How much do objet 3d printers cost

Objet30 Pro 3D Printer Review 2022

4.6

See Price

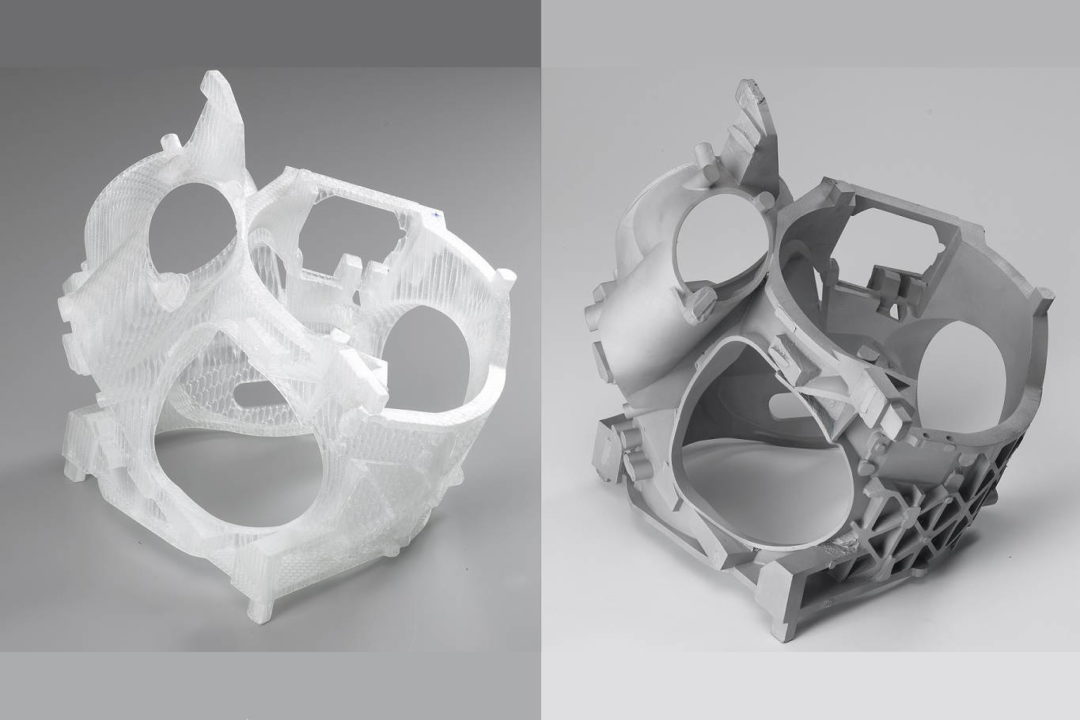

Stratasys’ ambition with the Objet30 Pro is to offer the precision and adaptability of an industrial-grade fast prototyping printer within a device with physical dimensions nearing those of an inkjet printer or office photocopying machine – a compact workhorse capable of highly detailed prints.

We’ve taken a look at the Objet30 Pro to see how well it lives up to these claims. Here’s our honest opionion.

| Printing Area | 294 x 192 x 148.6 mm |

| Layer Resolution | 16 to 28 microns |

| Supported Filament | Rigid Opaque, Transparent, High Temperature, Simulated Polypropylene, FullCure |

| Printing Tech | PolyJet |

| Extruders | 2 |

Table of ContentsShow

Design & Features

Touted as a desktop printer, the Objet30 Pro has all the allure of a professional grade printer with a sleek black and white color scheme that shapes a rectangular body that interestingly curves inwards vertically towards the center of the unit. The plastic casing will be familiar to anyone having used a consumer-grade ink printer making it very much at home in a design studio, home office or university alongside similar devices.

The total weight of the printer is a robust 106 kg, which apart from making transportation a hassle, ensures near unwavering stability, even when the print heads are whizzing away at the highest speed setting.

The components are all heavy duty and of the highest quality, positioned for maximized functionality but also a certain aesthetic, mechanical appeal especially when opening the hood and peering inside. The extruder mount can only be described as chunky with one of the most prominent profiles we’ve come across from a printer with this footprint.

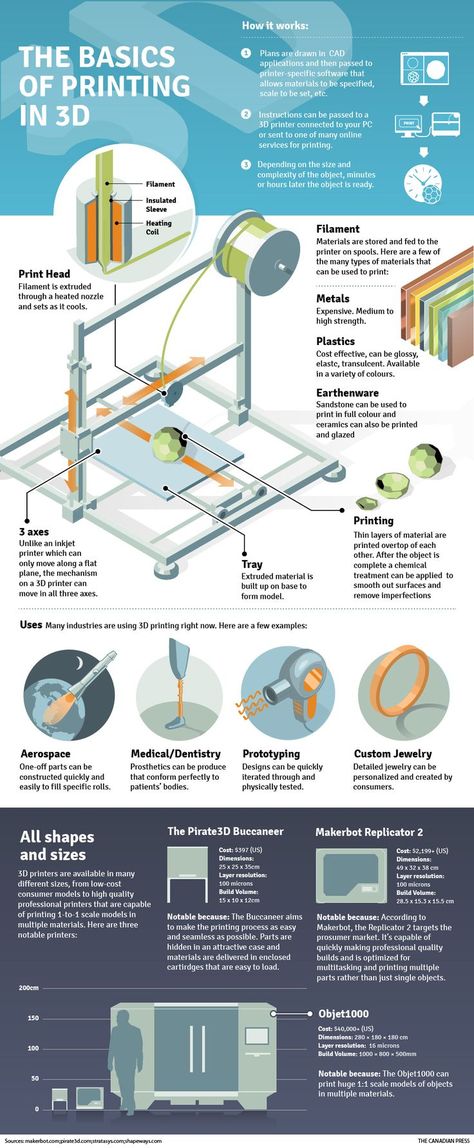

The Objet30 Pro employs Stratasys’ patented PolyJet printing technology, which sits somewhere between typical FDM and precision SLA printers. The process resembles the inkjets found in standard printers whereby a jet places drops of liquid photopolymer material onto the build plate and then hardens or cures it by shining UV light onto it. This method is uncommon with results that offer precision unseen in printers using FDM technology.

This method is uncommon with results that offer precision unseen in printers using FDM technology.

The build area tallies up to 294 x 192 x 148.6 mm with axis resolutions of 600 dpi, 600 dpi, and 900 dpi for the X-axis, Y-axis, and Z-axis respectively. Generally speaking, the Objet30 Pro attains software to real-world print accuracy levels correct up to around 0.1mm, but this vacillates important waging on the type of model, size, the materials used, and the complexity of the design.

The Objet30 Pro has a dual extruder setup; one for printing material and the other for support material, both sitting alongside the UV light that does the curing work. The configuration allows layer resolutions ranging from 16 to 28 microns depending on whether it prints on the high quality or high-speed setting. The precision makes it one of the most detailed printers on the market regardless of cost and is a world away from the 100 microns best of most consumer models.

The material support of the Objet30 Pro is where the printer comes into its element with different liquid photopolymers endowed with a range of physical properties for all manner of situations, the only real downside being that only materials sourced from Stratasys are compatible.

Rigid Opaque in white, black, gray, and blue allow for high detailed prints that reach the quality level of end products for prototyping. Transparent VeroClear is ideal for fine-modeling used to simulate end-product transparent materials. High-Temperature RGD525 is geared towards functional testing for scenarios where high temperatures, be it air or liquid, are required. Lastly, the printer supports DurusWhite Simulated Polypropylene designed for durability and robust usage for example low tolerance hinges and snap-fit products.

The printer also uses the non-toxic gelatinous FullCure 705 support material that is not only ideal for crafting complex overhangs and the like but is removable via the DT3 Clean Station that ships with the printer.

The materials are housed in a convenient slide out draw sitting below the main printing area. Should any of the liquid photopolymer cartridges run dry, the printer has an inbuilt feature that pauses the building process to allow the user to load in a replacement, when the device picks up where it left off.

Connectivity is limited to a local network via ethernet cable, which is the standard for industrial sized printers that need a connection to multiple workstations.

As for software, the Objet30 Pro functions with Stratasys’ Objet Studio that converts any STL or SLC 3D CAD file into a sliced model that the printer can interpret and render. All controls are managed from Objet Studio with no LCD or controls on the printer itself.

Functionality ranges from automatic support creation, a range of editing tools, material selection, auto-positioning, maintenance, and the like. Compatibility is reserved for Windows systems. Overall, Objet Studio is as intuitive as it is versatile and rivals open source slicers such as Simplify3D.

Assembly

The Objet30 Pro arrives fully assembled with no installation other than fitting the liquid photopolymer cartridges into the loading tray and loading the roller bath/blade assembly into its berth below the build plate.

The package includes the Objet30 Pro waste containers, roller bath assembly, wiper blade assembly, sanding sponge, ethernet cable, nozzle ruler, loupe, tool kit (scraper, Allen key, mirror, spatula), cleaning cloths, transparency sheets, pink paper, nitrile gloves, scale, spray bottle, support cleaning fluid, model cleaning fluid, user guide notebook, USB flash drive, and a stylus pen.

Due to its complexity, the Objet30 Pro does require quite a bit of maintenance from cleaning the innards, replacing printheads, emptying waste containers, but nothing a versed lab or office technician couldn’t handle.

Printing

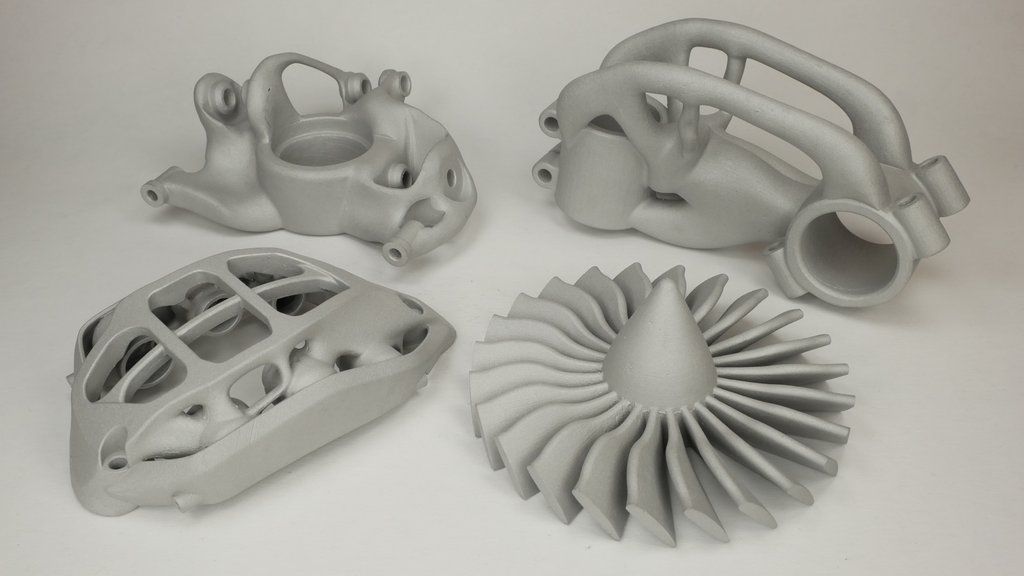

For a price tag nearing $20,000, we wouldn’t accept anything short of extraordinary, and the Objet30 Pro fits the bill. Prints are more or less immaculate, and the range of printing materials allow a varied selection of models. All our test prints were smooth, precise, and showed a level detail usually found in pre-assembly line models. We encountered no issues whatsoever with the printing process.

The results are suited to all manner of ends from engineering, consumer goods, low tolerance prototyping, end-user small scale manufacturing, dentistry, electronics, medical, and of course design. Virtually any industry can benefit from the quality of the prints generated by the Objet30 Pro.

Objet Studio is packed with choices and is incredibly simple to use even though it controls such a strong beast of a machine.

Support

As you’d expect from Stratasys, the support is of the highest caliber with a rich vault of guides, tutorials, and videos peppering its web site alongside the Stratasys Service Offering which includes on-site technical service and maintenance, part replacement, user training seminars, and discounts on accessories among other benefits.

Additionally, technical support teams are available throughout the world through phone, email or in person support. The printer itself ships with a standard one-year warranty.

Verdict

When reviewing leviathan grade printers with all the bells and whistle it is hard to produce a verdict other than excellent, but then again this is very much expected from the associated price tag.

The Objet30 Pro follows suits, and if you’ve got the budget to match (including maintenance and on-going production costs), then you quite simply can’t go wrong with this model.

It comes highly recommend for any professional context in need of a reliable, versatile, and precision-oriented 3D printer that won’t take up too much space yet deliver the same level of quality as pricier alternatives.

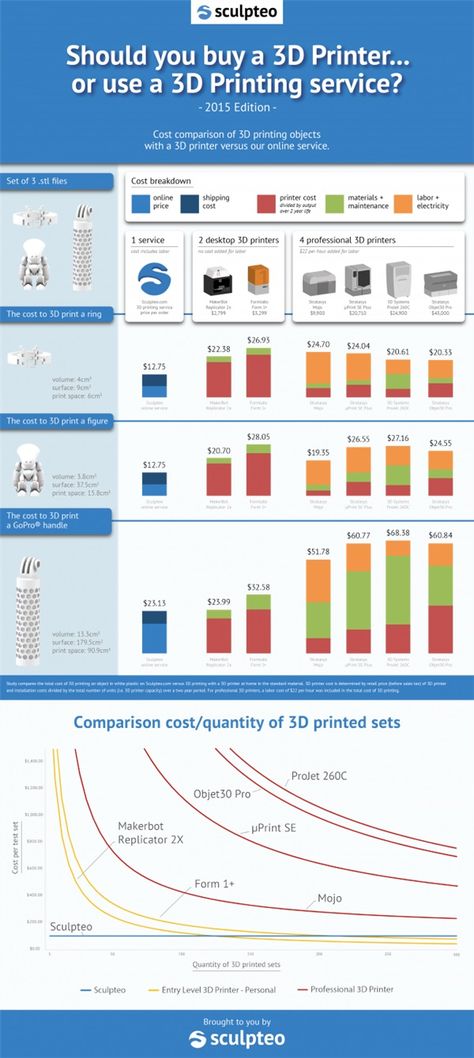

How much does a 3D printer cost? (2022 update)

David Durbin13 January 2022

Guide

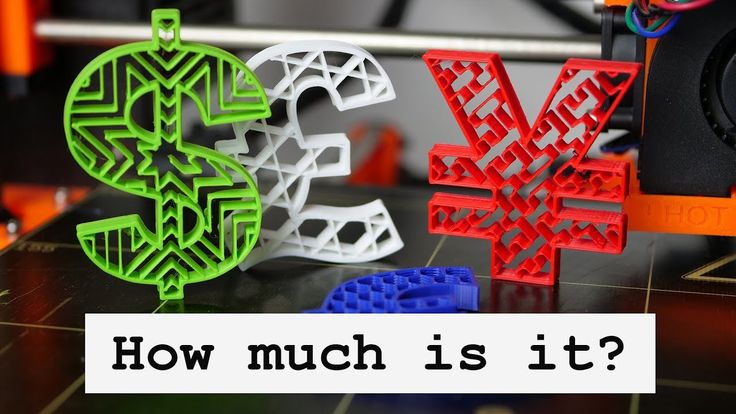

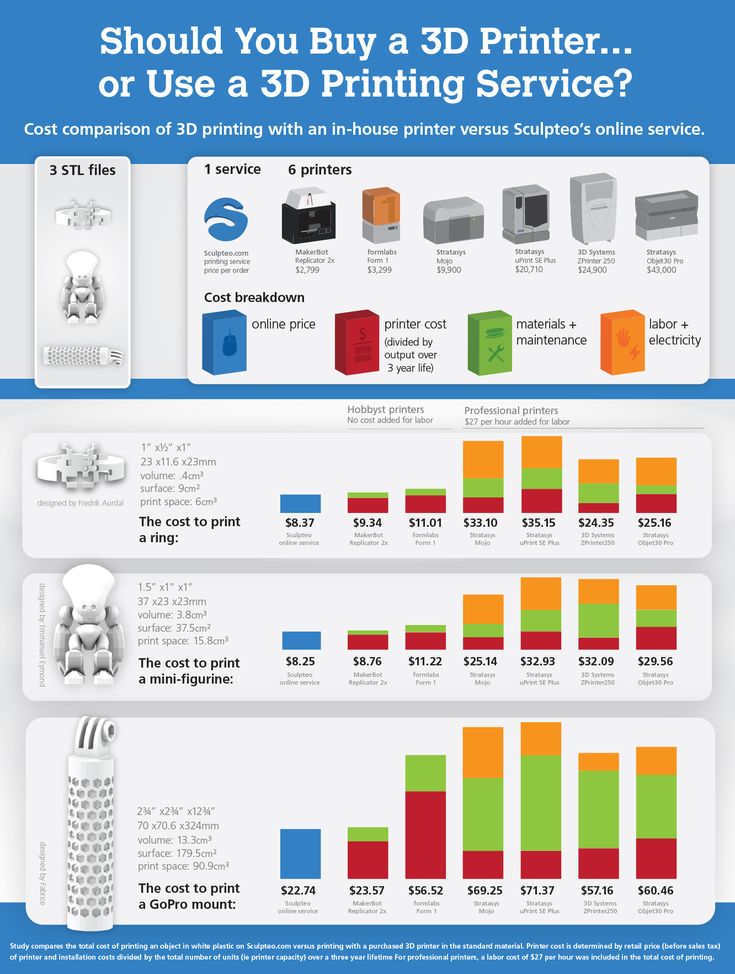

| 3D printer category | Average price |

|---|---|

| Low-cost 3D printers | $100 - $400 |

| Hobbyist 3D printers | $400 - $1,000 |

| Enthusiast 3D printers | $1,000 - $3,000 |

| Professional 3D printers | $3,000 - $10,000 |

| Industrial 3D printer price | $10,000+ |

If you're wondering how much a 3D printer costs. Or, if a 3D printer is worth it. You're in the right place.

The good news is this: These days you can find almost any 3D printer for any budget.

And while the average 3D printer price across the market is around $400...

That average is pulled down because of the high volume of low-cost 3D printers sold.

So is it worth it to buy a 3D printer in 2022? If yes, what is the best 3D printer for the price? And are there price range “sweet spots” that you should look out for?

You can prepare yourself to answer these questions by asking yourself:

Am I looking for a hobby or a tool?

And you can get the full answers by reading below.

How much does a 3D printer cost? Low-cost 3D printer prices start from $100 to $400. Then hobbyist 3D printers will set you back by up to $1,000. The next level of enthusiast and professional 3D printer prices range between $1,000 to $10,000. After that, the sky’s the limit – with industrial 3D printer prices starting at $10,000 but quickly reaching $100,000 or $250,000 for specialist technologies.

If you're looking to find out exactly how much Ultimaker printers cost, you can request a quote to find out now.

Request a quoteDIY / Low-cost 3D printer price $100 - $400

Low-cost 3D printers are all about the novelty of the technology. They exist for newbies who want to say, "Hey – check out what I just 3D printed!" Almost all will come as kits that the buyer puts together. And while these machines might have beginner-friendly price tags... It won't be a beginner who can get them to produce a good 3D print. That's because manufacturing problems are too common to overlook. And these lead to a painful setup and user experience. Also, when asking how much does a basic 3D printer cost? This tier can save you money. But expect to pay more for modifications, upgrades, and repairs down the line. That said, if it's a choice between "having a 3D printer" and "not having a 3D printer", this tier offers the biggest bang for your buck.

And these lead to a painful setup and user experience. Also, when asking how much does a basic 3D printer cost? This tier can save you money. But expect to pay more for modifications, upgrades, and repairs down the line. That said, if it's a choice between "having a 3D printer" and "not having a 3D printer", this tier offers the biggest bang for your buck.

The Ultimaker Original was sold as DIY 3D printer that you put together yourself

Hobbyist 3D printer price $400 - $1,000

3D printers at this price range can produce some great parts and models. But that's only after you have set them up and dialed in their settings. In this way, they are aimed at hobbyists. (People who are happy to spend time watching tutorials and tweaking settings to improve their prints.) This also limits your flexibility. Over time, you might be able to 3D print well with a basic material like PLA. But don't expect to switch filaments too easily. While these machines are often delivered as kits, manufacturing problems are less common.

Enthusiast / Prosumer 3D printer price $1,000 - $3,000

Up until this price range, almost all the 3D printers will have had an open design. But now you will begin to see more partially and fully enclosed printers that increase safety and print reliability. This also marks the end of the hobbyist range. And the start of 3D printing becoming a useful production tool. Therefore, the enthusiast and prosumer category is great for lower and higher education customers who want to avoid spending time on maintenance. Plus, they present a smart option to 3D print cheaply at home. These machines can 3D print a handful of materials with good reliability. However, these will often be own-brand filaments with carefully tweaked settings. The best enthusiast 3D printers include hardware and software features taken from the professional 3D printer price tier. On which note...

Safer, more reliable, and low maintenance – Enthusiast 3D printers are a great option for schools

Professional 3D printer price $3,000 - $10,000

A lot changes at this price point. Instead of being a technology to tweak and adjust, these 3D printers focus on easy use and adoption. They become one tool among many in an engineer's or designer's toolbox – giving a growing number of businesses a new way to innovate. And that's why, at this price point, FFF 3D printing is at its most disruptive. The only way this can happen is for the 3D printer to work – and for it to work hard. Expect a factory-tested machine that you can leave running over the weekend and come back to a finished part on Monday morning. Plus, prints start being repeatable. For example, if you 3D print the same part on the same printer in two or more locations...the part quality should be almost identical. The user also has more flexibility. You can choose to print with a build material and a support material in the same print (called dual extrusion), offering more design freedom. And you gain a growing range of engineering-grade material options. These can include materials reinforced with carbon fiber or even metal.

Instead of being a technology to tweak and adjust, these 3D printers focus on easy use and adoption. They become one tool among many in an engineer's or designer's toolbox – giving a growing number of businesses a new way to innovate. And that's why, at this price point, FFF 3D printing is at its most disruptive. The only way this can happen is for the 3D printer to work – and for it to work hard. Expect a factory-tested machine that you can leave running over the weekend and come back to a finished part on Monday morning. Plus, prints start being repeatable. For example, if you 3D print the same part on the same printer in two or more locations...the part quality should be almost identical. The user also has more flexibility. You can choose to print with a build material and a support material in the same print (called dual extrusion), offering more design freedom. And you gain a growing range of engineering-grade material options. These can include materials reinforced with carbon fiber or even metal.

Professional 3D printers are workhorse tools for an increasing number of engineers and designers

Industrial 3D printer price $10,000+

3D printers that cost tens or hundreds of thousands are made to do a few things at a high level of quality. This includes production technology for specific materials, like high-temperature polymers or metal. 3D printing these materials with a high success rate often requires you to stay within a manufacturer's material portfolio and software stack. If you are in the market for an enterprise-level machine, this will rarely be the first 3D printer your company buys. And you will know what's required to make the investment: a strong business case, competitor analysis, and a purchase order. You or your company may be happy to pay extra for increased speed, accuracy, and reliability. But also know that, the higher you go in this price bracket, the more you chase diminishing returns.

Is a 3D printer worth it?

These five price tiers cover the majority of 3D printers sold today.

If you consider 3D printing as a hobby, 3D printing successfully will largely be paid for with your time and patience. If 3D printing needs to be a tool for you, then you will pay extra for a user experience that saves time and attention.

But it's also in this second category where 3D printing offers significant business value. And the right 3D printer can end up paying for itself with substantial time and cost savings.

The total cost of 3D printing

Finding the best 3D printer for the price, then, is not only about the machine you buy. The picture is bigger than just the initial price tag.

It's also about the software, accessories, materials, and service that go with it. Together, these contribute to an easy-to-use, time and cost-saving 3D printing experience.

The Ultimaker platform creates a seamless flow between hardware, software, and materials

For example, every Ultimaker 3D printer works seamlessly with Ultimaker Cura, which is updated every few months. They also ship with a suite of free online tools and e-learning courses. Together these resources transform your ability to click-and-print with up to 239 materials.

They also ship with a suite of free online tools and e-learning courses. Together these resources transform your ability to click-and-print with up to 239 materials.

So it's no surprise that hundreds of leading companies – from Ford to L'Oréal – 3D print day and night with the Ultimaker platform to drive innovation and sustain their competitive advantage.

If you would like to do the same, click below to find out more.

Discover Ultimaker 3D printers

Photopolymer 3D printer, technologies, materials, working principle – 3dprofy

Turch October 21st, 2014

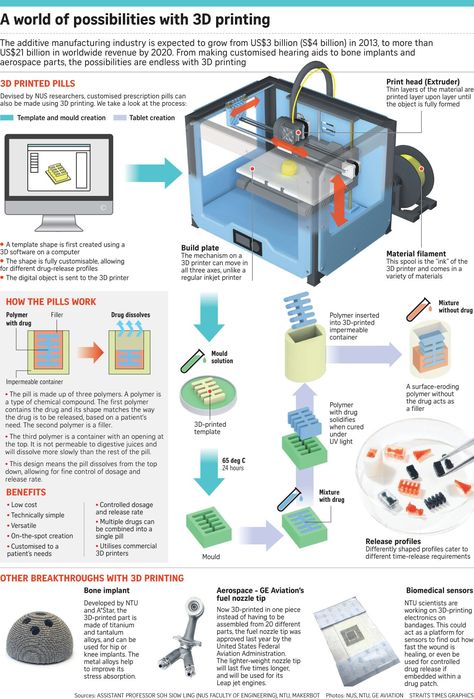

Resin-based printing is carried out using SLA stereolithography method . I printing process applied liquid polymer. The printer itself consists of a powerful laser, as well as a bath in which the base platform is located.

Features of the printer for SLA

The essence of the 3D printer is as follows. The platform is lowered into the bath to a depth that depends on the thickness of the print layer. Then a layer of the future model is projected onto it with a laser. Under its influence, the photopolymer hardens, that is, the formation of the part begins. The platform is then lowered to begin forming the second layer. And so on until a three-dimensional model is obtained. After the printing is completed, the product is treated with special compounds to remove excess material. In the final stage of work, the part is placed in an ultraviolet chamber, in which it hardens.

Then a layer of the future model is projected onto it with a laser. Under its influence, the photopolymer hardens, that is, the formation of the part begins. The platform is then lowered to begin forming the second layer. And so on until a three-dimensional model is obtained. After the printing is completed, the product is treated with special compounds to remove excess material. In the final stage of work, the part is placed in an ultraviolet chamber, in which it hardens.

Pros and cons of the SLA printer

Resin cures only 20% during printing, which is caused by difficulties in choosing the laser power. The advantages of this printer include the high accuracy of every detail and the ability to create prototypes for various fields. On the other hand, the equipment is quite expensive, and the printing itself takes too much time. In addition, the created parts require additional work, which is expressed in washing and hardening of the product. In addition, the liquid polymer is expensive.

How is printing done?

The prototype is grown on a special mesh platform. The first photopolymer layer is thin, but during the process, under the influence of a laser, it gradually hardens. The hardening of the model occurs in those areas that are specified on the computer model. At the final stage of work, an almost finished model is lowered into a container with a chemical solution - in it, unnecessary artifacts are removed from the product, and it is also cleaned. The printing process will require the preparation and alignment of auxiliary structures that will achieve optimal physical and chemical properties and will be removed upon completion of the prototype.

What is good about 3D printing using the SLA method? Firstly, the speed of the process - you can grow an object in just one day. Secondly, on the basis of this method, it is possible to create structures with complex relief. Thirdly, you can pick up a large number of materials that will allow you to conduct a high-quality and fast printing process.

Objet Printer

One of the popular devices that can be used for printing with photopolymer materials is the Objet brand. The peculiarity of the technology is that the layer thickness is slightly higher, while the finished product is durable and reliable. Objet brand printers can work with two materials at once, while they can be used to create one or two prototyping models. Each printing process can be given specific characteristics so that the final models meet the necessary requirements.

The Objet24 allows you to create highly detailed prototypes that can be equipped with moving parts. The final part will be durable, despite the thin walls, and the smooth surface will be an opportunity for further painting in the desired color scheme. This printer model is suitable for designers or engineers who need to create high precision models. This device works with VeroWhitePlus hard photopolymer, which is easy to use: it can be painted, drilled, machined.

More advanced SLA printer model - Objet30 Pro . Based on it, you can create prototypes from eight different materials, each of which is characterized by heat resistance, different structure and texture. Most importantly, the print quality will be excellent. The printer has a capacious tray, which allows you to print large quantities of goods, for example, for medicine.

Professional printers

Professional printer model 9 can be used0005 Objet Eden260V . This is a truly profitable investment because you can quickly create prototypes from 18 materials. The ultra-thin layers of the 3D model allow for exceptional detail, complex shapes and very thin walls. The device works silently, so it will be an excellent solution for office premises. This printer model works with several types of materials:

- transparent, on the basis of which you can create parts of strong shapes and with a smooth surface,

- opaque rigid materials in various colors,

- with polypropylene based raw material, which is flexible yet strong so you can prototype with moving parts,

- elastic materials that allow you to print parts with a non-slip or soft surface,

- with heat-resistant materials to create functional parts.

The main distinguishing feature of the finished product is a radiant color, which is ensured by the use of materials of various colors.

Objet500 Connex3 3D Printer is a prototyping device that can combine up to 46 colors. Several durable photopolymers can be combined in this printer.

Photopolymers: types and applications

This type of plastic is characterized by high temperature resistance and high strength. Based on the material, high impact resistance and toughness models can be printed. Based on Digital ABS , you can create:

- functional prototypes,

- molds,

- housing parts that operate at low or high temperatures,

- housings for electronic parts, e.g. for mobile phones,

- engine parts, covers.

High Temperature Material - White RGD525 Material . It is dimensionally stable. On the basis of a photopolymer, it is possible to create simulations of the thermal characteristics of industrial plastics. Ideal for functional testing, for example in hot air or hot water. This material is useful for shaping, fitting and functional testing of static parts, which require high quality in terms of surface and definition. Photopolymer RGD525 is used to create models for the exhibition, moving parts, pipe taps and household appliances.

Ideal for functional testing, for example in hot air or hot water. This material is useful for shaping, fitting and functional testing of static parts, which require high quality in terms of surface and definition. Photopolymer RGD525 is used to create models for the exhibition, moving parts, pipe taps and household appliances.

In the dental field, photopolymers are used, which have rigidity and an opaque structure. When creating prototypes, excellent detail and high accuracy play an important role. Based on VeroDent, VeroDentPlus and MED610 photopolymers, you can create plaster models, removable mouthguards, surgical guides and other devices for dentistry and orthodontics.

Tango elastic photopolymer 3D prints prototypes that are extremely hard and tear resistant. Based on them, you can print products for exhibitions, various pens, hoses and shoes. Thus, photopolymer 3D printing based on SLA technology is an opportunity to obtain high-quality models that can be used in various fields.

Budget 3D printers for printing with photopolymers / Sudo Null IT News

tedbeer

Gadgets Computer hardware

While there are already a great many printers for printing with molten plastic, until recently there were practically no amateur printers printing with photopolymers. The main advantage of such printers is high resolution, smooth surface of the product, which practically does not require additional processing. The price tag of professional printers goes off scale for tens of thousands of dollars. But now printers have begun to appear in the budget category.

MiiCraft

Miniature printer based on DLP pico projector. The photo above shows that the device includes two parts - a printer and a fixative (provides additional illumination of the printed model, although this can be done just in the sun) While blue and transparent polymers are available, others are being developed.

Projector resolution : 854 x 480

Printable area : 43mm x 27mm x 180mm (XYZ)

Product size : 20.5cm (W) x 20.8cm (L) x 3.5cm30021 Resolution : 56 microns XY, 100 microns Z

Print speed : 2-3 cm per hour

Price of resin : $250 per kilo ($0.25 per cubic cm)

project website: com

Printer Price : $2000

Project Status : By mid-June of this year (2012) it is planned to complete the construction of samples and start a fundraising campaign for production on the site indiegogo.com.

B9Creator

Projector resolution : 1024 x 768

6-100µm Z (software selectable)

printable area at 100 micron precision: 102 mm x 76 mm x 203 mm (XYZ)

printable area at 50 micron precision: 51 mm x 38 mm x 203 mm ( XYZ)

Product size : 79 cm x 47 cm x 30.5 cm

Print speed : 12~20mm per hour

Resin price : $99($132 for international orders) per kilo ($0. 10 per cc)

10 per cc)

Printer price (complete assembly kit plus 1kg of resin): $2375 ($2675 for international orders)

Project website : b9creator.com

Youtube channel : user:B9Creations

Project status : Kickstarter is collecting money until June 12th. The entire amount has already been collected - $ 232,750 (it was necessary $ 50k).

Prices shown are current on Kickstarter. What will happen after is unknown. So hurry, there's still 10 days left. The current plan is to complete production and delivery by the end of August. After that, drawings and software will be released to open source.

Veloso 3D

At the moment, funding has failed, perhaps another attempt will be made.

Printer from Singapore. It prints with high quality, a lot of positive reviews, the price is much lower than commercial ones. But, apparently, the price per whale was not low enough, or a high bar was ordered to finance the project.