wedding, couple real or fictional image.

Bride and groom figurines - this is just the beginning!

The industry of wedding paraphernalia, in addition to commemorative figurines of the newlyweds, can use 3D printing of figurines to create original decorations for invitations, decoration of a wedding cake, festive table, use mini-copies as props for an original wedding photo shoot and video shooting of a romantic love-story.

Online services and their features

It is worth saying a few words about online 3D scanning services. This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

Actually, the results of scanning and allow you to remotely provide services of three-dimensional modeling of a person. The more diligently the scan is made, the more similarity will be between the model and the figurine. By the way, the service of 3D printing of people can be provided not only on the basis of a scan of a real person, but also on the basis of photographs taken from different angles.

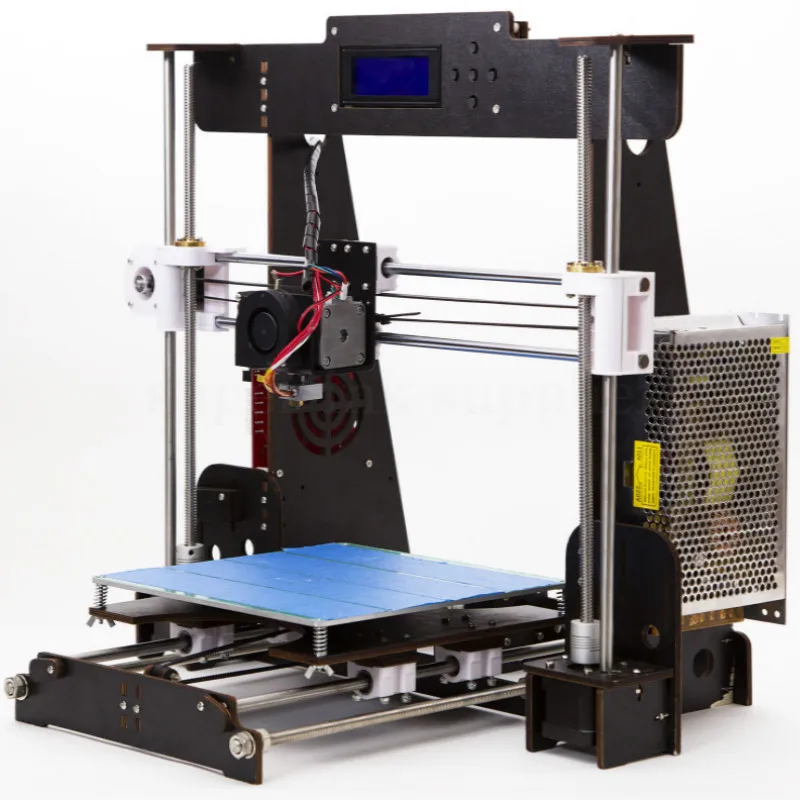

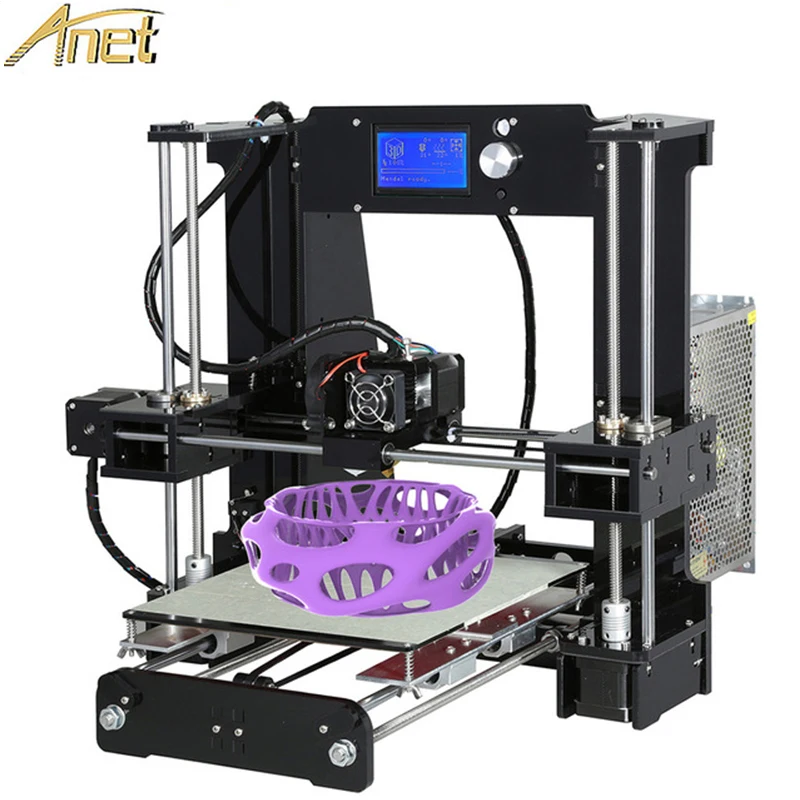

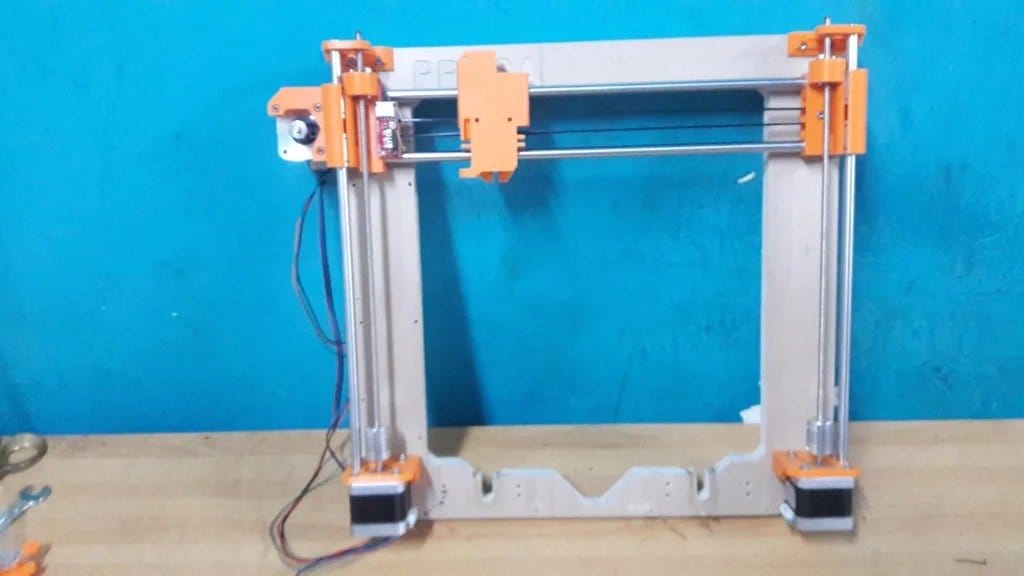

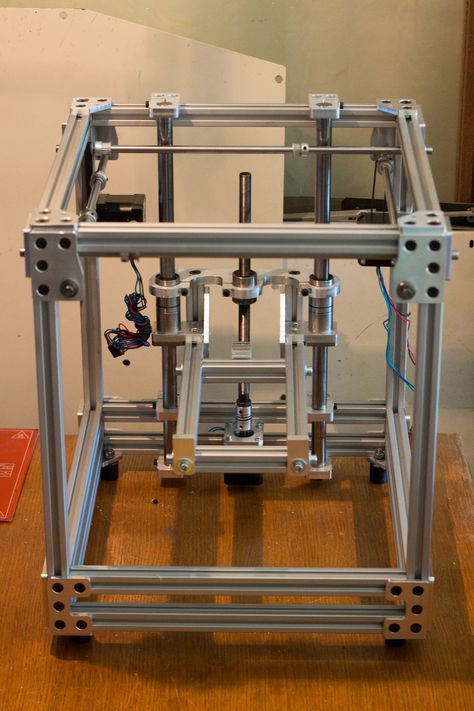

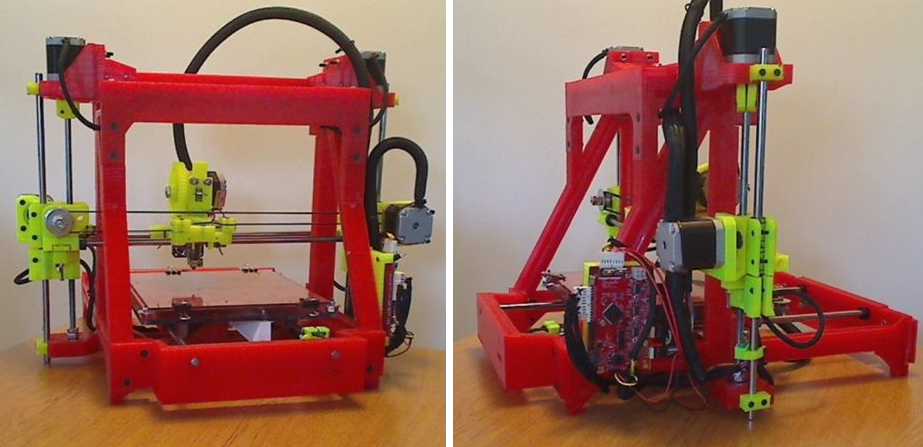

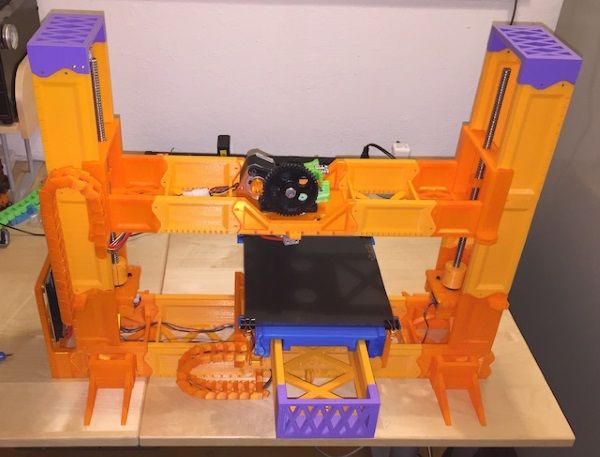

Increased rigidity will lead to better print quality.

Increased rigidity will lead to better print quality.