Rapidia metal 3d printer price

Fast & Simple Metal 3D Printing

-

Versatility

Internal structures, solid or infill, complex parts, water and sinter bonding. Your parts the way you want them

-

Access Time

Quick printing, no debinding process and you get your parts the next day. Prototype and iterate faster.

-

Water-based

No chemicals, no loose powder, simple facilities requirements. Truly office friendly.

Straight from printer to sinter

Rapidia’s water-based metal paste is solvent-free, safe to handle and unlocks a new world of opportunities for creating complex parts. Have your parts by the end of next day by going straight from printer to sintering furnace, with no need to debind.

Have your parts by the end of next day by going straight from printer to sintering furnace, with no need to debind.

See system features

Faster parts, lower costs

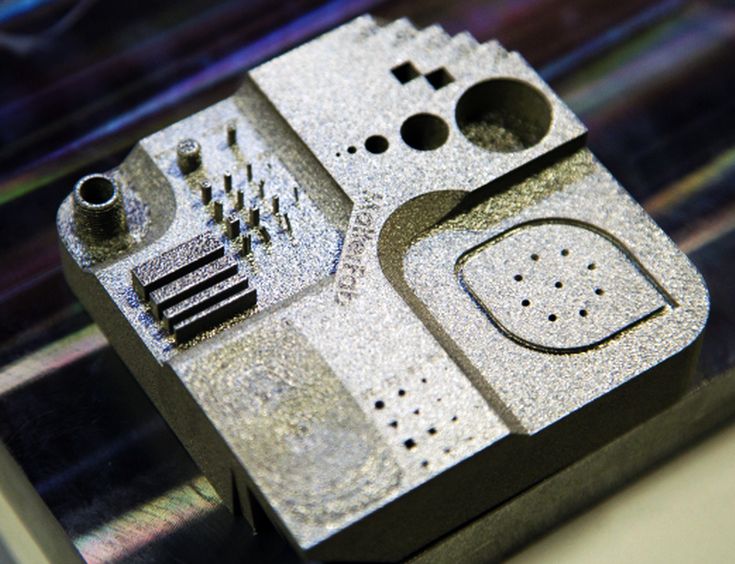

Water-based metal paste eliminates the debinding step, enabling the two-stage Rapidia process to produce parts faster than other bound metal processes or laser sintering. The innovative support system cuts printing time further by avoiding the need to print most metal supports. Choose any infill percentage from 100% for full strength parts without thickness limit, down to 20% for light-weighting. It all adds up to significant time and cost savings.

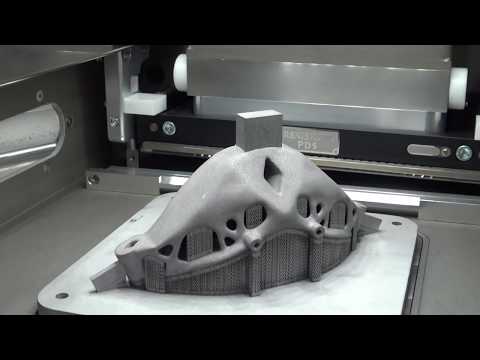

The capability to create the most complex parts

The Rapidia metal 3D printing system is the only system able to print parts with complex internal structures, using proprietary evaporative support technology. The unique water-based paste allows complex assemblies to be created with ease by water bonding 3D printed parts together, or by fusing 3D printed parts to machined parts.

Learn more about Rapidia's technology

Wide range of materials

Print with a wide range of metals, with options for excellent strength, high temperature capabilities, and superb corrosion resistance.

See material options

The first truly office-friendly metal 3D printing system

The Rapidia metal 3D printing system is water-based from start to finish, which means no solvents or polymer disposal. Metal paste eliminates the industrial hazards that require additional facilities. Low footprint, with no extensive electrical work required and a large number of metal 3d printing applications.

Enquire to order

Our price

Technology - Rapidia - Fast & Simple Metal 3D Printing

Rapidia’s unique water-based technology revolutionizes how metal is 3D printed

Water-based from start to finish, the Rapidia metal 3D printing system is the simplest and safest way to create strong metal 3D printed parts.

Water-based metal paste is solvent-free, safe to handle and unlocks a new world of opportunities for creating complex parts.

Water-based metal paste is solvent-free, safe to handle and unlocks a new world of opportunities for creating complex parts. Clean and safe

Rapidia’s water-based metal paste technology is the foundation of the Rapidia metal 3D printing system. It takes the advantages of bound metal 3D printing a step further by accelerating the production process and doing away with solvents. The result is a fast, simple to use system that is environmentally friendly and completely solvent-free.

No debinding required

The Rapidia metal 3D printing system takes parts straight from printer to sinter, with no need to debind. Parts printed with conventional three-stage processes need to be prepared for sintering by dissolving the polymer binder, a process called debinding. This step can take upwards of several days, and requires treating the printed part with a chemical solvent - a messy and hazardous process in an office. The Rapidia process eliminates debinding by using water to bind the metal powder, making the material safe to handle. The water evaporates during printing, saving time and removing the need for a debinding machine or solvents.

The Rapidia process eliminates debinding by using water to bind the metal powder, making the material safe to handle. The water evaporates during printing, saving time and removing the need for a debinding machine or solvents.

Evaporative supports for complex internal structures

The Rapidia metal printing system is exceptionally suited to produce parts with complex internal structures, using proprietary evaporative polymer supports. These supports are unique to Rapidia, and are made possible by the water-based metal paste, as the polymer supports can be retained into the sintering stage.

Water bonding and sinter welding

Rapidia’s water-based metal paste is water soluble, enabling the unique ability to fuse unsintered parts together using only water. Complex assemblies can be created by printing simple parts and attaching them by dipping the area to be joined in water. After sintering, the resulting assembly is as strong as a single part. A similar process can also be used to sinter weld finished printed parts to machined parts of the same alloy, using the Rapidia metal paste.

Watch the video to see it in action.

100% solid infill capability

When maximum strength is required, Rapidia’s technology allows you to create parts with fully solid sections.

Wide variety of finishing options

For many applications, parts printed with the Rapidia metal printing system don't require any finishing. However, if a specific surface finish is required, parts can be water-smoothed before sintering or finished with any standard postprocessing technique after sintering.

Unfinished

Isotropic Superfinishing (ISF)

Water-smoothed

Electropolished

Print with a wide range of materials

See material options

Enquire to order

Our price

Rapidia Metal Extrusion 3D Printers Enter European Market

News

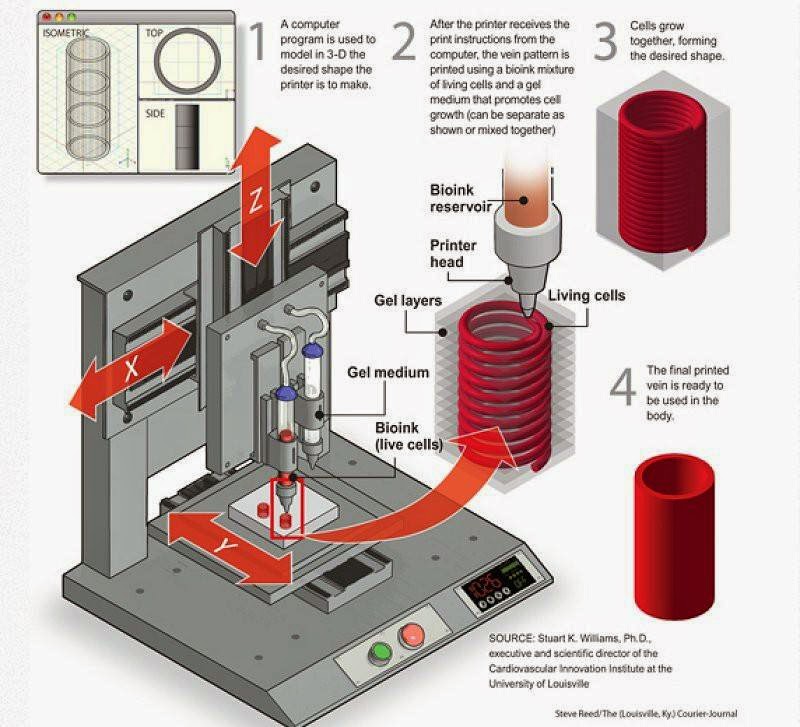

The technology is based on extrusion 3D printing with metal pastes followed by sintering into finished products.

Rapidia was founded by engineer Daniel Gelbart, an inventor with over 100 patents, founder and former CEO of Creo, a developer and manufacturer of digital printing solutions, acquired by Kodak Corporation in 2005 for about a billion dollars. Daniel's next project was a startup with a rather unusual approach to metal 3D printing.

The proprietary technology is based on a step-by-step process that involves 3D printing blanks and then sintering them into solid metal parts. Typically, extrusion printing in this area uses polymer-metal filaments, but Rapidia prefers to rely on water-based metal pastes. Alternatively, ceramics can be printed. The process eliminates the need for an intermediate debinding step and is highly safe due to the absence of toxic chemicals and flammable fine powders.

Last year, Rapidia entered the US market by signing a distribution agreement with ExOne, another developer and manufacturer of additive systems, but using sand and metal inkjet-powder 3D printing technology. Shortly thereafter, ExOne came under the control of Desktop Metal, which offers 3D printers using the competitive FDM 3D printing technology with polymer-metal filaments, and the agreement was terminated. Now the startup is ready to explore the European market: Rapidia developments were demonstrated at the recent Formnext 2022 exhibition, and will go on open sale next year.

Shortly thereafter, ExOne came under the control of Desktop Metal, which offers 3D printers using the competitive FDM 3D printing technology with polymer-metal filaments, and the agreement was terminated. Now the startup is ready to explore the European market: Rapidia developments were demonstrated at the recent Formnext 2022 exhibition, and will go on open sale next year.

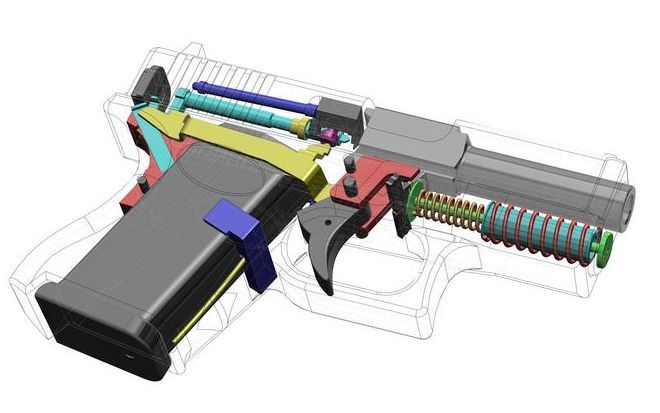

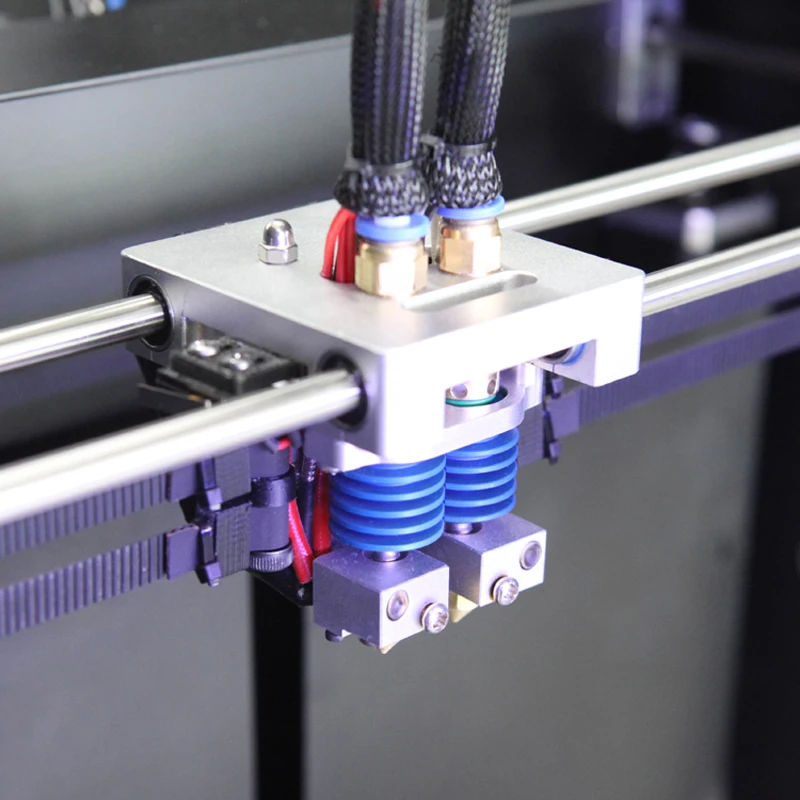

The set of equipment consists of a dual-extruder 3D printer with IDEX kinematics (independent positioning along the X axis) and a vacuum argon furnace with a temperature of up to 1400°C. The second head is used to apply the support material. The equipment allows growing parts up to 200x200x150 mm in size with a productivity of up to 50 g/h. Consumables are 316L and 17-4PH stainless steels.

Additional information is available on the manufacturer's website.

rapidia robocasting

Follow author

Follow

Don't want

4

Article comments

More interesting articles

eight

Subscribe to the author

Subscribe

Don't want to

The F2 Gigantry system will enable manufacturing companies, in particular those in the aerospace industry, to. ..

..

Read more

5

Subscribe to the author

Subscribe to the author

Don't want to

An upgraded version of the Ender-5 system with MakerBot kinematics is positioned as a new flagship and...

Read more

59

Follow author

Subscribe

Don't want

The 3Dtoday portal, with the support of Creality and Bestfilament, invites everyone to participate in...

Read more

KBA Rapida 105-5+L CX ALV2 SAPC Five-color offset press Used equipment

- Description

- Detailed information

- About this seller

located in Moscow

Sheet sizes

maximum 720 x 1. 050 mm

050 mm

minimum 360 x 520 mm

Print format

maximum 710 x 1.040 mm

printing plate 795 x 1.050 mm

offset blanket 860 x 1.060 mm

Standard copy margin

plate 50 mm

Media:

Standard 0.06 - 0.7 mm

When equipped with CX carton package Up to 1.2 mm

Grip area 10 mm

Production speed **

Maximum speed Up to 16,000 l/h

Stack height from floor

Feeder 1.300 mm

delivery 1.200 mm

delivery in Non-Stop mode 1.100 mm

Additional options

000.500 High-Speed add-on package (speed increase)

001.000 CX add-on package;

445.000 Sheet advance control in the printing unit

380.000 Mech. thick cardboard unit after printing area

380.020 Blaskasten für Kartonbogenführung

004.000 "High performance antistatic" add-on package

360.040 Electrostatic discharge device feeder system,

high performance equipment incl. side. ion blowing 9Add. compressor for removing static charge from films

360. 310 Device for removing electrostatic charge feeder system and

310 Device for removing electrostatic charge feeder system and

take-up, special equipment for foil printing

005.120 Mixed production for printing section

005.010 Preparation of printing section for intermediate UV dryers

510.000 Rollers for normal and UV inks

005.130 Mixed production for varnishing section

005.020 Preparation of varnishing section for intermediate UV dryers (04L097 varnishing unit) 04L097 with chamber squeegee and delivery extension 2400 mm

(ALV2)

042.020 Coating section (L) with chamber squeegee (HARRIS & BRUNO), without

washer without lacquer supply and cleaning device

070,000 lengthening for acceptance 2400mm (ALV 2)

070.000 Establishment extension 2400mm (ALV 2)

Office

370,000 installation for removing dust

290.400 The device of the Simplex telephone communication and acceptance

Colorful apparatus

515.1

ductor, incl. high-tech refrigeration combi. device

CombiLiner;, refroidi par air (BALDWIN)

571. 210 CombiLiner;, 97 657.160 1 piece Varnish supply and cleaning system for dispersion and UV varnishes, with

210 CombiLiner;, 97 657.160 1 piece Varnish supply and cleaning system for dispersion and UV varnishes, with

connection to the control panel, with pump power depending on viscosity

(HARRIS & BRUNO)

657.130 1 piece Varnish heating device

PRIYOMKA

660. Nonstop, drop down

665.000 EES - Emission Extraction System

GALLERY

161.000 3 pcs.0097 Air from the building (price reduction)

Cooling devices

571.040 Thin filter, integrated (Baldwin)

575.040 Connection to central water cooling

SUSHLED DEVICES

9000.800 KBA Varidry IK/TLV2 930 2 Interchangeable position for intermediate UV dryer940.870 3 piece KBA VariDry UV intermediate dryer

930.310 Control module for universality of intermediate UV dryers and

post UV dryers

Technique for measuring and adjusting

287.200 Densitronic Professional C Densitronic PDF

Process automation / Automation to the network

274.100 ANLINE connection for an additional new machine

Equipment

. 000 Documentation and catalog of springs in compound dvinop in big numbers

000 Documentation and catalog of springs in compound dvinop in big numbers

766.020 1 piece Machine documentation and spare parts catalog on CD

770.000 digital machine speed display in big numbers

| Max. paper length | 720cm |

| Max. paper width | 1050cm |

| Number of copies | 120 Mio |

| Duplex printing | No |

| Dryer | UV+IR |

| Coating block | Yes |

| ------------------- | |

| Operating hours | |

| Switching hours | |

| Condition | in good condition |

| CE marked | yes |

| Status | included |

| Data sheet | Kba Rapida 105-5+L CX ALV2 |

| Client type | End user |

| Active with | 2018 |

| Online offers | 1 |

| Last activity | October 27, 2022 |

Description

located in Moscow

Sheet sizes

maximum 720 x 1. 050 mm

050 mm

Minimum 360 x 520 mm

Print format

Maximum 710 x 1.040 mm

Printing form 795 x 1.050 mm

Offset canvas 860 x 1.060 mm

Standard indentation when copying

printed form 50 mm

printed materials:

Standard 0 .06 - 0.7 mm

When equipped with CX carton package Up to 1.2 mm

Grip field 10 mm

Production speed **

Maximum speed Up to 16,000 l/h

Stack height from floor

Feeder 1.300 mm

Delivery 1.200 mm

Non-Stop delivery 1.100 mm

Additional options

000.500 High-Speed option package (increased speed)

001.000 CX option package;

445.000 Sheet advance control in the printing unit

380.000 Mech. thick cardboard unit after printing zone

380.020 Blaskasten für Kartonbogenführung

004.000 "High performance antistatic" add-on package

360.040 ESD eliminator feeder system,

high performance equipment incl. side. blown with ionization

004. 900 Additional contents of the package Change of feeder and delivery for

900 Additional contents of the package Change of feeder and delivery for

printing on thin papers

002.100 Additional package "Printing on films and plastics"

002.900 Additional contents of the package Change for printing on plastics on

feeder and overlay

746.010 add. compressor for removing static charge from films

360.310 Device for removing electrostatic charge system feeder and

receiving, special equipment for foil printing

005.120 Mixed production for printing section

005.010 Preparation of printing section for intermediate UV dryers

510.000 Rollers for normal and UV inks

005.130 Mixed production for varnishing section

005.020 Preparation of intermediate varnishing section dryers

042.030 Coating section (L) with chamber doctor blade and delivery extension 2400 mm

(ALV2)

042.020 Coating section (L) with chamber doctor blade (HARRIS & BRUNO), without

Washing devices without a device for supplying and cleaning varnish

070. 000 Establishment extension 2400mm (ALV 2)

000 Establishment extension 2400mm (ALV 2)

070,000 Certification of acceptance 2400mm (ALV 2)

370,000 installation for removing dust

290.400 The device of sympolecular telephone communications and acceptance

UNIT

515.100 Thermoregulation device for inking units without inking unit cooling

incl. high-tech refrigeration combi. device

CombiLiner;, refroidi par air (BALDWIN)

paints

503.000 CleanTronic UV

VARNISHING UNIT

657.160 1 piece Varnish supply and cleaning system for dispersion and UV varnishes, with

connection to the control panel, with pump power depending on the viscosity

pieces (HARRIS 103) 6

Varnish heating device

RECEPTION

660.000 Nonstop grate, lowering

665.000 EES - Emission Extraction System

GALLERY

161.000 3 piece Hanging gallery shelf (1m wide, stainless)

EXCLUSIONAL

745,000 Air supply for adjusting pneumatics, excluding the supply system of

from the building (reduction of price)

cooling devices