Flexible plastic for 3d printer

Ultimate Materials Guide - 3D Printing Flexible Filament

Overview

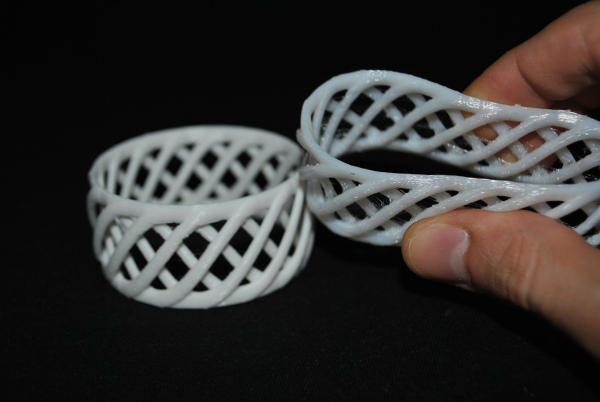

Flexible filaments are made of Thermoplastic Elastomers (TPE) which are a blend of hard plastic and rubber. As the name suggests, this material is elastic in nature allowing the plastic to be stretched and flexed easily. There are several types of TPE, with Thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. In many cases, these terms are used interchangeably, along with popular brand names such as Ninjaflex. The degree of elasticity in the plastic depends on the type of TPE and the chemical formulation used by the manufacturer. For example, some filaments can be partially flexible like a car tire but others can be elastic and fully flexible like a rubber band. This guide will cover tips to help you with both of these variations of flexible filaments.

- Flexible and soft

- Excellent vibration dampening

- Long shelf life

- Good impact resistance

- Difficult to print

- Poor bridging characteristics

- Possibility of blobs and stringing

- May not work well on Bowden extruders

Hardware Requirements

Before 3D printing with flexible filaments, make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure Not Required

Build Surface

PEI

Painter’s Tape

Extruder

Temperature: 225-245 °C

Direct Drive Extruder Recommended

Cooling

Part Cooling Fan Required

Best Practices

Flexible filaments come with many unique challenges that you want to be aware of. These tips will help you reduce the chances of common 3D printing issues such as clogging, kinking, and stringing.

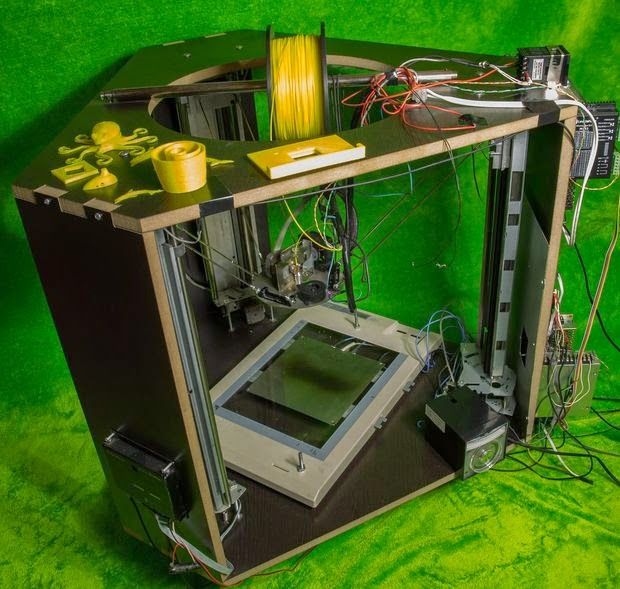

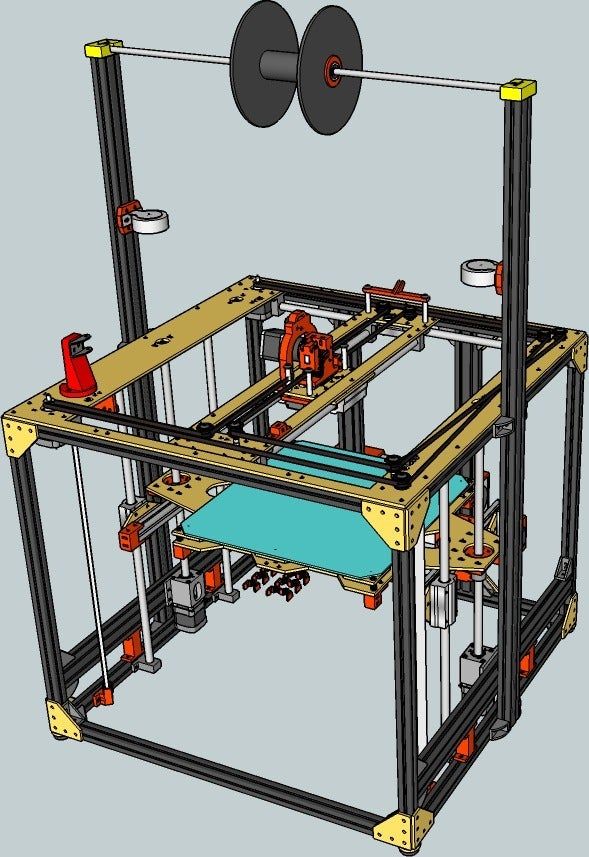

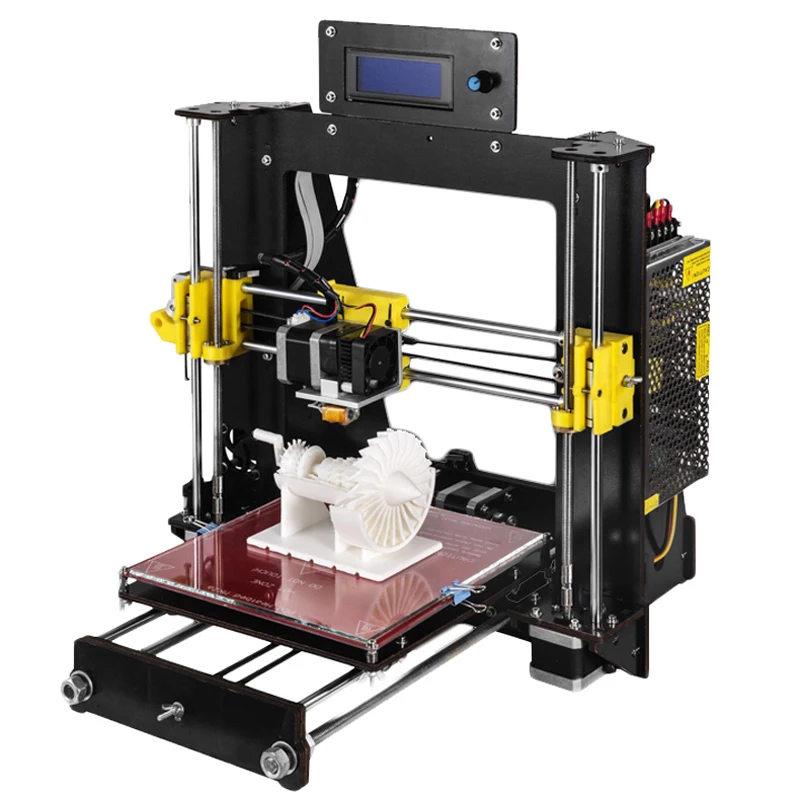

Use Direct Drive Extruders

While some partially flexible filaments work fine with Bowden Extruders, most fully flexible filaments require a Direct Drive extruder for best results. The distance between the drive gear and the melt zone of the hot-end needs to be as short as possible to efficiently feed the filament into the nozzle. Additionally, the pathway through which the filament travels into the melt zone should have tight tolerances to prevent the filament from kinking or coiling inside. For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

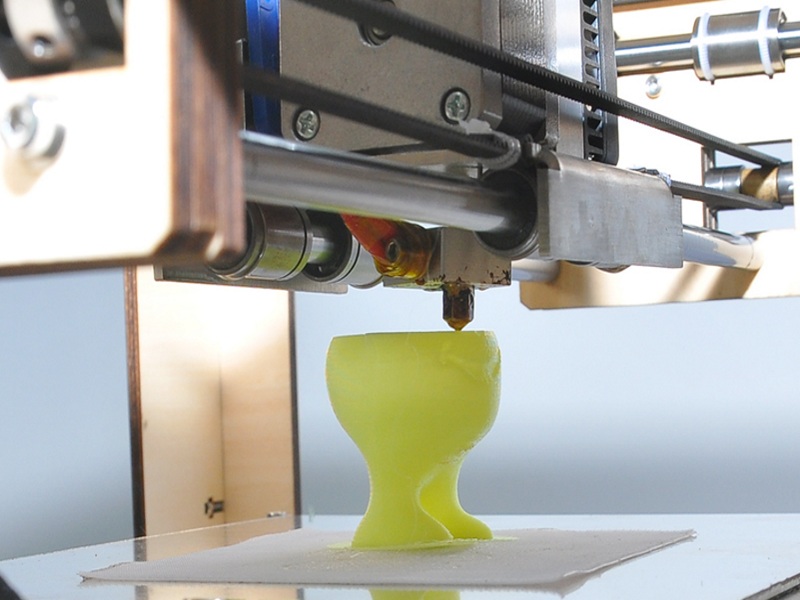

Use Slow and Consistent Feed Rates

Flexible filaments typically print best using a slow and consistent feed rate. Because the material is elastic, it can be very difficult to control sudden changes in the print speed. Higher print speeds can cause the filament to compress and will most likely result in a jam. Slow and steady is the best approach. Simplify3D provides all of your feed rate settings on the Speeds tab of your process settings so that you can easily configure these values. Finding the optimal print speed for your material can take several attempts based on trial and error. We have seen that speeds of 1200 mm/min (20 mm/s) can be a good starting point for most materials.

Reduce Resistance from the Filament Spool

A few tweaks to your material spool can also make a big difference with flexible materials. Typically, your extruder will pull the filament into the nozzle, forcing the filament spool mounted on your printer to unwind a bit of plastic in the process. However, because flexible materials are elastic, this will stretch the filament out as it is being pulled in and can actually result in under-extrusion. Try mounting the spool above your printer so that the filament unwinds in a downward direction which can reduce the resistance. It can also be incredibly helpful to mount the spool’s hub on a bearing to allow the spool to spin as freely as possible.

Tune Your Retraction Settings

The elastic nature of flexible filament makes it sensitive to quick movements such as retractions. In order to successfully print the filament, you will need to optimize your retraction settings to reduce these movements. While you are first starting with this material, we would recommend disabling retraction completely. You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

Optimize Your Travel Movements

Retractions can be particularly troublesome for flexible materials, so it is typically best to minimize the number of retractions required for your print. Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Pro-Tips

- Optimize the feed rate by printing at lower layer heights in the 0.1mm – 0.2mm range. The lower layer height requires less plastic, so it allows your extruder to use a lower feed-rate, relieving the burden on the filament.

- Try to avoid using rafts with flexible materials, as the base layers of the raft have higher extrusion rates which may create issues.

- If you are designing a flexible part that needs to fit on top of another object, try using a negative tolerance between the parts so that the flexible part will need to stretch to fit over the other object snugly.

Get Started with Flexible Filaments

Now that you’re ready to start printing with flexible materials, we have a few tips to help you get started. View some typical applications below, try out a few of our sample projects, or choose a popular filament brand to purchase for your next project.

Common Applications

- Vibration dampening

- Grip Sleeves

- Phone cases

Sample Projects

- RC Car Tire

- Phone case

- Bike Handle

Popular Brands

- NinjaTek Ninjaflex, Armadillo, Cheetah

- Polymaker PolyFlex

- eSun TPE

- Sainsmart Flexible TPU

Flexible Filament for 3D Printers

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

colorFabb Varioshore TPU Black 2 diameters- Variable hardness

- Active Foam Technology

- Reduced weight/density

-

Recreus 70A Filaflex Black Ultra-Soft 2 Model types- High adhesion

- No heating bed required

- Resistant to acetone, petrol and solvents

-

Recreus Filaflex Black 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Extrudr TPU Semi-soft - Black 2 diameters- Extreme layer adhesion

- Excellent impact and break resistance

- Hardness Shore A85

-

Extrudr TPU hard Black 2 diameters- Shore D58

- High temperature resistance

- Chemical resistance

-

3DJAKE TPU A95 Red 2 Model types- Made in the EU

- High flexibility

- Good layer adhesion

-

Extrudr TPU medium Black 2 diameters- Shore A98

- High temperature resistance

- Chemical resistance

-

Recreus Filaflex White 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex 60A Pro Nude 4 Model types- High flexibility

- Odourless and non-toxic

- Very good adhesion

-

Recreus Filaflex Gold 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Orange 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Red 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex 60A Pro Black 4 Model types- High flexibility

- Odourless and non-toxic

- Very good adhesion

-

3DJAKE TPU A95 Light Blue 2 Model types- Made in the EU

- High flexibility

- Good layer adhesion

-

Polymaker PolyFlex TPU95 Black 2 diameters- Easy application

- New range of application

- No heated building board required

-

Recreus Filaflex Fluor 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Transparent 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Aquamarine 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Yellow 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Recreus Filaflex Blue 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

3DJAKE TPU A95 Transparent 2 Model types- Made in the EU

- High flexibility

- Good layer adhesion

-

Extrudr TPU medium Neon Yellow 2 diameters- Shore A98

- High temperature resistance

- Chemical resistance

-

Recreus Filaflex Grey 4 Model types- Extremely elastic

- High adhesion to the printing bed

- Odourless

-

Fillamentum Flexfill TPU 98A Traffic White 2 diameters- Shore hardness 98A

- Flexible

All prices incl. VAT.

VAT.

Flexible TPU plastic for printing on a 3D printer in Moscow: 1.75 mm, weight 1 kg

Learn more

Only high-quality products

Learn more

Subscribe to newsletter

Be the first to know about discounts!

TPU plastic Description Parameters

for printing and

for post-processing Physical

mechanical characteristics

Material: TPU - thermoplastic polyurethane

Thermoplastic polyurethane (TPU) is a modern polymer material based on polyesters. The elasticity of printed products is the main property that determines the use of this plastic.

Press parameters:

Print temperature: 175-190 ° C

Table temperature: 50 ° C

Table cover: clean glass, glue BF-2, glue for 3D printing

speed speed prints: 15-20 mm/s.

Cooling: is recommended to be printed using efficient, annular airflow.

Density: 1.25 g/cm3

Features of TPU plastic and handling:

- Elasticity is the main property that determines the application.

- High resistance to deformation in both compression and tension.

- High strength, very soft. Shore hardness 75A

- No smell when printed.

- Excellent interlayer adhesion.

- The print speed is slow.

- Resistant to most solvents, fats, oils. Relative resistance to gasoline.

- Machining is very difficult due to the specific properties of the plastic.

- Wide operating temperature range.

- Bar accuracy ± 0.05 mm (reduced geometry tolerance).

- The FDM extruder head needs to be modified to eliminate gaps and cavities in the path of the bar from the feed gear to the hot zone of the print head. The use of bowden tube extruders is difficult due to the very low hardness of the material.

- Machining of TPU plastic products is difficult.

- Chemical treatment not applicable.

Thermoplastic polyurethane (TPU) is a unique material, one of the most sought after polymeric materials. Operational and chemical properties have provided this material with a wide distribution in all industries with high requirements for the quality of materials.

Thermoplastic polyurethane (TPU) combines wear resistance, lightness and elasticity, the ability to not change its color during its use. The material is resistant to low temperatures. rupture and aggressive environments, adheres well to the surface, restores shape when deformed, is able to perfectly resist punctures, has slip resistance.

TPU plastic is the first flexible, Flex-plastic in the line of plastics produced by the Moscow FDplast plant. Possessing excellent structural and technological properties, thermoplastic polyurethane is used in various industries, ranging from winding power cables, use in the development of the design of the bottom of shoes, the manufacture of protective accessories for electronic devices, and ending with a decorative overlay in the car interior.

Information on the properties of plastics and printing requirements can be found in the booklet "Flex for 3D printing FDplast".

Plastic storage

3D printing plastic must be stored in a dry place. Moisture and dampness greatly affect the filament, as a result, the plastic deteriorates, it becomes impossible to print from such plastic. There are no problems with the storage of plastic, it is practically not affected by the normal humidity of the ambient air. However, in order to obtain an ideal printing result, it is advisable to store the filament in a dry place, with silica gel.

3D Printing Tips

More >>

Download

Presentation. Plastic for 3D printing FDplast

Booklet. Plastic for 3D printing FDplast

Do you need a pipe? Call us and we will help you!

Send an order to the Plant's e-mail and our managers will contact you as soon as possible!

Update form

Contacts

Moscow plant FDplast

Office in Moscow

Construction facilities

Types of plastic for 3D printer

Blog / Useful / Plastic types for 3D printer

09. 04.2021

04.2021

Content

- PLA

- 9005 ABS 9005 ABS

- ABS

- HIPS

- PVA

- PETG

- SBS

- Nylon

- Soft plastics

- Decorative plastics Engineering plastics Total2

- 0057

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good resistance to impact loads.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

-

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

-

Easily processed mechanically or chemically.

-

Allowed contact with food.

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled. -

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which surface quality is important?

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

Cons:

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

Cons:

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model in ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

Cons:

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Esun

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

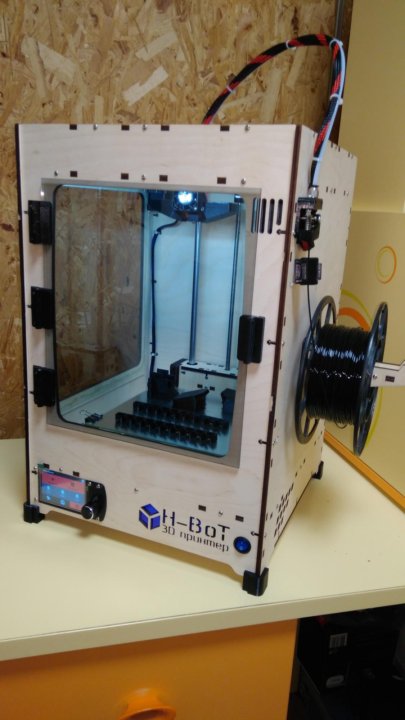

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

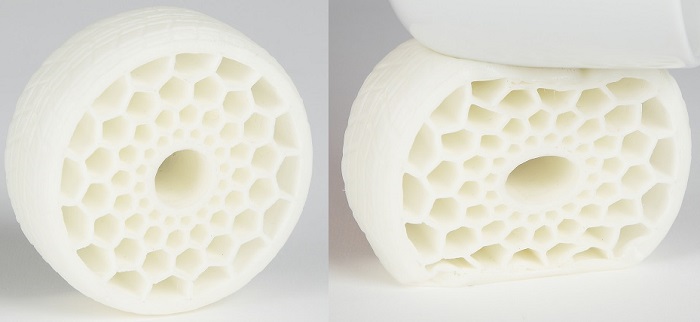

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional carbon fiber composite prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags.