Full scale 3d printer

Large Scale 3D Printers - Builder 3D Printers

Name

Company

Phone Number

Over 1 x 1 meter in build capacity with the Extreme 3000 PRO

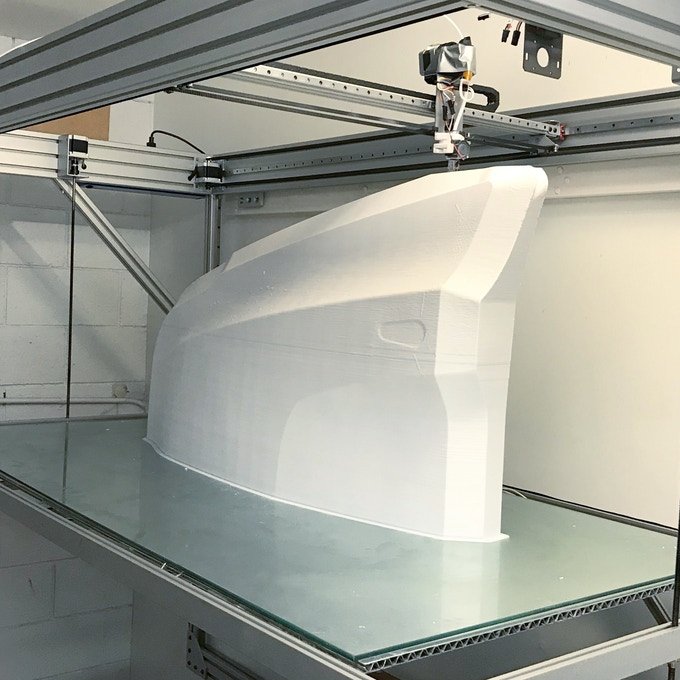

With a build capacity of over 1 meter x 1 meter (XY axis), it is the perfect machine for creating large and full size parts, tools, jigs & fixtures in-house and on demand. Within days you can have a fully functional high quality prototype. Features such as automatic bed leveling, a battery pack and filament detection, make large scale 3D printing worry free. Manufactured to the highest standards.

Discover more

Your browser does not support the video tag.3D PRINT FULL SIZE PARTS - TOOLS - PROTOTYPES

IN-HOUSE PROTOTYPING

REDUCE PRODUCT DEVELOPMENT TIME BY WEEKS

Builder Extreme 3000 PRO

IN STOCK

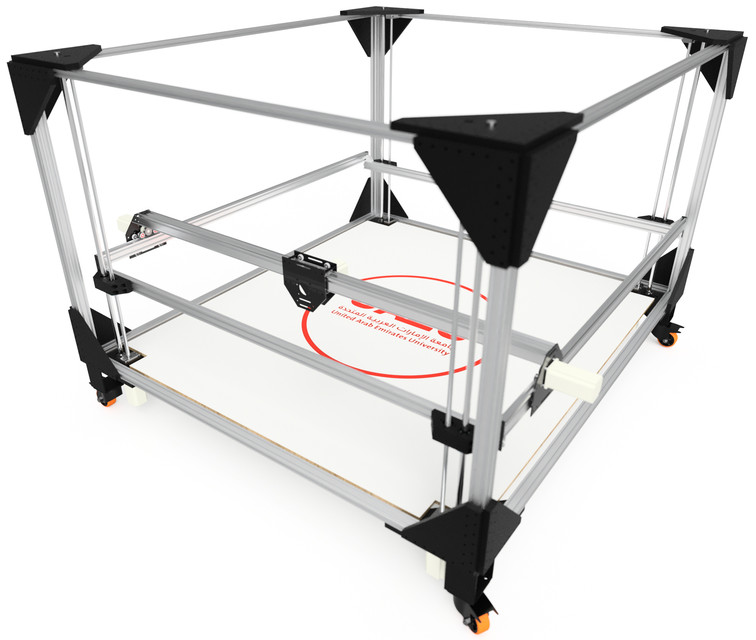

The Extreme 3000 PRO is the perfect fit for industrial 3D printing applications. The extremely large build volume of 1100x1100x820 mm YXZ, allows you to 3D print large and complex shaped parts and prototypes on full scale. The frame has been designed in a way that you have easy access to the build plate from both sides by removing the side panels. 3 different nozzles diameters, 0.4, 0.8 and 1.2 mm, are included to optimize print quality and time for your specific needs.

Find out more

Builder Extreme 2000 PRO

IN STOCK

The Builder Extreme 2000 PRO is one of the tallest industrial 3D printers available today. With a print volume of 700 x 700 x 1700 mm (XYZ), it is the perfect 3D printer for extremely tall objects. Elements such as a 7-inch touch display, filament detection, UPS system that resumes operation after a power outage, door locking system and available extension for a BOFA air filter, make it a fully equipped large format 3D printer.

Find out more

Your browser does not support the video tag.Business Cases

Interested to see how other companies have integrated large industrial 3D printing into their product development process?

Take a look at the different business cases. 54% of our European customers invested in a second, third or fourth Builder Extreme within 6 months after their initial purchase.

From extremely large prototypes to customized mannequins, marketing displays and dinosaurs, industrial 3D printing is great asset for all industries.

View business cases

Builder Extreme 1500 PRO

IN STOCK

The Builder Extreme 1500 PRO is one of the longest industrial 3D printers available on the market. With its unusual large X axis size, it fits perfectly into the smallest office corners. The print volume is 1100 x 500 x 820 mm (XYZ), and the machine is comes with features such as a 7-inch touch display, filament detection system and the UPS system that resumes the print job after a power cut. This combination makes it a fully equipped large format 3D printer.

This combination makes it a fully equipped large format 3D printer.

Find out more

Builder Extreme 1000 PRO

IN STOCK

The Builder Extreme 1000 PRO is one of the biggest industrial 3D printers available on the market. With a print volume of 700 x 700 x 820 mm (XYZ), it is the perfect printer for large prototypes, molds, tooling or even functional parts. Features such as a 7-inch touch display, filament detection and a UPS system that resumes printing after a power cut, make large scale 3D printing uncomplicated.

Find out more

The Builder Extreme is preferred by industrial leaders

“We needed to print larger prototypes in 1 piece and without worrying about failed prints – the Builder 1500 ticked all the boxes”.- Eventuri

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish.Accept Read More

We'll assume you're ok with this, but you can opt-out if you wish.Accept Read More

Installation - Builder 3D Printers

Thank you for your trust in our company and products. Please, read the following information carefully so as you can install your Builder Extreme smoothly and start printing your first project soon.

Step 1. Installation / Quick start of the Builder Extreme

Please find the Quick Start for the Builder Extreme 3D printer here. The page guides you through the process of removing the printer from the pallet, installing filaments and running the test print. Following the Quick Start enables you to start your first project without any issues. If you have any questions during the set-up, please fill in this form.

Step 2. Install Simplify3D and import the FFF profileSimplify3D is the slicing software used to convert your 3D model (.STL) into a gcode. The software is used to determine print speed, infill percentage of the print and more. You have received the Simplify3D license for 2 devices by email, so you can now create your personal log-in.

You have received the Simplify3D license for 2 devices by email, so you can now create your personal log-in.

Note: The Builder Extreme is not listed in Simplify3D as a standard printer, so choose Other printers and click OK.

We have created standard FFF profiles for a 0.4, 0.8 and 1.2 mm nozzle. With these optimized settings, you are able to use the Builder Extreme directly after installation. Please download the FFF profile for your model of the Builder Extreme here. Open Simplify3D and go to File, Import FFF profiles and import the FFF profile. Now you are ready to start slicing.

Builder

Extreme 1000 PRO

ZIP

Builder

Extreme 1500 PRO

ZIP

Builder

Extreme 2000

ZIP

Builder

Extreme 2000 PRO

ZIP

Builder

Extreme 3000 PRO

ZIP

Trouble shooting for Simplify3D can be found here: https://www. simplify3d.com/support/

simplify3d.com/support/

Step 3. Manual Builder Extreme 3D printer

Please find the manual of the Builder Extreme 3D printer below. Make sure you download the correct version for your Builder Extreme as we have also listed manuals for the previous models. Read the manual carefully before 3D printing your first project.

Step 4. Check whether your software is up to date (V1.35)

Every few months we upload an updated version of the software for the Builder Extreme PRO 3D printers. Please, make sure you have the latest software version to keep your machine up to date. NOTE: IF YOUR SOFTWARE IS V1.21 OR LOWER, PLEASE CONTACT US BEFORE YOU DO THE UPDATE. You can download the latest software version here:

Please follow these steps:

The Builder Extreme has now successfully been updated. Note that the software recognizes which Builder Extreme you have, so please follow the instructions to prevent issues with updating and upload all 6 files.

If you need any help during the update, please contact us on helpdesk@builder3dprinters. com

com

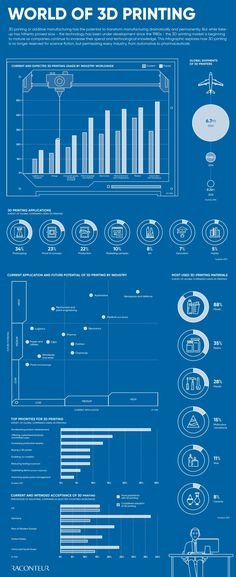

Classification of 3D printers / Sudo Null IT News

3D printing is steadily gaining momentum and we are increasingly seeing posts that a 3D printer has been taught to print parts for the ISS, organs, houses and much more. Foreign technology publications are beginning to say that 3D printing is able to resurrect the industry in the states, and the shapeways service, before our eyes, is showing interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale while impressing the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut.

I’ll make a reservation right away that the standards in the industry are very conditional, so far. But a brief overview with the order of prices can be generated now. And so, let's get started.

And so, let's get started.

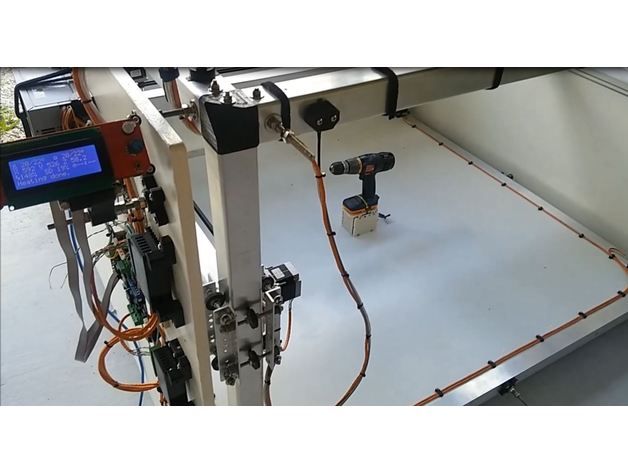

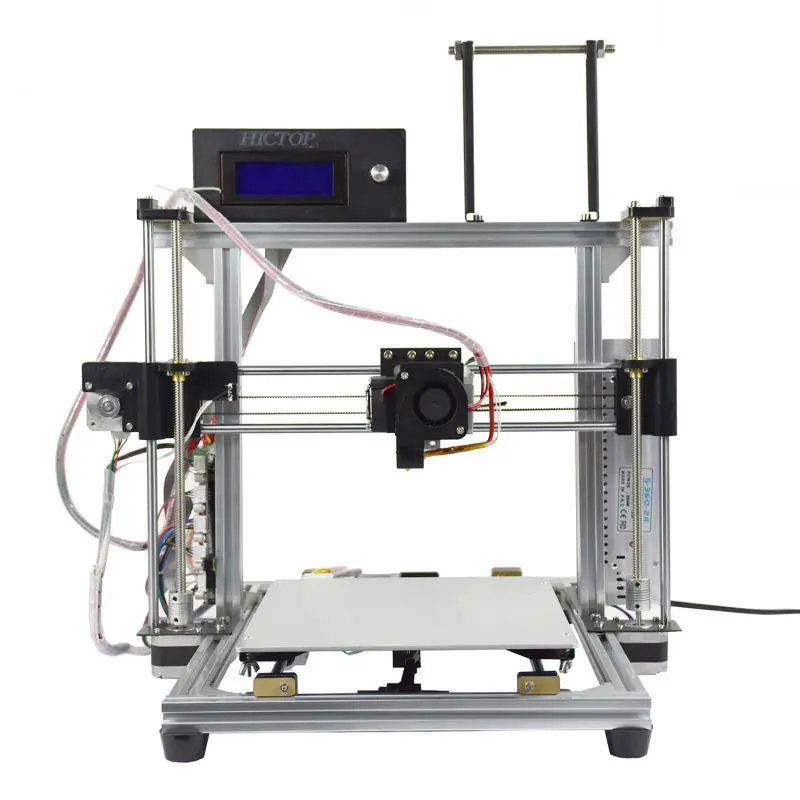

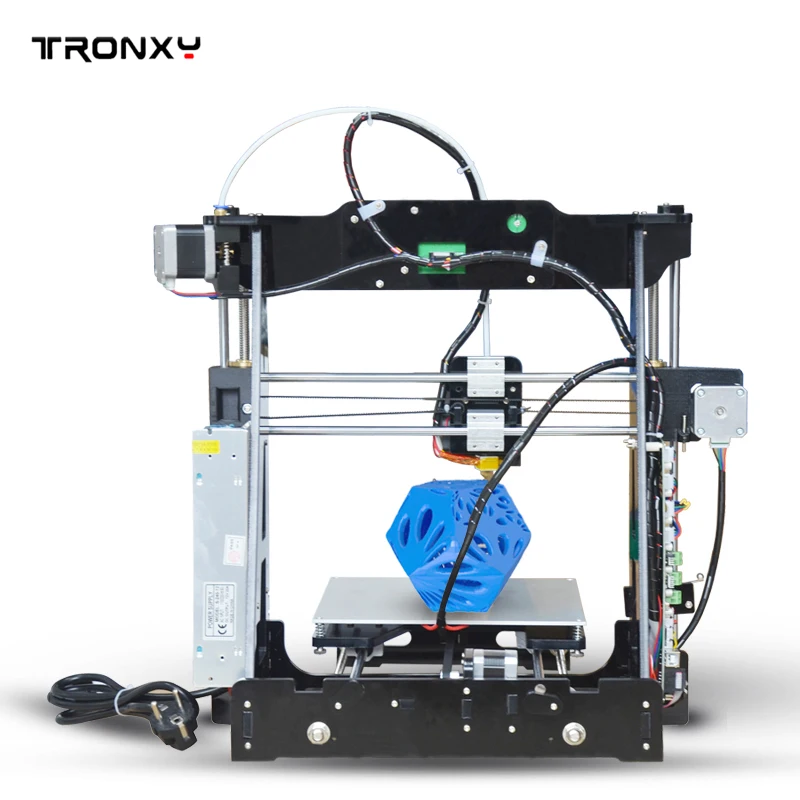

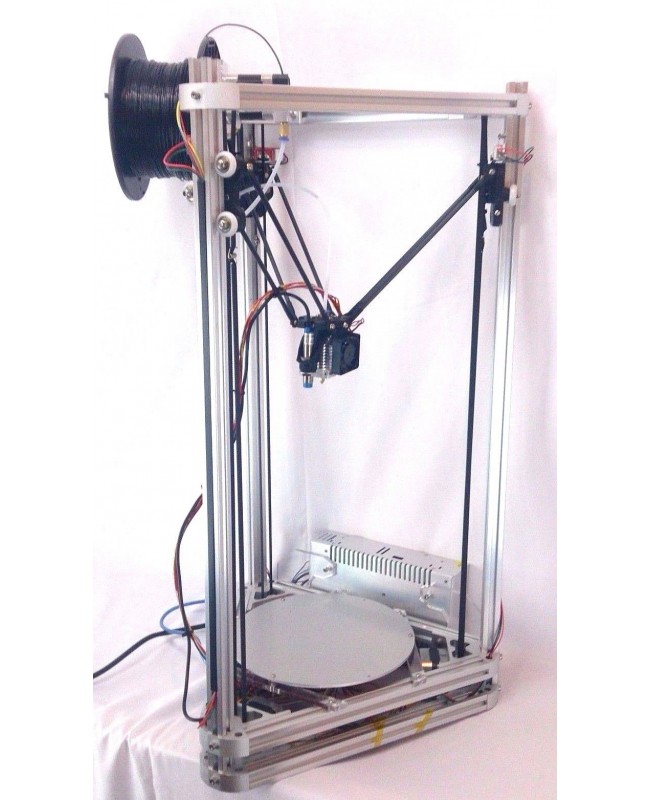

Consumer

A type of printer intended primarily for personal use. Supplied in the form of a designer, or assembled. The vast majority of printer models of this type are derived from the open source RepRap project. Since they have basically the same platform, their characteristics are also very similar.

Designed with an eye on the average user and equipped with a fairly simple and intuitive interface. Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.

Price range: $500 - $3500

Target audience:

Designers / artists / inventors who work from home.

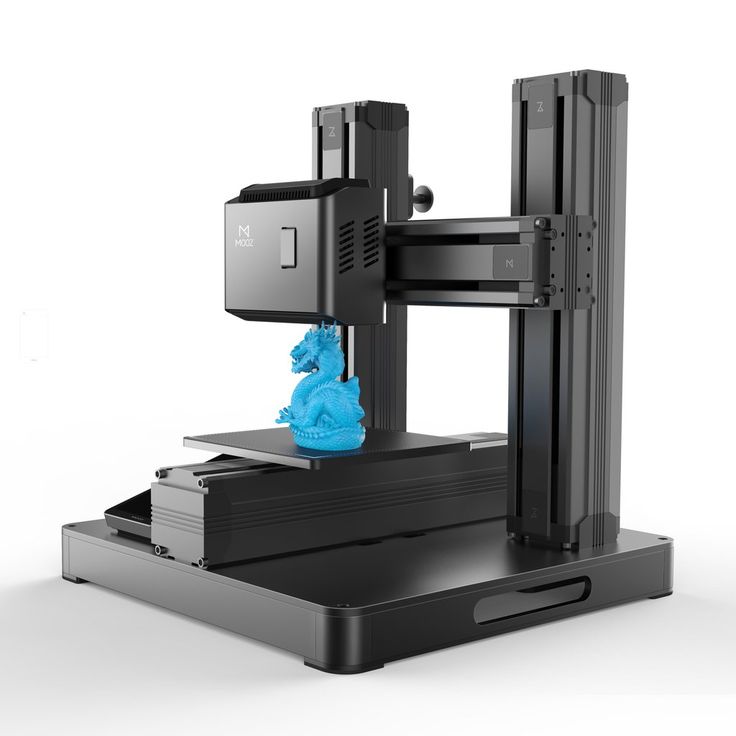

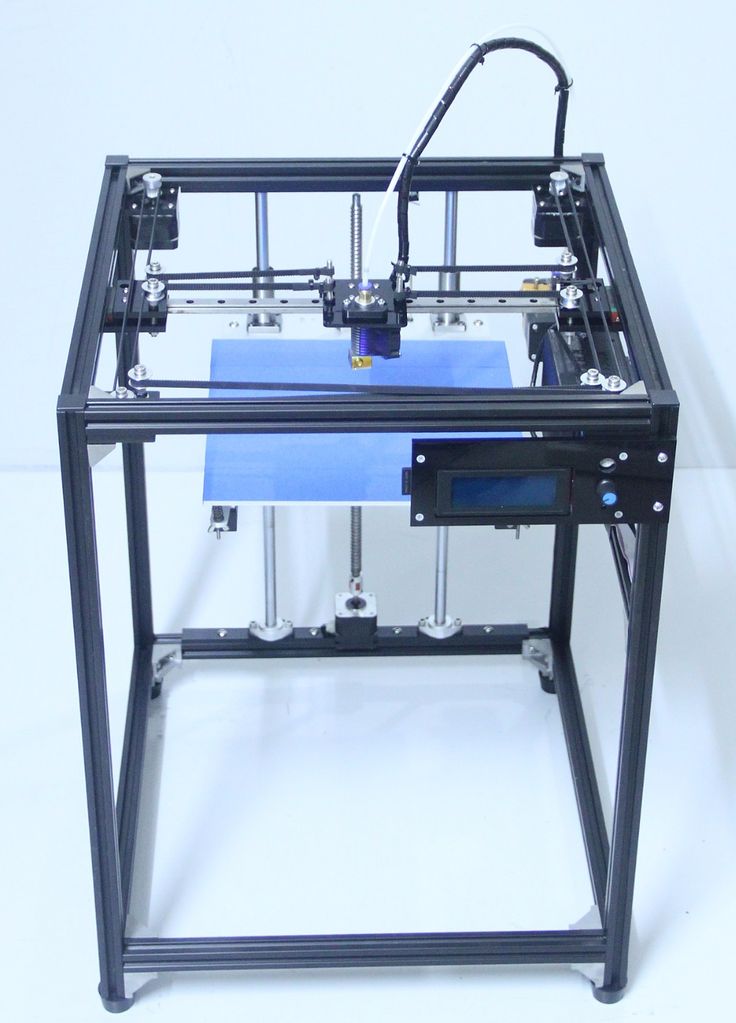

Personal

An edge class of printers that is home but also the lower rung of industrial business printers. These devices have much in common with their consumer-grade brothers, but have the higher quality and precision of printing that is inherent in professional 3D printing systems. The appearance of such printers is rather a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have offered reduced models of professional systems with performance close to them.

The appearance of such printers is rather a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have offered reduced models of professional systems with performance close to them.

Operating printers of this class is just as simple and boils down to loading an image and pressing the start button. At the same time, this limits the possibilities in terms of various advanced printing options.

Suitable for use in offices, however, the noise and high temperature conditions of some models require their placement at some distance from the working area. The ease of cleaning output objects was not carried over to this class from industrial models, so it would be logical to place them in a separate workspace.

Price range: $7,000 - $40,000

Target audience:

Small business with a small budget but need to use 3D printing occasionally. It can be engineering companies, design studios, marketing agencies.

Professional

Systems in this class no longer look compact, but rather look like large refrigerators. This is the basis of 3D printing technology, which includes all the achievements and possibilities available to the industry. The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of this class.

Unlike their small brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you cannot do without an operator.

In terms of the workspace, everything is not so simple here either. They are very large and noisy, so they require a separate room with good ventilation. Space requirements vary, but the space should be something like a laboratory and have a high-voltage line connected.

As a result, we get a universal 3D printing machine that provides the highest print quality and increased product sizes compared to the lower grades. ShapeWays, for example, collects several objects per print cycle, placing them at some distance from each other, which ultimately has a positive effect on the speed of order processing.

Price range: $30,000 - $750,000

Target audience:

Companies that have a constant need for prototyping, modeling, manufacturing of various kinds of objects with high quality and accuracy.

Production

The name of the class speaks for itself. These machines combine the precision and quality of professional printers, large print area, high level of automation and process control. On them, as well as on professional installations, it is possible to print not only prototypes, but also the final consumer product.

Systems of this kind are not intended for ordinary users, and the amounts that will have to be invested in such production will make you logically want to hire an experienced operator who will make the whole mechanism work 24 hours a day without downtime.

Small spaces are no longer enough. Here you need to clearly plan the future line and take care of the supply of the high-voltage line and gas pipe.

The result is a high-tech production that can quickly change the profile and use materials from ABS plastic to titanium.

Price range: $300,000 - $1,000,000

Target audience:

Companies with a need to produce high-precision large-sized products, or companies with a need to produce a large number of smaller volume items with high accuracy and high level quality.

Summing up, I would like to add that despite the fact that the threshold for entering this industry is still very high, the future belongs to such systems. Within the event horizon, we will be able to see a real revolution, at least in high-tech manufacturing. General Electric was one of the first to realize this and has already begun to produce complex titanium parts for aircraft engines using 3D printers.

As Albert Einstein said:

It's very simple. All people think that this is impossible. But there is one daredevil who does not agree with this ...

All people think that this is impossible. But there is one daredevil who does not agree with this ...

Top 10 biggest 3D printers in the world

Share on Facebook Share on Twitter Share on Vkontakte

Have you ever wondered how big 3D printers can be? If this has happened to you, then it's time to satisfy your curiosity, we will tell you about 10 largest 3D printers in the world. The selection criterion was the size of the object that can be created in the camera (or workspace) 3D printer .

At the end of the article you will find a slider with examples of the work of 3D printers included in this top ten.

So, let's start with the smallest large printer in our top ten.

10. Norsk Titanium

This 3D printer was created by the American company "Fabrisonic" . The technology by which it works is direct metal deposition. The size of the 3D printed parts is 120 x 120 x 180 cm. Although the maximum length of the product can be up to 215 cm according to the company.

Although the maximum length of the product can be up to 215 cm according to the company.

9. ExOne Exerial

This is Dual Chamber 3D Printer, each chamber measures 220 x 120 x 70 cm, can use metal, ceramic and sand as material, the latter is used to create sand cores and molds .

8. Voxeljet VX4000

The chamber measures 4 x 2 x 1 m and is currently the largest industrial machine, mainly used for making sand molds.

7. D-shape

The working surface of this 3D printer is a 6 x 6 meter aluminum frame. To create three-dimensional objects, a special sand material is applied layer by layer, the layers are fixed with a special binder.

The printer was patented in 2006 by Enrico Dini, founder of the British company "Monolite UK Ltd" . The first model of the printer used epoxy resin as a binder, but Dini later switched to using a magnesium-containing substance. After making this change, he again patented 3D printer in 2008. In the future, Dini wants to use the 3D printer to create full scale buildings.

In the future, Dini wants to use the 3D printer to create full scale buildings.

6. Sciaky EBAM 300

The working chamber size of this 3D printer is 7.620 x 2.743 x 3.353 m. The electron beam melts the metal, which is fed in the form of a wire, and a three-dimensional object is created layer by layer according to the CAD model. Sciaky EBAM 300 works with metals such as titanium, titanium alloys, inconel 718 and 625, tantalum, niobium, stainless steel, aluminum alloy 2319 and 4043, steel 4340, zircalla and others.

5. KamerMaker

This printer was one of the very first large scale 3D printers, it uses fusing technology. With his help, the first 3D printed house was built on one of the canals of Amsterdam. The sizes of printed objects reach dimensions of 2 x 2 x 3.5 m, bioplastics and bioplastics are used as materials. This is an open public project that anyone can join.

4.

WASP GigaDelta

WASP GigaDelta This 3D printer can grow objects up to 8-10 meters high. The creator of this machine, Massimo Moretti, dreamed of building houses using clay as a material and with minimal energy consumption. Now the company is developing a printer with a special extruder. After the work is completed, it will be possible to create objects up to 12 meters high.

3. Cincinnati Incorporated's BAAMCI

Workspace is 25 cubic meters.

This huge thermoplastic machine was created to print the "Strati" car for "Local Motors" , which was shown at an international technology event in Chicago in 2014. Now the creators of BAAM are working on the next, even larger version of the machine, its name will be "Bertha" .

2. BetAbram P1

Working space 288 cubic meters.

Slovenian company BetAbram manufactures (on request) 3D printers in three sizes for house printing. The largest of them has a span of 9 x 16 m (the average is 12 x 6 m, and the smallest is 4 x 3 m).