3D scanner supplier in singapore

3D Scanning | Prototyping Services

Let us take you through the exciting journey of 3D printing

From idea to finished product, we are with you every step of the way

Consultancy on 3D strategy and readiness for upcoming trends, identification of capability and technical gaps using solution-driven approach

Learn More

Either create fresh designs from 2D drawings, scan from originals or engineer from source files. Storage of digital ready designs in cloud platform.

Learn More

Optimize and identify improvements to structure or design. Integration with most CAD systems, and ensure end product printability and function.

Learn More

Select the most optimal material from our extensive range of resins, sandstone, carbon fibre, nylon, metals and other composite materials, that suit your project budget and requirements.

Learn More

Printer set up and print-bed alignment. Configuration to print in multiple materials as needed. Finishing, polishing and other value-added package options.

Learn More

Our experience shows us that companies should be preparing for:

often driven from the front line rather than HQ – for example, multiple prototyping cycles can now be achieved in the time that a single cycle used to take

driven by 100% customisation and virtually flat unit costs

The full power of additive printing to unleash local customer centred printing is only just starting to be understood

in new production technologies as well as new ways to serve customers

For example, Maersk printing spare parts on board its ships will radically change the traditional port services industry

We offer a full range of consulting and diagnostic services that helps you develop a full-fledged additive printing strategy that not only unravels the status of your 3D printing needs, opportunities and challenges; but also proactively identifies areas of productivity gains for competitive advantage.

Our sales team is highly experienced with decades of top level management consulting and well-versed across specific sector domains. Additionally, we also have other experts in materials supply chain, design and marketing to complement your business development strategy.

Additionally, we also have other experts in materials supply chain, design and marketing to complement your business development strategy.

One of the most exciting opportunities in 3D printing is being able to re-design traditionally manufactured equipment to take maximum advantage of the opportunities presented by additive manufacturing. For example – embedding electronic circuits within the walls of equipment or producing lighter finished products made from more versatile materials.

We offer specialist advice on the following example areas to help customers get the best out of their investment into 3D printing:

Optimal material selection balancing strength, cost, production and durability

Design implications from different types of materials

Printer optimization for different types of material, including avoiding material contamination and structural weaknesses during the printing process

From left to right: White Resin, Nylon, Titanium, ABS/PLA Plastic, Transparent Resin

Choosing the right materials for your project

Choosing the correct material type for your project can have profound implications on cost, delivery time, durability, design options and functionality. One of the most exciting and challenging areas is being able to re-design traditionally manufactured equipment to take maximum advantage of the opportunities presented by additive manufacturing.

One of the most exciting and challenging areas is being able to re-design traditionally manufactured equipment to take maximum advantage of the opportunities presented by additive manufacturing.

| Materials | Typical Applications | Resolution | Strength | Flexibility | Price | Surface Quality |

| Sandstone | • Display pieces • Full colour models • Figurines | |||||

| Clear Resin | • High accuracy prototypes • Functional parts • Engineering parts | |||||

| White Resin | • High accuracy prototypes • Functional parts • Engineering parts | |||||

| Nylon | • Engineering parts • Form fit & functional parts • Live hinges / movable parts • Toys | |||||

| PLA/ABS Plastic | • Hobby projects • Low quality models • Low quality prototypes | |||||

| Stainless Steel (Ph2, UTS 1300 Mpa) | • Engineering parts • Functional parts • Motor sport • Maritime applications | |||||

| Titanium | • Medical implants • Surgical tools • Aerospace & defense • Motor sport • Maritime applications |

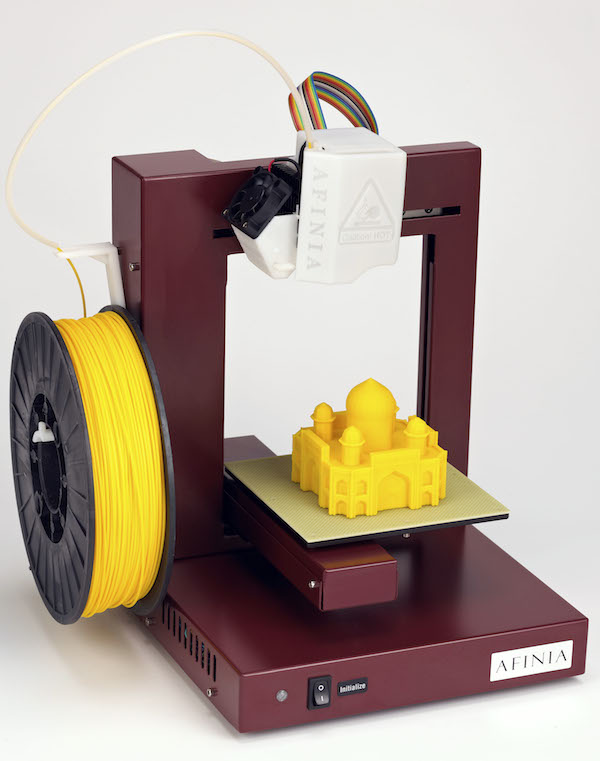

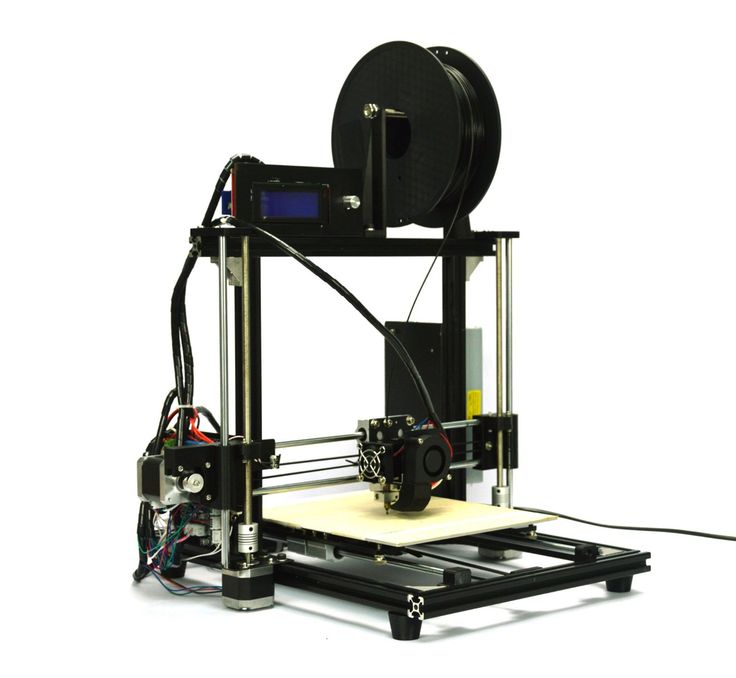

Additive manufacturing is the creation of parts and products one layer at a time. We have experience printing in the full range of materials including resin (coloured and clear), nylon, PLA, ABS, carbon fibre, sandstone as well as various metals. We are constantly adding to our list of quality assured printers to ensure the latest technology is available to us and our clients.

We have experience printing in the full range of materials including resin (coloured and clear), nylon, PLA, ABS, carbon fibre, sandstone as well as various metals. We are constantly adding to our list of quality assured printers to ensure the latest technology is available to us and our clients.

We have deep expertise in areas such as

- Printing: printer calibration, tool path creation, production scheduling and in-print monitoring and adjusting

- Post-production: heat treatment and stress relief, cutting, polishing, blasting and finishing

- Testing & Certification: external certification, reporting standards and machine analytics

Did you know? A little understood fact is that some 3D printed products need a considerable amount of post print finishing such as polishing, grinding and colour coating. 3D Matters has the necessary equipment and expertise to complete such post-processing work immediately after print production.

Cubicon

CubiconMaterial: PLA | ABS |

Markforged

MarkforgedMaterial: Material: Carbon Fibre | Fibreglass | Kevlar |

Form 1

Form 1Material: Material: Resins (standard, tough, flexible, castable) |

Blueprinter and Nylon cleaning and processing

Blueprinter and Nylon cleaning and processingMaterial: Material: Nylon | Tough nylon |

Projet 660

Projet 660Material: Material: Sandstone |

ZCorp 450

ZCorp 450Material: Material: Cermamic | Glass (under R&D) |

Renishaw AM 400

Renishaw AM 400Material: Material: Various types of metal such as aluminium, stainless steel, titanium |

Visit www. 3dmetalforge.com

3dmetalforge.com

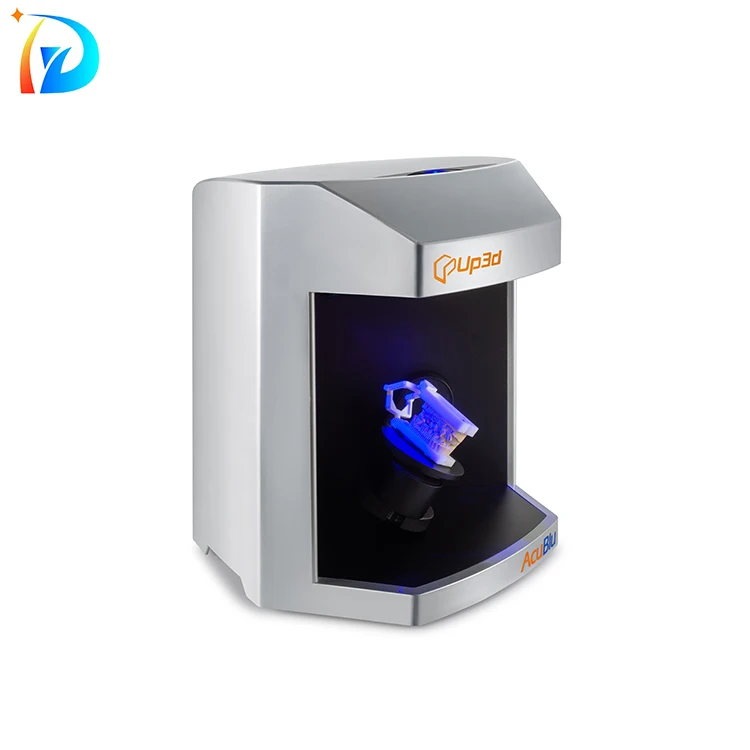

3D Scanning Courses in Singapore

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Instructor-led Classroom Adult Training in Singapore - Modular Fast Track Skill-Based Trainings

We offer a number of instructor-guided 3D scanning training courses in Singapore

You can apply WSQ funding, SFEC funding, PSEA subsidy, UTAP subsidy, SkillsFuture Credit (SFC) for these courses if applicable.

2 Item(s)

Sort By Position Name

Show 20 40 60 80 All per page

-

26 Review(s)

Rapid prototyping with 3D scanning and printing is the quick, easy, cost effective way to turn great ideas into successful products.

This is a comprehensive all in one 3d prototyping course, starting a product design with Fusion 360 and 3D scanning, and test out the design using 3D printing

Course Highlights

What is 3D Prototyping

How to go from ideation to a prototype

Design your prototype with Fusion 360

C....

This is a comprehensive all in one 3d prototyping course, starting a product design with Fusion 360 and 3D scanning, and test out the design using 3D printing

Course Highlights

What is 3D Prototyping

How to go from ideation to a prototype

Design your prototype with Fusion 360

C....$248.00 (GST-exclusive)

$265.36 (GST-inclusive)

-

This course is not yet approved for WSQ funding 3D printing is a complex additive process. Many things can go wrong. But with the right knowledge, design, and materials, you can get amazing, high-quality prints. This course includes the machinery and techniques behind 3D printing, machining, resin casting, injection molding, 2D prototyping, and laser scanning.

In this course, you will learn h....

In this course, you will learn h....$800.00 (GST-exclusive)

$856.00 (GST-inclusive)

About Us

Tertiary Courses is established in 2014, offering modular skill based Industry 4.0 courses. We are WSQ Approved Training Organization (ATO), IBF Standard Training Scheme (IBF-STS) Approved Training Provider, Approved Training Provider (ATO) for Singapore Chartered Accountant Qualification, IMDA CITREP+ Approved Training Provider , Autodesk Authorised Training Center (ATC) and Authorized Pearson Vue Test Center. We are also Singapore GeBiz registered supplier.

Training Grants and Subsidies

We have various grants and subsidies for different courses. Please check the respective funding available on individual course page.

WSQ: Company and Singaporeans/PR can apply WSQ 70-90% funding depending on eligibility

SkillsFuture Enterprise Credit (SFEC) - Eligible Singapore-registered companies can tap on $10000 SFEC to cover up to 90% of out-of-pocket expense

SkillsFuture Credit: All Singaporeans aged 25 and above can use their $500 SkillsFuture Credit from the government to pay for a wide range of approved skills-related courses.

IBF-STS Companies and Singaporeans/PR can apply IBF-STS 70-90% funding depending on eligibility

IMDA CTIREP+: All Singaporeans and PR can apply CITREP+ 70-100% funding depending on eligibility

UTAP: NTUC members enjoy 50% subsidy for unfunded course fee support for up to $250 each year when you sign up for courses supported under UTAP

SGTech STAR Fund: SGTECH members enjoy $500 grant per pax for SGTech STAR courses

Authorized Training Provider:

1

Autodesk Authorised Training Center

2

Pearson VUE Authorised Test Center (Site ID: 87824)

3

WSQ Approved Training Organization

4

Institute of Banking & Finance (IBF) Approved Training Provider

5

Singapore Chartered Accountant (SAC) Accredited Training Organisation

6

IMDA CITREP+ Approved Training Provider

7

GeBiz Registered Supplier

Regional Training Centers

2

Malaysia Kuala Lumpur and Penang

3

Ghana Accra

Contact Us Information

Tel: +65 6100 0613

Whatsapp: https://wa. me/6561000613

me/6561000613

Email: [email protected]

Training Centers venue :

12 Woodlands Square, #07-85/86/87, Woods Square Tower 1, Singapore 737715 (Disabled-Friendly) .

Mailing address:

45, #06-13, Choa Chu Kang Loop, The Warren, Singapore 689679

Information

Enquires

Training Grant and Subsidy

- SkillsFuture Credit (SFC)

- Step by Step Guide for WSQ Courses

- WSQ/SSG TG Application Form

- SkillsFuture Enterprise Credit (SFEC)

- IBF-STS TG Application Form

- Step by Step Guide for IBF Courses

- UTAP Claim Application

- PSEA Ad-Hoc Withdrawal Form

- iPREP Application

- Workfare Skills Support (WSS) FAQ

- Grant Calculator and Absentee Payroll FAQ

Our Websites

- Tertiary Infotech

- Tertiary Courses

- Tertiary Robotics

Certified Trainers

Copyright © 2022. Tertiary Infotech Pte Ltd. ROC/GST #: 201200696W. All Rights Reserved.

Tertiary Infotech Pte Ltd. ROC/GST #: 201200696W. All Rights Reserved.

Einscan h in combination with MSOFT saves the time and money of doctors and patients

9000 9000 Hanzhou, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China, China May 27, 2021 - SHINING 3D, the world's leading technology provider for 3D digitization, and TechMed3D, the leading provider of human body measurement software solutions, today announced a collaboration on a powerful duo: SHINING 3D's EinScan H and TechMed 3D's MSoft.

“We are pleased that together with TechMed we can now offer a complete body scanning solution for medical applications. For us, working with trusted software partners not only enriches the potential of our 3D scanners, but to a greater extent helps our customers to continuously progress in their 3D digitization efforts. ”

”

- Rebecca Hu, EinScan Product Manager, SHINING 3D

“At Techmed 3D, we're impressed with the evolution of products that Shining 3D can bring to market. Einscan H, with its ease of use and speed, allows us to expand our digitization offering and gain access to other growing markets.”

-Michel Babin, Founder & CEO, TechMed 3D

The EinScan H is a handheld 3D scanner that enables efficient and safe 3D scanning of the human body. This scanner, combined with TechMed's 3D's MSoft Solution , gives clinicians the ability to access clean scanned images within minutes. The scanner has been integrated with white light technology, making 3D scanning safe for the eyes. The scanner has a body scanning mode ideal for orthopedics and prosthetics. This mode provides a high tolerance for movement, and its alignment algorithm is tuned to handle non-rigid objects. At the same time, doctors can scan all parts of the body, including the head, in 3D with the EinScan H. Weighing only 703g, this versatile handheld scanner is easy to use for doctors of all levels of 3D scanning knowledge, including novice scanner users.

Weighing only 703g, this versatile handheld scanner is easy to use for doctors of all levels of 3D scanning knowledge, including novice scanner users.

With this solution, clinicians can easily and quickly obtain ready-made files for modification, cutting, 3D printing, design and fitting. Using the software with the EinScan H allows clinicians to see what they are scanning in real time directly in MSoft thanks to the scanner's built-in camera.

TechMed 3D and SHINING 3D are pleased to announce that joining forces by combining their technologies will better serve the orthotics and prosthetics market. The two companies together hope that this collaboration will create a powerful tool for professionals around the world who are ready to move into 3D digitization.

If you would like more information on how the products can benefit your business, please contact us today.

Contact us here

About TechMed 3D

TechMed 3D offers software solutions for measuring the human body. TechMed 3D is committed to providing the best and most user-friendly human body scanning software to provide the easiest, fastest and most accurate 3D scanning on the market.

TechMed 3D is committed to providing the best and most user-friendly human body scanning software to provide the easiest, fastest and most accurate 3D scanning on the market.

About SHINING 3D

Since its founding in 2004, SHINING 3D has been a pioneer in the independent research and development of technologies for 3D digitization, inspection and digital dentistry; SHINING 3D has over 300 patents and over 100 copyrights in these fields. As one of the market leaders, SHINING 3D offers 3D serial products, advanced 3D digital technology and one-stop service for its worldwide customers. SHINING 3D has set itself the goal of offering efficient and affordable 3D scanners and 3D printers that allow the flexibility to produce very powerful and complex designs and make 3D digitizing technology accessible to everyone.

Overview of Creaform Metrascan 3D scanners / Sudo Null IT News Learn more from this article.

About Creaform

Source: coarchitecture. com

com

In 2002, Bank of Canada invested $200,000 in a 3D scanner startup led by Martin Lamontagne. From that moment began the history of Creaform. Two years later, Lamontagne was named the "Best Young Entrepreneur of Quebec." His business brought in $5,000,000 and grew by 50% annually.

Source: pressreader.com

Creaform creates and markets 3D measurement equipment and participates in the development of innovative solutions in partnership with other companies.

Manufacturer specializes in the creation of tools for 3D scanning, non-destructive testing, reverse engineering, quality control and digital modeling (FEA/CFD).

Creaform equipment is in demand in various fields:

- In heavy engineering;

- In healthcare organizations;

- In the manufacture of household appliances;

- In the automotive industry;

- In the aerospace industry;

- In mining and processing industries;

- In the production of electricity;

- In educational and scientific institutions.

In 2013, Creaform became part of AMETEK Ultra Precision Technologies, a division of AMETEK Inc., a world renowned manufacturer of electronic tools and electromechanical devices with over $4 billion in annual sales.

Source: trends.directindustry.com

On March 1, 2018, Fanny Truchon took over the Creaform Business Line. For the previous 5 years, she served as the company's vice president of customer service.

Creaform's headquarters and manufacturing facilities are located in Quebec. Scientific and technical centers operate in Grenoble and Levis. Sales centers operate in Europe, Asia and America: Italy, France, Germany; China, Korea, Japan, Thailand, Singapore, USA and Brazil.

Creaform Metrascan 3D Scanners

Source: industryarena.com

Creaform's 3D scanner principles are:

Protect measurements from adverse environmental conditions. Vibrations, unstable lighting, temperature fluctuations and inexperience of the operator do not affect the accuracy of the result. Creaform scanner algorithms are aimed at facilitating the measurement process and increasing the accuracy of the information received

Vibrations, unstable lighting, temperature fluctuations and inexperience of the operator do not affect the accuracy of the result. Creaform scanner algorithms are aimed at facilitating the measurement process and increasing the accuracy of the information received

TRUporability – 3D scanning anywhere.

Compact size, light weight, easy transport - everything you need to work 3D scanners almost anywhere.

TRUsimplicity - simple workflow.

Less than 5 minutes take information gathering, data processing, visualization and meshing for objects of almost any size, color and material. To work with the device does not require pre-configuration or special user experience.

How it works

Source: creaform3d.com

The laser beams of the 3D scanner are directed at the subject, the camera captures the intersection points of the beams and the object. A laser tracker or accessory monitors the spatial position of the scanner. To connect parts of the image, small stickers of a given size, called marks, are used.

To connect parts of the image, small stickers of a given size, called marks, are used.

Source: creaform3d.com

MetraSCAN, Go! SCAN, HandySCAN - three models, three ways to collect data.

Each device determines its location in space in relation to the scanned object using different algorithms.

MetraSCAN is the most accurate device in this range. The principles of operation are similar to those of HandySCAN. MetraSCAN can operate as a stand-alone handheld instrument. However, it was originally designed to work with the C-track device. More about it in the paragraph "Optional equipment".

METRASCAN 750 (Elite)

Source: creaform3d.com

Specifications

Price METRASCAN 750 on request

METRASCAN 750 ELITE price on request

METRASCAN 350 (Elite)

Source: creaform3d. com

com

Price METRASCAN 350 on request

METRASCAN 350 ELITE price on request

Scope of supply

Source: aniwaa

Scope of supply:

- MetraSCAN 3D scanner

- VXelements software

- Stand

- Calibration sphere

- FireWire cable

- Flight case

- 1 year labor and parts warranty

Optional Equipment

C-Track

Source: aniwaa.com

The MetraSCAN handheld scanner is housed in a frame with marks to determine its location in space. The work of the scanner is to process data about the shape and surface of the scanned object, it is not tied to reference marks. They are searched for by the C-track, which is equipped with two cameras spaced apart to "capture" a large amount of space.

To obtain a coordinate reference system for the scanner, at least 4 marks, C-track tracks an area up to 16. 6 cubic meters in front of it. To bind the coordinate system to the object, marks can be placed on the part under study. When changing the relative position of the C-track and the object, the relationship between the scanner and the object is preserved.

6 cubic meters in front of it. To bind the coordinate system to the object, marks can be placed on the part under study. When changing the relative position of the C-track and the object, the relationship between the scanner and the object is preserved.

Scanning starts immediately after the C-track finds several marks to create a reference frame in space. C-track keeps track of marks on the device so as not to lose its position in the working coordinate system. Collaboration of devices provides ample opportunities to scan large objects, such as aircraft and cars, in automatic mode and using a relatively small number of tags.

CUBE-R

Source: creaform3d.com

The CUBE-R intelligent scanning system includes several devices: robotic arm, turntable, C-Track, C-Track, managing computer complex.

System features:

- High performance: checks up to hundreds of objects per day, including details of complex geometric shapes;

- Multifunctionality: simultaneously collects and analyzes information;

- Reduced footprint: 4.

1m x 4.1m x 3.1m;

1m x 4.1m x 3.1m; - Processing of large and heavy parts: weighing up to 1.5 tons, volume - up to 3 m along any coordinate axis;

- Ready to work: the system is completed, does not require integration;

- Automatic calibration mode during continuous data processing;

- Industrial design: adapted to the production environment.

Software

Source: creaform3d.com

Creaform offers several software license options:

- Computer license;

- Hardware key license;

- Network license.

Comparison of Creaform software features:

VXelements

Source: creaform3d.com

VXelements is an integrated software platform for combining all Creaform 3D scanning and measurement technologies. It is a working environment for other software modules (VXscan, VXprobe, VXshot, etc. ) and a convenient, simple user shell.

) and a convenient, simple user shell.

VXmodel

Source: www.youtube.com

VXmodel is an easy-to-use program for preparing a 3D scan mesh for reverse engineering or 3D printing. Software options:

- Screen cleaning;

- Filling voids;

- Grid alignment;

- Mesh simplification;

- Create mesh-based surfaces.

VXinspect

Source: youtu.be

VXinspect - The software integrates the results of digital information processing and photogrammetric measurements. Solves the following tasks:

- Comparison of the resulting digital models in CAD with the original objects;

- Control of parameters of received models and original parts and tools;

- Control of conformity of manufactured parts to originals or standard;

- Checking the tool and its fixtures;

- Alignment;

- Warp tracking;

- Dynamic measurement.

VXtrack

Source: creaform3d.com

VXtrack is designed to solve the following tasks:

- Robot calibration and orientation;

- Track and control complex assembly processes;

- Real-time correction of inaccuracies that occur during data processing;

- Deformation tracking during testing.

Compare with Shining Freescan Trak

Both devices: Shining Freescan Trak and Creaform Metrascan operate on a similar principle: a symbiosis of a 3D scanner with a tracking tracker that determines the position of the scanner in relation to the digitized object.

Specification comparison:

Application examples

Product quality control at MDC DESIGN srl

Source: creaform3d.com

MDC DESIGN srl is a rapidly growing company and a leading supplier of control systems and sensors for process automation in the automotive and aerospace industries. The work of MDC DESIGN srl is based on strict compliance with quality standards. The company produces a wide range of devices, from simple instrument stands to innovative systems with complex electronic components.

The work of MDC DESIGN srl is based on strict compliance with quality standards. The company produces a wide range of devices, from simple instrument stands to innovative systems with complex electronic components.

Source: creaform3d.com

During the production of large equipment, the company was faced with the task of finding a device for measuring and creating models of parts in three-dimensional space. The tool had to process information and transform data with maximum accuracy.

MDC DESIGN management said they chose Creaform because their values matched. Accuracy and speed are priority principles of both companies. MDC DESIGN was pleased with the choice of supplier, also due to the high level of staff training and high-quality technical support.

The Creation of the American Magic, New York Yacht Club

Source: sail-world.com

The American Magic is the United States candidate for the 2020 America's Cup, regarded by yachting enthusiasts as the most prestigious international event. The history of the competition began in 1851, forty-five years before the Olympic Games.

The history of the competition began in 1851, forty-five years before the Olympic Games.

Source: creaform3d.com

Creaform is the official 3D technology provider for the nearly 23m American Magic. The yacht develops a speed of more than 92 km/h thanks to innovative technologies and modern materials used by Airbus engineers to create a hydrofoil yacht.

Source: creaform3d.com

Working with sailing experts and engineers, Creaform's metrology team scanned the carbon fiber hull of the yacht. We analyzed the influence of the geometry of parts on the streamlining of the vessel, studied the possibilities of improving the characteristics of the hull. The Creaform team was delighted to be part of the evolution of American Magic and are proud to have helped improve the yacht's design features.

24 Hours of Le Mans

Source: sport. ru

ru

To control the cars of the race participants, the FIA used the Creaform MetraSCAN 3D scanner.

Source: creaform3d.com

The task before the experts was to check the compliance of each car with the rules of racing. Each test was to take no more than 10 minutes. The problem was solved using MetraSCAN scanners.

https://youtu.be/bJPw8UEuoNA

Conclusion

Source: creaform3d.com

3D laser scanners are high-precision, high-speed equipment for use in various fields where accuracy and speed of obtaining three-dimensional models of physical objects are required. The devices do an excellent job of processing data regardless of the location of the object - on the street, in the laboratory or on the production floor.

Buy Creaform Metrascan 3D Scanners from Top 3D Shop and get an ultra-accurate 3D scanner, an official warranty and the best possible service.