3D printing vacuum forming moulds

Ultimate Guide to Vacuum Forming 3D Prints

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

Vacuum forming is a manufacturing process by which a sheet of plastic is heated and pressed over a form to create a part. This process is used to create many of the products in your home such as plastic containers, tubs, sink units, and electrical enclosures.

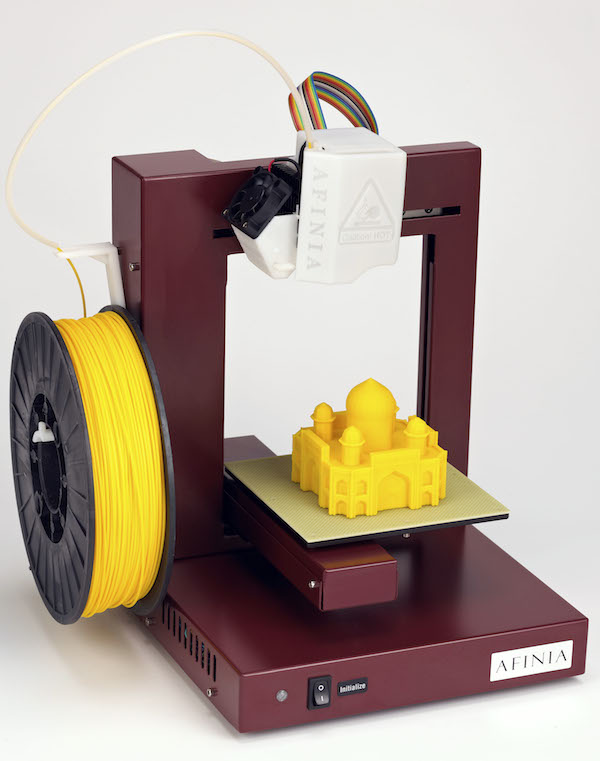

3D printing is a great way for manufacturers to create low cost molds for low volume manufacturing or prototyping.

While we used an industrial vacuum forming machine to achieve our application, you can also build one at home to achieve the same effect.

While working time will vary, this process took us about 1 hour from start to finish.

Supplies

Vacuum forming machine

Sheets of vacuum forming plastic

3d printed mold

Mold mounting fixture

Cutting tool

Eye protection

Heat resistant gloves

Need some of these products? We've curated an Amazon wish list for you.

STEP 1: OBTAIN YOUR MOLD

In order to vacuum form you will need a mold to vacuum form around. Your final parts will be nearly exact replicas of your mold.

You can download molds from sites such as GrabCAD, but we chose to design ours. For our model, we designed a common taxi sign used to show whether or not cars are available for service.

When designing a mold for vacuum forming consider drafting angles. Drafting angles allow your molded part to be removed from the mold. They should typically be anywhere from 3-5 degrees from 90 on any vertical surface.

STEP2: PREPARE AND PRINT MODEL

When preparing a model for vacuum forming in MakerBot Print, there are some print settings that should be taken into account.

We printed our model with 4 shells at 25% infill.

Next, print your model. We printed our model on the MakerBot Replicator Z18 because of the large size of our model.

Increase shells and infill settings to create a strong mold that will withstand the pressures of vacuum forming.

Because we used an industrial vacuum forming machine we needed to secure the mold to an additional fixture. This holds the mold in place against the various forces that occur when operating the machine.

A. Drill or tap holes in an inconspicuous place on the underside of your print & attach to Small plate or MDF board

B. Mount board to vacuum forming machine

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

STEP 4: LOAD AND HEAT PLASTIC

A. Load your plastic.

We started with 12 x 24 inch sheets of white polystyrene plastic about .75mm thick and worked up to ¼ inch thick sheets of PET-G.

When choosing plastic sheets for vacuum forming, consider the thickness of the plastic and the size of the sheet as well. Thicker sheets will need to be heated to higher temperatures and will require a higher power vacuum.

B. Heat plastic to desired temperature.

Because we used an industrial vacuum forming machine, our plastic was heated automatically to temperature based on the type of plastic, thickness, and density.

While 400 degrees fahrenheit is close to the melting point of PLA, only the sheet is heated and not the form. This means the heat is not necessarily a concern in low volume production or prototyping.

Choose thinner sheets of plastic if your vacuum forming machine does not create large amounts of consistent heat or suction.

Typically plastics will be heated somewhere around 400 degrees fahrenheit.

STEP 5: PRESS PLASTIC OVER FORM

Once plastic is heated, it is pushed over the form.

At this point you will notice that the vacuum suction will pull all of the air out from under the heated plastic sheet and it will be forced down over your mold.

The plastic will begin to cool instantly.

Once all of the air has been removed from under the plastic and it has been formed over your mold, remove the formed part and set it aside to cool.

The mold is not removed from the machine between shots

This process can be repeated to produce many of your desired product.

If you notice that over time your 3D printed mold becomes deformed due to heat or pressure, it might be time to print another.

Because printing is such an inexpensive option for mold production, producing 2-3 spares up front is not cost or time prohibitive.

STEP 8: POST PROCESSING

After you have produced the desired number of parts, cut away any spare plastic.

You can cut away spare plastic using a manual cutting tool, or with a CNC. If you’re using a CNC, 3D printing is a good solution for creating custom fixtures.

Here, you can see what successfully vacuum formed plastic sheets look like.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Sanding

Painting

Silicone Molding

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Contact Us

Special thanks to our friends at COMCO Plastics for all their help.

Powered by MakerBot Learning.

Prototyping Packaging With Vacuum Forming and 3D Printed Molds

Vacuum forming is among the most ubiquitous manufacturing methods for creating the packaging of various goods. From grocery store salad mixes, the lid of your to-go cup of coffee, and high-end consumer electronics, vacuum forming is useful for producing lightweight, cost-effective packaging.

The process of vacuum forming is quite simple. It requires four basic elements: a mold or tool that will create the shape of the final part, a sheet of plastic, a heat source, and a source of vacuum.

The sheet of plastic is heated as evenly as possible, until it becomes soft and pliable, and is brought down onto the mold or tool. Then the vacuum is applied, and the part is allowed to cool before being removed from the mold.

Creating vacuum forming molds with traditional manufacturing processes like machining or casting is time consuming and costly, especially for complex geometries, textured surfaces or fine features. Increasingly, designers and engineers are turning to 3D printed molds and tools for vacuum forming for significant cost and time savings. Additionally, 3D printed molds and tools can easily incorporate small features like text and intricate textures without impacting part cost.

Increasingly, designers and engineers are turning to 3D printed molds and tools for vacuum forming for significant cost and time savings. Additionally, 3D printed molds and tools can easily incorporate small features like text and intricate textures without impacting part cost.

A vacuum forming mold printed in Formlabs High Temp Resin accompanied by the final vacuum formed part. High Temp Resin has a HDT (heat deflection temperature) of 238 degrees Celsius, high enough to hold up to thermoplastics like PETG and ABS.

White Paper

Download our white paper to see how to create complex molds with 3D printing fast and learn about tips and guidelines that you’ll want to follow when preparing your mold parts.

Download the White Paper

As with any manufacturing process, there are design guidelines to follow for successful vacuum forming. First, let’s define some terminology before we look at best practices for designing vacuum forming tooling.

There are two basic styles of vacuum forming molds: male and female. When creating a dome style part, a male mold would use a convex geometry, while a female mold would be concave.

Male mold, defined by positive or convex features.

Female mold, defined by negative or concave features.

While certain part geometries can be formed without any draft angle, draft is beneficial in aiding part removal and getting consistent finish on your vacuum formed parts.

For male molds, 4-5 degrees of draft is recommended. For female molds, draft recommendations are lower, at 1.5-3 degrees of draft. For deeper parts, adding additional degrees of draft can be helpful to yield quality parts that are easy to remove from the mold.

The use of textured surfaces will increase the draft angle requirements in most cases, so keep that in mind if your design is highly textured.

For internal pockets, it’s often necessary to add vent holes through the mold or pattern. This allows the vacuum to reach all areas of the mold, pulling down the softened plastic sufficiently.

Without venting of internal negative features, plastic will tend to merely drape over contours, rather than tightly conforming.

With the addition of vent holes, vacuum can be pulled through interior pockets, aiding the vacuum forming process.

Whenever possible, sharp edges of the mold should be broken with chamfers or radii both to reduce stress concentrations in the finished part, and to decrease the chance of tearing or webbing during vacuum forming.

It is important to keep the mold and vacuum formed part as shallow as possible. The deeper the draw required to produce the part, the more the sheet of plastic needs to stretch. This means deeper draw parts will require thicker stock, have more variation in wall thickness, and generally be more difficult to produce successfully.

There is a simple formula, known as the the draw ratio, which can be used to understand whether or not a part is likely to form successfully, and what thickness of plastic sheet you will need, at a minimum, to achieve the ultimate part thickness desired.

The draw ratio is expressed as the surface area of the part divided by the footprint of the part. A 3:1 draw ratio is generally considered to be the maximum for most vacuum forming operations.

To determine what sheet thickness to start with, multiply the desired gauge of the finished part by the draw ratio: draw ratio multiplied by the desired gauge of the finished part will produce the minimum sheet gauge.

An example of a part with print-supports only on the bottom of the object.

The peel forces that separate parts from the resin tank during printing vary based on part size and geometry.

A closed volume, such as you might have with a female mold oriented parallel to the build platform, will have higher stresses during printing due to cupping from closed internal volumes. Solid male molds will not have the same likelihood of cupping, and are better candidates for printing directly on the build platform.

In some cases, male molds may be printed directly on the build platform to reduce print time.

When a print build finishes, the next steps are to wash away any residual resin left on surfaces and post-cure the parts to achieve optimal physical properties.

Formlabs Wash and Cure units complete the part production process and 3D printing ecosystem, ensuring consistent results.

There are several post-curing options for High Temp v2. Refer to the technical data sheet to understand how different options affect mechanical properties, and choose the post-cure option that is best suited to the intended application. To achieve the highest HDT of 238 °C @ 0.45 MPa: (1) Post-cure parts in Form Cure for 120 min at 80 °C. (2) Thermally post-cure parts in a non-food oven for 3 hours at 160 °C. For applications that do not require the maximum heat resistance, post-cure parts in Form Cure for 60 min at 60 °C.

More often than not vacuum forming will produce near-net shape parts, which means there are aspects of the part that need to be processed in some way before the full manufacturing process can be considered complete.

Most vacuum formable plastics can be easily trimmed either by hand with a sharp knife, or using a machine tool like a router or mill.

Vacuum forming molds in High Temp Resin, with finished vacuum formed plastic parts trimmed to final size.

3D printing is a powerful tool for expediting design, engineering, and manufacturing workflows. Hopefully you now have a better sense of what materials to use when creating quick-turn vacuum forming molds, and if you’re new to vacuum forming, how best to design mold geometries. With proper care, 3D printed molds will last for dozens and dozens of vacuum formed parts.

Explore our Engineering Resins and request a free sample to evaluate materials like High Temp Resin first hand.

Request a Free Sample Part

Webinar

Accelerate product development, reduce costs and lead times, and create custom or low volume products with ease by combining 3D printed rapid tooling and thermoforming.

Watch the Webinar Now

3D printing + vacuum forming: car dashboard prototyping.

Application

Subscribe to the author

Subscribe

Don't want

20

3D printing can greatly assist in prototyping a new product by reducing design time. The undoubted advantage is the ability to create almost any geometry, and the disadvantage is the problems when printing large parts. Large parts take a long time to print. When printed, they may warp. In the case when such parts are made composite, a loss of accuracy during gluing is possible. To be successful, you can use a "hybrid" of 3D printing with some other technology. When creating a prototype dashboard for a promising car, it was decided to combine 3D printing technology with vacuum forming. The instrument panel itself will be made on an injection molding machine. To speed up the preparation of production, it was necessary to create the first three samples using the "bypass" technology. Thermo-vacuum forming is widely used in the automotive industry. For example, some parts of the interior of the PAZ-3205 bus are made using this technology. These are the rear seat cover, instrument panel, door opener cover, etc. From the exterior — bumper. In addition, thermo-vacuum molding is useful when you need to quickly and inexpensively create a luxury interior for a small series of buses or minibuses. To solve this problem, there are only a few options. The first (the most expensive one): sculpt the interior from model plasticine, remove fiberglass matrices from it, and details from the matrices. Details are covered with different fabrics, artificial leather, etc. Long, expensive, a lot of manual labor. The second option: if there are mathematical models of the body or a 3D scanner, then you can develop the interior on a computer, create a tooling using a CNC milling machine. Parts can be made by fiberglass molding (low manufacturability) or by thermal vacuum molding. The thermal vacuum molding method is quite productive.

Thermo-vacuum forming is widely used in the automotive industry. For example, some parts of the interior of the PAZ-3205 bus are made using this technology. These are the rear seat cover, instrument panel, door opener cover, etc. From the exterior — bumper. In addition, thermo-vacuum molding is useful when you need to quickly and inexpensively create a luxury interior for a small series of buses or minibuses. To solve this problem, there are only a few options. The first (the most expensive one): sculpt the interior from model plasticine, remove fiberglass matrices from it, and details from the matrices. Details are covered with different fabrics, artificial leather, etc. Long, expensive, a lot of manual labor. The second option: if there are mathematical models of the body or a 3D scanner, then you can develop the interior on a computer, create a tooling using a CNC milling machine. Parts can be made by fiberglass molding (low manufacturability) or by thermal vacuum molding. The thermal vacuum molding method is quite productive. Its main disadvantage is that not every geometry can be obtained. In the presence of complex geometry, places with deep drawing, and other problems, composite parts are usually made. We also decided to follow this path. All bosses and small elements were printed on a 3D printer from ABS plastic and glued onto ABS diluted in acetone. For example:

Its main disadvantage is that not every geometry can be obtained. In the presence of complex geometry, places with deep drawing, and other problems, composite parts are usually made. We also decided to follow this path. All bosses and small elements were printed on a 3D printer from ABS plastic and glued onto ABS diluted in acetone. For example:

Changed the geometry of the bosses so that they can be molded. The top cruciform boss was 3D printed and glued on. The same with other parts:

The base of the instrument panel turned out to be composite. Some sections were molded on a vacuum machine. The main part was 3D printed with a thickness of 2mm from many parts, which were then glued onto a fiberglass reinforcement. The amplifier was made according to the same geometry minus the thickness of the printed parts.

All 3D printing was done by Eugene. The most difficult task was undoubtedly to print the front of the instrument panel. It was made of many parts and 2mm thick. Some parts were printed with supports that took up most of the material. A total of 3 samples were printed. Each one took several coils of plastic. ABS plastic from Synthetic Technologies.

It was made of many parts and 2mm thick. Some parts were printed with supports that took up most of the material. A total of 3 samples were printed. Each one took several coils of plastic. ABS plastic from Synthetic Technologies.

I worked on mathematical models. In this work, I had to take a few more assistants, because the deadlines were very short, and the amount of work was decent: separating parts into parts for 3D printing and vacuum forming, reworking the geometry for better manufacturability, designing tooling for molding the wrong side of the instrument panel with fiberglass. The assembly and gluing of 3 samples was performed by the customer.

Due to the short production time, not everything went as well as planned. Much could have been done better if we had more time. But, I believe, 3D printing can be used for such purposes, combining it with other technologies.

Follow author

Follow

Don't want

20

More interesting articles

fifteen

Subscribe to the author

Subscribe

Don't want

Yes, and this happens, but not quite like in a recent video from Pryusha.

Good idea...

Read more

one

Follow author

Subscribe

Don't want

PLAZ specializes in the development and production of unmanned aerial systems....

Read more

146

Subscribe to the author

Subscribe

Don't want to

3D printing, as an activity, makes it possible to create not only decorative crafts and toys...

Read more

3D printing master models for vacuum forming

When buying a 3D printer DISCOUNT on plastics and polymers up to 10%

3D printing of master models for vacuum forming

08/30/2019 powernic

3D printing of master models for vacuum forming used for a variety of products. For example, cups for yogurt, molds for headphones and small appliances, etc.

For this purpose, a PVC or PET plastic sheet is used, which is vacuum formed according to the matrix. And the main task and problem in this case is a high-quality matrix that will repeat the shape of the product. And this is where 3D technologies come to the rescue.

For this purpose, a PVC or PET plastic sheet is used, which is vacuum formed according to the matrix. And the main task and problem in this case is a high-quality matrix that will repeat the shape of the product. And this is where 3D technologies come to the rescue. 3D modeling software creates an exact model of the item to be packaged. Based on this model, it is possible to form a matrix that repeats the shape of the product. This matrix is printed on a 3D printer. For this purpose, models of 3D printers of the brands RAISE3D, Hercules, PICASO are ideal. These are FDM technology devices, and durable engineering plastics, such as ABS or ABS MAX, can be used as a material. During vacuum forming, the plastic heats up a little. As a rule, the temperature does not exceed 120 degrees. It is important to ensure that the material can withstand this temperature and does not change its qualities. As a result, such matrices will serve for a long time.

The advantages of 3D printed matrices are obvious:

- easy to obtain;

- affordable price, which is very noticeable for small-scale production;

- any geometry;

- speed - the finished matrix can be obtained in the shortest possible time.

The disadvantage of this approach is the restriction on the construction area. 3D printers, even with the largest build zones, are still limited and getting a large matrix is a difficult task. Although it can be solved by breaking the model into several sections and gluing them together. However, all the same, when choosing a 3D printer for printing matrices for vacuum forming, it is better to choose equipment with the largest possible construction area.

Vacuum forming technology is used not only for the production of packaging, but also in general for the production of some parts. The technology is used in the advertising industry for the manufacture of acrylic letters and forms, in the automotive industry for the production of panels, interior parts for refrigerators and other equipment. And 3D printed matrices can be used in production as the most efficient, reliable and affordable option.

3D scanning capabilities

You can also use another 3D technology - 3D scanning.![]()