Raidy 3d printing

Raidy Brings 3D Printing to Lebanon

-

Like

-

Subscribe

-

Follow

-

subscribe

As the phenomenon of 3D printing is taking shape on a global scale, new avenues in the world of consumerism are solidifying, giving way for what is being touted as the biggest revolution since the phenomenon of the internet.

New visions for the formative technology have already been molded into creation at the Raidy Printing Group headquarters, so that being able to churn that curious resin into action and watch 3D prints materialize at the push of a button is now an accessible reality – and not just by veteran designers, but just about anybody.

“People tend to assume that 3D printing is a complex process which requires an auto-cad designer background. That isn’t true at all,” quips Doumit Raidy, Managing Director of Raidy Printing Group, motioning at the machines with a Gopro harnessed to his hand in a four prong grip-cum-phone holder he 3D printed himself. “There are a multitude of websites with pre-designed structures of all shapes and sizes as big as google, where all you have to do is browse, then download the pre-designed Auto-cad file, save it on your SD card, and bam, you have a 3D print in the making. It’s that simple.”

Raidy Printing Group, standing at the cusp of the sector as one of the main players in the industry on a region-wide scale, has taken perfect measure and will soon be wowing the Lebanese market with the cutting edge technology as the exclusive distributor of two European brands already under wraps. With machines of both industrial and retail capacities already available for purchase, heeding the entrepreneurial call to pioneer the technology in the Middle East involves re-orienting a market to the all-new technology, and evening out the fallacies that attach to it.

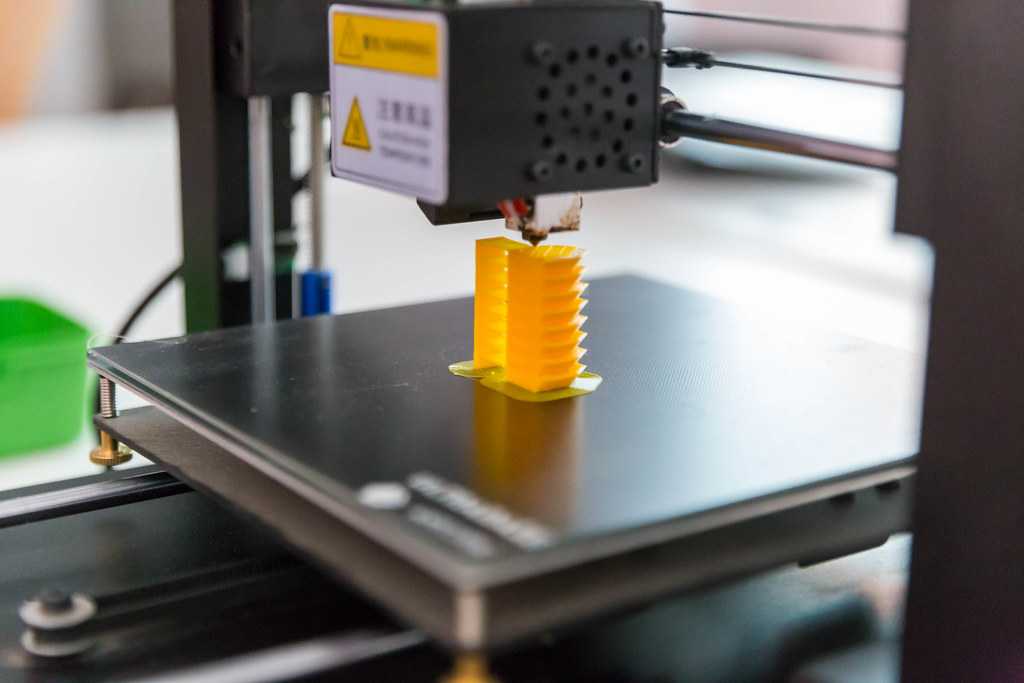

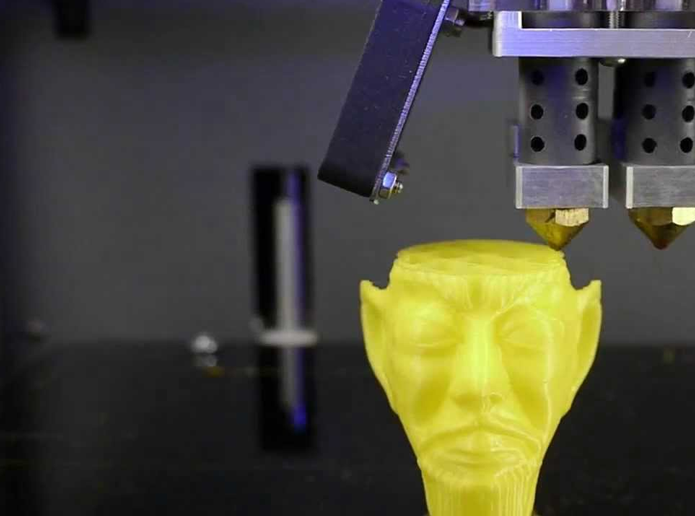

“3D printing is a technology called additive manufacturing. What this means is that it is the result of adding one layer on top of the other,” he explains, as we scrutinize three machines propped back-to-back in his office while in mid-action. “This is in stark contrast to conventional manufacturing as we know it, which is called ‘subtractive manufacturing’ – a process in which you subtract material to achieve the shape”, says an animated Doumit, while running his fingers across a 3D printed iPhone holder to highlight the difference. “From this perspective, it answers to an environmental need inasmuch as it offers a wealth of benefits to anybody with a vision.”

But beyond the wow factor, 3D printing is a breakthrough as the versatile concoction is oozing into multiple fields, from architecture, to medicine, to carpentry, to prototyping, to the fashion industry – the list goes on. “What you’re essentially doing is giving the consumer the ability to be his own prototype designer”, quips Doumit, building on the dynamism that 3D printing has to offer to the general populous.

“You’ll often find yourself needing a tiny tweak for a household good that broke, and you can’t find commercially, because that tiny piece in question isn’t mass produced. That would often mean you have to live with your product being damaged, or buy a new one. Not any more. With 3D printing you can custom design any structure and fit it right back in”.

Therein lies the magic in 3D printing. As seen from this vantage point, what it essentially does is transform every customer into being their own prototype designer. “The beauty is that you can now create any structure by yourself. You don’t need to go to a third party to produce a model, or be hampered by paying an arm and a leg for mass production when aiming to create a prototype. You can do away with the middleman and watch your own visions materialize into concrete – or platic models, to be more precise”, he goes to say while building on the notion that many industries can benefit from this tenfold, from architecture and beyond.

And on a consumer level, the benefits are baffling. Customizing your own Samsung Galaxy S6 Edge or iPhone case is no longer a question of browsing through retail store aisles. It is instead a question of browsing the World Wide Web, zoning in on the design you like, tweaking it according to your preferences and making a 3D print.

The time consumed in the printing process depends on the resolution needed, as well as the size and the complexity of the shape. Higher resolutions and more sophisticated objects require more time, with prints spanning 2 hours to 24 hours, Doumit explains with “print time varying according to the size of the printer you’re using, the size of the prints you’re aiming for, and the materials and filaments you would have opted in”

But today, 3D printers are accessible to the public, with more standardized machines becoming more affordable and simpler to use.

“An architect or a designer would use Autocad, but for anyone like you and I, or your day-to-day hobbyist, there are a lot of platforms where you can download files for free. Everything you see here that’s printed is downloaded free one hundred percent, I didn’t pay any penny”, he says while motioning to the vicinity of his office which is strewn with 3D prints of all shapes and sizes, ranging from basic iPhone holders to Go Pro stands to ornate Christmas decorations to intricate mini-

skyscraper models.

Everything you see here that’s printed is downloaded free one hundred percent, I didn’t pay any penny”, he says while motioning to the vicinity of his office which is strewn with 3D prints of all shapes and sizes, ranging from basic iPhone holders to Go Pro stands to ornate Christmas decorations to intricate mini-

skyscraper models.

“You download the file for free, you scale it to the size that you need, depending on your machine as well, you choose the color that you want, several filaments, you have red, black, grey and bronze to name a few, and you print. It’s a very easy machine to operate.”

3D printers are charged with filament spools to top horizontal layers of material with specified types and colors. Using additive manufacturing, solid objects are rendered via digital files from a Computer Aided Design Software. The printers manipulate Fused Filament Fabrication technology in which filaments of a specific material such, as plastic or resin, are deposited by layers to produce the final shape.

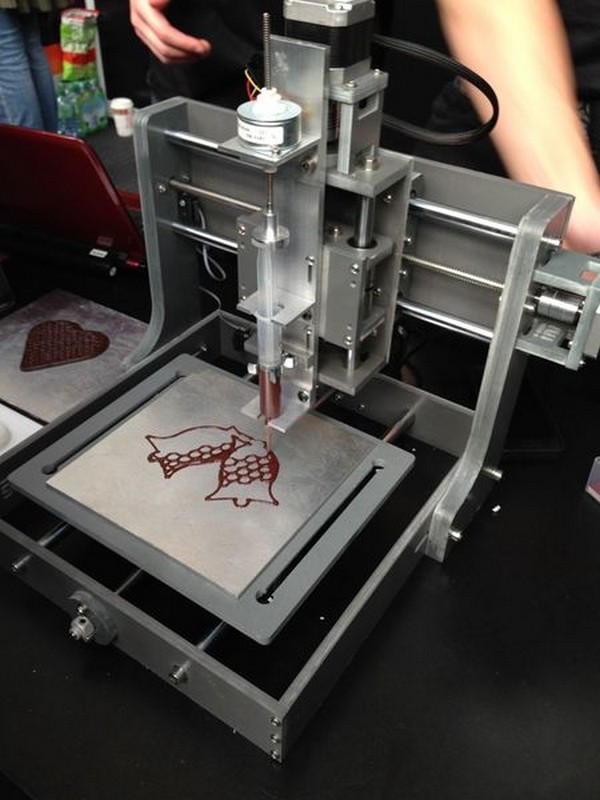

But 3D printing, contrary to what is normally assumed, is not limited to plastic only. “I mentioned that we mainly print in plastic, but I have a machine that can print in clay, in bronze, in silver and in wood. It’s a flexible material, and it becomes a composite of wood covering the PLA material. It might not be actual wood, but it really looks like it. The same applies to bronze and silver. In Europe there are even machines that create 3D prints in chocolate. I saw it myself!”

TAGS : 3D Printing

by Ghassan Khayyat

Ghassan was tuned into the writing world on a transistor radio-wave of an unbeknownst frequency, once upon a daydream dreary. With a firm belief in Dr. Seussims and all things gadget and gizmo-tronic, he tinkers before he speaks, and chooses his words technologically. He is Editor for T3 Middle East’s Levant English publication and English website, and Associated Editor for the GCC English publication. Reach him at [email protected].

Reach him at [email protected].

IDAL - Sectors in Focus - Industry

I want to

apply for IDAL’s incentives

know if I qualify for IDAL’s incentives

request IDAL’s support through the BSU

know if I qualify for the BSU Support

to know what are the BSU services

know what are the steps to open a business

know what are the licenses and permits needed to open a business

know more about Investment Opportunities in Lebanon

operate in Lebanon

export from Lebanon

access Global ICT Bids

home › Sectors in Focus › Industry ›

Printing Industry

Sectors in Focus

Agriculture Agri-Food

Industry

Pharmaceutical IndustryChemical IndustryPrinting IndustryFurniture and Wood IndustryICT Media Technology Telecommunication Tourism

Sectors in Focus Agriculture Agri-Food >> Olive Oil Industry >> Pharmaceutical Industry >> Chemical Industry >> Printing Industry >> Furniture and Wood Industry ICT Media Technology Telecommunication Tourism

Printing Industry

The printing sector has been transformed significantly over the last decade fueled by the digitization of information. Lebanon, a longtime leader in printing services in the MENA region was able to maintain its market share by adopting the latest innovative trends. Packaging, especially for the Agrofood industry, and 3D printing are the biggest opportunities available in the sector.

Lebanon, a longtime leader in printing services in the MENA region was able to maintain its market share by adopting the latest innovative trends. Packaging, especially for the Agrofood industry, and 3D printing are the biggest opportunities available in the sector.

KEY FACTS AND FIGURES:

- The Gross Value-added of the printing industry stood at USD 156 million in 2017.

- Printing companies account for 6% of the total industrial firms in Lebanon, comprising 305 companies.

- More than 80% of printing companies are located between Mount Lebanon and Beirut.

- Exports stood at USD 142 million in 2017, accounting for 3% of total industrial exports and ranked in the top 10 of Lebanese exports.

- Printed books and brochures account for around 50% of total printing exports.

- The leading exporting countries are Iraq (13%), Saudi Arabia (12%) and Egypt (9%).

- Lebanon imported around USD 300 million worth of printing products in 2017 mainly from China (10%), United States (8%) and France (7%).

- Top market players are Arab Printing Press, Chemaly & Chemaly, Dots, Ipex Printing Press and Raidy Printing Press.

MARKET OPPORTUNITIES:

- Packaging: The sub-sector is expected to grow at an annual rate of 5% during the 2015-2019 in the MENA region, faster than global growth projections estimated at 4%. Lebanese printing companies are well positioned to meet the growing regional demand for packaging services.

- 3D Printing: Lebanon has great potential to be the leader in 3D printing in the MENA region given its highly-skilled labor force. The country is already home to the biggest 3D printer in the MENA region (Big Voxel) developed in 2015 to manufacture furniture and machine components.

- Security Printing: Lebanon has an advanced ICT ecosystem that enables it to develop innovative printing solutions with the use of the latest technologies. Security printing is already provided in the Lebanese market however there is potential to serve regional markets.

Sources: Lebanese customs, Ministry of Industry, Central Administration of Statistics, Arabnet

PRINTING INDUSTRY FACT BOOK 2016

Get in Touch

Lazarieh Tower, 4th Floor, Emir Bechir Street, Riad El-Solh Beirut, Lebanon, P.O.Box 113-7251

Phone

+961 1 983306

Fax

+961 1 983302

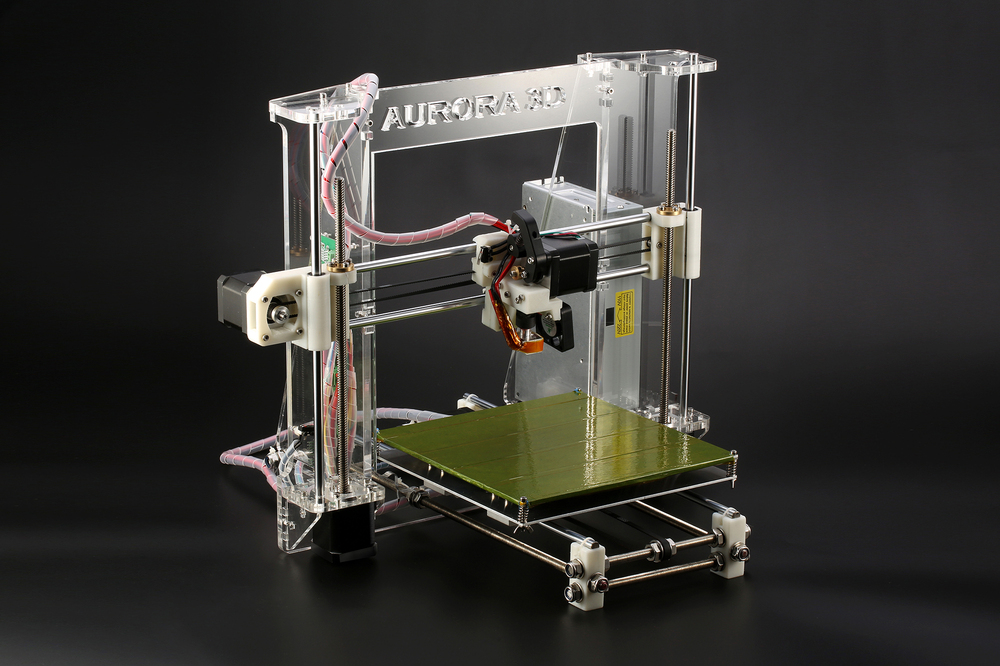

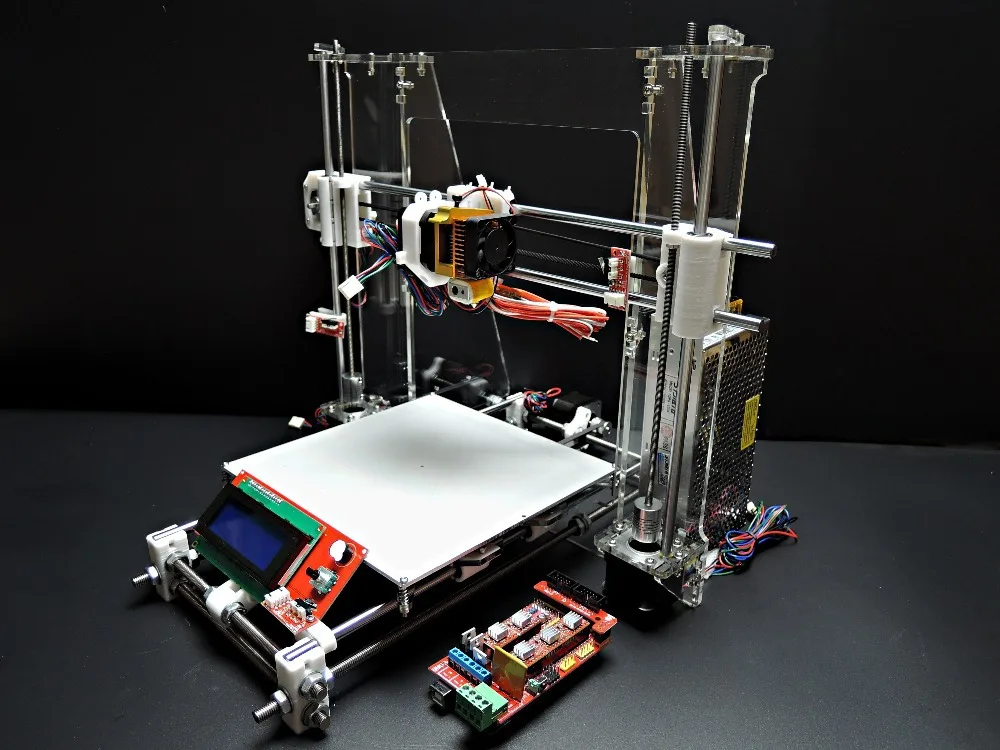

The main types of 3D printers, and how to choose them

3D printing has come a short way from the curiosity that causes the collective "Wow!" when creating voluminous souvenirs, to an advanced tool that allows you to solve complex problems in the most important industries, whether it be medicine, construction or engineering.

What opportunities this technology will bring to the world in the future is still unknown, but it is already clear now: they will be unprecedented. Today, together with the specialists of the 3Dvision online store, we will talk about what types of 3D printers exist and how to make the right choice.

How to choose a 3D printer

When choosing a 3D printer, first of all, you need to understand for what purpose you are purchasing it - personal or professional. Experts identify two approaches to buying a printer for novice users. In the first case, they try to purchase a multifunctional device at a high price, rightly believing that it has great potential. The second option, which is supported by many experts, involves buying an inexpensive printer. It can be used for the initial study of this technology in order to later solve more complex problems.

The choice of professional equipment is also classified according to the needs of the user. If you are going to work in the jewelry industry, then you should pay attention to the print resolution; if in engineering - on the ability of the printer to work with complex materials. If your needs lie in the architectural industry, then you will need high-quality detailing and dimensionality of printed products. Based on the above, when choosing a 3D printer, it is important to consider in which area you are going to work, what quality of products you need and what experience you have.

If your needs lie in the architectural industry, then you will need high-quality detailing and dimensionality of printed products. Based on the above, when choosing a 3D printer, it is important to consider in which area you are going to work, what quality of products you need and what experience you have.

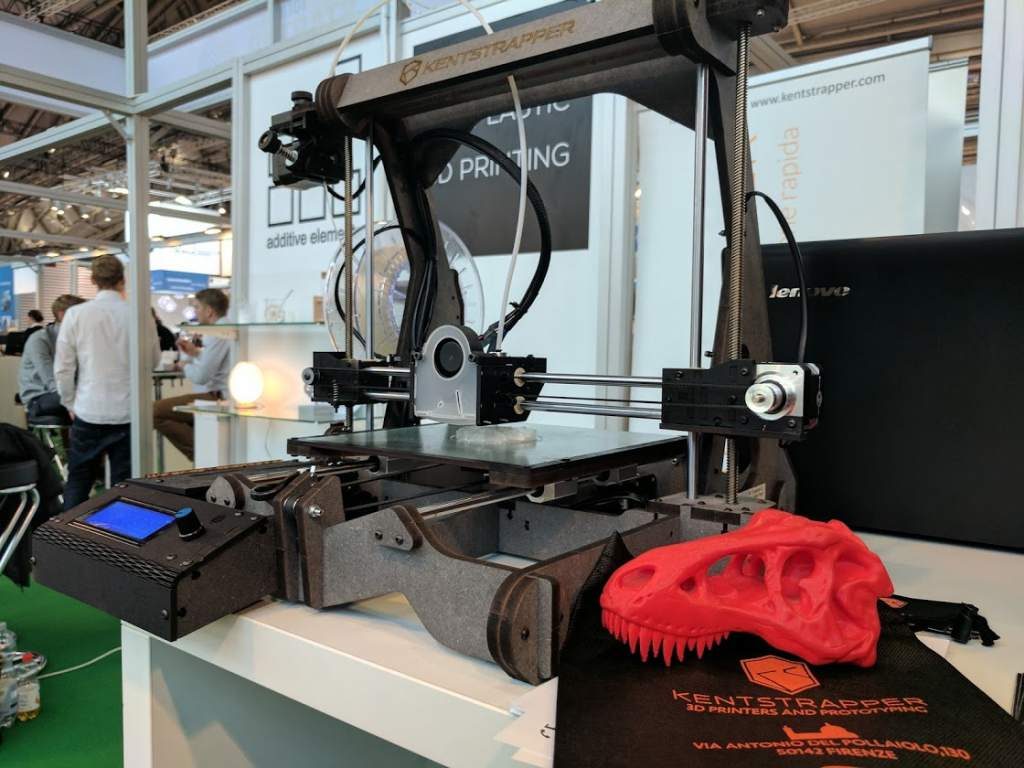

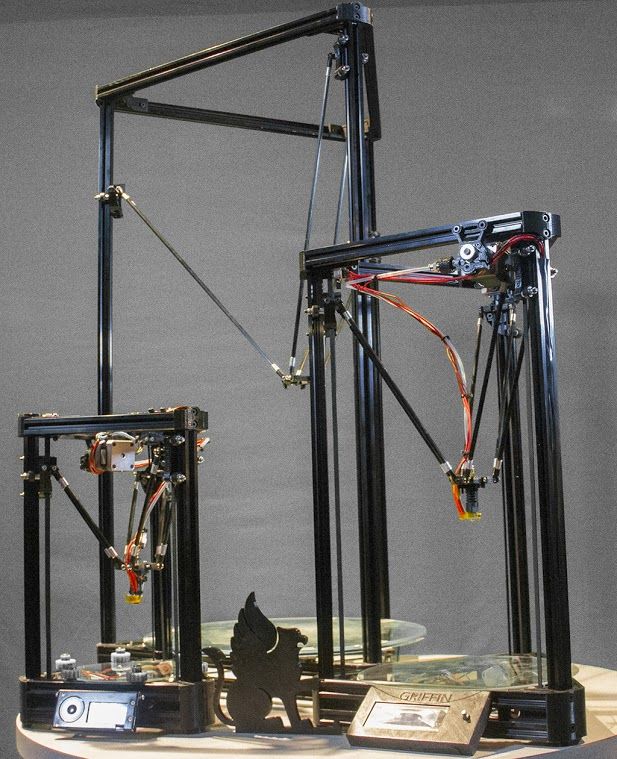

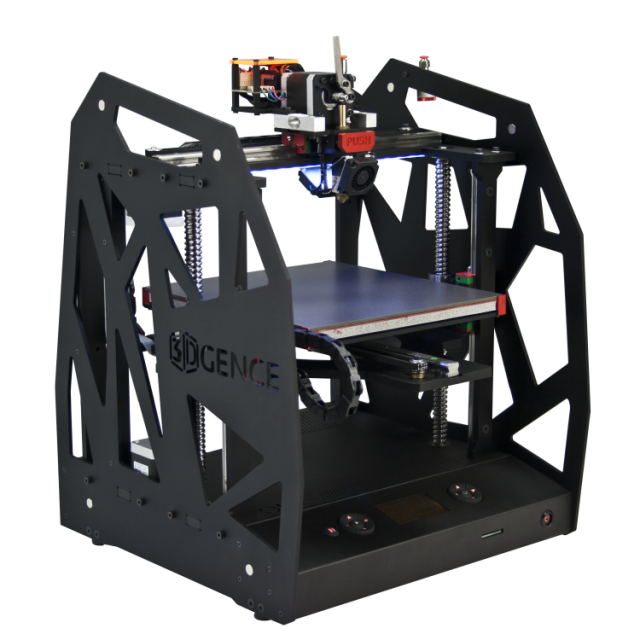

Professional 3D printers

Professional 3D printers have a wide range of applications, primarily due to high printing precision and large build area. Some models are technically equivalent to industrial grade equipment. That is why professional 3D printers are used both in design and construction development, and in the field of education, research or medicine.

Editor's Choice

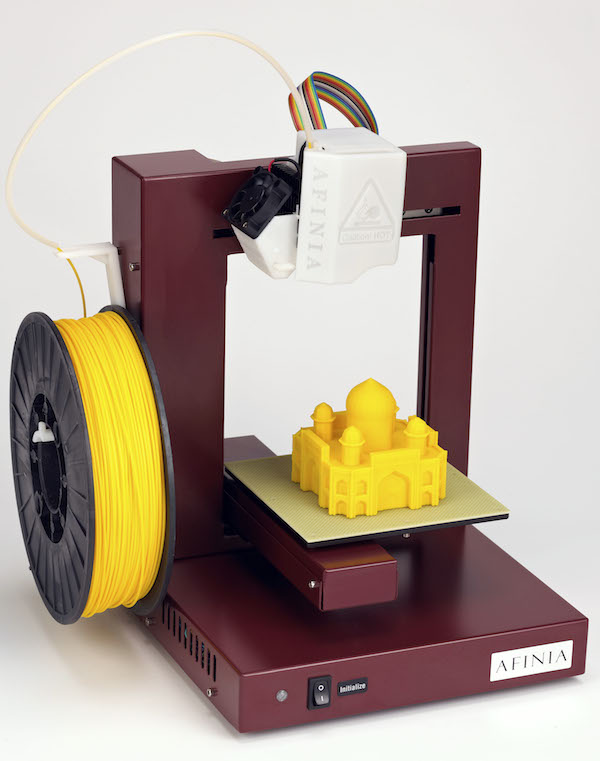

Home 3D printers

Home 3D printers are usually small enough to fit on a table. But the main thing is their practical potential. This tool successfully fits the entire length of the household spectrum: it allows you to make furniture, dishes, and decor.

Financial savings are only half of the expected benefits. An additional argument is time optimization and convenience. Instead of making long raids to IKEA and then transporting what you bought home, a 3D printer allows you to make the desired item in a few hours. Moreover, the uniqueness of this item can be one hundred percent.

Editor's choice

Construction 3D printers

These 3D printers allow you to produce building elements for structures of varying complexity and sizes. The advantages of such devices are obvious: it removes the difficulties associated not only with the transportation of heavy building materials, but also with their search, and most importantly, prices. At the same time, the quality of printed products is in no way inferior to that offered on the market. The 3Dvision store presents a comprehensive range of 3D construction printers that simplify and optimize the construction of structures of varying complexity.

Order construction 3D printers

On the company's website you will find a huge list of 3D printers with a detailed description of each model. The choice is simplified by a flexible feedback system: the specialists of the online store are ready to provide detailed information about the operation of any device and about the 3D printing itself. And for those who need a one-time use of technology or just want to get acquainted with its capabilities, 3Dvision accepts orders for the manufacture of products of any complexity. Perhaps after that, buying your own 3D printer will not be long in coming.

Learn more about 3D printing

Other related articles:

Techniquetechnologies

"I'm sure that in 5 years every home will have a 3D printer!"

- November 6, 2015

- 16+

- Veronika Morokhina

Veronika Morokhina

Igor Ivanov and Vyacheslav Ershov spoke about the possibilities of 3D printing

2 3D printing is a technology of the future, a way to layer-by-layer creation of a physical object from a digital 3D model: from shoes to jewelry, weapons and aerospace parts.

Not so long ago, a 3D printing workshop was opened in Syktyvkar and correspondent ProGorod11.ru hurried to get to know the new technology better. The founders of the workshop, Igor Ivanov and Vyacheslav Ershov, spoke about 3D possibilities.

Not so long ago, a 3D printing workshop was opened in Syktyvkar and correspondent ProGorod11.ru hurried to get to know the new technology better. The founders of the workshop, Igor Ivanov and Vyacheslav Ershov, spoke about 3D possibilities. - Tell us why 3D printing?

- He lived in St. Petersburg, and there he caught fire with this idea. Came here and suggested to a friend to open a workshop. He supported me and we invested in a new business.

- Tell us about your first impressions of printing?

- It was like magic! First, you imagine the future product in your head, then using a 3d modeling program you visualize it on a computer screen, then send it to print, and after a while, the digital object just becomes physically tangible, that is, you can hold it in your hands. It turns out that your thoughts materialize right before your eyes. And it can be anything. Feelings were just incredible! For example, you can print your small copy (mini-bust) and present it to relatives from another city.

- What materials does the workshop print with?

- We print with a special plastic filament. The printer heats it up to the melting temperature and applies a layer of a few microns. And so on, layer by layer. Materials can be of any color, in addition, there is a transparent plastic that imitates glass. But, look, this is plastic with imitation of wood, it is with the inclusion of wood shavings. When the thread heats up, the workshop smells like fresh wood.

- Anything can be printed. What do you usually print?

- More often these are various plastic parts, for example, a gear from Range Rover wipers, printing it again is many times more profitable than ordering and waiting for a new one. Souvenir products are also popular. As I said, the possibilities of a printer are almost limitless.

- Tell us about the most ambitious work?

- It was a mock-up of the VTB-24 bank building, which is located on the Communist. It took a total of 5 days to complete. At that time, we were just getting to grips with the capabilities of the printer, and only two days were spent on printing, the rest of the time was spent on creating a layout. But the customer was satisfied, this is the most important thing.

It took a total of 5 days to complete. At that time, we were just getting to grips with the capabilities of the printer, and only two days were spent on printing, the rest of the time was spent on creating a layout. But the customer was satisfied, this is the most important thing.

- Do you have any 3D printing ideas that you would like to bring to life?

- Yes, I would like to print nothing less than a city! Our Syktyvkar, for example. Allocate a separate place for him somewhere in the park and so that everyone can come and add or bring something. It would be interesting for active youth. It would immediately become clear where and what is missing. Together we could complete the city with our new projects and ideas, and then bring them to life. It would be such a large-scale constructor.

What would you 3D print? Write in the comments

- What about more accessible ideas?

- We could deal with dealers or implement training programs.