3D printer or cnc

3D Printing vs CNC Machining: Which is best for prototyping?

3D printing news News 3D Printing vs CNC Machining: Which is best for prototyping?

Published on March 16, 2018 by Jamie D.

3D printing is a rapidly growing technology with many advantages over traditional manufacturing methods. It however has its problems, including that 3D printing cannot be effectively used for mass production, and is limited in speed and accessibility. Another manufacturing technique for low-to-mid production is CNC machining (computer numerical control), a fairly common subtractive technique for part creation. We decided to compare the advantages and disadvantages for each method to establish where these technologies are most appropriate.

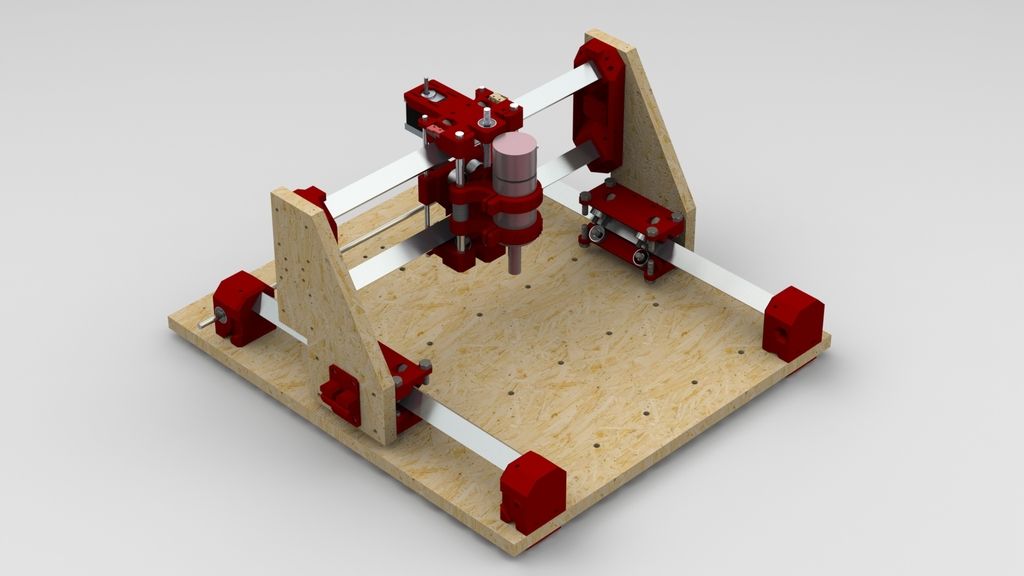

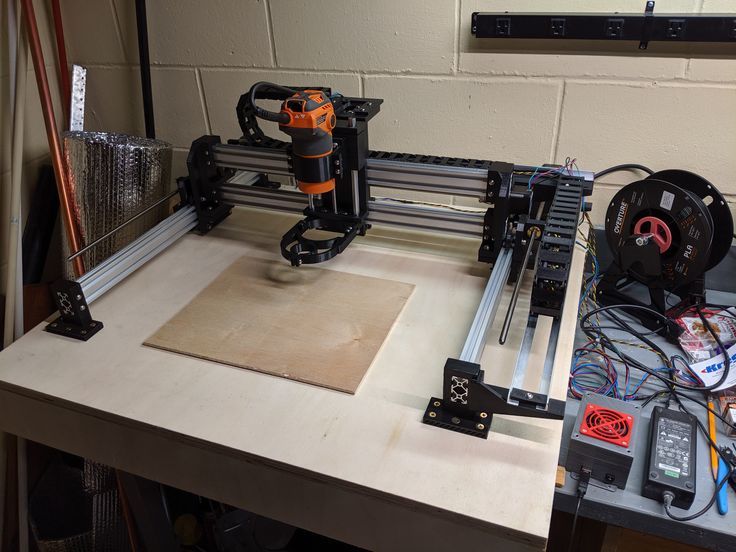

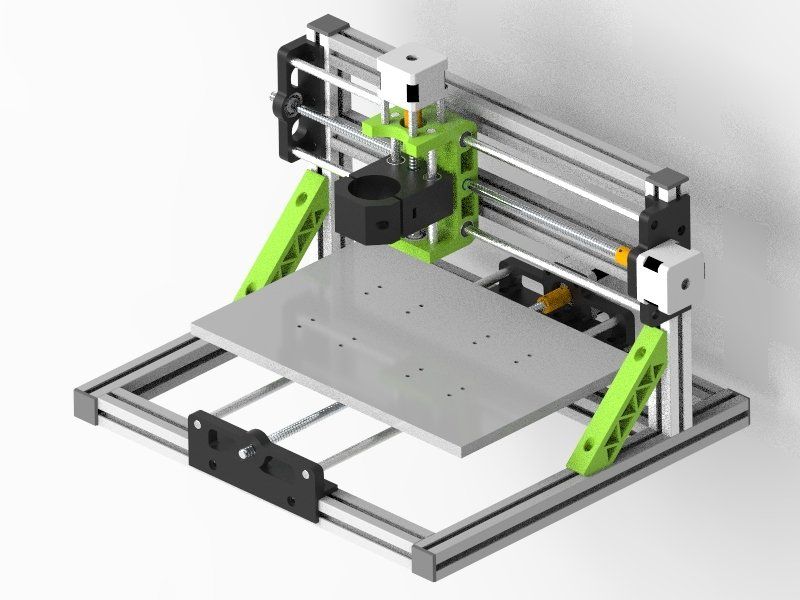

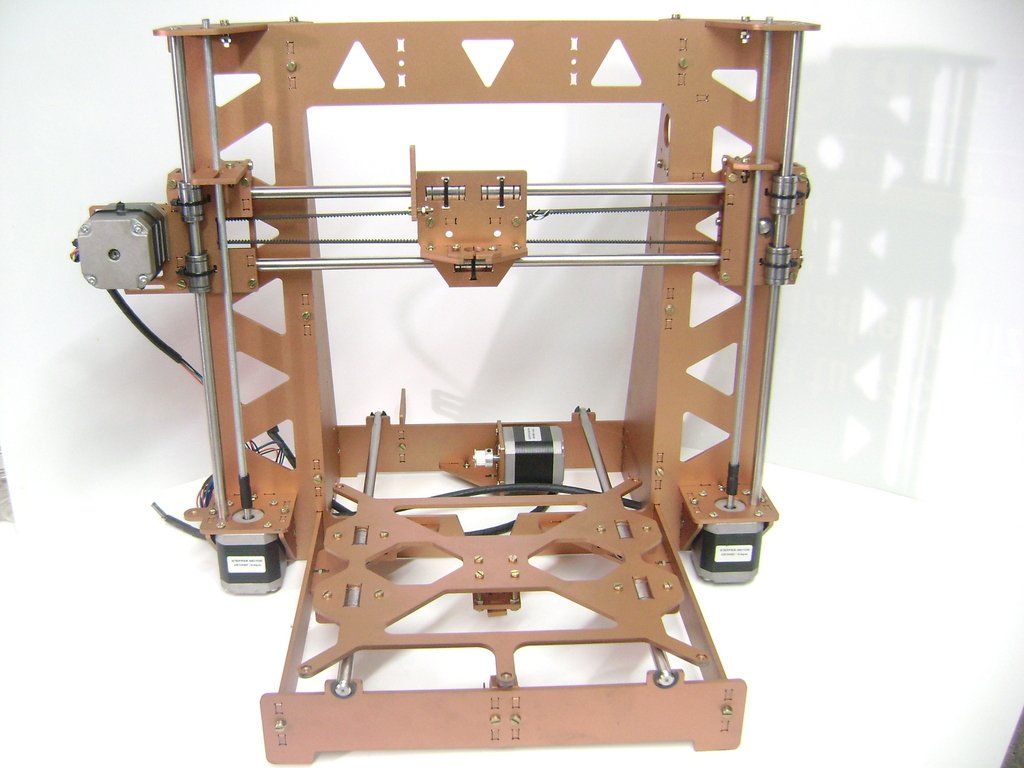

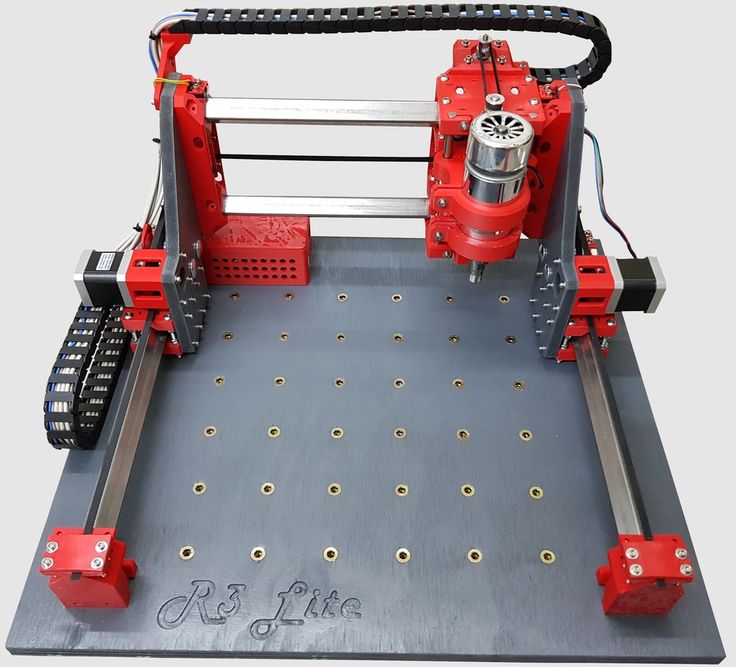

They key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, whilst CNC machining is subtractive. This means CNC machining starts with a block of material (called a blank), and cuts away material to create the finished part. To do this, cutters and spinning tools are used to shape the piece. Some advantages of CNC machining include great dimensional accuracy as well as many compatible materials, including wood, metals and, plastics.

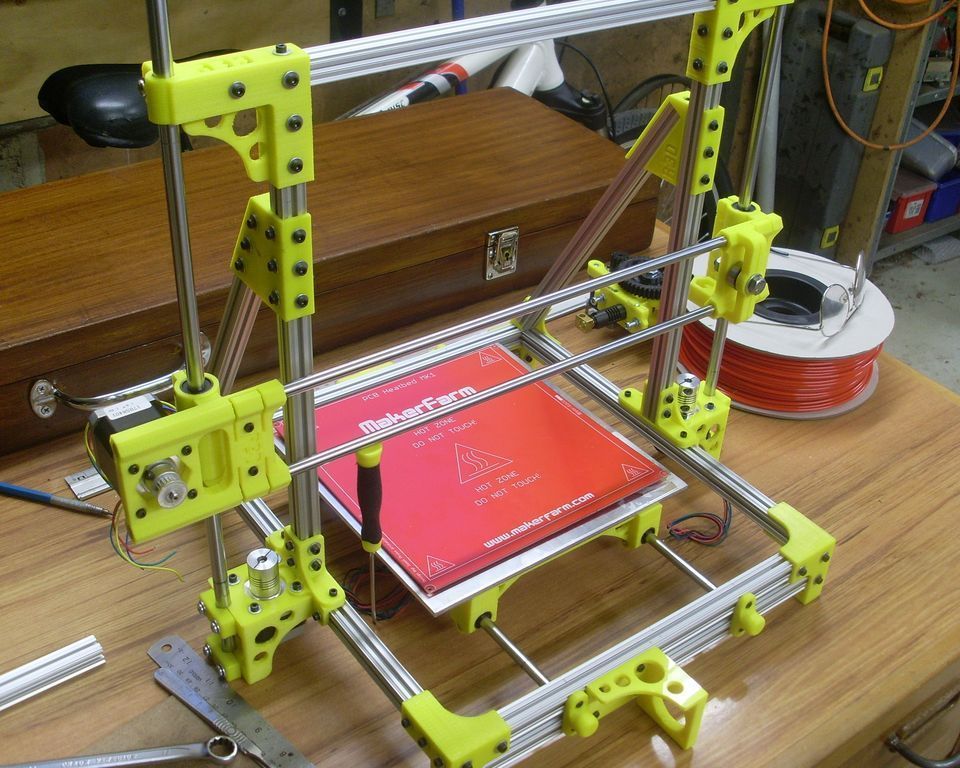

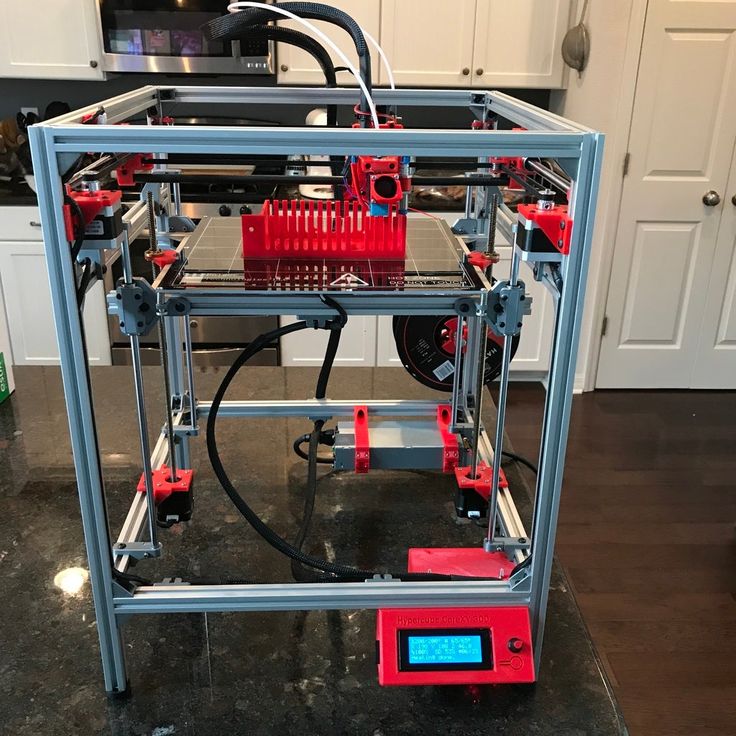

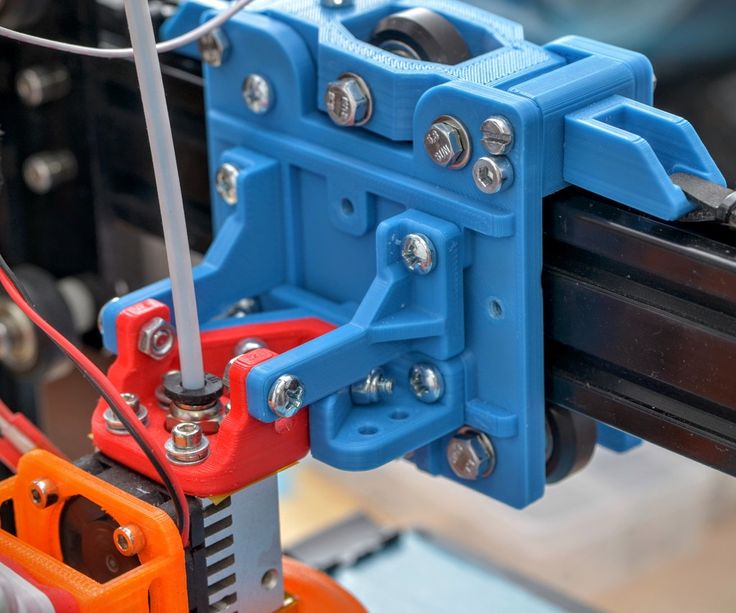

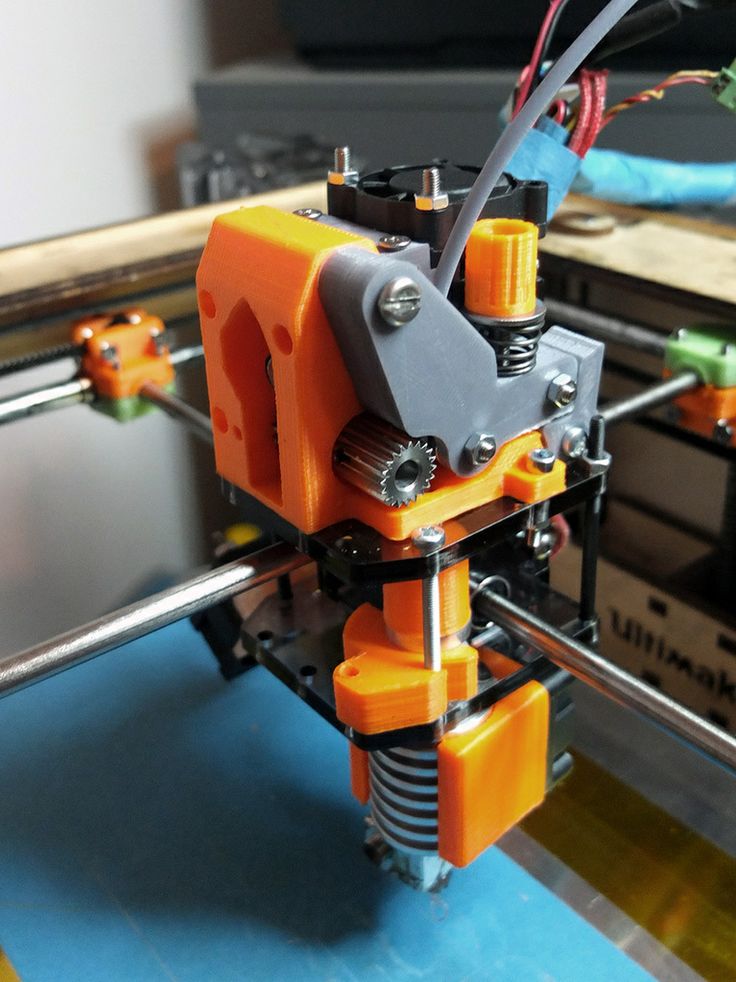

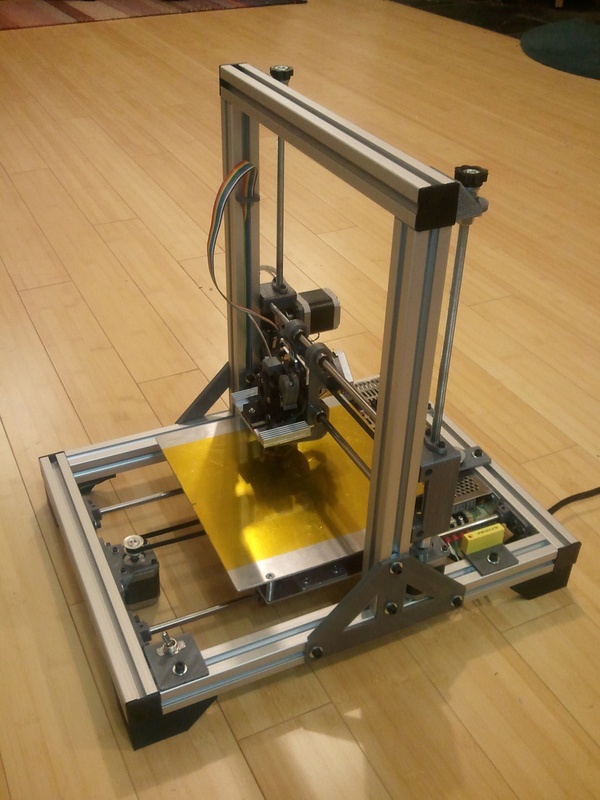

3D printing, or additive manufacturing, involves parts being created layer-by-layer using materials such as plastic filaments (FDM), resins (SLA/DLP), plastic or metal powders (SLS/DMLS/SLM). Using a source of energy such as a laser or heated extruder, layers of these materials are solidified to form the finished part. Advantages of 3D printing include its freedom of shape, applications in many sectors, accuracy, speed, and ability to cut costs and weight in parts.

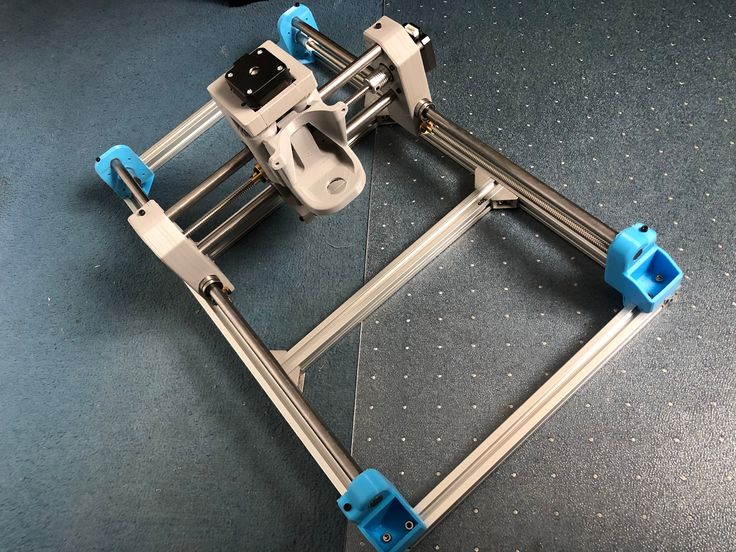

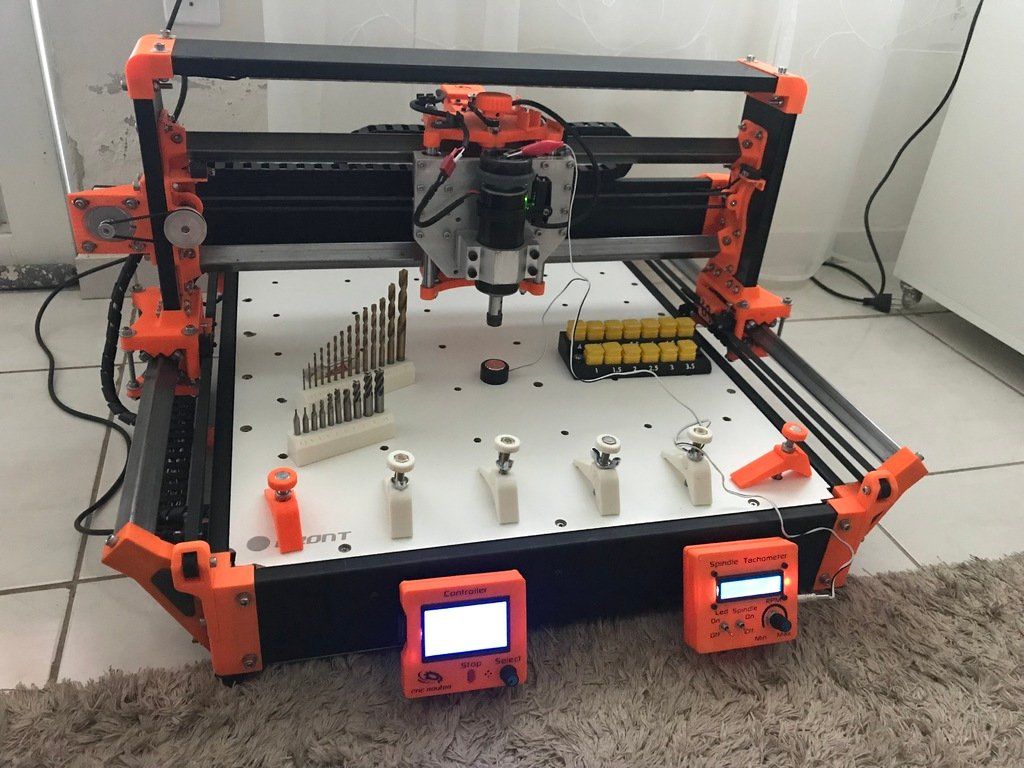

There are however several machines that have sought to combine these two forms of manufacturing in one. Most notably of these, the ZMorph 2.0 SX, is marketed as a CNC mill which also functions as a 3D printer. This includes a CNC mill with 3 axes as well as a print head due to its interchangeable heads. Moreover, several companies have recently closed successful Kickstarter campaigns with these combined machines, such as Mooz’s 3-in-1 3D printer.

Moreover, several companies have recently closed successful Kickstarter campaigns with these combined machines, such as Mooz’s 3-in-1 3D printer.

The ZMorph SX 2.0 includes interchangeable CNC and 3D printing heads.

3D Printing vs CNC Machining: Materials

Both 3D printing and CNC machining are compatible with a wide variety of materials, including both plastics and metals. 3D printing however is more focused on plastics overall, though this is changing rapidly as better and more affordable ways of 3D printing metal are being developed by manufacturers such as 3D Systems, Arcam, Desktop Metal and Markforged.

The most commonly used plastics used in CNC include ABS, Nylon (PA66), Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM and PEEK. A very commonly used metal in CNC machining is aluminium, used by prototyping companies to create high-quality prototypes in a variety of industries. Aluminium is recyclable, has good protective qualities, and can create effective prototypes for machining. Other commonly used metals include stainless steel, magnesium alloy, zinc alloy titanium, and brass.

Other commonly used metals include stainless steel, magnesium alloy, zinc alloy titanium, and brass.

Aluminium is a commonly used metal with CNC due to its good mechanical properties.

In 3D printing, commonly used thermoplastics include ABS, PLA, Nylon, ULTEM, but also photo-polymers such as wax, calcinable or biocompatible resins. Some niche 3D printers also allow for the printing of parts in sand, ceramics, and even living materials. The most common metals used in 3D printing include aluminium, stainless steel, titanium, and inconel. It is also worth noting that to 3D print metal, expensive ($100,000+) industrial machines are required. Some materials such as superalloys or TPU (flexible material) cannot be created with CNC, so must be used with 3D printing or rapid tooling technology.

Some plastics available to be 3D printed and CNC milled.

Ease of Use

3D printing is known to be simpler to use than CNC machining. This is because once the file is prepared, you just need to chose the part orientation, fill, and supports if needed. Then once printing has commenced, no supervisor is required and the printer can be left until the part is finished. Post-processing requirements depends on the technology.

Then once printing has commenced, no supervisor is required and the printer can be left until the part is finished. Post-processing requirements depends on the technology.

However, CNC machining is a far more labour-intensive process. A skilled operator is required to choose between different tools, rotation speeds of tools, the cutting path, and any repositioning of the material the part is being created from. There are also post-processing techniques which can require more time.

CNC requires an operator whereas 3D printing can be left alone when printing.

Accuracy, Size limitations & Geometric Complexity

Though there are a number of 3D printing technologies, we have chosen to compare CNC machining with SLS, industrial (not desktop) FDM, and DMLS metal 3D printing. In terms of tolerance, CNC machining is superior to all 3D printing processes, even DMLS. However, with minimum layer thicknesses the superiority is not so profound, and is not as precise as DMLS.

Powder bed fusion 3D printing processes such as SLS and DMLS are limited in their build volume however. Even technologies with larger build volumes such as FDM cannot compete with CNC in terms of maximum size of parts.

3D printing is well-known for its advantages in creating parts with high geometric complexity. Though supports are required for some technologies, 3D printing can create parts with geometries that no traditional manufacturing method can replicate. Technologies such as SLS and Multi Jet Fusion by HP can even do this without any support structures.

| Tolerance (mm) | Min. Layer Thickness (mm) | Max. build volume (mm) | |

| CNC Milling | ± 0.025 – 0.125 mm | cutting depth 0.01 mm | 2000 x 800 x 1000 mm |

| SLS | ± 0.3 mm | 0. 7 – 1.0 mm 7 – 1.0 mm | 300 x 300 x 300 mm |

| Industrial FDM | ± 0.5 mm | 0.8 – 1.0 mm | 900 x 600 x 900 mm |

| DMLS | ± 0.1 mm | 0.4 mm | 230 x 150 x 150 mm |

Cost

Though on average 3D printing is cheaper, costs depend on how many parts are required and how quickly you need them. For larger quantities (higher double digits to 100s) CNC is likely to be more appropriate. For low volumes, 3D printing is more appropriate and lower-cost. 3D printing is also more appropriate if you need your prototypes or parts very quickly. There are additional factors however that make comparing the two technologies more difficult. These include materials varying in cost (from cheap materials like ABS to materials that can cost $500/kg like PEEK), and repairing and changing machinery (such as CNC heads).

Environmentally Friendly

Since CNC involves cutting material away from an original block, there is always going to be mess afterwards. These pieces of material need to be cleaned afterwards and disposed of, which isn’t required from 3D printing. Since additive manufacturing forms an object on the build platform from material fed into the machine, there is no mess except supports (if used). This makes 3D printing the more ethical of two methods as there is less unused waste.

These pieces of material need to be cleaned afterwards and disposed of, which isn’t required from 3D printing. Since additive manufacturing forms an object on the build platform from material fed into the machine, there is no mess except supports (if used). This makes 3D printing the more ethical of two methods as there is less unused waste.

Conclusion

Overall to conclude, there is no perfect, one-size-fits-all technique. Though both methods are very competent and useful technologies, the most appropriate one will depend on the material, geometric complexity, manufacturing volume, and budget. To find out which is best for your particular job, we advise you approach a local or international service, and ask for their advice. If attempting to manufacture in-house, reflect on the machinery available to you and decide whether it is appropriate for the job at hand.

What did you think is the overall better method of 3D printing vs CNC? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

What's the Best Way to Make Your Part?

Introduction

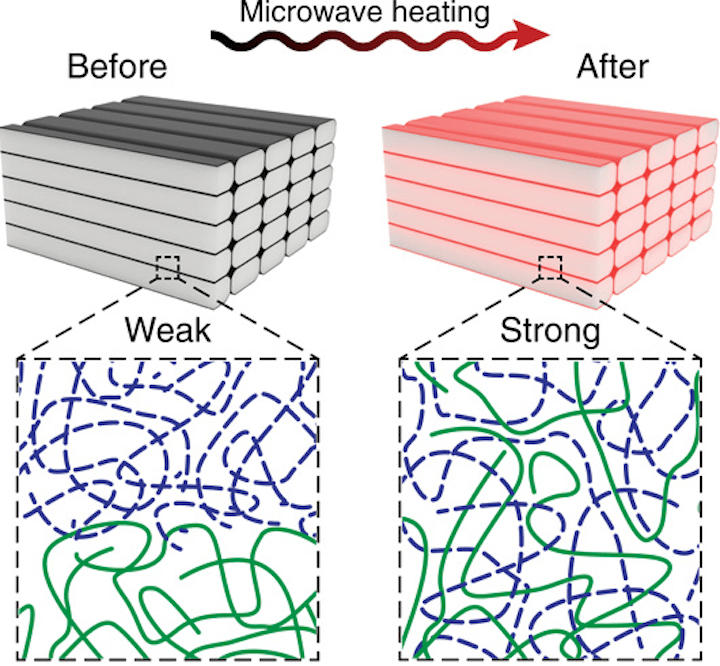

The development of stronger 3D printing materials has encouraged manufacturers across industries to explore CNC vs 3D printing, and find ways to 3D print functional parts that were previously CNC machined. The 3D printing process can save manufacturers considerable time and money, while still generating the quality necessary for industrial-level production.

The 3D printing process can save manufacturers considerable time and money, while still generating the quality necessary for industrial-level production.

Manufacturers that make the switch can leverage 3D printing software to prototype and produce parts in a single day, for a fraction of the cost of traditional CNC machining. However, there are still several key areas where CNC may still be the right choice for part production.

From physical to financial, let’s walk through some of the key areas to evaluate before deciding between CNC vs 3D printing.

Read our 3D Printer Buyer's Guide

Physical Considerations

Geometry

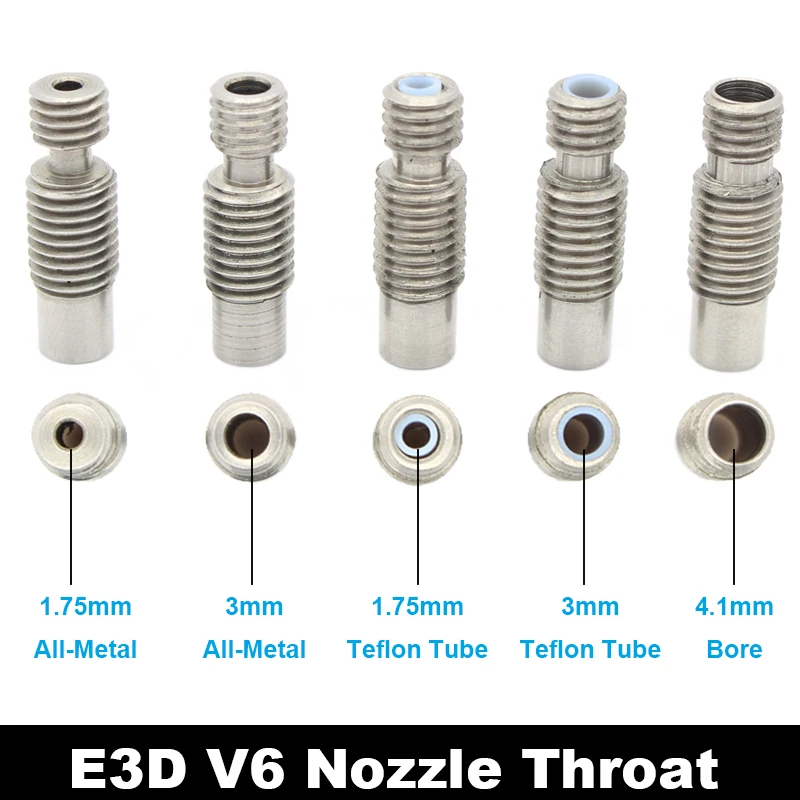

Feature Size: Both CNC and 3D printing processes are constrained by tool size; in the case of CNC, the tool diameter dictates the smallest negative feature that can be created. In the case of 3D printing, however, the nozzle diameter dictates the smallest positive feature that can be produced. The nozzle diameter for extrusion-based 3D printers is typically between 0. 25mm and 0.8mm, and the minimum feature size for those machines is 4 times that, resulting in a minimum feature size between 1.0mm and 3.2mm.

25mm and 0.8mm, and the minimum feature size for those machines is 4 times that, resulting in a minimum feature size between 1.0mm and 3.2mm.

For more detail on minimum feature size for continuous fiber reinforcement, we’ve created a guide to minimum fiber feature sizes.

Surface Finish: With the right tools, CNC machines are capable of producing much smoother surfaces than 3D printers. 3D printers are capable of producing parts for fit and finish, but for parts that require exceptional smoothness for mating with other precision components, CNC machining may be preferable.

Tolerances: Some of the best composite 3D printers can hold dimensional tolerances down to +/- 0.005”, and typically have a compliant surface for press fitting. Tight tolerance features on 3D printed parts can be post-machined. However, depending on the other features on the part, it may be easier to machine the whole thing. Your results may vary based on machine, material, and part geometry.

Get a free sample part

Loading: Non-structural parts are typically easy targets for conventional 3D printing. Structural parts that need to withstand significant physical loads can be produced with continuous fiber reinforcement, or by CNC machining. While continuous fiber reinforcement can provide significant strength improvement over other 3D printed parts, composite parts are stronger in two axes (X, Y) than in Z, and do not exhibit isotropic properties like metal parts. To learn more about how this might affect designs and orientation of parts for printing, read this piece on Isotropic Fiber Fill, which explores these parts in greater depth.

Check out our white paper on how to 3D print your own tools and fixtures

Environment

3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need.

Temperature: 3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need. The service temperature of a particular metal typically has some relation to its melting temperature. “Pure metals usually weaken seriously at about half the melting point on the absolute temperature scale (melting point in degrees F plus 459).” Alloys can typically push the useful range higher, in some cases to about 65% of melting temperature.

3D printed composites and polymers have service temperature limits lower than metals. Markforged materials typically should not be used for extended periods at elevated temperatures above 150 °C.

Moisture: Some polymer filaments absorb moisture and may lose strength through prolonged exposure or submersion. A coating, such as Liquitex, may be required. Moisture typically does not affect aluminum, but may cause steel to rust.

Chemicals: If your part will be subjected to any chemicals, check the chemical compatibility of your material with the chemical. While many metals are suitable for use with a variety of chemicals, always check for compatibility before introducing a new material or environment. Markforged nylon-based materials are chemically resistant and are unaffected by most petrochemicals. They are not suitable for use in strong acid or base environments.

Economic Considerations

When do you need it?

Machining in-house: If the part is needed immediately, there are no other holdups to the operation, and you have a machine, operator, materials, and workholding available, you should CNC machine your part. If there are more urgent jobs, or the part can wait, 3D printing can usually get you a part in hand the next day, freeing up operator time for more critical tasks.

CNC machining usually is capable of removing material much faster than 3D printing can deposit it. Size usually does not play into the time constraint as much for machining; the amount of material removal required is much more critical. If the part volume/stock volume ratio is very low (material removal is high), 3D printing may be a good option.

Size usually does not play into the time constraint as much for machining; the amount of material removal required is much more critical. If the part volume/stock volume ratio is very low (material removal is high), 3D printing may be a good option.

With 3D printing, the part size does affect time; larger parts take longer to print. if a part fits in the palm of your hand, you can usually have it the same day. With smaller parts, it can often be faster to 3D print than to machine. With a CNC machine you have to spend time getting stock, writing G-code, figuring out work holding, setting up tools, and cleaning up after. Some parts can print in the time it takes just to get a CNC machine ready.

Machining out-of-house: The process of outsourcing machined components to CNC machining services typically requires several days at minimum, between part review, creating drawings, sending out for quote, and reviewing with purchasing. This, plus shipping and lead time from the shop, can sometimes result in a very lengthy process. Printing, in this case, may be a suitable way to check fit and finish or have a part ready the next day while a permanent part is being cut.

Printing, in this case, may be a suitable way to check fit and finish or have a part ready the next day while a permanent part is being cut.

How many do you need?

When you break down the cost of low-volume machined parts, the bulk of the cost comes from the time required for programming and setup; the actual time for cutting metal is generally fairly short. Scaling up production volume is generally achieved by making larger setups to cut more parts unattended. As part complexity and the number of features increases, programming time and the number of required setups may also increase. However, the cost of additional units drops off fairly quickly. Depending on geometry, CNC per unit cost scales well into orders of hundreds or low thousands of units per month since the programming and setup can be reused.

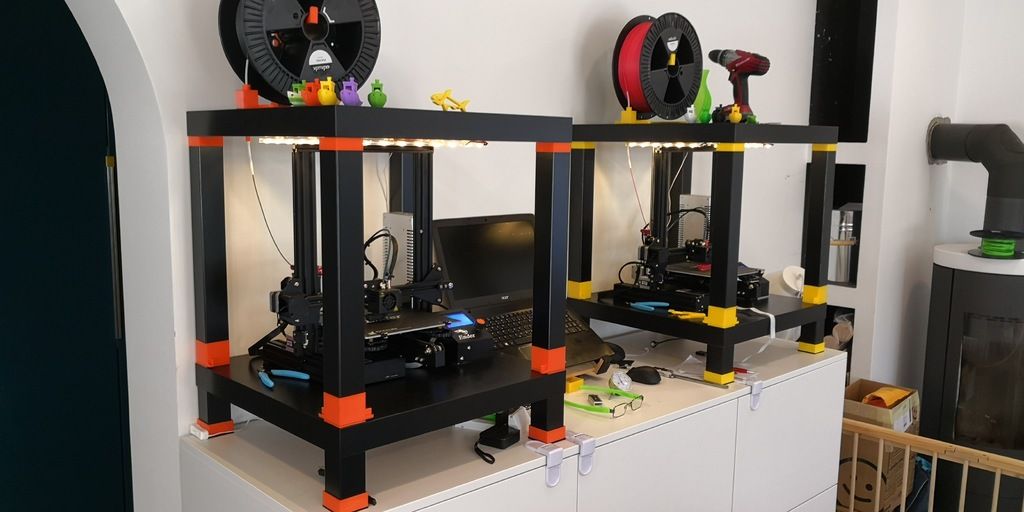

With 3D printing, the programming (slicing) happens in a matter of minutes, and complexity has little effect on the programming time. While the first unit cost and effort is low, the per unit cost is not affected much by volume. Scaling up production volume is generally achieved by bringing more machines online.

Scaling up production volume is generally achieved by bringing more machines online.

What is your budget for equipment and operators?

CNC machines can run unattended when properly set up, but typically trained full-time operators and programmers are critical to success. Machines are not always easy for owners to service, requiring expensive maintenance plans.

3D printers can easily run fully unattended, operators require minimal training, and programming is made easy by software. Machines are typically easy to service and have far less expensive maintenance costs.

CNC machines and 3D printers come in a range of prices based on features and build quality, but typically 3D printers can be owned for a significantly lower investment than a CNC machine.

The upfront cost and operating cost of additive manufacturing is low, making it ideal for low volume applications such as prototyping and tooling. However, when scaling to higher volumes, subtractive manufacturing and forming are more cost effective.

Request a demo

Where should you fall on the CNC vs 3D Printing Debate?

The case is seldom as simple as a one-to-one process replacement, and 3D printing is not going to solve all of your production problems overnight. Economic constraints limit the cost effective part quantity for 3D printing to low volumes, and the materials and process constraints may limit the application space. CNC machining, on the other hand, sees favorable economies of scale once quantities are a bit higher, usually on the order of hundreds of units per month.

3D printing or CNC machining

Accelerate product development, reduce costs with a digital manufacturing platform.

Get an instant quote

Upload to production in 5 min.

CNC milling technology has been around since the 1950s and is essentially the opposite of 3D printing. In the case of 3D printing, the computer controls the printer's print head, which "adds" material in three dimensions, with CNC machining, the milling tool is controlled, which removes material. The key difference between the two technologies lies in the way the given geometry is formed.

The key difference between the two technologies lies in the way the given geometry is formed.

Designing 3D models for CNC machines and 3D printers is often carried out on the same software, but already at the next stage of preparing the output data, completely different transformation methods are used. So, for CNC processing, a solid model is used, formed by three-dimensional elements - bodies, and for 3D printing, a surface model - consisting of polygons or a shell.

While 3D printing may seem like an evolving and underdeveloped technology, new printers continue to appear in factories as alternatives to CNC machines. Many companies, getting acquainted with 3D printing, are faced with the complexity of the new technology, but continue to look for ways and areas to apply it in their business.

Miscellaneous

CNC milling machines and 3D printers have different technological capabilities and limitations that allow them to solve different problems.

CNC milling machine allows you to efficiently produce large, heavy and high-precision products in large runs, which can be used for the production of commercial and industrial equipment, machines, engines. CNC technology also allows the production of small batches of products, but usually with a higher unit cost.

The flexibility of 3D printing makes it possible to quickly switch between different products. However, since the unit cost of a product is always the same regardless of the quantity, 3D printing is not economically viable for large print runs.

The adaptability of 3D printing makes it useful for creating unique, personalized designs, such as custom trauma or dental implants.

Technology selection

When choosing between CNC and 3D printing, there are a few simple guidelines that can be applied to your decision making process.

Choose 3D printing if:

• traditional methods do not allow the production of a part, for example, for very complex geometries

• production time is critical, printed parts can be produced within 24 hours

• low cost for small runs, number of identical parts (less than 10)

• materials that are difficult to process, but it is possible to print, such as alloys of certain metals

CNC machining:

• offers high accuracy and uniformity of mechanical properties throughout the volume of the product (isotropy, as opposed to anisotropic properties in printed products), but usually comes at a higher cost, especially for small volumes

• stability of time costs and the result with a proven technological process

In this case, the key factor is the total number of products - circulation. And if mass production of items (hundreds or more) is required, then neither CNC nor 3D printing can be a cost-effective option. Traditional molding techniques such as investment casting or injection molding will be the best choice.

And if mass production of items (hundreds or more) is required, then neither CNC nor 3D printing can be a cost-effective option. Traditional molding techniques such as investment casting or injection molding will be the best choice.

Materials

CNC machining is mainly applied to the processing of metals and modeling plastics:

• Plastics: ABS, nylon, polycarbonate, PEEK

• Metals: aluminium, stainless steel, titanium, brass

3D printing predominantly works with plastics and, to a lesser extent, with metals:

• Plastics: Nylon, PLA, ABS, ULTEM, ASA, TPU

• Metals: titanium, stainless steel, cobalt-chromium alloys

Product geometry complexity

CNC

There are a number of constraints to consider when designing CNC parts, including tool access and tolerances. A feature of CNC machining is the internal corners of the product, which always have a radius due to the shape of the cutting tool, but the outer surfaces can have sharp edges. Also, most non-standard geometries require rotation of the part to access different sides. Rearranging the workpiece increases the processing time, non-standard fixtures and additional fasteners may also be required, which together affect the final cost of the product. Read design guidelines for CNC machining.

Also, most non-standard geometries require rotation of the part to access different sides. Rearranging the workpiece increases the processing time, non-standard fixtures and additional fasteners may also be required, which together affect the final cost of the product. Read design guidelines for CNC machining.

3D print

The ability to create very complex geometries is one of the key benefits of 3D printing. The technology has fewer restrictions, but it should take into account the possible wall thickness of the part, overall dimensions, as well as the need to build support for most types of printing.

Manufacturing process

CNC

The main difference between the CNC machining process is that after the CAD file is received for production, the technologist or engineer works out the choice of tool, processing speed, tool path and changing the position of the part. All these factors greatly influence the quality of the final part and the working time. That is, the preparation process is time-consuming, and the production itself in most cases requires the presence of an operator.

That is, the preparation process is time-consuming, and the production itself in most cases requires the presence of an operator.

3D printing

In 3D printing, the printer operator prepares the orientation of the model in the printer and adds support, and then sends the file to the printer, where it is printed without additional involvement of a specialist.

Post-processing

Also, parts both after machining and 3D printing can be applied a number of post-processing methods that improve the functionality and appearance of the product:

• blasting

• heat treatment

• anodizing

• painting, powder coating

• grinding and polishing

For printed products, post-processing can be additionally carried out on CNC machines to improve the accuracy and quality of the surface, parts are made with a built-in allowance, after which the material is removed mechanically.

Terminals

To a certain extent, CNC and 3D printing technologies overlap in their capabilities, but each of them has its own strengths and weaknesses that make them suitable for solving specific problems.

CNC milling machines are usually best suited for projects that require complex, high-precision parts with a production run of 100 to 1,000 pieces. 3D printing is ideal for prototyping and personalized, customized products.

Compare also:

Polyurethane injection molding vs injection molding

3D printing technologies

Types and properties of polyurethane

Benefits and features of 3D printer and CNC operation

Experts recommend

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

The benefits of metal 3D printing have long been familiar to most professionals: reducing waste, increasing production efficiency and expanding functionality through greater design freedom and flexibility. At the same time, high repeatability in high-volume production and precise surface finishes (especially when it comes to tight tolerances) are capabilities that are strongly associated with CNC machining. But what if there is no competition and there is no need to choose between two technologies?

Ingo Uckelmann, Chief 3D Printing Engineer at Materialize, explains why these technologies can (and should) complement each other rather than compete with each other.

- It is generally accepted that 3D printing is better for making metal parts than other technologies, including CNC machining. Is it really?

- No. This is a common misconception. Metal 3D printing, like any other manufacturing technology, has advantages and disadvantages that need to be evaluated for each specific task. The bottom line is that this technology offers manufacturers just another way to produce.

When comparing 3D printing with CNC machining, there are several fundamental differences. CNC machines use a subtractive process, which means more material consumption. If the cost of the material is high (as is usually the case with metals), then the reduction in its consumption becomes a significant advantage in itself.

Next, the machine forms the surface of the part with a cutter. If a suitable tool is not available - for example, in the case of undercuts - another production process is started to create it. During processing, the part must be securely fixed, and the cutter must have access to all its surfaces. Sometimes this is beyond the power of even a five-coordinate machine. Also, most of the cutters are cylindrical in shape, and it is problematic to ensure the perfect execution of the corners. Vertical inside corners will always be rounded - except when undercuts are used.

Sometimes this is beyond the power of even a five-coordinate machine. Also, most of the cutters are cylindrical in shape, and it is problematic to ensure the perfect execution of the corners. Vertical inside corners will always be rounded - except when undercuts are used.

3D printing is an additive process and does not require any special tools other than supports. The processing of corners and edges is not difficult. With the help of 3D printing, it is possible to produce parts of complex geometry, including those with internal channels and cavities, which makes it possible to reduce the weight of products and expand their scope. When using a 3D printer, the need to make physical tools disappears, giving way to software.

Many manufacturers think that one of the two technologies must be chosen! In fact, you can achieve outstanding results by correctly using the advantages of both.

– But don't these advantages mean that 3D printing is always better?

- Of course. CNC machines also have their advantages, and one of them is high accuracy, up to several microns on each axis, which allows you to get perfect surfaces without additional processing. When it comes to tolerances, CNC machining is also generally superior to 3D printing, as the material does not need to be heated and reshaped. In addition, CNC machines are excellent for end parts made of heavy materials.

CNC machines also have their advantages, and one of them is high accuracy, up to several microns on each axis, which allows you to get perfect surfaces without additional processing. When it comes to tolerances, CNC machining is also generally superior to 3D printing, as the material does not need to be heated and reshaped. In addition, CNC machines are excellent for end parts made of heavy materials.

When there are no design requirements that make 3D printing a necessity (internal channels, complex geometries, weight reduction, monolithic structures, etc.), subtractive processing is more attractive for small-scale production in terms of speed, cost.

The problem is that many manufacturers think that one of the two technologies must be chosen! In fact, you can achieve outstanding results by correctly using the advantages of both.

- Can you give examples? How can manufacturers use both technologies at the same time?

- I already talked about tolerances. In the automotive, aerospace, and other industries that require high precision in the manufacture of metal parts, it is impossible to ensure acceptable errors using only 3D printing. On the other hand, the benefits of 3D printing in such cases are the ability to reduce weight and improve the ergonomics of parts. When processing printed parts on CNC machines, manufacturers “kill two birds with one stone”: in some cases, an error of ±0.005 mm can be achieved.

In the automotive, aerospace, and other industries that require high precision in the manufacture of metal parts, it is impossible to ensure acceptable errors using only 3D printing. On the other hand, the benefits of 3D printing in such cases are the ability to reduce weight and improve the ergonomics of parts. When processing printed parts on CNC machines, manufacturers “kill two birds with one stone”: in some cases, an error of ±0.005 mm can be achieved.

Tight tolerances require a perfect surface finish, especially when absolutely precise fitting of parts is critical. In such situations, it is possible to print oversized parts and then process them, for example, on a five-axis CNC milling machine, achieving the required accuracy.

Materials are a distinct advantage. Previously, 3D printers were often unable to provide the mechanical properties (strength, corrosion resistance, thermal insulation properties) of titanium, aluminum, inconel or stainless steel. Now these materials, as well as many other alloys and superalloys, are fully available for 3D printing. By using CNC machines for high-precision post-processing of printed products, design engineers have much greater flexibility in working with materials they already know.

By using CNC machines for high-precision post-processing of printed products, design engineers have much greater flexibility in working with materials they already know.

It is important not to forget such a moment. 3D printing opens up new possibilities for design optimization; similarly, files intended for 3D printing can be optimized for CNC machines, further savings. Turns, movements, complex and long technological process, special fixtures - all the known disadvantages of CNC processing when using 3D printing are completely eliminated. The 3D printer does the bulk of the work, creating the initial design, while the final processing (such as cutting fine threads) - a simple but very important production step - is left to CNC machines.

Finally, 3D printing metal parts followed by CNC machining is often much faster and cheaper than creating a new injection mold. Add to this the benefits of working with CAD models, and it becomes immediately clear why this “star pair” of technologies is attracting the attention of manufacturers.