Professional 3d printers comparison

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

More About Our Picks

Original Prusa Mini

4.5 Outstanding

Best Overall Budget 3D Printer

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

Pros

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

Cons

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

4.0 Excellent

Best Budget 3D Printer for Schools, Community Centers

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

Pros

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

Cons

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

4.0 Excellent

Best Budget 3D Printer for Children

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Pros

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

Cons

- Tiny build area

- Not ideal for importing 3D files created elsewhere

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

4. 0 Excellent

0 Excellent

Best Budget 3D Printer for Beginners, Non-Techies

Bottom Line:

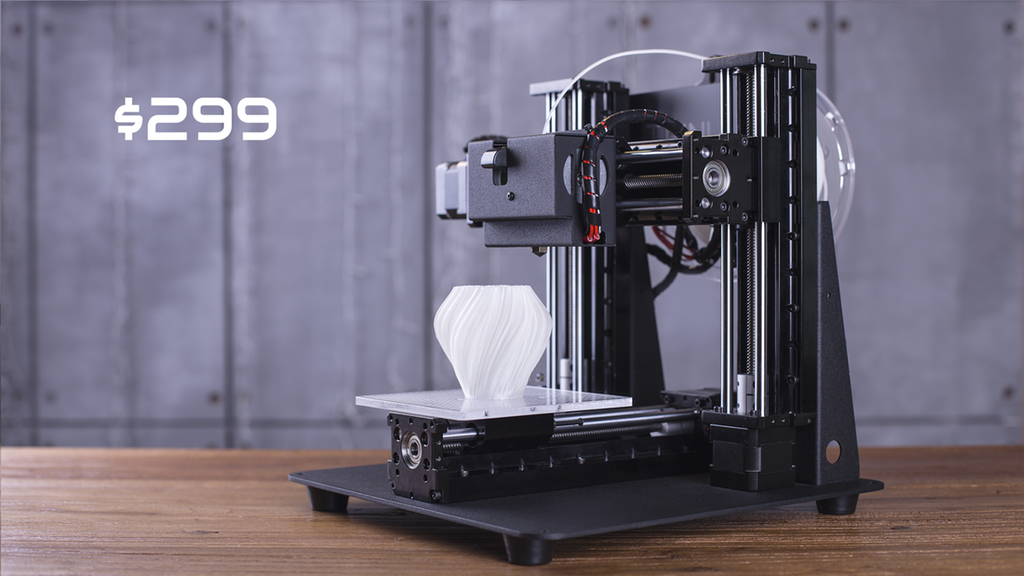

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

Pros

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

Cons

- Tiny build area

- So-so print quality

- Mere one-year warranty

Read Our Monoprice Mini Delta V2 3D Printer Review

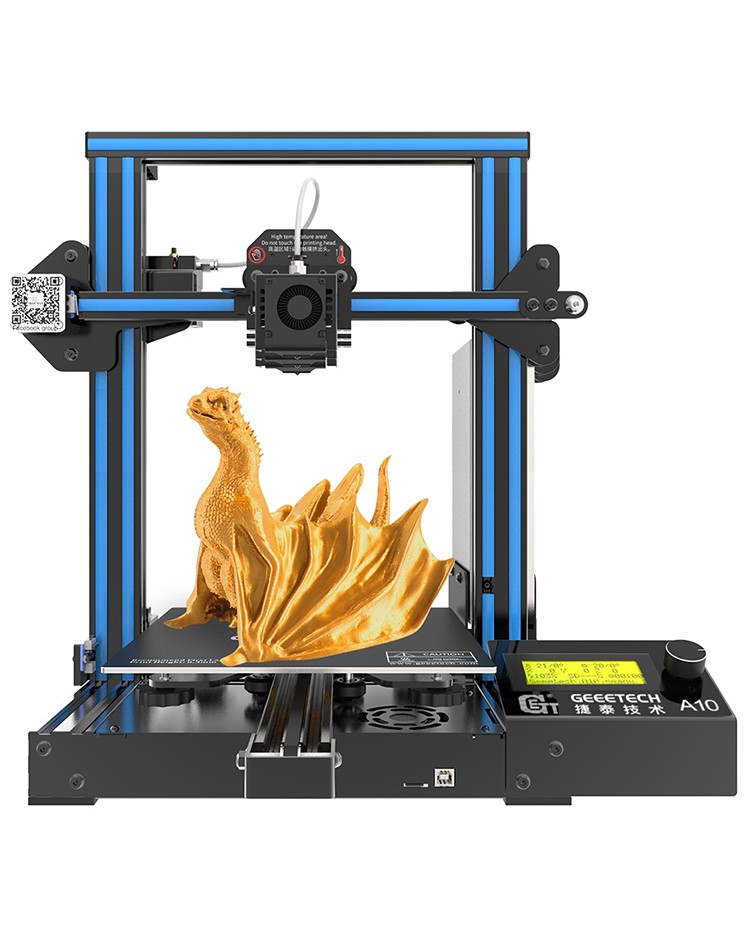

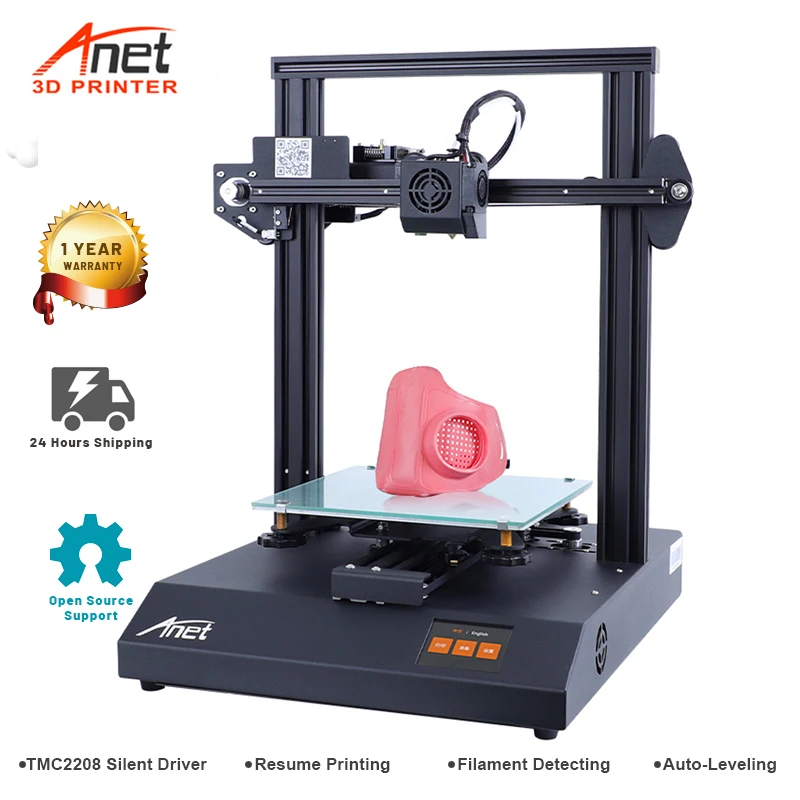

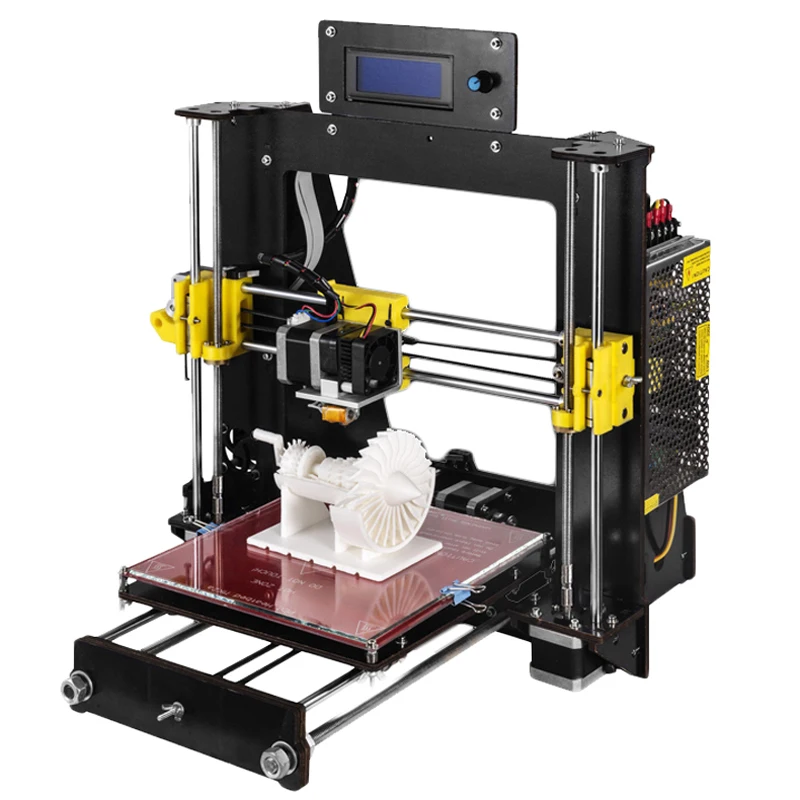

Anycubic i3 Mega S

3.5 Good

Best Budget 3D Printer With an Open Design, Big Build Area

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

Pros

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

Cons

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

Read Our Anycubic i3 Mega S Review

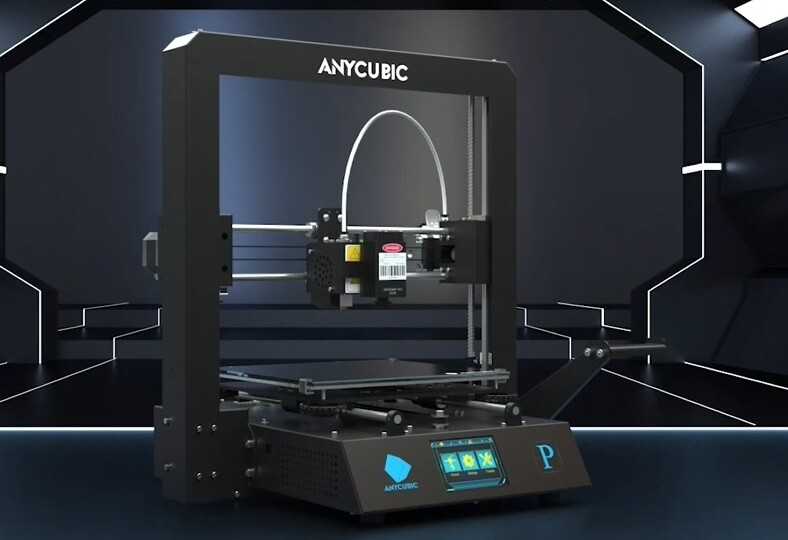

Anycubic Vyper

3.5 Good

Best Budget 3D Printer for the Biggest Build Area Possible

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

Pros

- Relatively large build area

- Automatic bed leveling

- Simple assembly

Cons

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

Read Our Anycubic Vyper Review

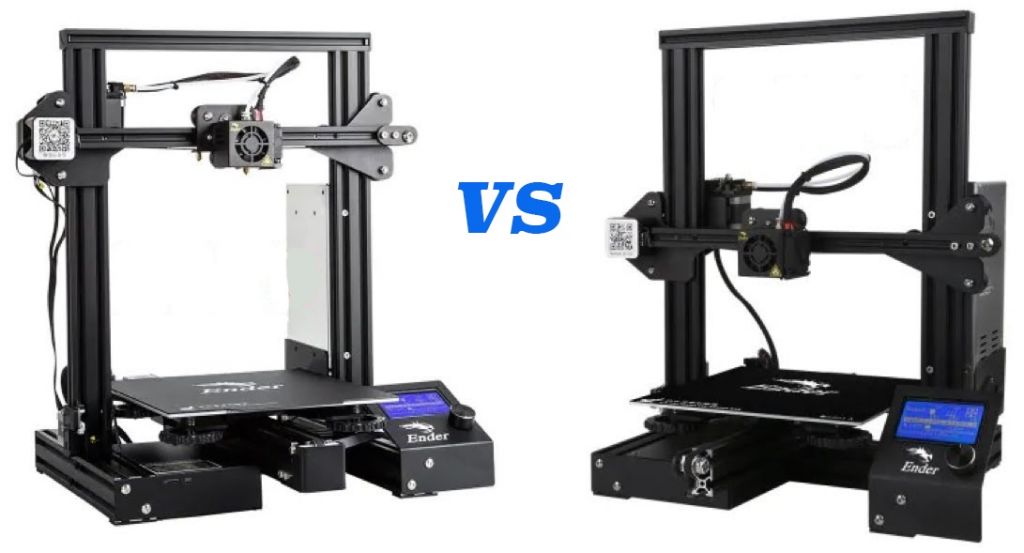

Creality Ender-3 V2

3. 5 Good

5 Good

Best Budget 3D Printer for Tinkerers and DIY Types

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

Pros

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

Cons

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

3.5 Good

Best 3D Printer for the Very Tightest Budgets

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

Pros

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

Cons

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

3.5 Good

Best Budget 3D Printer for Dabbling in Small Objects

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

Pros

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

Cons

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

3.5 Good

Best Budget 3D Printer With Closed Design, Roomy Build Area

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

Pros

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

Cons

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

3. 0 Average

0 Average

Best Budget 3D Printer for Cheap Filament

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

Pros

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

Cons

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

Read Our Monoprice Voxel 3D Printer Review

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together. ) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

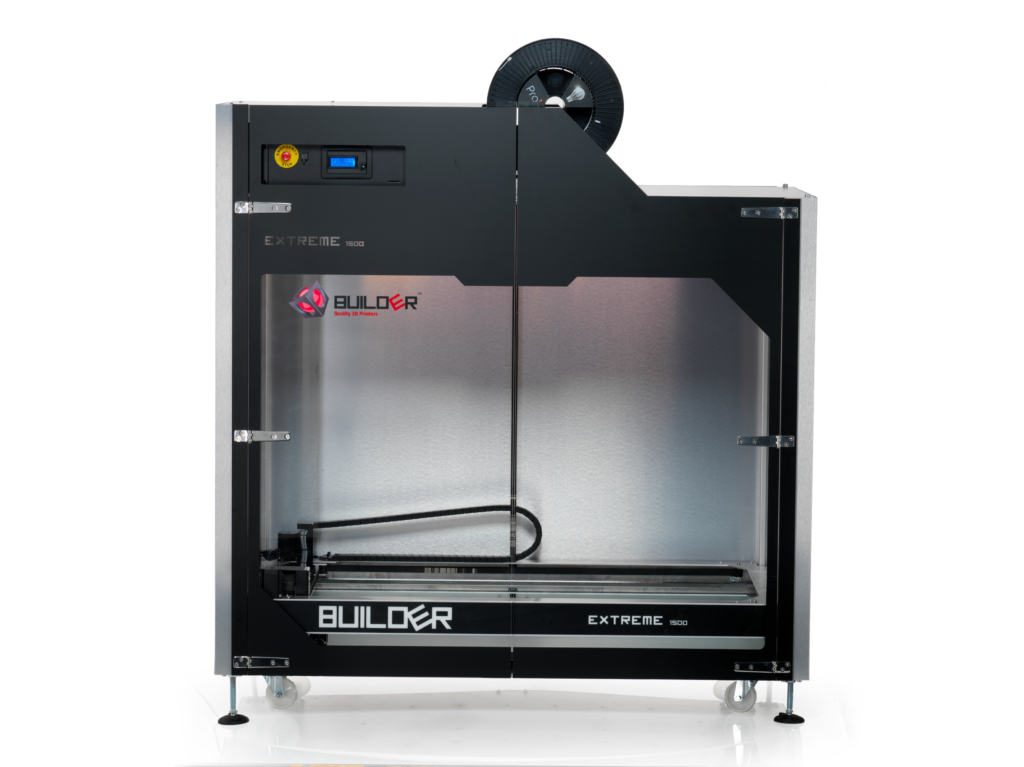

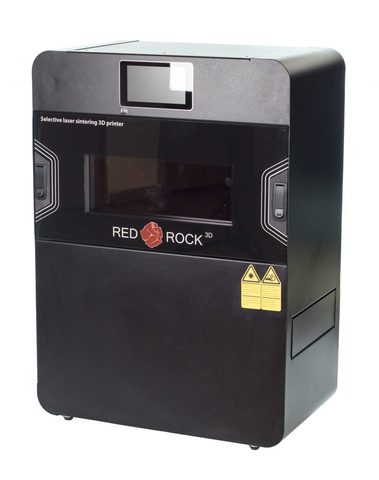

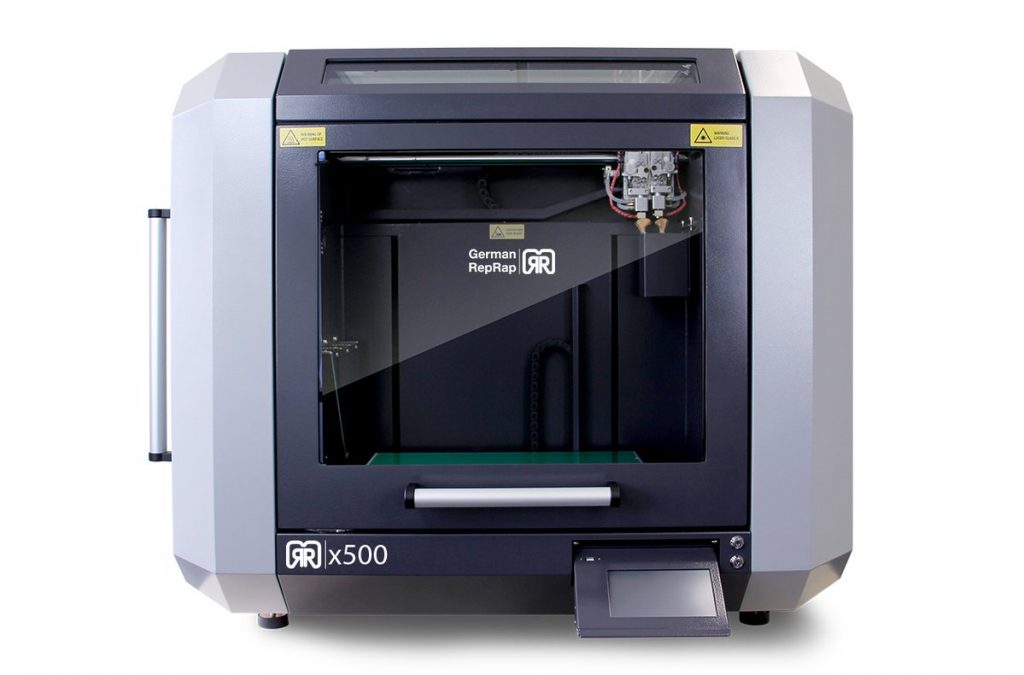

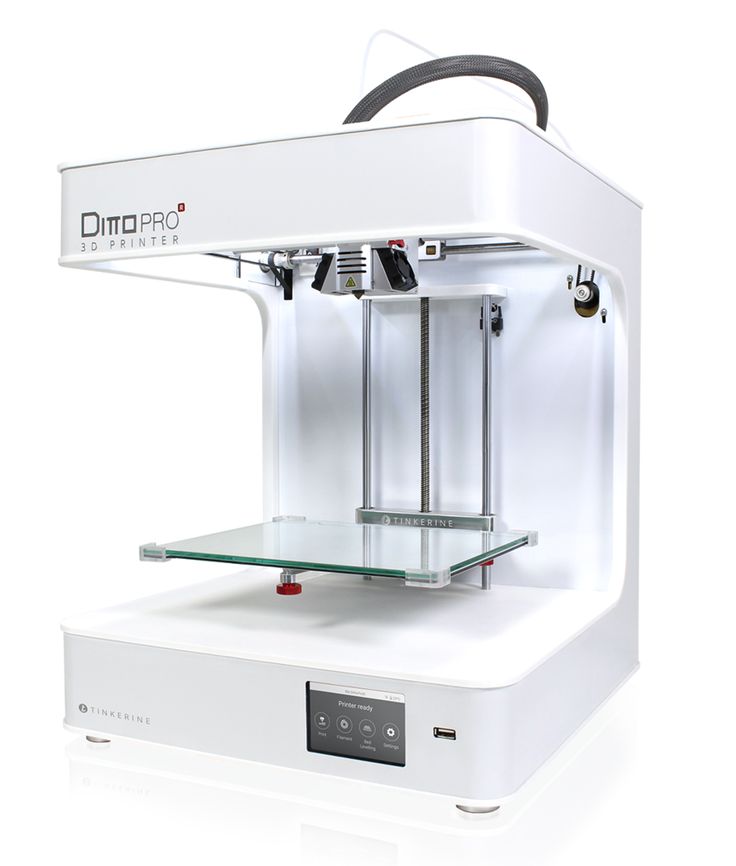

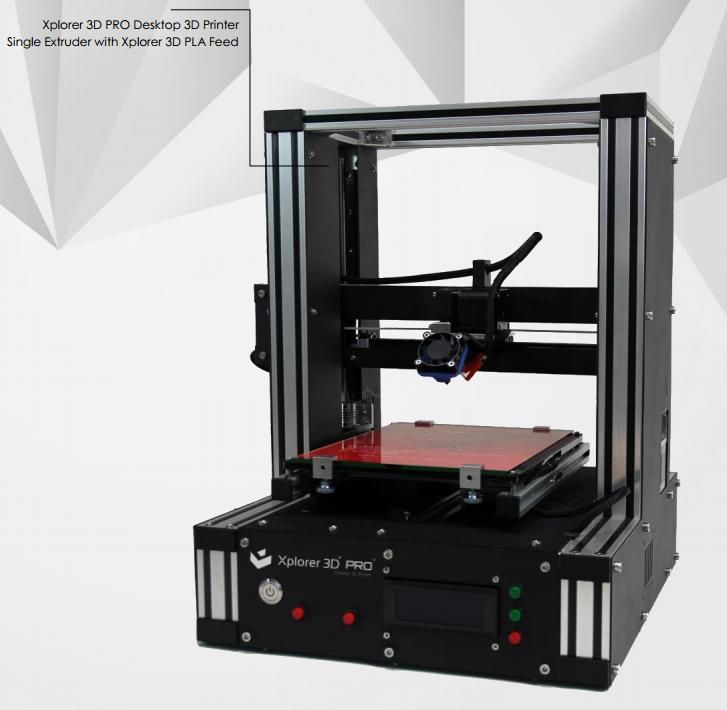

Should I Get an Open-Frame or Closed-Frame 3D Printer?

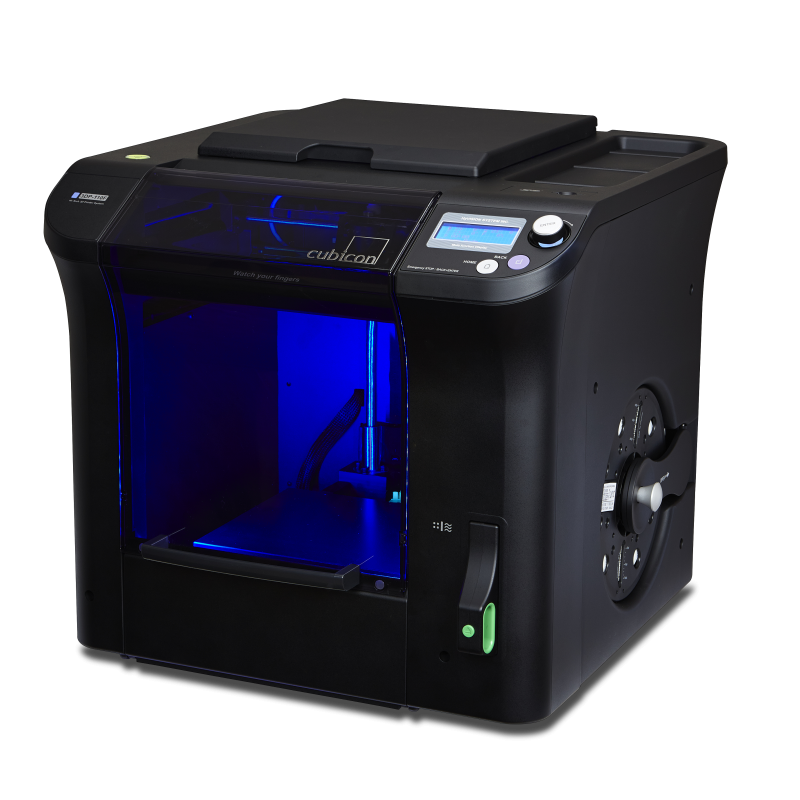

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

mix of features, performance, and price

What is the best professional desktop 3D printer?

There are so many different 3D printers on the market today that it can be a real challenge to choose one.![]() When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

To help you cut through the clutter, we made a shortlist of some of the best professional 3D printers available this year. These benchtop and desktop FFF (fused filament fabrication) 3D printers for professionals offer a great combination of features, performance, and reliability, and come from well-established brands. They are ideal tools for rapid prototyping and iterative design processes, and are also suitable for low-volume production series. Keep in mind, though, that while part quality does depend on your printer’s performance, it also greatly relies on your choice of materials.

Towards the end of this article, we also provide a brief buying guide where you can learn more about different 3D printer specifications such as printing temperatures, layer thickness, dual extrusion, and more.

Best benchtop 3D printers for professionals in 2022: our selection

The table below recaps our selection of some of the best professional 3D printing options for office use. Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | Czech Republic | $ 9991 027 €896 £146,656 ¥ | Buy |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16. 54 × 11.81 × 7.87 in 54 × 11.81 × 7.87 in | Spain | $ 3,9953 495 €3,584 £586,478 ¥ | Quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | Netherlands | $ 5,9955 495 €5,378 £880,084 ¥ | Quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | United States | $ 6,4996 682 €5,830 £954,073 ¥ | Quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | United States | $ 7,2496 249 €6,503 £1,064,175 ¥ | Quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | United States | $ 9,60010 000 €8,612 £1,409,309 ¥ | Quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | United States | $ 12,00011 000 €10,766 £1,761,636 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | 11.03 L | 300°C | Czech Republic | $ 9991 027 €896 £146,656 ¥ | Buy on Prusa |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16.54 × 11.81 × 7.87 in | 25.2 L | 300°C | Spain | $ 3,9953 495 €3,584 £586,478 ¥ | Get a quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | 23.76 L | 280°C | Netherlands | $ 5,9955 495 €5,378 £880,084 ¥ | Get a quote |

| MakerBot | Method X | 190 × 190 × 196 mm7. 48 × 7.48 × 7.72 in 48 × 7.48 × 7.72 in | 7.08 L | 260°C | United States | $ 6,4996 682 €5,830 £954,073 ¥ | Get a quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | 54.45 L | 300°C | United States | $ 7,2496 249 €6,503 £1,064,175 ¥ | Get a quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | 6.5 L | – | United States | $ 9,60010 000 €8,612 £1,409,309 ¥ | Get a quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | 16.39 L | – | United States | $ 12,00011 000 €10,766 £1,761,636 ¥ | Get a quote |

Overview of the best professional 3D printers in 2022

In this section, we give some more context and information about each pro 3D printer from our selection.

The Prusa Research Original Prusa i3 MK3S+ is a desktop 3D printer manufactured by Prusa Research, based in the Czech Republic. Prusa Research is a well-known brand created by Josef Prusa, inventor of the open-source Prusa i3 3D printer design.

Prusa 3D printers are highly reliable machines and can produce excellent parts right out of the box. Priced just under $1,000, the MK3S+ offers a very good price-to-performance ratio. With its open chassis and customizable “everything”, it’s a great option for those that like to get manual. Professionals who are looking for easy and low-maintenance operation may want to look at options in a higher price range.

Full review: Original Prusa i3 MK3S review

Buy on Prusa Add to comparison

The BCN3D Sigma D25 is a large desktop 3D printer for office use made by BCN3D Technologies. BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

The Sigma D25 pro 3D printer offers a relatively big build volume and boasts BCN3D’s IDEX technology. This means that there are two separate print heads that can both move independently to either print two identical objects at the same time or print in mirror mode.

Contact manufacturer Get a quote Add to comparison

The Ultimaker S5 is a professional desktop 3D printer made by Ultimaker, a manufacturer based in the Netherlands. Users may control their S5 from a distance thanks to the Ultimaker App and a Wi-Fi connection. There is also an onboard camera to monitor 3D prints from a distance. Furthermore, to maximize production efficiency, it is possible to group multiple S5 3D printers together with Cura Connect.

Today, the Ultimaker S5 is often referred to as the best professional 3D printer, especially when equipped with the Pro Bundle. The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc. ), and an “air manager” that closes up the build area and filters particles.

), and an “air manager” that closes up the build area and filters particles.

Contact manufacturer Get a quote Add to comparison

The Method X is a professional benchtop 3D printer produced by MakerBot (a Stratasys-owned brand). It was designed to 3D print ABS filament reliably and efficiently, thanks to a number of features– including a 100°C heated build chamber– than enable comprehensive environmental control.

Makerbot’s Method X is equipped with a 5-inch touchscreen with real-time feedback and status on print jobs, and offers automatic calibration. This pro 3D printer also boasts “SmartAssist Material Loading”, for fast and easy filament changing. Users can log in to the manufacturer’s proprietary CloudPrint software to monitor prints remotely at any time.

Contact manufacturer Get a quote Add to comparison

The Markforged Onyx Pro is a professional desktop 3D printer made by Markforged, a manufacturer based in Somerville, Massachusetts (USA). With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

The main available materials for the Onyx Pro are Onyx (a carbon fiber filled nylon) and Precise PLA. Markforged advertises parts up to ten times stronger than non-reinforced plastic ones.

The MarkForged Onyx Pro is delivered with Markforged’s browser-based Eiger software, powerful and easy to use. Eiger allows precise control over the 3D printing process.

Contact manufacturer Get a quote Add to comparison

The Raise3D Pro3 Plus is a professional, industrial-grade 3D printer made by Raise3D, an ISO9001:2015 and ISO14001-certified manufacturer based in the US (California). Raise3D also has offices in the Netherlands (Rotterdam) and in China (Shanghai).

This 3D printer for office environments is a true workhorse, capable of printing for hours without any hiccups. It does an impressive job with complex overhangs and features an intuitive, user-friendly workflow. The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

Raise3D’s Pro3 series also includes the Pro3, featuring a smaller build volume. Both printers are a follow-up to the Pro2 Series.

Full review: Raise3D Pro3 Plus review

Contact manufacturer Get a quote Add to comparison

Stratasys is the Apple of the 3D printing industry. Their 3D printers, including the F120, are reliable machines with industrial-grade components and printing quality. However, Stratasys 3D printers generally only work with Stratasys materials and hardware. At the moment, less than a handful of filaments are available for the Stratasys F120.

The F120 is one of the most affordable FDM printers from Stratasys and is destined to be a desktop workhorse for professionals. Stratasys emphasizes on the printer’s ease of use, durability, and industrial quality.

Contact manufacturer Get a quote Add to comparison

Professional 3D printer buying guide

There are several features and specifications to take into account when choosing the best professional 3D printer for your needs.

Technology

For this professional desktop 3D printer selection, we focused on FFF (fused filament fabrication) 3D printers. They are ideal for creating both prototypes and end-use parts.

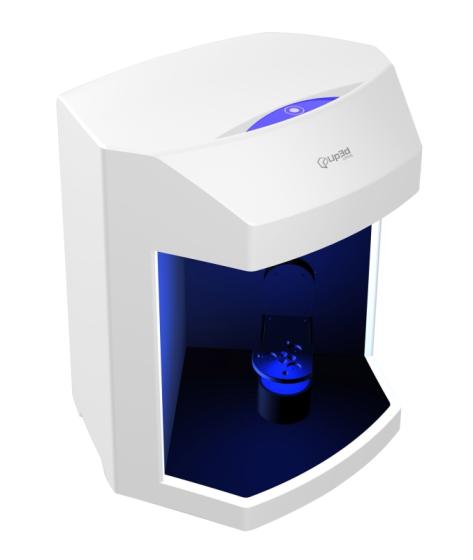

For professionals in dental or jewelry industries where high precision and detail are required, resin 3D printers are more adapted, with SLA, DLP, or LCD-based technologies.

There are also desktop SLS 3D printers (powder 3D printers), PEEK 3D printers, continuous fiber 3D printers, and more for advanced applications. Explore these topics with all of our other 3D printer guides.

Build plate or print bed

A heated print bed is mandatory for users that need to 3D print with ABS and other more demanding materials. The heat helps prevent warping and offers better first-layer adhesion.

While today’s 3D printers almost always feature heated build plates, they don’t all reach the same temperatures. It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

Some professional 3D printers have interchangeable build trays to help speed up the workflow, enabling users to quickly launch new prints while the previous build plate cools down. On higher-end 3D printers, there can even be vacuum systems for instant part release from the print bed.

Print head

PLA and ABS can be considered the most common and basic 3D printing materials in general. Professionals, however, often need to print more complex materials, such as Nylon, Polycarbonate, PETG, ASA, or other engineering-grade polymers.

They don’t all have the same melting or glass transition temperature and therefore have to be 3D printed at different temperatures. For example, PLA can be extruded at around 200°C, PC at around 260°C, and some high-performance materials like PEEK or PEKK need the extruder to reach at least 450°C.

Popular professional filaments also include plastics filled with carbon fiber or glass fiber for increased strength and resistance. These materials are abrasive and require tough nozzles; many professional printers are already compatible with these composites, but it’s important to make sure beforehand.

Some 3D printers are compatible with multiple types of nozzles with varying diameters, and even paste-type print heads exist to 3D print clay.

Automatic calibration

Most professional 3D printer systems are equipped with automatic calibration features to make the process as plug-n-play as possible. It’s important to recalibrate a 3D printer from time to time to ensure consistent print quality.

There are two main types of calibration:

- Print bed leveling (making sure the print bed is perfectly parallel to the nozzle, and not tilted)

- Nozzle offset (determining the right gap between the nozzle and the print bed)

Most 3D printers for professionals feature a probe attached to the print head to automate these processes instead of users having to use a piece of paper or business card.

Some 3D printers also have NFC readers to automatically adjust their temperature settings according to the detected material (so long as the spool is chipped, too).

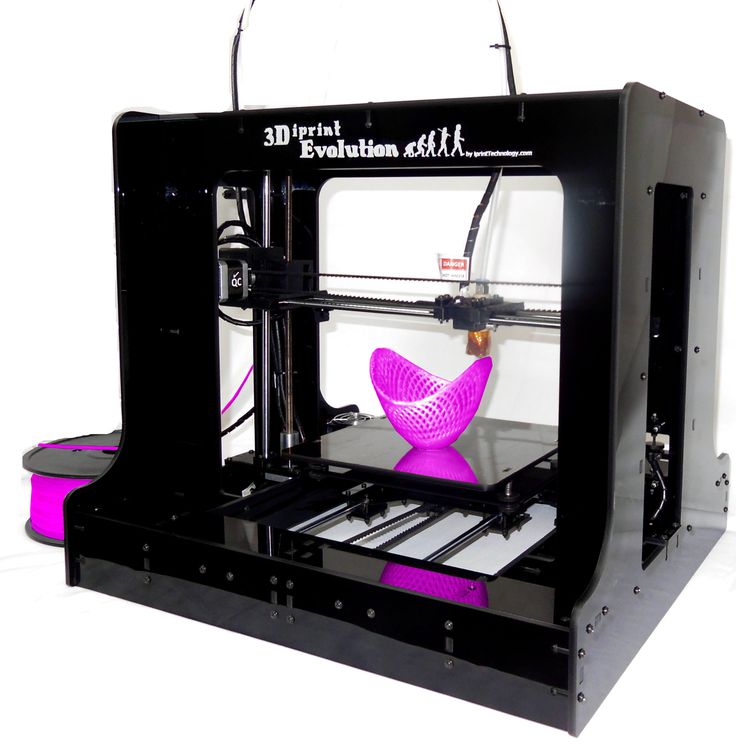

Dual extrusion and independent dual extrusion (IDEX)

A dual extruder enables users to 3D print with two different colors or materials simultaneously, including soluble support material for complex objects.

If there are two separate print heads, the system is referred to as IDEX (independent dual extruder). BCN3D Technologies was one of the first manufacturers to offer this feature a few years back.

In addition to being able to 3D print two materials at a time, independent dual extrusion offers different 3D printing possibilities:

- Duplication mode: 3D prints two identical objects at the same time.

- Mirror mode: to 3D print an object twice as fast as with just one extruder, each nozzle completes one-half of the object.

Onboard camera

Some 3D printers are equipped with an onboard camera that monitors prints remotely or saves time-lapse videos. This feature can be useful if the printer must be left unattended for long periods of time. We found it to be quite practical when we launched a long print for our Pro3 Plus review.

With the right 3D software, onboard cameras can help with quality control. Quality control can also be done during post-processing workflows with a metrology 3D scanner.

Minimum layer thickness

3D print quality is intricately linked to layer thickness, a.k.a. layer height or Z resolution. It’s the minimum height of each successive layer that forms the 3D printed object. The thinner the layers, the less they are distinguishable and the smoother the object will be (similar to the ratio of pixels in an image).

Thinner layers also mean that more layers are required to complete the object, which translates into more 3D print time. Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

The typical minimum layer thickness for mid-range FFF 3D printers is 100 microns or 0.1 millimeters, but it can go down to 0.01 mm in some cases.

A simple representation of layer height. Source: Primantes3DBuild volume

The build volume is the maximum size that your prints can be. If you need a bigger volume than what the 3D printers in this guide provide, you may be interested in these selections:

- L: Large volume 3D printers

- XL: Large format 3D printers

- XXL: Large scale 3D printers

Now, there are even large-sized resin 3D printers for those that need both volume and finer surface quality.

Closed frame

Many variables can interfere with 3D print quality, such as temperature changes and room drafts. Hence, 3D printers with an enclosed build chamber tend to provide better quality prints, in addition to reducing noise, odors, and– with a HEPA filter– harmful particle emissions.

A closed frame is almost mandatory when 3D printing with basically anything other than PLA. Today it is quite rare to see a professional 3D printer without an enclosure.

FAQ

Are 3D printers safe?

With basic precaution, 3D printers are relatively safe to use, although there has been some concern over harmful particle emissions from the melted filament. It’s best to use closed 3D printers with filters and to use 3D printers in well-ventilated areas. Users should also be careful not to burn themselves on a hot build plate or extruder; some 3D printers feature door safety sensors to lock the printer while it is printing.

Can 3D printers print metal? What 3D printers can print metal?

Yes, some FFF 3D printers are able to print metal-filled filaments. This is called metal FFF. Once the part has been 3D printed, however, it must undergo two processes called debinding and sintering. Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

What is the best 3D printer for jewelry?

For jewelry, resin 3D printers are more adapted than FFF 3D printers. They use SLA, DLP, or LCD-based technologies to produce objects with fine details and smooth surfaces.

Can 3D printers print in color?

Yes, some 3D printers can print in color. They are called full-color 3D printers and often use powder-based technologies. Systems that mix CMYK filaments exist, but cannot reproduce photorealistic colors like powder-based 3D printers.

8 nuances worth paying attention to

Sooner or later, everyone learns about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

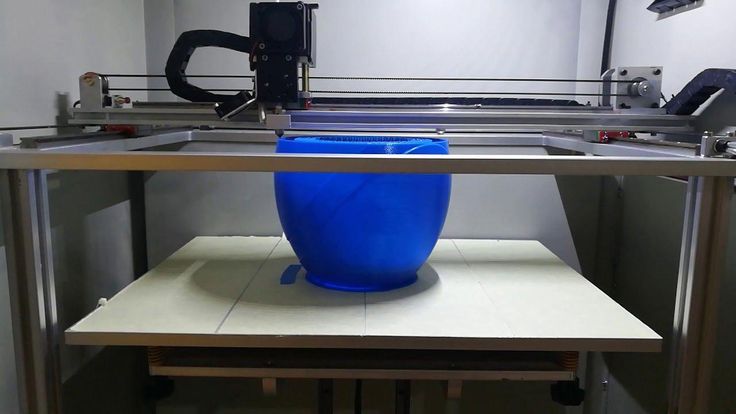

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends.

In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

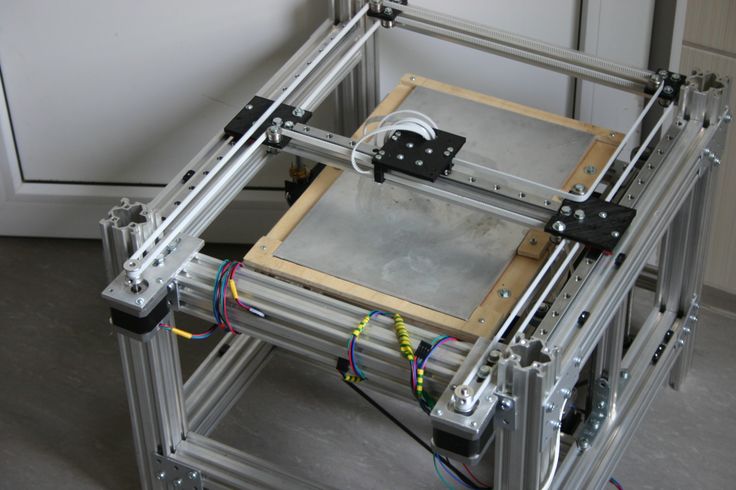

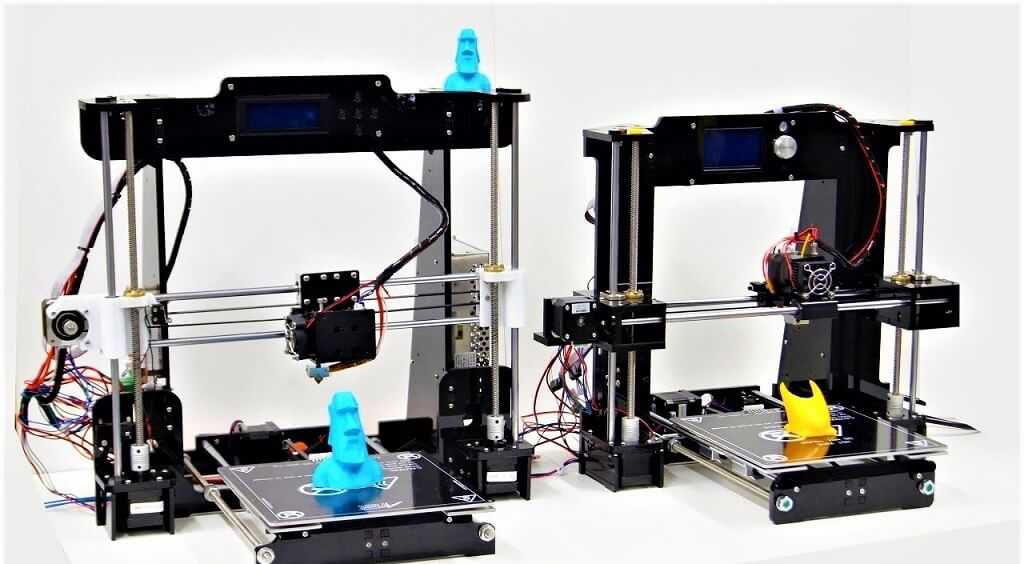

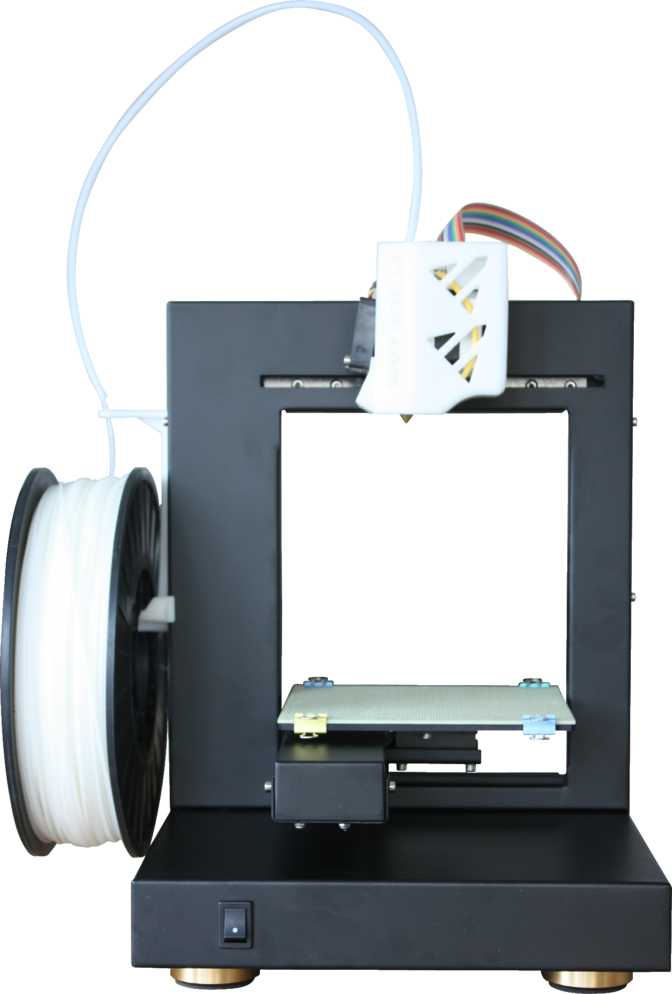

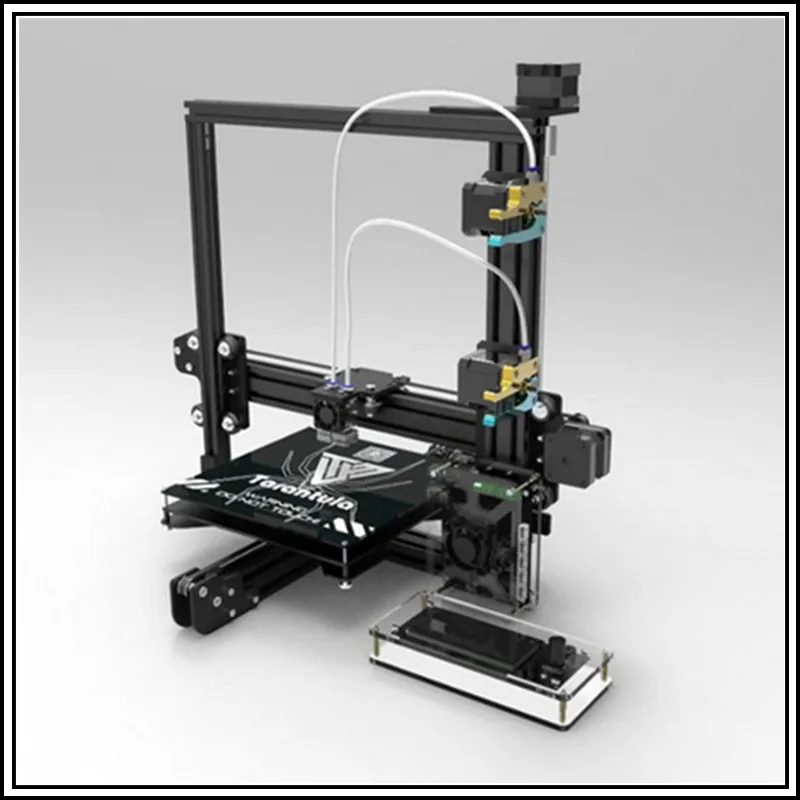

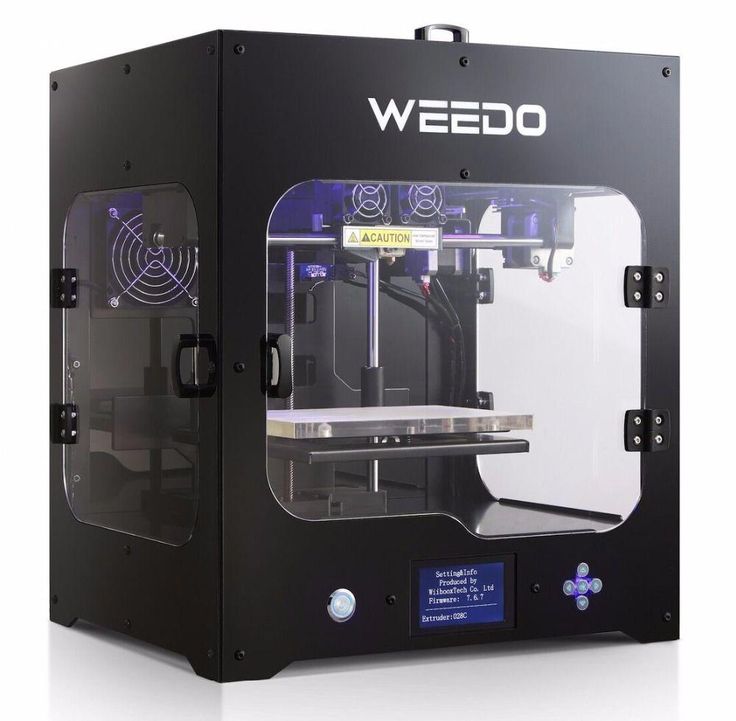

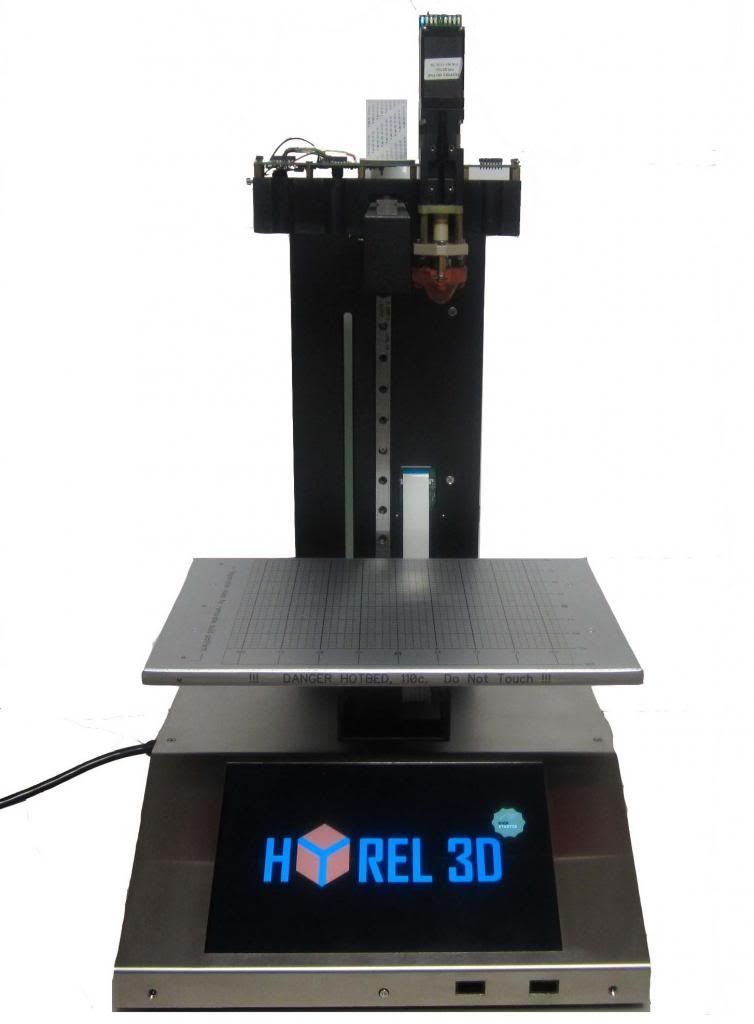

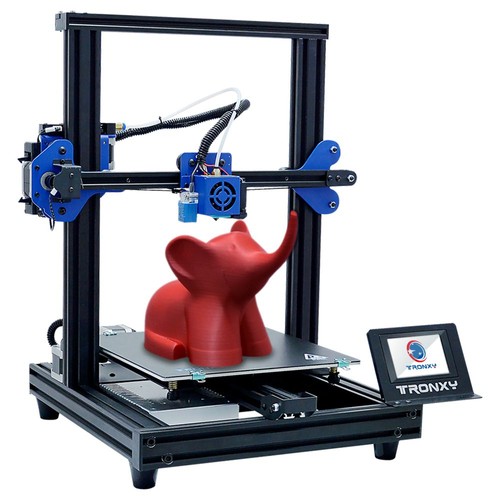

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0. 3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0. 1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: sales@3dtool. ru and our employees will be happy to give you a detailed consultation on any topic of interest.

ru and our employees will be happy to give you a detailed consultation on any topic of interest.

Creality Halot One Pro 3D printer review professional upgrade

3D printer for your attention!

The world is filled with more than just FDM printers, today we will talk about a photopolymer 3D printer.

In case you didn't know or forgot, photopolymer printers are those that grow models rather than print them. And such printers work with photopolymer liquid resins. Okay, enough theory.

You are on the official website of LIDER-3D and reading the review of Creality Halot One Pro 3D printer!

Content:

- On company

- unpacking, equipment and appearance

- Technical characteristics

- Data screen and transfer of data

- Software

- Video Vine

- Company business card LIDER-3D

About the company

I don't know if it's worth saying something about Creality once again, this Chinese company is a frequent guest of our reviews.

The company is large, well-known and has a good reputation. Creality develops 3D scanners, FDM and photopolymer 3D printers, laser engravers, and also produces all kinds of consumables. Creality provides a wide range of devices ranging from budget desktop solutions to large industrial devices.

Equipment and appearance

The Creality Halot One Pro 3D Printer is the latest update to the popular Halot One. Therefore, there are no big differences in terms of appearance. All the same recognizable design from Creality, a large control screen, a red protective cap with a logo. The connection ports are located on the front of the printer like the screen, the power cable is connected on the back.

As usual, the package includes (almost) everything you need to start your first print.

Print bed, resin bath, instruction manual, metal spatula, plastic spatula, necessary tools for plate mounting and alignment, USB stick with digital instructions and test objects, disposable resin filters, power cord.

The only thing I want to find fault with is that they didn't put gloves and masks on. Every photopolymer 3D printer should have gloves and masks, at least disposable ones.

Specifications

Remember Creality ILS lighting technology? Still here, still great. The 12 120 watt light sources are angled and use a system of mirrors to project light onto a screen. Illumination uniformity is excellent. We have already talked about this lighting system more than once and there are still no complaints about it.

Now let's look at what has been improved compared to the Halot One model. So, in the Pro version, the matrix has been increased. Now it is a 3K matrix, with a diagonal of 7.04 inches, and a resolution of 2400 × 2560 px.

The build area has also been enlarged, now the printer has a platform measuring 130×122×160 mm.

Otherwise, there are no differences, the same quad-core ARM Cortex M4 processor running Linux, the same mechanics, and other details.

Like all companies that respect their customers, Creality has taken care of security. Air filters are installed in Creality Halot One Pro, after all, the printer is photopolymer, which means that you are waiting for evaporation from the resin, but the filters will save you.

Control screen and data transfer

5 inch touch screen with user-friendly interface, fast response and print preview. Everything works, no complaints. The interface supports 14 languages, including Russian.

Data transfer is carried out both via USB and via WiFi. Moreover, the printer supports Creality Cloud, which can be accessed via a smartphone. Through the Creality Cloud App, you can even print remotely.

File transfer via WiFi works fine, it's very convenient not to run between the computer and the printer with a flash drive.

A selection of articles from the "Knowledge Base" section from the LIDER-3D website: 1) How and with what 3D printers print • 2) A guide to choosing plastic for 3D printing • 3) 3D printing using FDM technology: problems and their solutions.Part 1

Software

Creality offers its Halot Box slicer. And if you thought the same thing as us (oh no again branded slicer!) then you can be calm. No one at the company is going to limit your user experience, and Halot One Pro is supported by third-party popular slicers like Chitubox and Lychee. All programs are included on a flash drive.

But even the basic slicer is not bad in principle, of course it has room to grow, but it has all the basic and not only functions. It is worth working only on optimization, as is the case with the Creality Cloud App.

Examples

Video

9000 Crelyity did a good work on the excessiveness. Halot One was great and now we have a Pro version of it. Of course, there is no limit to perfection, and it was possible to cram more new features and chips, but then there would be a risk of spoiling what is already there.