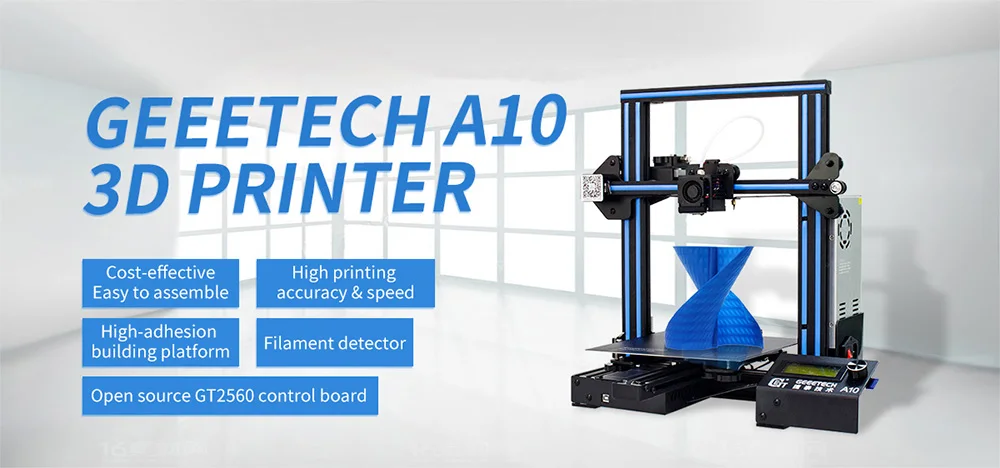

Geeetech 3d printer review

Geeetech i3 Pro B User Review; Is it worth getting? – 3D Solved

This article is intended to be a review as complete as possible of the Geeetech i3 Pro B 3d printer, which is one of the most popular printers in the world, given its low cost and the ease of buying it and getting it delivered in any country from its many resellers.

I will go over its assembly process, general characteristics, known issues, print quality, and the pros and cons.

So, without any further ado, let’s get started!

Assembly

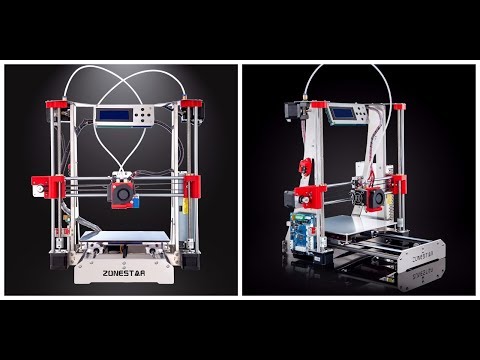

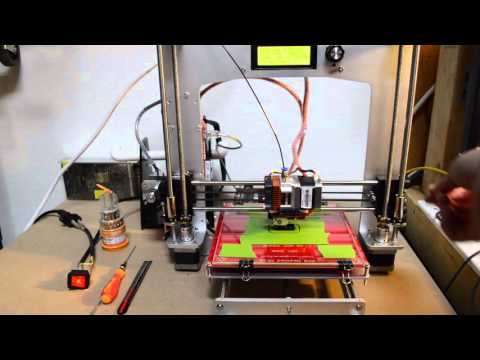

This printer comes in a DIY kit, unlike the Ender3 which comes partially pre-assembled. That means you will have to assemble the entire printer yourself which can be either entertaining or very frustrating, depending on your skills and your desire to learn.

As a first piece of advice, I would say that the i3 Pro B is not the best printer to get started with in the world of 3d printing, although it is inexpensive and can give good results, it is necessary that you master certain aspects related to the mechanics and electronics of a 3d printer before assembling one of them yourself. Otherwise, it is possible to run into simple problems that someone with some basic-level knowledge can quickly figure out, but you can’t.

Before starting, I must clarify that when I bought the Geeetech i3 Pro B I already had some years of experience in the use and assembly of 3d printers. Due to this, I was able to solve many problems during the assembly of the printer that are not clearly explained in the manuals and video that the company provides to guide users.

Having an idea of what I was doing, it still took me more than 10 hours to put all the parts together (in their correct position, by the way…). Perhaps, with the help of a friend I could have done it in half the time, since looking for the necessary piece in the parts list and identifying it sometimes takes more time than the assembly itself.

This is important to keep in mind, especially if you don’t have a large table at home. Do not use the table where you and your family eat, as it will probably take a day or two to finish the assembly and you will get some very disapproving looks.

The printer comes completely disassembled down to the last screw and wrapped in a large cardboard box. You will need a large space to verify that no parts are missing which can be done with the help of the list provided. In case any parts are missing, Geeetech’s after-sales service is very good and will gladly send the missing parts over to you, although this can be somewhat frustrating if you were excited to get started.

You may replace some screws or washers, but a stepper motor or a control board aren’t things you usually have at home (Those will generally not be missing though).

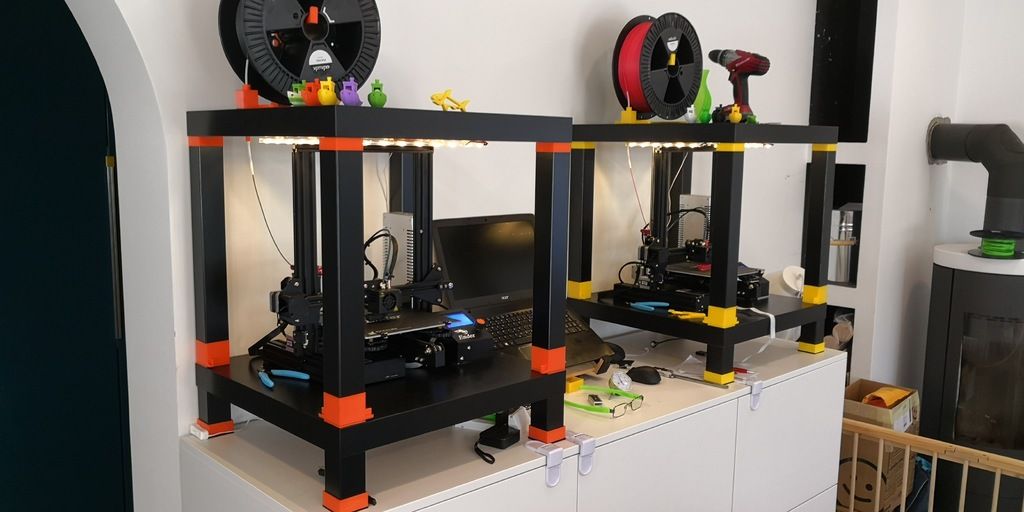

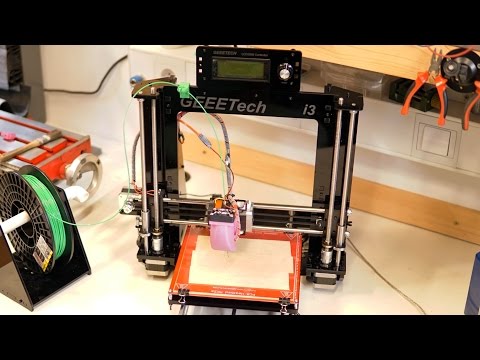

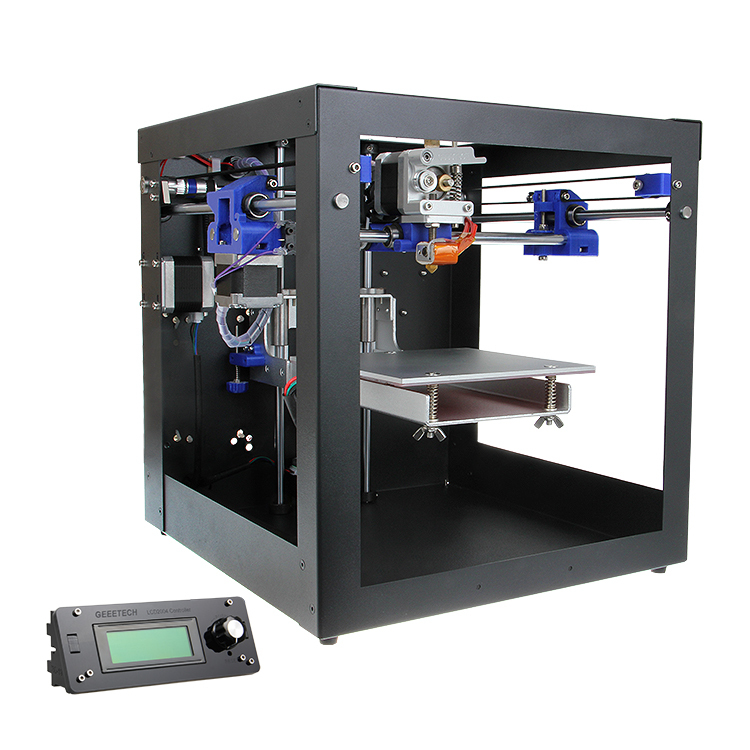

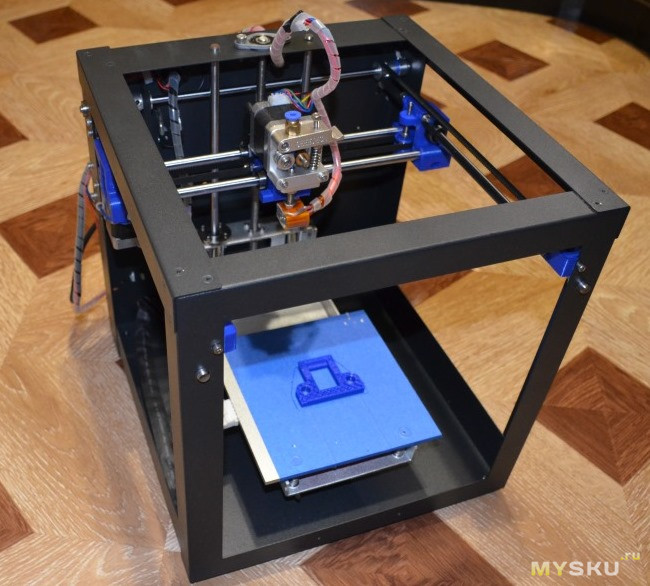

Final assembly, with the addition of a filament guide on top and a 5015 layer fan.On the official Geeetech website you can find the assembly manual, which is very helpful but it is much better to follow the video tutorial available on YouTube. It is normal that you get stuck in some steps, since many pieces are similar or are not perfectly labeled in the assembly manual. Again, take it slow and be VERY patient at this point, as you only need to assembly the printer once.

With patience (and a lot of free time), you can have your 3d printer working and won’t need to ever go through the process again. In addition, the complete assembly of this machine will allow you to know in depth each one of its components, which will give you an additional experience that other pre-assembled printers cannot give you.

General characteristics

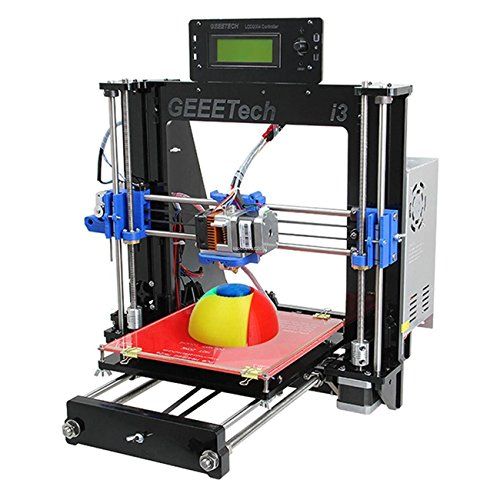

The i3 Pro B mounts its components on an 8mm thick laser cut acrylic frame held together by heavy duty threaded rods. The dimensional tolerances of its parts are adequate and they tend to generate some friction between them, so it is recommended to use the file provided to wear the joints a little before assembling them. Some users skip this and acrylic tends to break under pressure.

The printer has no printed parts, which is often the weak point of many low-cost Prusa clones. The metal parts are rigid and look very strong.

The X/Y axis belts have their corresponding tensioners, so there is no need to modify the mechanism ever.

The quality of its components is somewhat related to its price: The bearings look low quality and the Z axis brass nuts are a bit loose when mounting. Anyway, once the printer gets assembled it feels stiff. I have a different Prusa i3 clone at home, armed with a steel frame that transmits much more vibrations to its parts than the Geeetech printer.

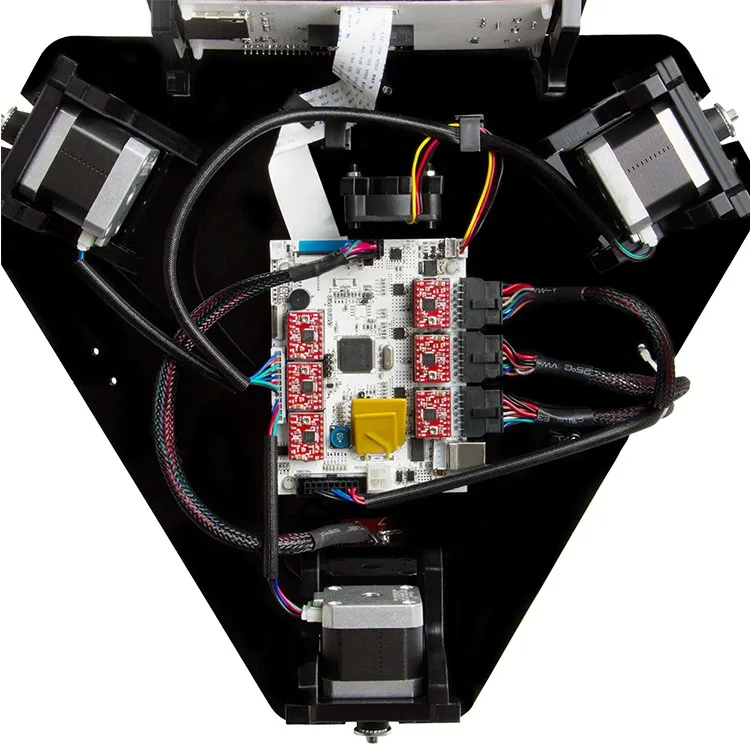

The control board in this printer is the GT2560, which integrates in a single board all the functionalities of the Arduino Mega + Ramps 1.4 set. The configuration that its firmware brings is adapted to the hardware of the printer, so it does not require any modification such as calibrating the steps of the axis or the extruder. It mounts to one side of the printer, and has a small fan to cool the drivers. As it does not have a case to protect it, it is usually filled with dust that needs to be cleaned frequently.

One point to note is that the printer does not have a layer fan, although the board does have the jack available to place it, and the printer menu allows you to control its speed. Considering that the layer fan is a great help when printing, I think Geeetech could supply it and achieve a more complete 3d printer. As a tip, I suggest that your first piece printed with this machine is a fanduct for a 5015 blower fan.

Considering that the layer fan is a great help when printing, I think Geeetech could supply it and achieve a more complete 3d printer. As a tip, I suggest that your first piece printed with this machine is a fanduct for a 5015 blower fan.

The printer’s screen is located on top of the acrylic frame and due to this, the filament spool cannot be placed on the frame of the printer. I think it is somewhat uncomfortable and it would be better to have it placed on the front of the machine. If you like modifying your printers, this might be a good idea.

In addition to the printer, a support for the filament spools is included in the kit. To make it stay in place, I fastened it to the table using a wood screw and washer. Of course, it is not a good idea to punch a hole in a table. The downside of this stand is that it is too small, and large spools cannot be fitted. The solution I found is to use an 8mm rod and pass it through the top hole.

Left: material provided. Right: my great solution.

Also, since the filament can catch on some moving part of the printer, I printed this part:

This screen mount doesn’t seem to last much longerThis little upgrade allows the filament to be guided and prevents it from tangling.

The extruder provided is an old acquaintance: the MK8. In my case, it is aluminum, but I know people who received the extruder made of plastic. It works very well and there are no jamming problems.

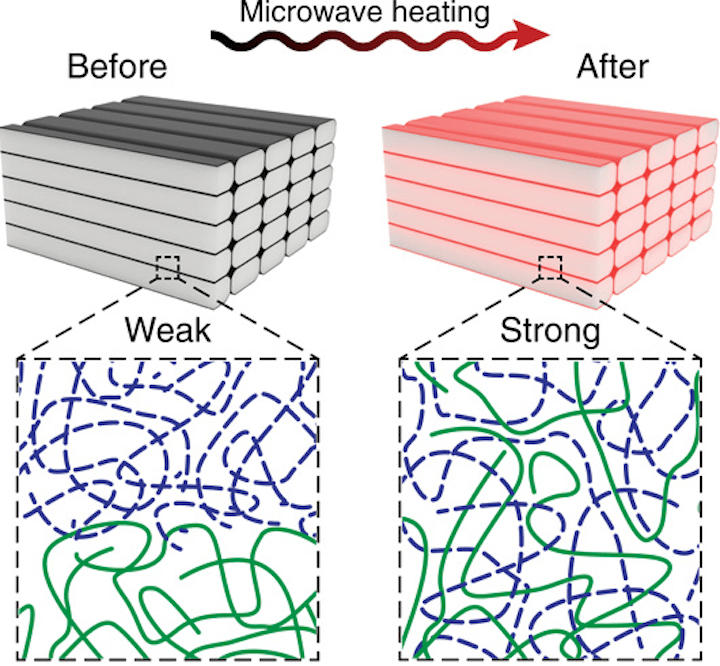

Usually this extruder is used for Bowden type printers, but the i3 Pro B has a direct extrusion system mounted on it. The way it is assembled, there is a gap between the barrel and the extruder sprocket. This means that when printing TPU, the filament can escape through that space and ruin the whole printing process. I use a small piece of PTFE tube to eliminate the gap, but sometimes it gets out.

There are some pieces available on Thingiverse that allow you to solve this issue, but if you only print stiff filaments, there is no need to use those upgrades.

The hotend withstands very high temperatures, but since the printer does not have an enclosure, it is not easy to print more demanding materials such as Nylon. So far, I had no problems printing PLA, ABS, PETG and TPU.

The Z axis is moved by 2- 8mm trapezoidal rods, which are not bent and do not generate any wobbles.

Since the stepper motors are driven by A4988 drivers (the cheapest ones), they produce some noise during movement, but it is bearable. After a few months of use, linear bearings (also low quality bearings) begin to rattle, so it is advisable to replace them with more expensive ones.

All things considered, however, it is a fairly quiet printer.

Operation and known issues

The Geeetech i3 Pro B is a machine that divides opinions among its users: there are those who think that it is the best 3d printer in relation to price/quality on the market, and there are those who believe that it is not worth spending money and time on a machine that brings more problems than solutions.

My opinion is that this 3d printer is the best you can get for a budget of around $150. In addition, since you are the one who assembles the printer, I believe that the reliability of this machine depends purely and exclusively on your skills. Until now, after more than 2 years of using it, almost all the problems I had were the result of my mistakes when putting it together, that’s just how it is.

For example, I had some issues related to loss of steps in the motors, in the movement axes and with the extruder. This was because the supplied A4988 drivers do not come with the proper voltage/current calibration and that’s because you are the one who should regulate them according to the torque they will need, which is an easy task.

Electronics is simpler than Arduino’s, but you still have to calibrate tension on the driversAt another time, I had problems when changing filament, since there was a clog in the barrel that prevented the placement of the new filament. To fix this, I found that it was necessary to manually extrude some material before making the filament change.

To fix this, I found that it was necessary to manually extrude some material before making the filament change.

This way, the plastic is soft and does not block the barrel. I suspect this is a recurring problem with the MK8 extruder, as a metal tool is provided inside the box. At first, I didn’t know what it was for, but at the third blocking of the barrel, I realized that this tool allows you to push the hard filament in and unclog the barrel. I did not find this information in the manual or documentation for the printer, however, which they definitely should’ve included.

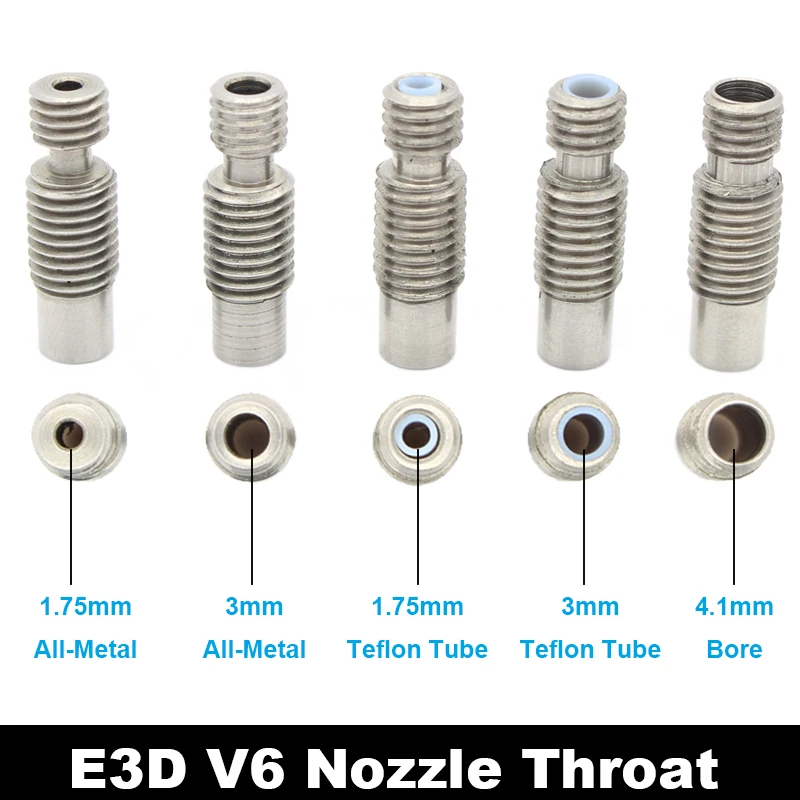

Another problem I had was during my first printing, after finishing the assembly of the machine, I did not pay attention to the nozzle size and tried to print as I always did with my other printers. The loss of steps alerted me and when checking, I verified that the nozzle provided in the Geeetech i3 Pro B is 0.3mm, when the diameter in my other printers is 0.4mm. Fortunately, the thread on the heater block is M6, which is also used by most nozzle manufacturers. By replacing it, it started working perfectly.

By replacing it, it started working perfectly.

Print quality

Compared to most low-cost clones of the famous Prusa i3, the Geeetech i3 Pro B is the best 3d printer you can get for under $200. Its structure is very firm and the metal parts are rigid. This means that no vibrations are transmitted to the printed objects when printing at 40mm/s. When this value is exceeded, you start to see some ghosting in very sharp corners.

Notable ghosting in the eyes: this was printed at 60 mm/s0.3 layer height at 50 mm/sNo wobble is observed on the Z axis and the geometric precision is at correct values on all axis.

Smaller objects show more flaws but they are still OKPros

- Its price / quality ratio is the best in its range

- assembling it gives you a lot of experience

- The quality of your printed objects is quite good

- The structure is well designed and very resistant

- As this printer is based on the Prusa i3 model, it is very easy to find spare parts and pieces to modify it on the internet.

Cons

- Its low-quality components have a short service life, so they need to be replaced.

- The extruder is difficult to disassemble, and it has no reduction in its gears, so it needs a larger motor to work, adding unnecessary weight to the X axis.

- The glass of the heated bed is too short, and does not cover the entire printing area. You will have to buy one that allows you to take advantage of all the space.

- The assembly process is very complicated and it is normal to make mistakes, causing you to have to disassemble some parts several times until you get to do it correctly.

- The PSU could be of higher power, to speed up heating.

Conclusion

The Geeetech i3 Pro B is a really good printer if you consider the price. Sure, it’s a clone of the Prusa i3 and maybe the components aren’t as high quality, but it also costs about 5 or 6 times less.

Like I mentioned throughout the article, I think that this printer is ideal for anyone who already has experience with electronics and with 3D printer assembly, at least if you want to avoid a lot of headaches.

If you’re a complete newbie, then I’d recommend going with something simpler, like the Ender 3 (link to the review of my own Ender 3 Pro 3D printer) since it comes partially assembled and you should have it running in less than one hour.

I hope this information was useful!

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

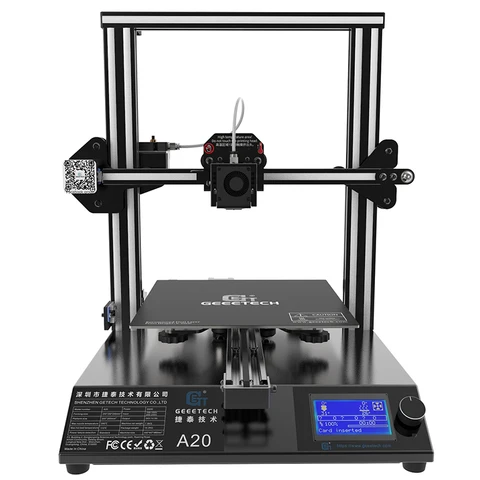

Geeetech A20M Review - Specs, Features, Pro & Cons

- Author

- Recent Posts

Martin

Martin has a M. Sc. in physics and has gained many years of experience in industry as a lab manager and quality assurance manager. He has now tested dozens of 3D printers and is happy to share the collected experience with each new article.

Sc. in physics and has gained many years of experience in industry as a lab manager and quality assurance manager. He has now tested dozens of 3D printers and is happy to share the collected experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

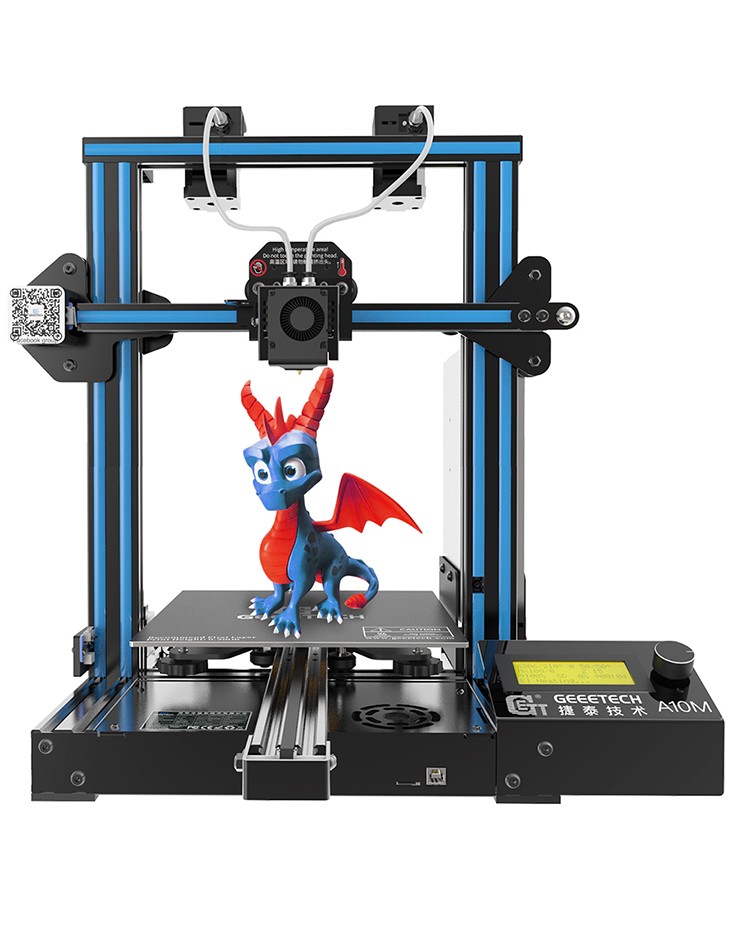

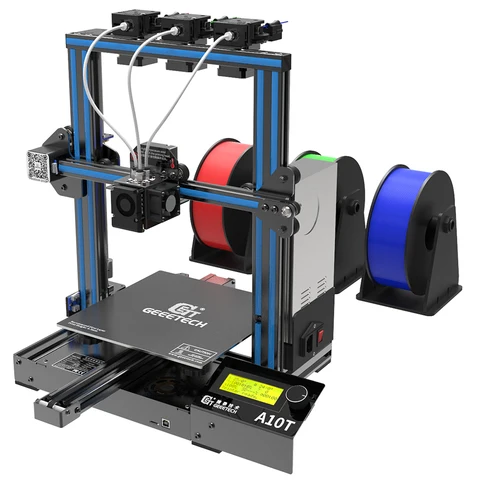

Since its launch in November 2018, the Geeetech A20M* has made many friends around the world. The printer is affordable, offers a large build volume and is equipped with numerous features that you would otherwise only find in much more expensive 3D printers. Find out what you can expect from the Geeetech A20M in our detailed review.

Geeetech A20M*Check Price at:

Amazon*

Table of Contents:

- 1 Specifications

- 2 Unboxing

- 3 Setup

- 4 Design, Equipment and Processing

- 5 Operation

- 6 Connectivity

- 7 Software

- 8 Print Resume

- 9 Auto-Leveling Optional

- 10 Gradient Prints

- 11 Dual Color Printing

- 12 Noise Level

- 13 Optional Accessories

- 14 Related Questions

- 14.

1 Can the Geeetech A20M be operated with a smartphone and app?

1 Can the Geeetech A20M be operated with a smartphone and app? - 14.2 Is the Geeetech A20M available with 2 print heads?

- 14.3 Is there a cover available for the Geeetech A20M?

- 14.

- 15 Our Conclusion about the Geeetech A20M

Specifications

Let’s first take a look at the technical specifications of the Geeetech A20M*. According to the manufacturer, the printer offers the following technical features:

- Printing technology: FDM

- Construction volume: 255 x 255 x 255 mm

- Printing accuracy: 0.1 mm

- Positioning accuracy X/Y: 0.011 mm

- Positioning accuracy Z: 0.0025 mm

- Print speed: 120 mm/s (max.)

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Heating bed: max. 100 °C

- Extruder: max. 250 °C

- Filament: ABS / PLA / Wood Polymer* / PVA* / HIPS* / PETG etc.

- Operating system: Windows, MAC, Linux

- Control software: EasyPrint 3D, Repetier-Host, Simplify 3D, Cura, Slic3r, etc.

- App: EasyPrint 3D App (with optional 3D WLAN module)

- File format: .stl, gcode

- Power supply: Input 110V/220V

- Power supply output DC 24V/15A

- Connectivity: SD memory card (max. 32 GB), WLAN (optional), USB cable

- Screen: LCD Display

- Frame: Aluminum profile

- Dimensions: 442 x 447 x 480 mm

- Weight: approx. 8.8 kg

The Geeetech A20M is a very affordable FDM 3D printer with a large build volume and good features. However, it also has a few weaknesses.

Pro:

- Affordable price

- Large construction volume

- High printing accuracy

- Two-color printing is possible

- Color gradients can be printed

- Filament detectors

- Heatable print bed

- Compatible with many filaments

Contra:

- Open construction

- Automatic leveling only optionally available

- Plastic extruder gearbox

- WLAN module only optionally available

Unboxing

The Geeetech A20M is delivered as a mostly pre-assembled printer. The delivery is very well packed in a sturdy cardboard box with styrofoam inserts. The box contains everything you need to assemble the printer – including tools, cable ties and screws. A good assembly manual with numerous pictures is also included.

The delivery is very well packed in a sturdy cardboard box with styrofoam inserts. The box contains everything you need to assemble the printer – including tools, cable ties and screws. A good assembly manual with numerous pictures is also included.

In detail, the delivery contains the following things:

- Portal frame (pre-assembled)

- Printer base with power supply, display and card reader

- 2 extruders

- 1 hotend

- 2 filament detectors

- 2 filament holders

- 1 power cord

- 1 SD card

- 2 filament samples

- 1 USB cable

- 1 mouse pad

- 1 assembly instruction

- several cable ties

- all screws

Setup

Assembling the Geeetech A20M* is really easy. In principle, you can assemble the printer on your own. However, the assembly is easier if you have someone to help you. The printer comes with a detailed illustrated and clear assembly manual.

Even without much experience in assembling 3D printers, you should not need more than 15 to 30 minutes to assemble the printer ready for use. The setup is assisted by the fact that the motherboard, the display and the power supply are firmly installed in the base of the printer. The cables are clearly pre-assembled and labeled.

The setup is assisted by the fact that the motherboard, the display and the power supply are firmly installed in the base of the printer. The cables are clearly pre-assembled and labeled.

The main task is to screw the gantry frame onto the base of the printer and attach the two extruders to the crossbar. For this, you need only 4 screws each. If you are alone, it is best to lay the print base on its side so that you can screw the portal frame in place. To do this, you must insert the screws through the print base from below.

If you have someone to help you, it is easier to move the printer with one side a few inches beyond the edge of a table so that you can insert the screws from below. Loosely tighten all screws at first to make sure that all screws are gripped.

You can then tighten the screws alternately from left to right. The two holders for the filament rolls are screwed to the crossbar with two screws each, both lengthwise and crosswise. Then the two filament detectors are mounted and the printer is wired. The final step is to mount the print bed on the heating plate. No more effort is required to set up the Geeetech A20M ready for operation.

Then the two filament detectors are mounted and the printer is wired. The final step is to mount the print bed on the heating plate. No more effort is required to set up the Geeetech A20M ready for operation.

During assembly, you should check whether the screws of the already preassembled components are tightened properly. The Geeetech A20M takes a long time to get to you, so screws can come loose. Some buyers report that they had to retighten various screws during assembly so that the printer is really stable.

A very important point to pay attention to before you switch on the Geeetech A20M for the first time is the position of the voltage switch on the back of the printer. Here you can set whether the printer is powered by 110 volts or 220/230 volts. If the switch is set to the wrong voltage, you run the risk of destroying the printer’s electronics immediately when you turn it on.

Geeetech A20M*Check Price at:

Amazon*

Design, Equipment and Processing

The Geeetech A20M is a 3D printer whose design has been reduced to a minimum. It basically consists of only a printer base, a gantry frame and three movable axes. It is a printer with the classic gantry structure of the Prusa I3 3D printers and can make optimal use of the build platform.

It basically consists of only a printer base, a gantry frame and three movable axes. It is a printer with the classic gantry structure of the Prusa I3 3D printers and can make optimal use of the build platform.

The design is open in all directions. The frame of the Geeetech A20M, which is made of extruded aluminum profiles, is very sturdy and torsion-resistant. Overall, the build quality of the printer is high and leaves a solid impression. It is positive that the display, the power supply and the motherboard are located in the stable printer base. This is exactly the area where other inexpensive 3D printers leave the available space unused.

One shortcoming is the somewhat difficult access to the y-axis under the print bed. It is not uncommon for the axis to require readjustment. If the adjustment is too tight, the bed cannot move freely. If the adjustment is too loose, the bed wobbles during printing.

The heated print bed heats up very quickly. It is equipped with a glass cover. One side provides a protective layer that leaves a small pattern on the models during printing. However, you can turn the glass plate over so that the smooth side is facing up.

One side provides a protective layer that leaves a small pattern on the models during printing. However, you can turn the glass plate over so that the smooth side is facing up.

You can process a variety of filaments with a diameter of 1.75 mm with the printer. The printer is compatible with HIPS, PLA, ABS, PETG, PVA and WOODFIL. The positioning accuracy of the xy-axis is 0.011 mm and for the z-axis 0.0025 mm. The hotend has a diameter of 0.4 mm.

To prevent finished printed models from being melted again by the hot end, the print head automatically moves away from the model when printing is complete. The finished printed model can cool down completely.

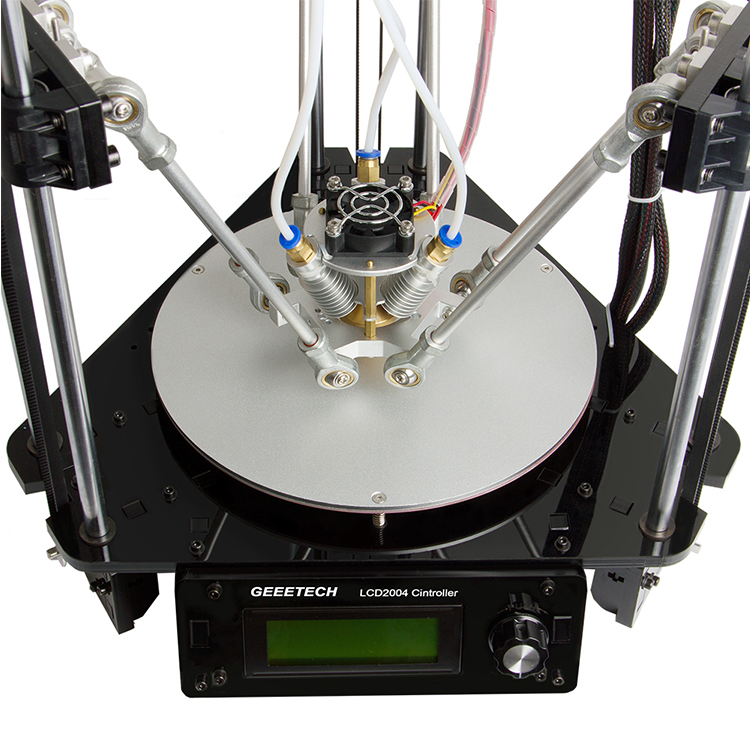

As standard, the Geeetech A20M is equipped with 2 extruders and two filament detectors. Two-color prints or the printing of models with color gradients are thus possible without changing filaments. The two plastic strands are mixed in the hotend or printed one after the other.

The extruder drives work with a reduction ratio of 1 to 3. Unfortunately, some of the gears are only made of plastic gears. If you print a lot, it is advisable to replace them with metal gears.

Unfortunately, some of the gears are only made of plastic gears. If you print a lot, it is advisable to replace them with metal gears.

Operation

The Geeetech A20M is operated via an LCD display in the beveled front of the printer base. This is not a touchscreen. Menu items are selected with the rotary control placed to the right of the display. The menu navigation is not always intuitive but does not require a long training period.

A reset button is installed under the rotary control. By pressing this button, you reset the printer to the factory settings. The bright font on a blue background is easy to read on this display. You can also use the display to change settings while printing.

Connectivity

The Geeetech A20M is equipped with a card reader for SD memory cards as standard. You can use memory cards with a maximum capacity of 32 GB for the printer.

With the help of this card, you transfer the print data to the printer. Stand-alone or offline printing is thus possible without any problems. A USB port is available as a further connection. The printer is compatible with most Windows, Mac and Linux operating systems.

A USB port is available as a further connection. The printer is compatible with most Windows, Mac and Linux operating systems.

The connection with your PC or notebook should therefore not cause any problems. A WLAN module is only optionally available.

Software

The Geeetech A20M comes with the latest version of the Marlin firmware installed. This software is open-source and has already been extended for the A20M with the mixer. For slicing and creating your models, you can use almost all known slicing programs. For example, Repetier-Host, Simplify 3D, Cura, Slic3r and others. The printer can read files in .stl and gcode format.

Print Resume

The Geeetech A20M is equipped with a print resume function. Resuming printing after a power failure or filament breakage works flawlessly with the Geeetech A20M.

Print-Resume (source: geeetech)However, it can sometimes happen that, depending on the position of the nozzle, a small hump is formed by the residual filament running out of the nozzle. This bump can sometimes be so large that the print head cannot subsequently pass over it. The possible consequence is a layer shift in your model. However, with a very sharp knife or a scalpel, you can easily cut off this bump before you continue printing.

This bump can sometimes be so large that the print head cannot subsequently pass over it. The possible consequence is a layer shift in your model. However, with a very sharp knife or a scalpel, you can easily cut off this bump before you continue printing.

The printer finds the last print position precisely and continues printing at this point. If a layer shift appears, pull the power plug again, remove the hump and then continue printing. At the end, the spot should no longer be visible or barely visible.

Geeetech A20M*Check Price at:

Amazon*

Auto-Leveling Optional

The mainboard of the Geeetech A20M is programmed to support auto-leveling. However, to use this feature, you will need to purchase a 3D Touch* sensor separately. Installing the sensor on the print head is quick and easy.

You then only need to activate the automatic leveling in the software of the printer. After installation and activation of the auto-leveling function, the Geeetech A20M always moves to 9 points of the print bed during leveling.

Check Price at:

Amazon*

Auto-Leveling (source: geeetech)Gradient Prints

With the Geeetech A20M, you can easily create gradient prints. For example, from red to orange. The ratio of the two colors of the right and left extruder to each other is controlled.

For example, you start with a ratio of 100% to 0%. Then you gradually reduce the ratio of the left extruder and increase the ratio of the right extruder. For example, 90 % to 10 %, 80 % to 20 %, 70 % to 30 % and so on. You can change these settings at any time during printing via the display. When printing color gradients, you should only use compatible filaments. However, the two filaments are not actively mixed in the hotend.

For best results, you’ll usually need to experiment a bit with the temperature settings, the amount of color in each, and the number of layers you print with a setting.

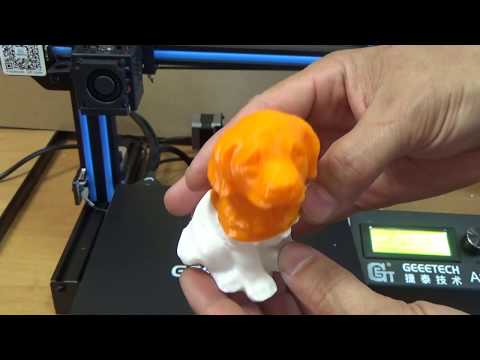

Dual Color Printing

You can produce two-color prints with the Geeetech A20M without changing filaments and without much effort. For example, a red and white striped lighthouse. To make the color change really abrupt, however, you must either print a purge tower, also called a prime tower, or use a purge basket.

For example, a red and white striped lighthouse. To make the color change really abrupt, however, you must either print a purge tower, also called a prime tower, or use a purge basket.

The Purge Tower has the disadvantage that it grows in height at the same rate as your model. This means that the printer prints a layer of your model and then a layer of the Purge Tower.

When changing colors, the printer prints the hotend on this tower empty, so that the next layer on your model has the other color and the color change takes place seamlessly. Because the Prime tower always grows with the model, you consume a lot of filament.

The second option, the so-called purge basket, is much more economical. With this method, the print head simply moves to the side to change colors, empties the hotend until the other color appears, and then prints the next layers of your model.

Noise Level

As far as the noise level during printing is concerned, the Geeetech A20M is in the midfield. Some inexpensive 3D printers are significantly louder, while others are audibly quieter. The noise level depends on various factors, such as the printing speed and the number of direction changes.

Some inexpensive 3D printers are significantly louder, while others are audibly quieter. The noise level depends on various factors, such as the printing speed and the number of direction changes.

In general, the noise is not disturbing or annoying. You can place the printer in the office and keep an eye on it while doing other work. However the Geeetech A20M’s printing noise is too loud to place the printer in the bedroom.

Optional Accessories

You can easily expand the functionality of the Geeetech A20M with various accessories. The accessories include the already mentioned 3D sensor for automatic leveling of the printer.

Also available as an accessory is a Wi-Fi module so you can control the printer with your smartphone or tablet and print files from a cloud. The Wi-Fi module comes with the Easyprint app, which you can download for free.

Related Questions

Can the Geeetech A20M be operated with a smartphone and app?

In principle, yes, but you have to purchase the optional Wi-Fi module and install the free Easyprint app on your smartphone or tablet. Thus, you can integrate the printer into your Wi-Fi network or print files from the cloud.

Thus, you can integrate the printer into your Wi-Fi network or print files from the cloud.

Is the Geeetech A20M available with 2 print heads?

No, unfortunately not. The Geeetech A20M comes with a print head by bringing the two filaments together and printing them at the same time. This facilitates the printing of color gradients. However, printing 2 models at the same time is not possible.

Is there a cover available for the Geeetech A20M?

No, the manufacturer does not offer a cover. However, it is possible for you to make your own side walls and a door from Plexiglas or a similar material to protect the installation space and your models from temperature fluctuations caused by drafts.

Our Conclusion about the Geeetech A20M

With the Geeetech A20M*, you get an inexpensive but very well-equipped FDM 3D printer with an exceptionally large build envelope for this price range. The print quality is very good with a minimum layer thickness of 0.1 mm.

However, the printer’s optimal setting is not always easy to find. The ability to produce color gradients and two-color prints without much effort is particularly pleasing. The heated large print bed and the two filament sensors are further plus points of this printer.

The ability to produce color gradients and two-color prints without much effort is particularly pleasing. The heated large print bed and the two filament sensors are further plus points of this printer.

The only real drawbacks are the two extruders that are mainly made of plastic, which you should probably replace with metal extruders early on. All in all, the Geeetech A20M 3D printer offers a very good price-performance ratio and can convince with its qualities.

Geeetech A20M*Check Price at:

Amazon*

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

10 reasons to choose the Geeetech E180 3D printer

→ GEEETECH E180 INTEGRATED 3D PRINTER $239. 99

99

This is one of the best office style 3D printers in its price range, which is not ashamed to put on the table, show to colleagues or friends.

Geeetech E180 is a fully assembled printer with great functionality: Wi-Fi access, full print pause, large 3.2" touch screen. The whole design is made very neatly, thoughtfully, in a strict office style.

The printer has been in use for more than six months, I add my summary point by point:

1.

A well-thought-out approach to packaging and product packaging

A well-thought-out approach to packaging and product packaging The printer comes with everything that is required for active printing right out of the box.

The printer is packed in a foam shell, in the cells in their places are the parts of the kit (power supply, spare nozzles, filament tester).

2. Interesting "office" design

I liked the printer for its accuracy and rich functionality. Movable table, interesting console design with print head.

Inside the case there is a rather successful design with three (!) vertical rails.

3. Easy to use

Just warm up the nozzle and fill the plastic and the printer is ready to print.

Simple extruder design for reliable feeding and easy maintenance.

4. 3.2" touch screen

A special feature set adds a large touch screen. You can configure the printer, control settings, adjust the print mode on the fly.

5. Wi-Fi

Yes, yes. This is one of the few budget 3D printers that comes with Wi-Fi out of the box. It is enough to activate this setting in the options, and find and connect to the network that appears.

This is one of the few budget 3D printers that comes with Wi-Fi out of the box. It is enough to activate this setting in the options, and find and connect to the network that appears.

6. Pause, full, with saving the results

I will dwell on such a useful function as a print pause. If during printing it was necessary to turn on the pause, just click on the corresponding icon on the display. The printer goes to the “home” position, remembering the place where it stopped. You can check the progress and quality of printing, you can change the color of the filament. If it runs out, replace the coil completely. Then continue printing without any problems. Start coordinates after a pause are stored in non-volatile memory. It is possible to disconnect the printer from the network completely, and transfer it, continue, for example, the next day. Very comfortably.

7. EasyPrint3D cloud application

We raise a Wi-Fi network on the printer, connect, download the EasyPrint3D application, and authenticate the printer.

The application provides printer settings and management, as well as many models in the cloud. Directly from a smartphone, you can select, download a model, select settings and a print profile and immediately send it to the printer, controlling the progress of printing. In this case, a computer is not required, only a tablet or smartphone.

8. Repairability

Geeetech is assembled on the basis of standard components that are available on the market. Maintenance and repair of a 3D printer will not be difficult. Software and firmware are also freely available.

9. Smart design that provides the required rigidity

I mentioned above about the smart design on three vertical rails. For movement, a T8 screw is used. In X and Y, a GT2-6mm belt is used to move.

10. Price

Now you can buy this interesting 3D printer for a modest $ 239.99

→ GeeTECH E180 Integrated 3D Printer $ 239.99

If my article interests you, I propose to get acquainted with a more detailed

Pressure 3d.

News

Publications

Headset A4TECH Bloody G230 is a godsend for the gamer. Comfortable and affordable headphones with great sound and original design. The presence of a microphone with a hardware shutdown function will be convenient when...

The very first Apple device that I saw live and felt with my own hands was the iPad 2 and it happened in 2012. The device made a unique impression on me, I saw it for the first time...

The GMNG brand is already known as a manufacturer of computer peripherals for gamers and modern computer users. They have released a mouse that fans of active games will definitely like, because...

Winter has come and dryness in the apartment is increasingly observed. Ventilation helps, but for a rather short time, and if there are small children in the family, then you won’t keep it open all the time ...

An oriental fairy tale attracts, the city of Dubai in the UAE has become a modern tourist Mecca for travelers from all over the world. What is the value of the tallest building in the world - the Burj Khalifa tower with a height of 828 ...

What is the value of the tallest building in the world - the Burj Khalifa tower with a height of 828 ...

Buildings swallowed up by wild vegetation, windows without glass that look like empty eye sockets - all this is the current island of Hasim, where you can shoot a horror movie. And so they did. Some...

Geeetech E180 3D Printer Review - Budget Workhorse

Well, like a horse. Hurry pony...

Lots of options - touch screen, Wi-Fi, pause, smartphone app. And the print area is only 130x130x130 mm.

This is a brand new development from Geeetech and one of the best office style 3D printers in its price category, which is not ashamed to put on the table, show to colleagues or friends.

Geeetech E180 is a fully assembled printer with great functionality: Wi-Fi access, full print pause, large 3.2' touch screen. The whole design is made very carefully, thoughtfully, in a strict office style.-kupit-v-soin-store.ru-7.png) Despite the L-shaped design, the Z-axis is rigid, made on 3 guides and a trapezoidal screw.

Despite the L-shaped design, the Z-axis is rigid, made on 3 guides and a trapezoidal screw.

The printer has been in use for about a year, I add my summary point by point:

1. A well-thought-out approach to packaging and product packaging

The printer comes with everything you need for active printing right out of the box.

The printer is packed in a foam shell, in the cells in their places are the parts of the kit (power supply, spare nozzles, filament tester). Nothing is bent or broken in transit. It is especially convenient if you take not for yourself, but as a gift.

Nothing is bent or broken in transit. It is especially convenient if you take not for yourself, but as a gift.

2. Interesting "office" design. Sophisticated design - no protruding wires, all axles are covered with casings and body structures. The carriage and extruder are also covered with covers. The table is not heated - there are practically no dangerous parts in which a child's 'finger' can be pinched. In this regard, a 3D printer is suitable for home use too.

I liked the printer for its neatness and rich functionality. Movable table, interesting console design with print head. The table, by the way, has an adjustment, you can align it manually by tightening the screws in the corners (seen in the photo under the adhesive tape). A rather successful design with three (!) vertical guides is hidden inside the case.

3. Ease of operation. A 3D printer is suitable for a novice user, with no experience in assembling, setting up and printing.

Unpack, choose a place on the table, connect the power supply. A computer, in fact, is not required - you can control it from your smartphone. It is possible to print offline from a microSD card.

Just warm up the nozzle and fill in the plastic and the printer is ready to print. We assemble the stand for plastic, fill the extruder with a rod. Heating and running plastic to the nozzle are available in the menu. There is also a 5-point calibration

Simple extruder design ensures reliable feeding and easy maintenance. But soft plastics, most likely, will be too tough.

4. Touch display 3.2'.

A large touch display adds a special feature set. You can configure the printer, control parameters, adjust the print mode on the fly. There is also a pause and continue printing, calibration, acceleration and temperature changes right during printing.

5. Wi-Fi module.

Yes, yes. This is one of the few budget 3D printers that comes with Wi-Fi out of the box.

It is enough to activate this setting in the options, and find and connect to the network that appears.

6. Pause, full, with saving the results

I will dwell on such a useful function as a print pause. If during printing it was necessary to turn on the pause, just click on the corresponding icon on the display. The printer goes to the “home” position, remembering the place where it stopped. You can check the progress and quality of printing, you can change the color of the filament. If it runs out, replace the coil completely. Then continue printing without any problems. Start coordinates after a pause are stored in non-volatile memory. It is possible to disconnect the printer from the network completely, and transfer it, continue, for example, the next day. Very comfortably.

7. EasyPrint3D cloud application

We set up a Wi-Fi network on the printer, connect, download the EasyPrint3D application, authenticate the printer (by serial number).

The application provides printer settings and management, as well as many models in the cloud. Directly from a smartphone, you can select, download a model, select settings and a print profile and immediately send it to the printer, controlling the progress of printing.

A computer is not required in this case, only a tablet or smartphone.

8. Repairability

Geeetech is assembled on the basis of standard components that are available on the market. Maintenance and repair of a 3D printer will not be difficult. Software and firmware are also freely available.

All detachable connections are fixed with hot melt adhesive.

Nozzles are sold in 'cartridges' from Geeetech. Change does not present any problems. Just snap the 'lever' to the side, no long disassembly required.

Nozzle seat.

I mentioned the blowing of the model - the photo shows a separate fan and a separate nozzle for blowing.

9. Smart design that provides the required rigidity when printing.

Models are obtained very, very decent quality.

I have already mentioned the well-thought-out design on three vertical rails. For movement, a T8 screw is used. In X and Y, a GT2-6mm belt is used to move. Simple and reliable solutions.

10. Budgetary cost.

Now you can buy this interesting 3D printer for a modest $219.99

I liked the printer.

Has a thoughtful interface (display, application) and design. I expected any pitfalls - they are not. I don’t know how wear and tear will manifest itself over time, but it served for almost a year.

I note that the nozzle from Geeetech can heat above 230 ° C, but the manufacturer limits this figure, so ABS / PETG can be used, but at the lower temperature limit .