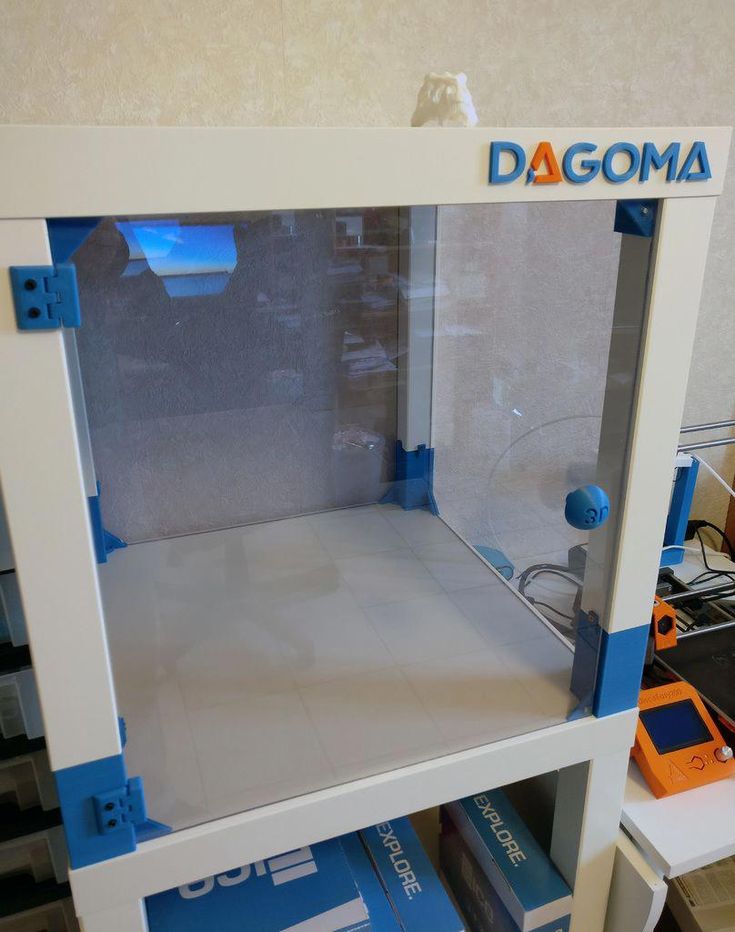

3D printer casing

9 Amazing DIY 3D Printer Enclosure Ideas – Clever Creations

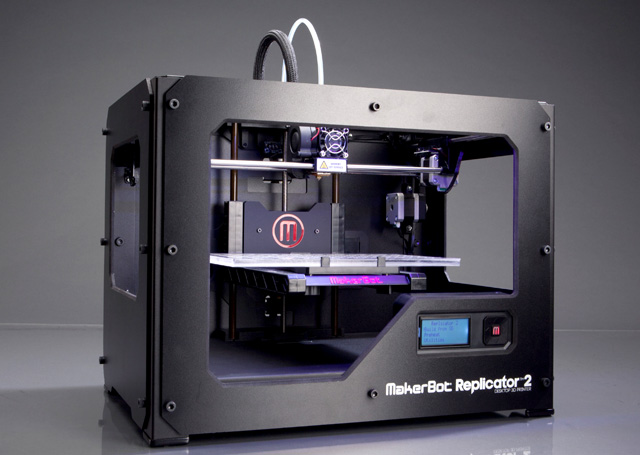

Open-frame 3D printers, like the Ender 3, have become a common sight amongst consumer printers. Open frames help to keep the manufacturing costs low but make it difficult to 3D print with high-temperature filaments such as ABS and Nylon.

A 3D printer enclosure is an ideal solution for this issue. It increases the safety of your printer and isolates it from the external environment. 3D printer enclosures can be bought off-the-shelf, but there are also plenty of DIY enclosures made of cardboard, plastic, or metal.

Let’s take a look at some of the best DIY 3D printer enclosures that you can build for your printer that do not cost a fortune!

Why Use a 3D Printer Enclosure?

Open-frame hobbyist 3D printers offer limited material compatibility and safety. They expose components to dust and dirt and have no air-filtration system. There is also a risk of pets and children interfering with the 3D printing process or touching the hot elements of the printer.

An enclosure minimizes these drawbacks by isolating the 3D printer in an enclosed space. It helps to maintain a constant temperature which comes in handy when 3D printing with high-temperature filaments like ABS and Nylon. It further aids in noise reduction, making 3D printing at home or in offices more convenient.

You can also add an air filtration system to the enclosure to filter out any 3D printer fumes, thus increasing the safety of your 3D printing area. Not to mention, enclosures also make 3D printers more aesthetically pleasing and easier to integrate into your workspace.

To summarize, a 3D printer enclosure increases the material compatibility, print quality, and usability of your printer.

Which Enclosure to Get?

There are a few options when it comes to 3D printer enclosures. You can buy an enclosure off-the-shelf or make your own from scratch.

DIY 3D printer enclosures can be cheap if you want them to be, but they do require a bit of effort and time to put together. The best enclosures are made from materials that are both sturdy and have good thermal insulation properties.

The best enclosures are made from materials that are both sturdy and have good thermal insulation properties.

If you’re looking for an enclosure that is easy to set up and does not require any DIY skills, then we suggest buying an off-the-shelf 3D printer enclosure. These are typically made out of plastic or aluminum and come with all the necessary fixtures and fittings.

Another alternative is to simply buy an enclosed 3D printer, but those come at a significantly higher cost.

Recommended:

The 9 Best Enclosed 3D Printers

Whichever direction you choose to go in, make sure to measure if you have enough space on your 3D printer table or workbench.

If you want a 3D printer enclosure that is fully customized to your 3D printer model and specific needs, then you will have to make your own. Now let’s look at some cheap and creative DIY 3D printing enclosures!

Cheap 3D Printer Enclosure Ideas

DIY Enclosures

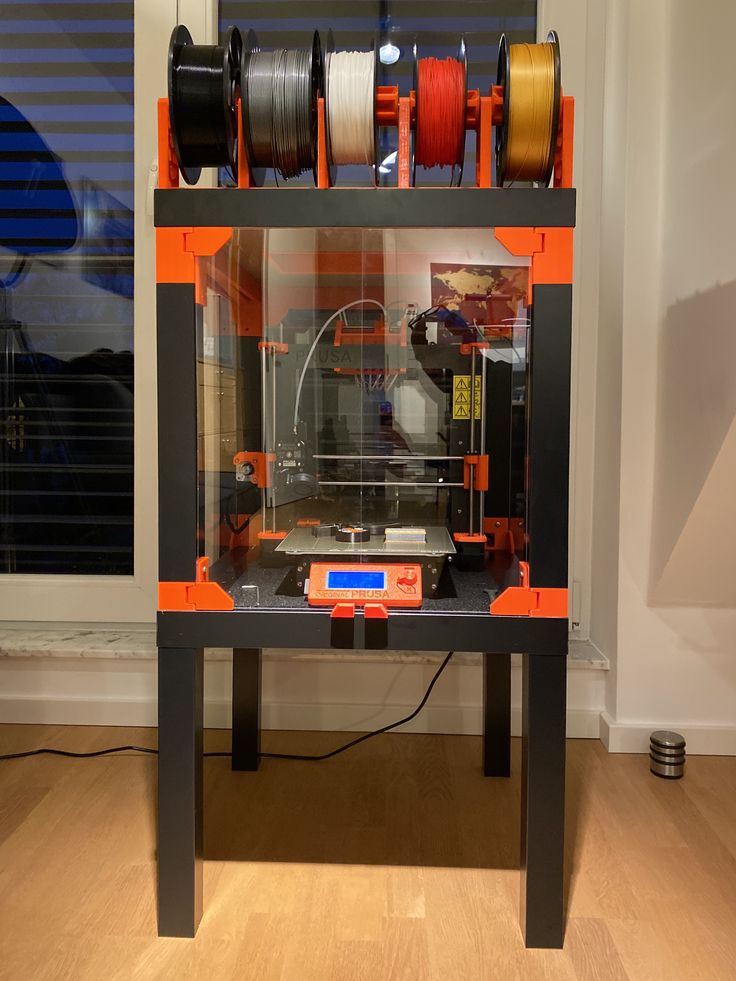

IKEA LACK 3D Printer Enclosure

Image: Mikolas Zuza via Prusa3D

The IKEA Lack enclosure is a recognizable and robust DIY 3D printer enclosure. It is cheap, easy to build and customize, and is modular enough to accommodate any future changes in the enclosure design.

It is cheap, easy to build and customize, and is modular enough to accommodate any future changes in the enclosure design.

This enclosure uses a couple of IKEA Lack tables stacked on top of one another. You can use these tables as per your preferences. Usually, though, the top one is used as a 3D printer bay, with the bottom one for storing tools. The design allows you to move your power supply outside and protects the electronics from high temperatures.

There are a variety of designs available for free with detailed guides, and you can build them within a day. The IKEA Lack table enclosure is great for small to medium-sized 3D printers like the Prusa i3 MK3S+ and Creality Ender 3 as it is. And with some 3D printed leg extensions, you can even fit taller printers like the Creality CR-10 Smart Pro.

If you want to make things as easy as possible, you can even buy the required plexiglass panels as a pre-made kit.

DIYE Pack of 5 Plexiglass V1 1/8 Acrylic Sheet for IKEA Lack 3D. ..

..

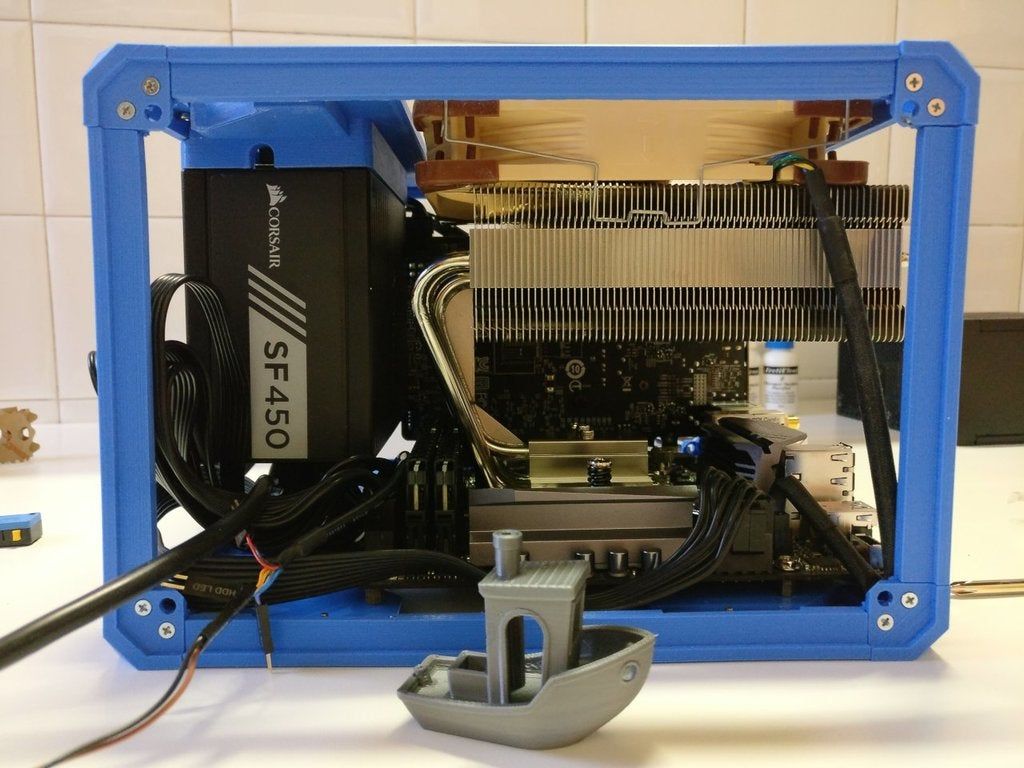

Aluminum Extrusion Enclosure

Image: Namsted via Imgur

Aluminum extrusions are a great and easy way of building a structural frame. These are lightweight, strong, and easy to machine, making them ideal for building a 3D printer enclosure.

This aluminum extrusion enclosure gives better stability and durability than the IKEA Lack design. The maker has used custom-sized aluminum extrusions to accommodate a Prusa i3 MK3S+ 3D printer in the middle. The top is used for filament spools, and you can store your tools in the bottom section.

The enclosure is covered up with acrylic panels on all four sides, giving the print chamber good visibility. You can adjust the height of all four feet to get a leveled horizontal plane.

The project is not for beginners, as you will need to have some experience with machining and building things. But, if you’re up for it, it will prove to be an excellent learning project for you. An aluminum enclosure is very customizable, lasts longer, and acts as a perfect house for your 3D printer.

DIY Smart 3D Printer Enclosure

Image: Jure Korber

This smart 3D printer enclosure comes with a suite of electronics and sensors. It has a 3.5 inch LCD screen, a smoke detector, door sensors, air filtration, temperature, humidity sensor, and controllable LED lighting.

The 3D printer enclosure is divided into two compartments. The bottom one is explicitly designed to fit a Prusa printer and the top one to store eight spools of 1 kg filaments at a time. The enclosure has a custom PCB board that lets you easily wire up and control its various features.

You can get the STL files of certain 3D printed parts for free on Thingiverse. But if you want a detailed guide, along with BOM, build photos, and other aids, you will have to pay a fee to the designer. If you have the time and money, a smart 3D printer enclosure like this is an excellent DIY 3D printer enclosure for most popular open-frame 3D printers

Sound-Insulated Enclosure

Image: Spare Time Shop via YouTube

Open-frame 3D printers can get noisy, and the constant buzzing and the whirring of stepper motors can get irritating after a while. This issue is most relevant if you 3D print in a living space or an office environment. This is where this sound-insulated enclosure steps in.

This issue is most relevant if you 3D print in a living space or an office environment. This is where this sound-insulated enclosure steps in.

As far as traditional enclosures go, they reduce noise up to a certain extent; yet, a sheet of acrylic can only do so much in terms of noise reduction. This sound-insulated enclosure, on the other hand, is made of wood, which has an acoustic foam lining to absorb the 3D printer noises.

This enclosure is big enough to accommodate a Creality CR-10 with filament spool and has dual doors and a transparent window to easily view your 3D printer. You can place the electronics of the CR-10 on the outside of the box, letting you control your 3D printer without opening the build chamber.

The enclosure is relatively easy to build and reduces noise considerably. The sound-insulated enclosure is a great option to get rid of any noises and 3D print in your living areas.

IKEA Pax 3D Printer Enclosure

Image: DollaSign via Reddit

This IKEA Pax enclosure is a wardrobe for your 3D printers. It is cost-effective and saves a lot of floor space when you want to enclose many 3D printers. Compared to the Lack enclosure from above, it offers similar functionality, albeit in a smaller footprint and relatively budget pricing.

It is cost-effective and saves a lot of floor space when you want to enclose many 3D printers. Compared to the Lack enclosure from above, it offers similar functionality, albeit in a smaller footprint and relatively budget pricing.

You can stack up to three 3D printers in the PAX enclosure and still have some room left for filament spools, tools, and other electronics. All power supplies can sit outside the enclosure, thus protecting them from high temperatures. To add to its functionality, you can include some Neopixel LED lights.

Adafruit NeoPixel Digital RGB LED Strip - Black 30 LED [ADA1460]

72 Reviews

Check PriceBecause the shelves are modular, you can easily move them around to fit 3D printers of varying heights. The major drawback of the PAX design, however, is its lack of transparent panels. Other than that, the IKEA PAX enclosure is an easy, quick and cheap solution for enclosing many 3D printers at once.

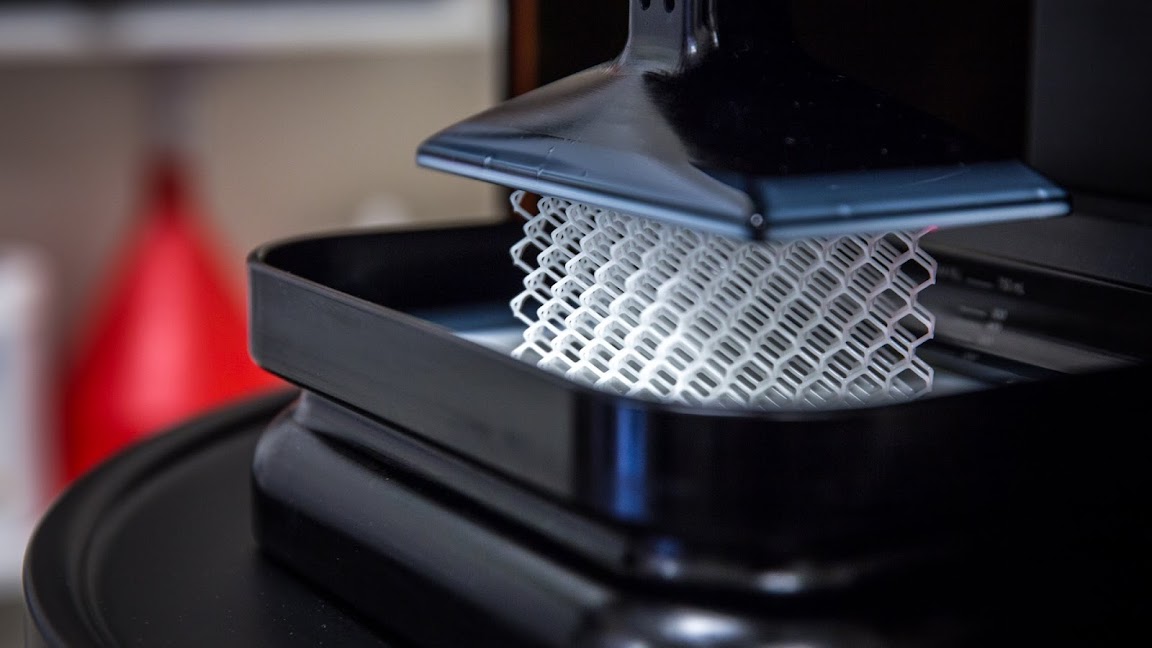

Resin 3D Printer Enclosure

Image: majorbrogains via Reddit

Even though resin 3D printers come with an enclosure, you need a separate space to store the printers, resin bottles, and prints like your 3D printed miniatures. This enclosure is an IKEA BRIMNES cabinet with ample space to store and display all your resin 3D printing equipment and minis.

This enclosure is an IKEA BRIMNES cabinet with ample space to store and display all your resin 3D printing equipment and minis.

The entire cabinet is divided vertically into two separate parts, giving you the ability to efficiently sort out your goodies. You can store the 3D printer itself in one half, while the other half can take in a washing station. And with a bit of DIY, you can vary the shelves’ heights and customize them to perfectly fit your minis’ collection, resin bottles, and other resin 3D printer accessories.

There is air ventilation within the enclosure with the exhaust on the top. It helps to throw out harmful 3D printer fumes and keep away the foul smell. You have enough space to accommodate popular resin printers like the Elegoo Saturn S and Phrozen Sonic Mighty 4K.

Considering the price, ease of use, and accessibility, using an IKEA BRIMNES as DIY 3D printer enclosure is an excellent solution for clearing up your resin workplace.

Repurposed Dishwasher Enclosure

Image: antialiasedpixel via Reddit

Repurposing things is an excellent avenue in the DIY area, and what better way than to use an old dishwasher as a 3D printer enclosure. This one easily fits an Prusa i3 3D printer and still has room at the top to mount a filament spool.

This one easily fits an Prusa i3 3D printer and still has room at the top to mount a filament spool.

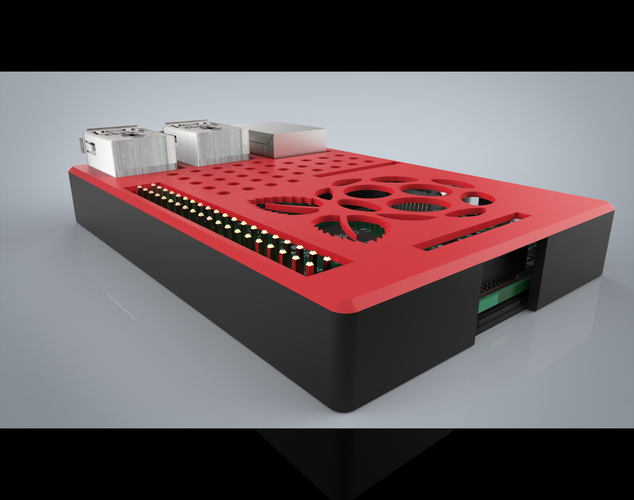

The Prusa’s footprint is 16.5×16.5×15 inches, while the area within the dishwasher is 21x23x25 inches. This dishwasher has enough room to fit in the Creality Ender 3 (Pro/V2) and others of similar sizes. And the spare room that’s left can be utilized to fit in some LEDs, a Raspberry Pi, and a webcam for remote monitoring and control of the 3D printer.

The main disadvantage is that there is not much room for further customization. You will need to change the dish washer to accommodate any future updates to the 3D printer, not very practical!

Otherwise, the enclosure is one of the best ways to repurpose an old machine into something useful and save some money.

Ready-to-Buy Enclosures

Official Creality Enclosure

The official Creality enclosure is one of the best ready-to-use designs to cover up your 3D printer. While it is designed for Creality 3D printers, you should have no issues using it for other 3D printers of similar sizes.

The enclosure uses aluminum rods for its structural strength and an aluminum-lined fabric to enclose the 3D printer on all its sides. The internal aluminum lining is made up of flame-retardant material.

The Creality enclosure does a good job at keeping hot air inside and maintains stable temperatures well. It also comes with a single window on the front of the box to view your 3D prints in progress.

With a little bit of wiring, you can move out the LCD controller and power supply to the outside of the enclosure to work with even higher temperatures. For just under $70.00, the Creality’s Enclosure is an effective solution to print with warping filaments while keeping fumes in and dust out.

Creality Ender Enclosure for 3D Printer, Fireproof Dustproof 3D...

Check PricePhotography Lightbox

Image: Make360

While a photo lightbox is not designed for 3D printers, it does a great job as a 3D printer enclosure. It doubles as both a photo studio tent and an enclosure and gives you great lighting for pictures of your 3D prints.

This lightbox has two adjustable LED bars that cumulatively house 126 LED lights giving you a bright and well-lit inside area. It also gives you four PVC backgrounds for shooting various scenes and highlighting different shades of your 3D prints. And you can adjust the front cover to either fully cover up the 3D printer, or keep it open for ventilation.

It is a decent step up over the Creality enclosure and aids in photographing and taking videos of your 3D prints. The enclosure is easy to assemble and use, while also being convenient to store when necessary.

This enclosure is an ideal choice for enclosing your 3D printer and still having the flexibility to use it as a photo lightbox when you need it.

Photo Box, SAMTIAN Photo Light Box 32x32x32 Inches 126 LED Light...

Check PriceBuying or making a DIY 3D Printer enclosure: What to consider

Size

The size of the DIY enclosure should be just enough to fit your 3D printer. It should not be too big, as this makes it more difficult to heat the print area and makes it harder to move around if you need to.

Ease of Access

You should be able to easily access your 3D printer when it is in the DIY enclosure. Locking latches are a great addition that lets you lock and open the enclosure at will

Material

A DIY 3D printer enclosure should be made of a durable and heat-resistant material. The material should also be easy to clean. Plexiglass is a good option for 3D printer enclosures as it is durable, easy to clean, and heat resistant.

Smoke Alarm

Installing a reliable smoke alarm at the top of the enclosure can alert you in time if your 3D printer catches fire. It is a worthwhile investment that can help keep you safe.

First Alert SCO501CN-3ST Wireless Interconnected Combination Smoke...

Check PriceFire Suppression

If you want to be extra safe, you can install a fire suppression system that kicks in when the 3D printer enclosure gets too hot. A popular choice is the Blazecut T-series.

Soundproofing

One of the main disadvantages of 3D printing is the noise it produces. This can be a problem if you are trying to print in a shared space or if you just want to keep the noise down.

This can be a problem if you are trying to print in a shared space or if you just want to keep the noise down.

3D printer enclosures can help with this by soundproofing the area around the printer. Adding acoustic foam panels to your enclosure will help reduce sound levels significantly. Always make sure you get fire resistant ones, however.

TroyStudio Acoustic Studio Absorption Foam Panel, 12 X 12 X 2 inches...

1,412 Reviews

Check PriceWindows

Adding a window to the 3D printer enclosure can help you monitor the progress of your 3D prints.

Lighting

You might want to consider installing LED lights inside the 3D printer enclosure. This will help you see the 3D prints better and also aid in taking pictures or videos of them.

Price

The price of 3D printer enclosures can vary depending on the size and features. 3D printer enclosures can be bought or made. If you are making your own 3D printer enclosure, you will need to factor in the cost of all the materials as well as your time.

Frequently Asked Questions

Is a 3D printer enclosure necessary?

A 3D printer enclosure is not strictly necessary, but it can be beneficial in terms of safety and maintaining optimal printing conditions. Enclosures can help to minimize drafts and other external factors that can impact the print quality, and they also provide a barrier between the hot printer components and curious fingers (especially important if you have young children or pets in the home).

If you are interested in purchasing a 3D printer enclosure, there are many different options available on the market to suit a variety of budgets and needs.

How do 3D printer enclosures work?

3D printer enclosures work by creating a controlled environment for the 3D printer. This helps to protect the 3D printer from dust, debris, and fumes. It also helps to maintain a constant temperature around the 3D printer, which is important for preventing warping of high-temperature filaments.

How do you enclose a 3D printer?

A 3D printer can be enclosed in a variety of ways. Some printers come with an enclosure that is already built in, while others use the addition of an enclosure for safety reasons.

Some printers come with an enclosure that is already built in, while others use the addition of an enclosure for safety reasons.

One common way to enclose a 3D printer is by using a box made out of cardboard or plastic. The box should be large enough to fit the printer and the printing material, and it should have openings for the print head, filament feeder, and other cables. The box can be sealed shut with tape or clamps to keep fumes and heat from escaping.

Another option is to build an enclosure out of plywood or acrylic sheeting. This type of enclosure is more permanent and can be customized to fit the specific needs of the user and 3D printer.

Do 3D printer enclosures need ventilation?

3D printer enclosures do not need ventilation if the material being printed is not fumes-emitting. If you are printing with PLA, for example, there should be no issue with keeping your enclosure sealed. However, if you are printing with ABS, it is recommended that you provide some form of ventilation to deal with the build-up of fumes.

Do I need an enclosure for PLA printing?

PLA prints very well without an enclosure, so you likely don’t need one unless you’re printing in extremely cold temperatures. If you do want to use an enclosure, make sure it’s well-ventilated so your print doesn’t overheat.

How hot should a 3D printer enclosure get?

There is no definitive answer to this question as it depends on the specific 3D printer and filament being used. As a ballpark range, a temperature somewhere between 30 and 60 degrees Celcius is the right range for FDM 3D printer enclosures.

Should I enclose my Ender 3?

You should enclose your Ender 3 if you want to protect it from dust, dirt, and other debris. Additionally, enclosing your printer will help to maintain a consistent temperature and protect against accidental contact.

An enclosure is one of the top Ender 3 upgrades we recommend people to start with when modding their printer.

Recommended:

The Best Ender 3 (V2 / Pro) Upgrades

Should a 3D printer enclosure be airtight?

There is no single answer to this question as it depends on the specific printer and application. In general, though, airtight enclosures can be helpful in preventing fumes and particles from escaping the printer and contaminating the environment. They can also help protect the printer from dust and other debris.

In general, though, airtight enclosures can be helpful in preventing fumes and particles from escaping the printer and contaminating the environment. They can also help protect the printer from dust and other debris.

However, if the enclosure is too tight, it can create problems with heat retention and airflow, which could lead to a decrease in printing quality or even damage to the printer. It’s important to find a balance between creating an effective enclosure and maintaining optimal printing conditions.

Conclusion

A 3D printer enclosure is an effective way to increase your 3D printer’s material compatibility. It further aids in printing with warping filaments like ABS and Nylon by maintaining a constant temperature. It saves the printer from external dirt and dust and improves the print quality.

With DIY 3D printer enclosure designs, you have the flexibility to customize the enclosure to your specific needs and install as many features as you’d like in it. It is also relatively easy to build a cheap, low-cost solution, for example with a simple cardboard box.

It is also relatively easy to build a cheap, low-cost solution, for example with a simple cardboard box.

But, it can be tedious for many users, requiring lots of time, effort, and money. Whereas the ready-to-buy designs lack customizability but offer an easy, quick, and cheap solution.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

How to build a simple, cheap enclosure for your 3D printer

Maybe you have already seen some of those fancy enclosures people build for their printers. How do they work? And do they work? Today, we will shed some light on this matter! Plus, we are going to dive into patent wars and explain why not all printers come with an enclosure. To top things off, we will even give you a full guide with information on how to build an enclosure for your own printer. But first, let’s start with the fundamental question: what is it good for?

- Stable printing environment – Drafts can negatively impact your print.

An enclosure will keep the temperature stable and high. Big differences in ambient and printing temperatures can lead to warping and shrinking of the printed object, especially when printing with ABS. Layer adhesion may also improve with higher ambient temps.

An enclosure will keep the temperature stable and high. Big differences in ambient and printing temperatures can lead to warping and shrinking of the printed object, especially when printing with ABS. Layer adhesion may also improve with higher ambient temps. - Reduce and contain smell – Some filaments (looking at you, ABS!) can release unpleasant fumes during printing. An enclosure will contain these fumes, and you can quickly vent them outside through an open window when the print finishes.

- Noise reduction – As if you needed the MK3 to be any quieter 🙂 But another level of sound isolation can’t hurt, especially if you place the enclosure next to your work desk or in a living room.

- Dust collection – The bearings and smooth rods will appreciate the reduced amount of dust that settles on your printer.

- It’s fun to build 🙂

However, if you’re not printing with ABS or other high-temperature filaments that suffer from warping, you won’t see much of a difference. You might actually want to keep the enclosure open with, for example, PLA to ensure there’s enough cool air around the printer for the part cooling fan.

You might actually want to keep the enclosure open with, for example, PLA to ensure there’s enough cool air around the printer for the part cooling fan.

Enclosure for the MMU2S

If you own the MMU2S, we created a modified version of the enclosure – check it out here.

Why aren’t all the printers on the market enclosed by default?

There are two factors here – price and patents. There is no doubt that the rise of consumer 3D printers was delayed by patents. Companies like Stratasys, Zcorp or 3D Systems have patented nearly every 3D printing technology you can think of. It’s pretty crazy when you look at the sketches from 1980s-1990s and realize just how much some of the current 3D printers are similar to them.

It was only after these key patents expired in 2009 (20 years after application) that the RepRap movement started. And cheap, easy-to-build 3D printers quickly started to be developed. Even though most of these basic patents have already expired, some of them (most importantly the ones owned by Stratasys) are either still active, or have just recently expired. For example, Stratasys’s (still active) patent describes an apparatus “That builds up three-dimensional objects in a heated build chamber” (…) “The motion control components of the apparatus are external to and thermally isolated from the build chamber.” That means if you put the stepper motors outside of an enclosure, you can’t sell the product, as it would violate the patent.

For example, Stratasys’s (still active) patent describes an apparatus “That builds up three-dimensional objects in a heated build chamber” (…) “The motion control components of the apparatus are external to and thermally isolated from the build chamber.” That means if you put the stepper motors outside of an enclosure, you can’t sell the product, as it would violate the patent.

Another obstacle is the price. We have considered and even developed a Prusa enclosure quite a while ago. It was made mostly of Plexiglass. Our target was $90 price tag and considering the packing, shipping and material cost, we just couldn’t make it work. It makes much more sense to build the enclosure yourself from locally sourced materials.

How hot should the enclosure be and can the PSU stay inside?

Let’s get something straight, we are not targeting really high temperatures inside the enclosure. You don’t need an extra heater. The printer itself produces a lot of heat and all you have to do is to not let it escape. The goal is to achieve stable temperatures without any sudden changes from wind or draught. Even just 35°C inside the enclosure will make a massive difference, increase layer adhesion and may prevent ABS from warping.

You don’t need an extra heater. The printer itself produces a lot of heat and all you have to do is to not let it escape. The goal is to achieve stable temperatures without any sudden changes from wind or draught. Even just 35°C inside the enclosure will make a massive difference, increase layer adhesion and may prevent ABS from warping.

The PSU is not made to work in extremely hot environments. By keeping the PSU in temperatures above 40-50°C can significantly shorten its lifespan. Ideally, you’d place the PSU outside the enclosure. You can even place the LCD outside to be able to control the printer without letting the hot air out.

2 simple enclosures

Photo studio tent – no work required at all

An enclosure can often be created from an object originally made for a completely different purpose. This photo (80×80) tent can be bought on eBay or Aliexpress for about $15-20. And all you have to do is place the printer inside the tent. It’s made of textile material, which means it’s porous. A textile enclosure won’t let you reach crazy high temperatures, so you can even keep the PSU inside. We reached temperatures around 38°C after 10 minutes of printing inside a room with the ambient temp. of 26°C – that’s a significant improvement. And as a bonus, you have a photo tent for your prints 🙂

It’s made of textile material, which means it’s porous. A textile enclosure won’t let you reach crazy high temperatures, so you can even keep the PSU inside. We reached temperatures around 38°C after 10 minutes of printing inside a room with the ambient temp. of 26°C – that’s a significant improvement. And as a bonus, you have a photo tent for your prints 🙂

Ikea Lack – when you care about looks as well

Using Ikea Lack as an enclosure is the most popular choice among the 3D printing community. If you search online, you’ll find dozens of Ikea Lack enclosure designs. The table can be bought for under $10 and has almost the perfect size for Prusa printers. You can stack the tables on top of each other to create bays for multiple printers, or use one as filament and tools storage. Even though some of the existing enclosure designs are pretty good, we wanted to give it our own spin.

Advantages of our enclosure

- PSU placed outside in a clip-on holder, but easily placed back if you need to move the printer

- LED lighting connected to the printer’s PSU

- Hinges built into corner extensions

- Double-door opening

- Individual tables can be lifted at any time

What you’ll need

Printable parts

Ikea Lack enclosure main parts

Frame brace replacing the PSU for the MK3 (silver PSU)

Frame brace replacing the PSU for the MK3 (black PSU)

Frame brace replacing the PSU for the MK2/S (remix by Martin Schnur)

60 degree heatbed cable cover for the MK3

45 degree heatbed cable cover for the MK2/S

Construction

- 2x or 3x Ikea LACK table

- 4x Neodymium magnets 20mm x 6mm x 2mm

- 3x Plexi 440 x 440 mm, 3mm thick (if you’re in the US, try Queen City Polymers)

- 2x Plexi 220 x 440 mm, 3mm thick

Electronics

- Fire/smoke detector

- Indoor/Outdoor Thermometer

- LED stripe 24V, 30 cm

- 24V for MK3, 12V for MK2/S

- If you want to use a 12V LED strip with the MK3, use a separate power supply.

- Twin cable, 100 cm

- 2x WAGO 221 or similar compact lever connector

Screws

- 12x 6×20 mm (12 x 3/4″)

- 4x 6×50 mm (12 x 2″)

Printed parts

- Upper table (enclosure box)

- Lower table (support table)

- Spool holders

Tools

- Philips screwdriver

- Allen keys

- Super Glue

- Drill + 3 mm wood drill + 10 mm wood drill

- Measuring tape

- Marker

Enclosure (upper table) assembly

Upper corner standoffs installation

Attaching the legs

LED stripe

For about $12, you can buy an LED strip with a power supply, like this one. However, if you’re feeling a bit adventurous and have some experience with wiring up electronics, you can power the LEDs directly from the printers power supply. Remember, that the MK3 runs on 24V, whereas MK2/S runs on 12V, so make sure you buy the correct LEDs.

Spool holders

Smoke detector installation

Place the smoke detector in the rear part of the table so it will not obstruct filament insertion or won’t get in the way when you’re taking the printer out from the box.

Bottom corner standoffs installation

Before you start screwing the bottom standoffs, make sure you place the Plexiglass in first. As soon as you tighten the standoffs, the Plexiglass will be fixed in place, and you won’t be able to remove it. This means you can easily lift this section of the enclosure without worrying that the glass would fall out. Note, that one of the four standoffs has a hole for cable pass-through. Make sure you place this standoff on the left side so that the cables can be routed directly to the EINSY board.

Support table (lower table) assembly

PSU holder

Electronics do not thrive in higher temperatures inside the enclosure. To preserve PSU in good condition, it’s better to place it out of the box. It is even safer!

To preserve PSU in good condition, it’s better to place it out of the box. It is even safer!

- Unplug the printer from the power socket. Remove zip ties on the frame to release PSU cables. (Tighten the rest of the cables with new zip ties.)

- Disconnect the cables from the EINSY board. Do not forget to unplug the Power panic sensor as well.

- Unscrew the PSU form the frame.

- Hold the PSU next to the rear left leg (the one with the cable pass-through). Tighten the PSU holder printed part with two screws and then install PSU catcher printed part.

- PSU is now fixed, but it is possible to slide it out when you need it.

- You can replace the PSU on the frame with this printed part to ensure the rigidity of the frame.

Frame brace and right-angle cable cover

After removing the power supply from the frame, it’s possible to replace it with a printed part and ensure frame stiffness. The heatbed cables may hit the plexiglass in the back of the enclosure. To prevent this from happening, print an alternative 60 degree heatbed cable cover. (EDIT: Users reported several problems with the right angle one shown in the video and on the pictures below, so we switched the suggestion to the 60 degree one).

To prevent this from happening, print an alternative 60 degree heatbed cable cover. (EDIT: Users reported several problems with the right angle one shown in the video and on the pictures below, so we switched the suggestion to the 60 degree one).

Plugs fixing and magnetic handles

Fix the four bottom plugs. One of them has a hole for cable pass-through. Place it in the rear left corner of the enclosure. Glue two magnets to the door stopper and screw it to the front of the table. Leave enough space for the plexiglass and the handles (1 cm).

Finished enclosure

Now just stack the two tables on top of each other and the enclosure is complete. Optionally, you can add another Ikea Lack table to the bottom to raise the printer to a more comfortable height.

Welcome to NIOZ.RU

Sort by

Product Name +/-

Product Price

Featured Products

Product Availability

Displaying 1 - 60 of 623

153060150

Products

400 ml

RUB 1940. 00

00

Product description

RUB 390.00

Product description

350 ml

RUB 850.00

Product description

Ready to print

RUB 23700.00

Item description

Ready to print out of the box

RUB 14500.00

Notify me when available

Product description

Ready to print

RUB 19900.00

Item description

Print ready

RUB 20900.00

Notify when available

Product description

Ready to print

RUB 23900.00

Item description

Ready to print out of the box

RUB 43500.00

Item description

Ready to print

RUB 39000.00

Item description

LCD 0.7/1.75 mm

RUB 1550.00

Report Admission

Product description

RUB 650.00

Product description

Wiznet W5100 Arduino Shield

RUB 650.00

Notify me when available

Product description

RUB 550. 00

00

Product description

Assembly kit

RUB 2500.00

Notify me when available

Product description

Volume: 1 l.

RUB 3100.00

Product description

Boscam 200mW, 5.8GHz

Chimera, e3d

RUB 1700.00

Product description

Print head 1.75mm 0.4mm

RUB 1100.00

Product description

Dual print head 1.75mm 0.4mm

RUB 2500.00

Notify me when available

Product description

Long

RUB 750.00

Item description

Short

RUB 700.00

Item description

RUB 1900.00

Notify me when available

Product description

APM2.6 mavlink

RUB 1350.00

Product description

RUB 250.00

Product description

11.1V, 20C

RUB 1900.00

Item description

11.1V, 25C

RUB 1250.00

Notify me when available

Product description

11. 1V, 25C

1V, 25C

RUB 2100.00

Product description

Heat block v6

RUB 150.00

Product description

cartridge type thermistor

Heat block Volcano

48V 12A

RUB 2700.00

Notify me when available

Product description

12V 20A

RUB 1550.00

Product description

12V 30A

RUB 1950.00

Notify me when available

Product description

12V 5A

RUB 450.00

Notify me when available

Product description

24V 15A

RUB 2100.00

Notify me when available

Product description

RUB 250.00

Product description

Hobbed bolt

RUB 150.00

Item description

Price per 10mm (free cutting)

RUB 13.00

Product Description

Price per 10mm (free cutting)

RUB 17.00

Product Description

Section 400mm

RUB 650. 00

00

Product description

Price per 10mm (free cutting)

RUB 25.00

Product description

10mm (cut to size)

RUB 70.00

Item description

10mm (cut to size)

RUB 90.00

Item description

Price per 10mm (free cutting)

RUB 7.00

Product description

Price per 10mm (free cutting)

RUB 10.00

Product description

Section 400mm

RUB 400.00

Product description

2x400mm, 2x350mm, 2x325mm

RUB 2100.00

Product description

2x420mm, 2x405mm, 2x350mm, 1x20mm

RUB 2200.00

Product description

25x25x10mm

RUB 150.00

Product description

25x25x10mm

RUB 150.00

Product description

30x30x10mm

RUB 150.00

Product description

30x30x10mm

RUB 150.00

Product description

40x40x10mm

RUB 150. 00

00

Notify me when available

Product description

40x40x10mm

RUB 150.00

Product description

50x50x10mm

RUB 150.00

Notify me when available

Product description

50x50x15mm

RUB 150.00

Product description

50x50x15mm

RUB 150.00

Product description

50x50x15mm

RUB 150.00

Product description

Turbine 40x40x10mm

RUB 250.00

Product description

preview / 3D Printers, Machine Tools & Accessories / iXBT Live

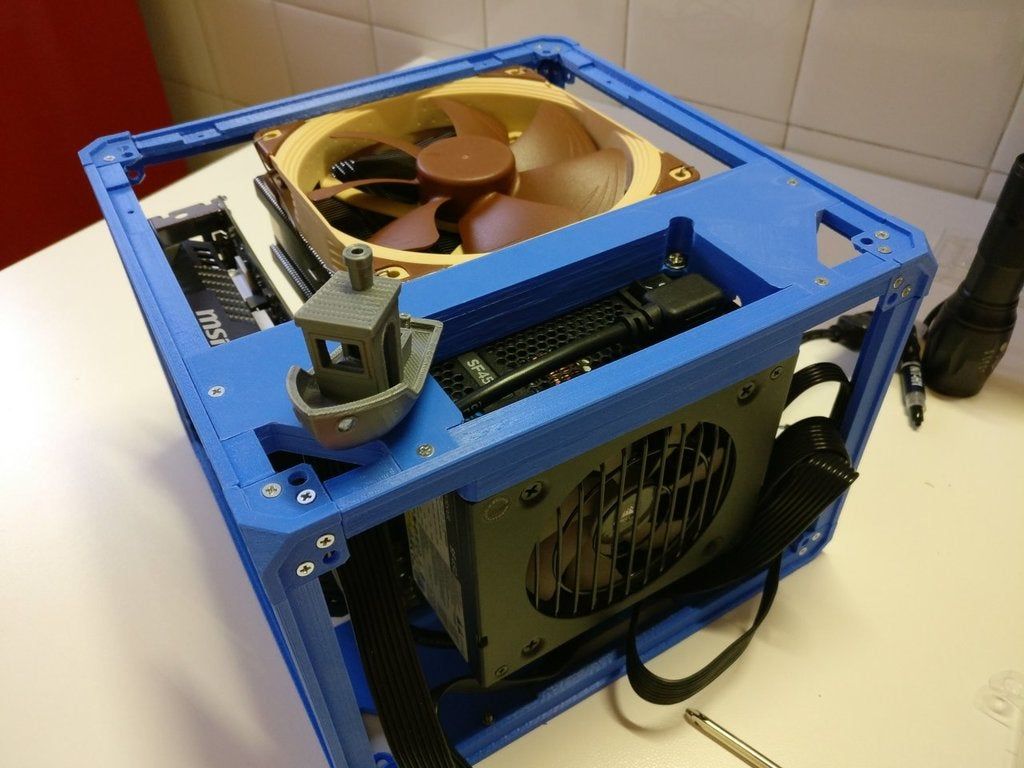

The B&R 3D project is growing and a PRO version of the kits is now available. Sets of body parts for self-assembly are universal and allow you to assemble a 3D printer both on H-bot and Core XY kinematics. The B&R PRO versions of the kits have received a number of changes in a positive way and have received larger “Plus” versions of the kits. Now this is one of the most affordable ways to assemble a steel printer, which outperforms its brethren with a plywood case or an aluminum profile frame in all respects.

Such a 3D printer allows you to assemble a fairly budget-friendly structure from metal, and not from plywood / profile. The side walls are sheathed with acrylic panels (if necessary). The design allows the installation of a direct feed (direct extruder) of plastic, as well as dual extruders for color printing.

The range includes three new B&R Pros and two basic build kits:

- The B&R PRO 3030 kit has a printable area of 300 x 300 x 350 mm. Overall size 615 x 471 x 481 mm with a set weight of 19kg.

- Kit "B&R PRO 3030 plus" has an enlarged print area of 320 x 320 x 350 mm. Overall size 615 x 496 x 501 mm with a set weight of 23 kg.

- Kit "B&R PRO 2525 plus" has a print area of 270 x 270 x 300 mm. Overall size 615 x 450 x 450 mm with a set weight of 19 kg.

- The B&R 3020 basic kit has a printable area of 300 x 200 x 300 mm. Overall size 570 x 455 x 370 mm with a set weight of 15 kg.

- The B&R 2020 basic kit has a print area of 200 x 200 x 300 mm.

Overall size 570 x 405 x 370 mm with a set weight of 14 kg.

Overall size 570 x 405 x 370 mm with a set weight of 14 kg.

A heavy printer is good. The massive body well dampens excess vibration when working at high print speeds. The body itself is rigid, made of thick stamped steel with a powder coating. There are holes for installing a touch display (diagonal options are possible), holes for installing encoders, switches, USB panels. The electronics compartment is located under the "floor" of the device. I covered the nuances of assembling the basic kit for assembling a B&R 3D printer in a separate article.

The peculiarity of the project is not only the openness and availability of information, but also the possibility of implementing a moving scheme both in the form of CoreXY and in the form of H-Bot. The top panel provides for the installation of one of two versions of kinematics.

Assembly of B&R kits is quite simple - fastening panels in turn, setting up a table, assembling guides (shafts, rails), motors, connecting electronics. It should be noted that only steel painted panels are included in the B&R kit. Additional components are purchased by the user according to the list based on his own preferences. There is both an opportunity to save money and a path to assembling the most advanced 3D printer.

It should be noted that only steel painted panels are included in the B&R kit. Additional components are purchased by the user according to the list based on his own preferences. There is both an opportunity to save money and a path to assembling the most advanced 3D printer.

The advantage of a 3D printer with a large printable area is that you can create large models without cutting into pieces and without subsequent gluing. An example of a complex layout mechanism is shown in the images below.

The B&R kit is one of the most affordable and smart options for DIY 3D printer assembly. Detailed information on assembling and setting up the printer can be found both in the official B&R group and in the project's telegram chat.

Source : Official B&R 3D printer project chat

News

Publications

frosts. Many smartphone users have experienced the problem of fast discharging the battery of the gadget in very cold weather. Today in the article we.