3D printed vegan steak

World’s First 3D-Printed Juicy Vegan Steak to Hit Restaurants This Year

With the speed 3D printing technologies are advancing, it looks like the question that will baffle couples and lead to indecisive fights will be "What shall we print for dinner?" in a few years. Redefine Meat, an Israeli company that was founded in 2018, has unveiled an "Alt-Steak" which looks and tastes like the real thing and it is to hit Israeli restaurants this year.

Redefine Meat is quite literally out to define meat, and the company states that it can create sustainable, high-protein, no-cholesterol steaks thanks to advanced 3D printing technologies.

SEE ALSO: 3D PRINTING WILL CHANGE THE WAY YOU EAT IN 2020 AND BEYOND

From lab to the restaurants

Eshchar Ben-Shitrit, who founded the company, first known as Jet Eat, back in 2018, stated that this announcement "marks the start of a new are in alternative meat. “We are actually printing steaks," he said. "We have a product. It is something we are doing already in large amounts."

The beef will be tested at selected high-end restaurants in Israel later in 2020. The product will be offered as part of a chef's dish and the production of the 3D meat printers and alt-meat formulations will be ramped up after getting feedback from high-level chefs and butchers.

Source: Redefine MeatThe next step will be market distribution in 2021.

Its charm is at its technology

The company developed the patented tech that does 3D prints meat substitutes using plant-based formulations. It quite literally uses "ink" to "print" the steaks, and the steaks are made out of soy and pea proteins, coconut fat and sunflower oil, natural colors, and flavors.

Most Popular

Source: Redefine MeatDuring a phone interview with the Times of Israel, Ben-Shitrit said, "It is very unique to us; we are the only ones doing this. We come very close to how the composition of meat is in nature, and our 3D printer essentially is like a very complicated robot that knows how to take each one of these ingredients and in a very accurate manner… builds a food product. "

"

Master food engineering

The plant-based products are combined with water and put into three ink cartridges. These cartridges are loaded into their 3D printer which is the size of a big fridge.

Source: Redefine MeatAfter the materials go through food engineering in the printer, the machine ejects the product, printing a mix of fat, blood, and meat to give the structure of muscle that is similar to a cow's.

Source: Redefine MeatBen-Shitrit stated that the machine prints "one dot over the other, and the product is built from almost one million dots." The software can dictate the type of steak the printer prints.

"By using separate formulations for muscle, fat, and blood, we can focus on each individual aspect of creating the perfect alt-steak product. This is unique to our 3D printing technology and lets us achieve unprecedented control," he said.

As of now, each machine can produce six kilograms (13.3 pounds) an hour and it will eventually reach 200 kilograms of meat a day.

Not only creating a vegan dish but also offering an option to everyone else

The company's main goal is not to create a vegan dish, but also to disrupt the food supply chain globally since meat production is known to have a negative impact on the environment.

The 3D printing revolution might remove the need to source meat from the cattle and provide a new, more sustainable way to enjoy meat in the future.

For You

innovation

Can AI rescue lab rats and guinea pigs? Science’s long-debated ethical question may finally have some answers.

Baba Tamim | 10/14/2022

innovationPhantom Space: A new rocket startup says it can launch at half the cost of SpaceX

Chris Young| 9/20/2022

scienceThe Moon keeps drifting away from Earth. Will it ever leave?

Paul Ratner| 10/29/2022

More Stories

innovation

China claims ‘world’s first’ kerosene-powered engine could propel jets nine times the speed of sound

Baba Tamim| 11/20/2022

science

In a first, researchers discovered a rare mineral that comes directly from Earth's lower mantle

Sade Agard| 11/28/2022

innovation

A Norwegian company is turning worn-out tires into oil

Ameya Paleja| 11/28/2022

Would you eat this 3D printed plant-based steak?

As the race quickens to provide diners with the best meat alternatives, one start-up is producing so-called 'whole cuts' of plant-based meat using 3D printers.

Israeli firm Redefine Meat say they better replicate the texture, flavour and smell of steaks and lamb.

A five-course lunch at London's Chotto Matte was organised for a large-scale tasting, where 50 chefs, restaurant owners and food critics were invited.

Most were positively surprised by the quality of the product, titled 'New Meat'.

A sustainable approach to meat consumption

More people are interested in reducing their meat consumption or adopting vegan dietAPJordan Sclare, Global Executive Chef at Chotto Matte which hosted the event, says New Meat is fairly close to the "real thing."

After all, it is composed of real muscle and fat cells, taken from animal cells and woven together.

"When you're slicing it, there's a hell of a lot of similarities. When you're cooking it on the barbecue, you can tell that it is a bit different because it cooks very fast and it sears quite quickly. Whereas different cuts of raw meat have different cuts, you know you have the fillet or the shin or the shoulder that slow cooks.

"So it looks kind of like a slow-cooked 'beef'. But then when you sear, it becomes like pink and seared, like how a 'beef' fillet would."

Redefine Meat hope to convince heavy meat-eaters and meat lovers to reduce their consumption.

"We're offering an easy switch and ability to continue eating meat without compromising on health, sustainability or taste. We are trying to convince more and more people to eat less meat," says Eshchar Ben-Shitrit, CEO of Redefine Meat.

How is 'New Meat' made?

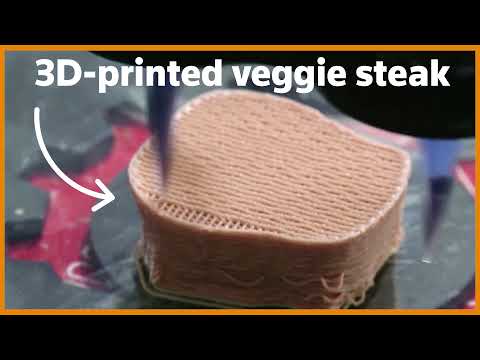

The complex 3D printing process gives the plant-based product it's meat-like textureAPTechnically, the R&D team of Redefine Meat first worked to study real cuts of meats — they even developed AI to observe the texture of meat to replicate it.

That's how they're able to match the look of a piece of 'beef' for example.

And to complete the trick, all senses have to be fooled.

"This is the blood and the perfume that actually are carriers of flavours and scents that go inside their final product," says Alexey Tomsov, food engineer for the R&D department of the company.

The exact list of ingredients is closely guarded. The company says that New Meat is made by "using a range of proprietary and patented technologies" and "plant-based ingredients," including chick peas.

"So actually, we have natural colours that are extracts from fruits and vegetables that give it that really typical colour that we expect to get from an animal product. And actually, we also have here flavours and additional elements that give it that really unique flavour that we get from animal-like flavour carrier," he says.

As for the blood, Tomsov is not allowed to say much more.

Regarding texture, Redefine Meat is using production facilities with 3D printers.

A new one will open in the coming months in the Netherlands, where 5,000 tonnes of New Meat will be produced per year.

"We call it actually additive manufacturing, where you build the product layer by layer. That enables us to control the fibre structure to trap fat and moisture within the fibres and to create a food product that is man-made, the one that you're eating today, which is the closest thing to the biological meat that we're used to eat. And when you see it, it looks like meat, when you put it in your mouth, it feels like meat and your brain associates it with meat," says Ben-Shitrit.

And when you see it, it looks like meat, when you put it in your mouth, it feels like meat and your brain associates it with meat," says Ben-Shitrit.

Changing attitudes towards plant-based alternatives

Chotto Matte will continue to build menu items around New MeatAPChotto Matte, the restaurant where the tasting happened, already offers New Meat on its menu.

For the last two months, it trialled the new product along with 32 other restaurants spread across the UK, the Netherlands and Israel.

Chef Sclare designed the menu around the plant-based New Meat.

He notably used the 'beef' New Meat in a spicy teriyaki, and cooked the 'lamb' New Meat with coriander and Peruvian chilli miso.

Redefine Meat intends to expand to more restaurants in Europe in 2022, and hopes to make its products available in supermarkets.

Watch the video above to see if you could tell the difference between New Meat and a regular steak.

3D printed vegan steaks coming to restaurants this year

Hardware animal husbandry July 7, 2020

Given the speed of development of 3D printing technologies, it seems that a new question will soon appear, baffling couples. It will sound like this: “Darling, what are we printing for dinner today?”.

It will sound like this: “Darling, what are we printing for dinner today?”.

The Israeli company Redefine Meat, founded in 2018, has introduced Alt Steak, and it should hit Israeli restaurants this year. The company says it can create cholesterol-free, sustainable high-protein steaks thanks to advanced 3D printing technology.

From laboratory to restaurants

Eshchar Ben-Shitrit, who founded Redefine Meat, originally known as Jet Eat, announced back in 2018 that he was "starting a new direction in alternative meat." “Actually, we print steaks,” he said. - We have a product. It's something we're already doing in large numbers."

The printed beef will be tested in select high-end Israeli restaurants in 2020. The product will be offered as part of the chef's dish, and the production of special 3D printers and "altmeat" recipes will be increased after receiving feedback from high-level chefs and butchers.

The next step will be market distribution in 2021.

The charm lies in the technology

The company has developed a patented technology that 3D prints meat substitutes using plant-based recipes. The printer literally uses "ink" to "print" steaks, and steaks are made from soy and pea proteins, coconut fat, sunflower oil, natural colors and flavors.

The founder of the company notes: “This is very unique to us; we are the only ones doing it. We've come very close to the natural composition of meat, and our 3D printer is essentially like a very complex robot that knows how to take each of these ingredients and very precisely... build a food product."

Master in Food Engineering

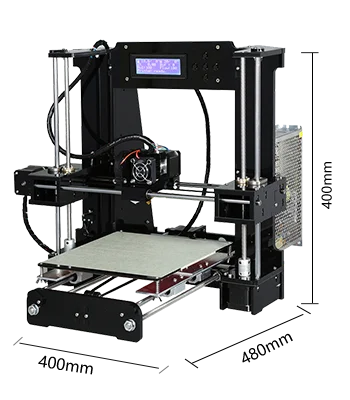

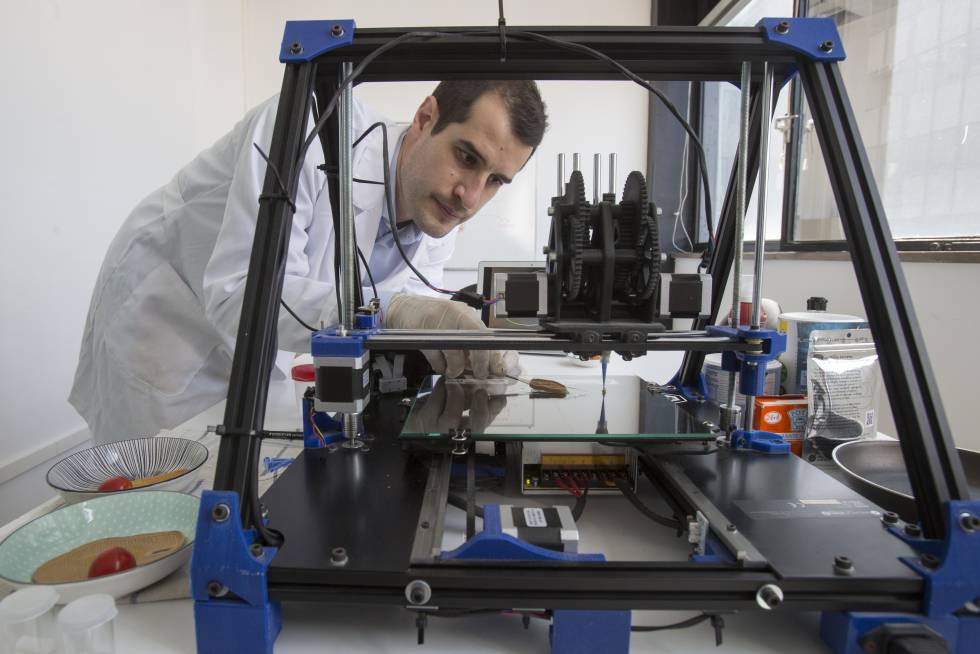

Plant components are combined with water and placed in three cartridges. These cartridges are loaded into a 3D printer the size of a large refrigerator.

After the materials go through food engineering in the printer, the machine delivers the product by printing a mixture of fat, blood and meat to give the appearance of cow-like muscle structure.

Ben-Shitrit stated that the machine prints "one dot on top of another, and the steak is built from almost a million dots." The software can determine the type of steak the printer is printing.

“By using separate recipes for muscle, fat and blood, we can focus on every single aspect of creating the perfect Alt Steak. This is unique to our 3D printing technology and allows us to achieve unprecedented control,” he said.

At the moment, each machine can produce six kilograms (13.3 pounds) per hour and will eventually reach a capacity of 200 kg of meat per day.

Not only creating a vegetarian dish, but also offering it to everyone else

The main goal of the company is not only to create a vegetarian dish, but also to disrupt the food supply chain around the world, since the production of meat is known to have a negative impact on the environment.

The 3D printing revolution could eliminate the need to source meat from cattle and provide a new, more sustainable way to enjoy meat in the future.

Tags: research scientists

3D Printer Capabilities: 2-Story House, Millimeter David Statue and Vegan Steak

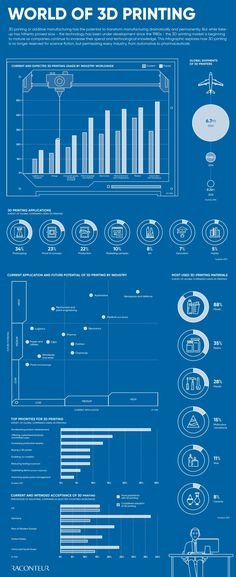

3D Printer Applications are extensive and often used for unusual purposes, often such situations remain behind the scenes. But not at this time. In this article, we have collected interesting cases of 3d printing applications that will not leave you indifferent.

Will 3D printers replace construction workers? Europe's largest 3D printed house

appears in BelgiumExperts have long predicted that 3D printers will revolutionize the construction industry, making home building cheaper, faster and greener. However, the implementation of this idea is slower than expected, because 3D technologies for creating fully functional houses have not yet been sufficiently considered. This perception may change after the opening of the world's first two-story house, printed in a single copy, in Antwerp, Belgium.

“What makes this house so unique is that we printed it on a stationary 3D concrete printer” said Emiel Ascione, Project Manager at Kamp C, the construction company that led the venture. “Other houses that have been printed around the world have only one floor. In many cases, the components were factory printed and assembled on site. However, we printed the entire shell of the building in-house” .

“Other houses that have been printed around the world have only one floor. In many cases, the components were factory printed and assembled on site. However, we printed the entire shell of the building in-house” .

Photos of the house:

Micro Angelo? Michelangelo's David statue 1 mm high

3D printing has made a name for itself in many industries, so there's no need to brag anymore, but some people just can't help it. Case in point: this is a millimeter-sized statue of Michelangelo's famous "David", printed in copper using a newly developed technique. The aptly named "Tiny David" was created by Exaddon, a subsidiary of Cytosurge. Its width is only a fraction of a millimeter, and its weight is two micrograms. It was created using an Exaddon "CERES" 3D printer, which emits a stream of ionized liquid copper at a rate of just a femtoliter per second, forming a rigid structure with micrometer-sized elements. David took about 12 hours to print, although something simpler in structure could probably have been done much faster.

David took about 12 hours to print, although something simpler in structure could probably have been done much faster.

Anyway, the level of detail is amazing. Although it is obviously impossible to recreate all the nuances of Michelangelo's masterpiece, even small textures like hair and muscle tone are reproduced quite well. No finishing or support legs required.

Of course, we can create much smaller structures at the nanometer level using advanced lithography techniques, but this is a complex and sensitive process that must be carefully designed by experts.

"It's more than just a copy and scaled-down model of Michelangelo's David" said Exaddon's Giorgio Ercolano on the company's blog. “Our deep understanding of the printing process has led to a new way of processing a 3D computer model of a statue and then converting it into machine code. This object was cut from an open source CAD file and then sent directly to the printer. This slicing method opens up a whole new way to print designs with the CERES additive micromanufacturing system. ”

”

3D printed steak was indistinguishable from the original:

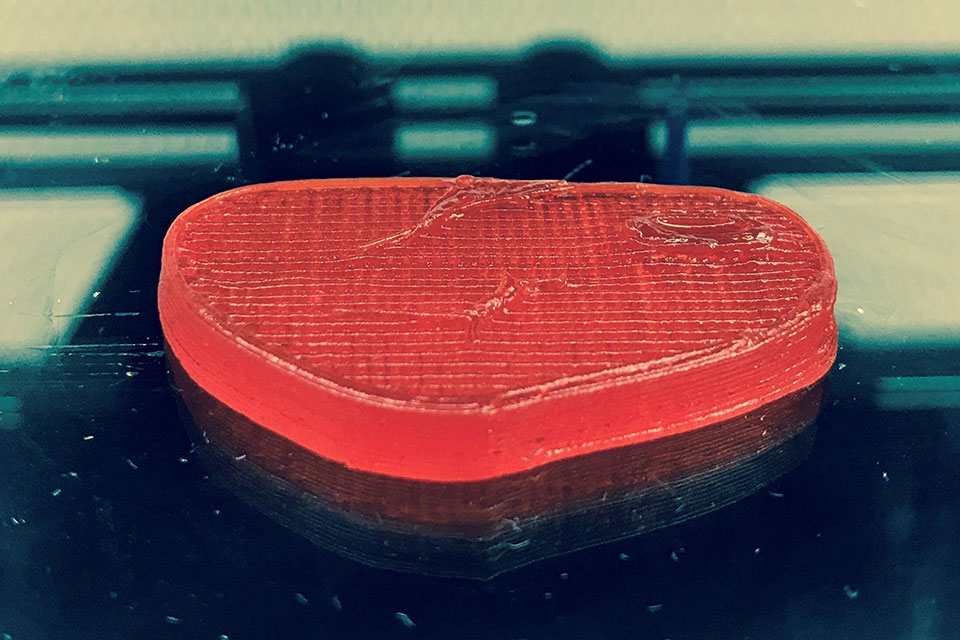

Israeli startup Redefined Meat has unveiled the world's first plant-based alternative steak and announced that market trials will begin at select high-end restaurants later this year. Created using Redefine Meat's patented 3D printed meat technology, Alt-Steak's products have the texture, taste and look of beef steak.

The company has developed a patented technology for 3D printing meat substitutes using plant-based recipes. They literally use "ink" to "print" the steaks, and the steaks are made up of soy and pea proteins, coconut fat and sunflower oil, natural colors and flavors.

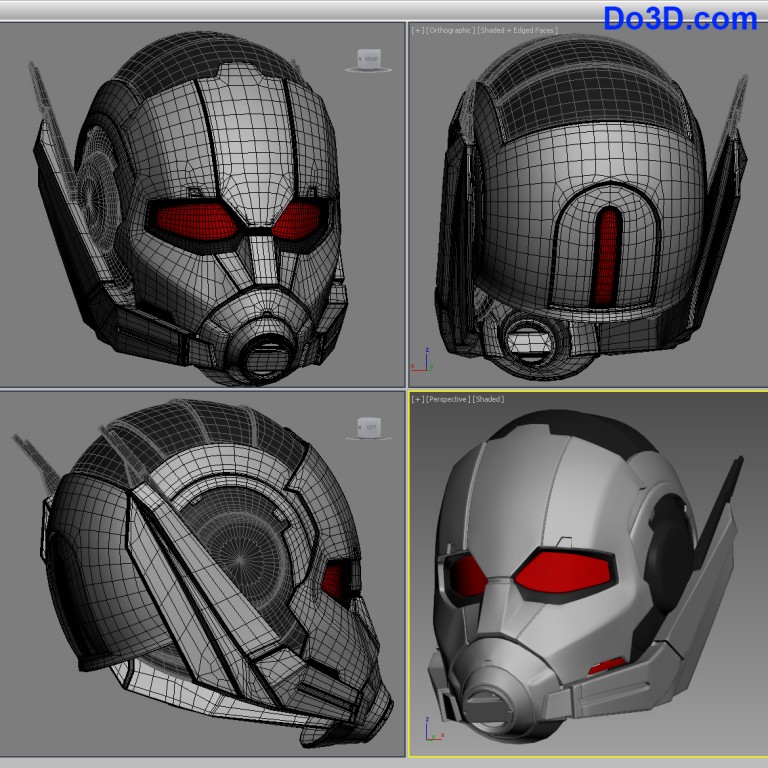

This photo shows how the printer works.

Plant-based products are mixed with water and placed in three ink cartridges. These cartridges are loaded into a 3D printer the size of a large refrigerator.

To test the quality of the steak, Redefined Meat asked renowned Israeli chef Assaf Granit for his opinion.