3D printers for sale philippines

PH Guide to 3D Printer Prices

PH Guide to 3D Printer PricesGUIDES

3D Printing

3D Printing

3D Printing

3D Printing Technology became popular in the development world. This additive manufacturing is making huge impacts on various industries including healthcare, education, architecture, engineering, consumer products, and a lot more.

The demand for this technology is increasing. Hence, it is a great way to start your business or incorporate it into your operations. If you are planning to buy a 3D printer, you might want to dig deep down on what you should buy. There are a lot of available 3D printers in the market and one factor that you should consider is the 3D printer price.

This question depends on your specific needs. 3D printers may vary in cost. The prices of 3D printers may differ depending on their features, quality, size, and performance.

If you want to know which is the right 3D printer price for you, you need to answer these questions: What do you want to print? And, what is your budget? This is a great start to narrow down your choices and to have a better decision.

To make the right choice in buying the perfect 3D printer for you, we’ve broken down the categories of each level.

Beginners 3D Printer (Php 5,000 to 10,000)

This category is for the entry-level or novices who want to learn 3D printing. If you are at this level, it is a great way to purchase 3D printers at this price range before upgrading to a more expensive one. Mostly, items that are used to print in this level are toys since they are a great way to experiment.

If you are planning to buy an entry-level 3D printer you need to consider the limitations in it. These 3D printers can only print 3-4 dimensions and have material restrictions. PLAs are often used here.

Moreover, 3D printers on this range can be noisy, slow, and not durable compared to expensive ones. The print quality is also not that good. You might also need to manually assemble the machine. Despite that, it does the job of printing smaller objects and serves as a guide in starting with 3D printing. Below are the best 3D printers for beginners:

Below are the best 3D printers for beginners:

- Elegoo Mars at Php 7,450

- Creality Ender 3 - at Php 9,450

- Monoprice Select Mini 3D Printer v2 at Php 9,500

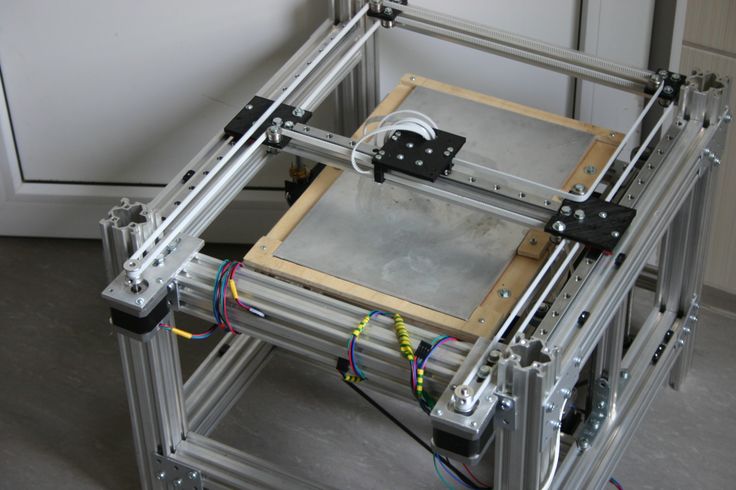

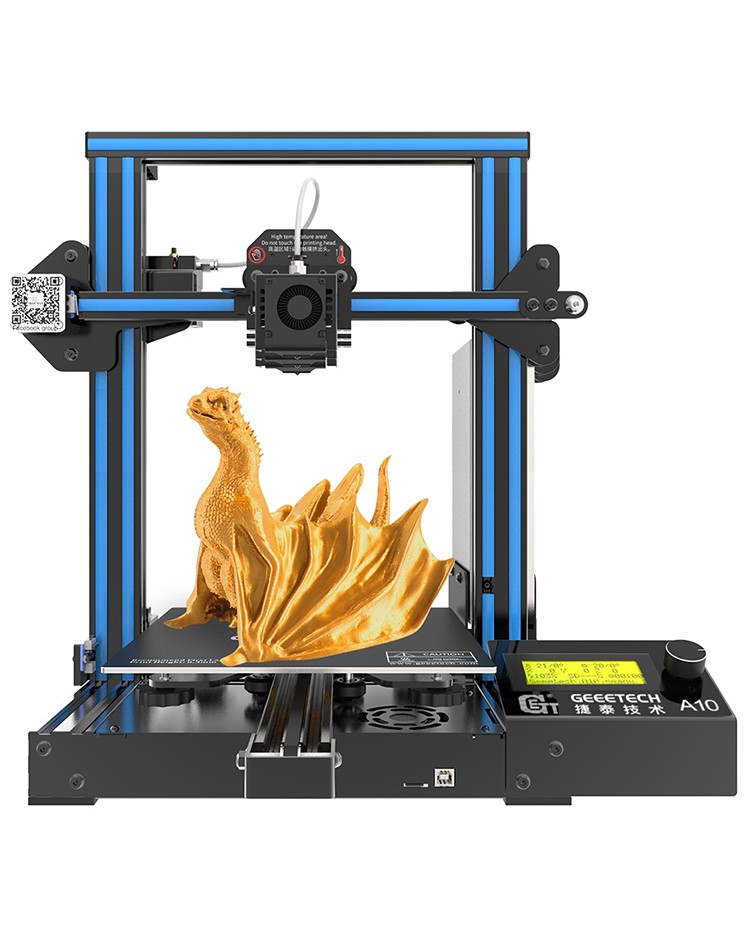

Hobbyist 3D Printer (Php 10,000 to 30,000)

3D printers in this category are for people who are already familiar with 3D printing. It is now clear to them that they want to continue their passion and be ready for more explorations.

Hobbyist 3D printers are capable of the job but often have a few flaws. Like the beginners 3D printer, this also needs to be assembled which can take you time. The printer capacity is larger and can make anything over 5-6 dimensions. They are much faster than entry-level 3D printers and you can have more choices of materials to use. Moreover, it has better software that’s capable of cleaning and auto-leveling.

The downside is, this printer does not run for significant time lengths. Meaning you have to do monitoring, repairs, and maintenance to keep it running. 3D printers in this category are only good for hobbyists or those seeking 3D printing pleasures. Check out these Hobbyist 3D Printers:

Meaning you have to do monitoring, repairs, and maintenance to keep it running. 3D printers in this category are only good for hobbyists or those seeking 3D printing pleasures. Check out these Hobbyist 3D Printers:

- QIDI Technology X-one2 Single Extruder 3D Printer at Php 12,450

- Creality Ender 3 V2 at Php 13,100

- Creality Ender 4 at Php 15,000

- Monoprice Voxel at Php 19,950

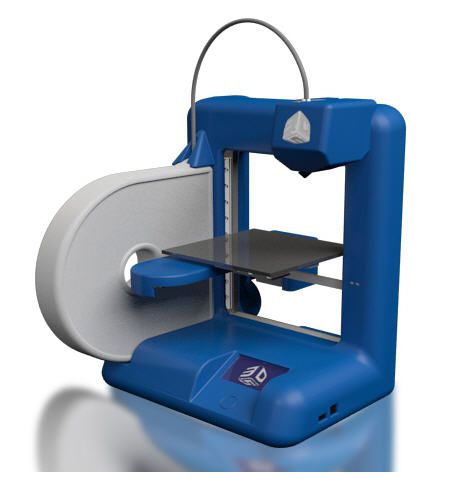

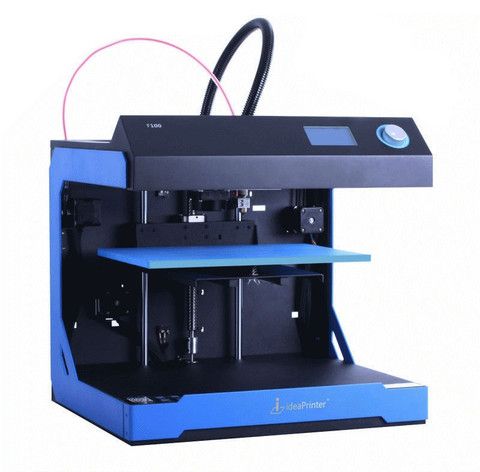

Enthusiast 3D Printer (Php 30,000 to 100,000)

This category is for mid-range applications. 3D printers for this category meet the needs of those 3D Printing Enthusiasts. They are sturdy and solid with friendly features. It can print as good as 8-12 dimensions.

Compared to the beginners and hobbyist category 3D printers, this is faster and quieter. You can also have more material selection but sometimes require branded filaments. This can be used in production but in a very low volume as it cannot hold extra time.

In addition, these are also prone to repairs and maintenance if running for too long. Small businesses are suitable for this category but should be prepared if it requires maintenance. Here are the best Enthusiasts 3D printers:

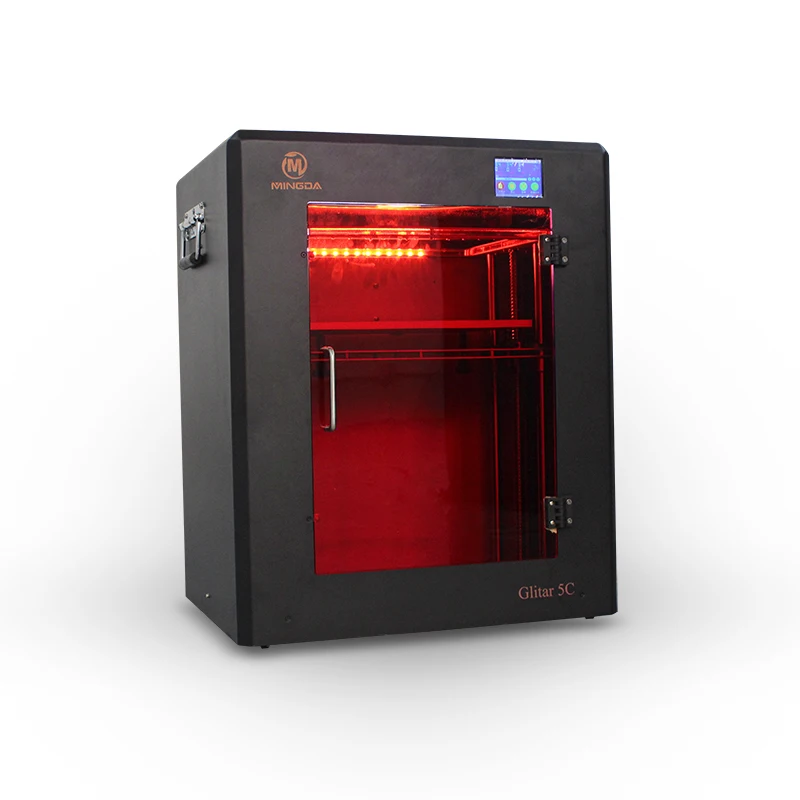

Professional 3D Printer (Php 100,000 to 400,000)

If 3D printing is for you and you have proper knowledge of it, you might want to buy professional or performance 3D printers. These printers have the greatest value among the other printers mentioned and are well-built and have high-quality parts. It can build bigger projects around 12 dimensions.

The 3D printing materials that can be used are expanded like ABS, Resins, Nylons, and Carbon Fibers with different textures and colors. The 3D printing machines in this category can print fast and still have good quality. These printers are more expensive and you have to make the right decision in choosing your model.

Printers in this category can be suitable for small to large businesses. See Professional 3D Printers here:

See Professional 3D Printers here:

- Raise3D E2 at Php 174,950

- Fusion3 F410 at 229,950

- Ultimaker S3 at Php 204,000

Industrial or Enterprise 3D Printer (Php 500,000 and up)

3D printers in the Industrial Category are for real and serious business. Above all the 3D printer categories, these 3D printers can print the fastest and have the highest quality. They are very durable and robust with great fabricated metal exteriors.

When it comes to interface, they are user-friendly and have the most features. To get all these leveled-up features, you will need to pay a significant amount of money. Not only for the 3D Printer but also the materials, filaments, and maintenance fee.

Before buying these big 3D printers, you should search for all the best options beforehand. While these printers are totally reliable, their prices are only suitable for large industries that can afford their large amount. Below are the best industrial printers:

Below are the best industrial printers:

- EnvisionTEC Perfactory P4K Series at Php 500,000

- Stratasys F120 at Php 600,000

- 3ntr A4 v4 at 750,000

Reliable 3D Printer Supplier in Manila, Philippines

If you are planning to buy good quality 3D printers, we can help you! MakerCarl has been in the 3D printing industry for years. Providing good quality 3D printers and 3D printing needs for all industries. Contact us to know more about our 3D printer prices.

Read more blogs on this topic

Practical Applications of 3D Printing in Medicine

Out of all the contributions of 3D printing, its applications in the medical industry are the most important. It helps doctors deliver better patient treatments.

Read More

PH Guide to 3D Printer Prices

3D Printing Technology became popular in the development world. This additive manufacturing is making huge impacts on various industries including healthcare, education, architecture, engineering, consumer products, and a lot more.

Read More

3D Printing in Automotive: A Metamorphosis Ahead

As it requires intensive labor, automobile manufacturing needed a change. Then comes, 3D printing paving the way for smarter additive manufacturing. Discover its benefits, applications, and real samples of 3D printed projects in this article.

Read More

10 Best 3D Printers in Philippines 2022

The market for 3D printers has been expanding rapidly over the past few years. It is not a question given their level of development and innovative specifications. In contrast to conventional printers, 3D printers produce physical objects from materials like plastic, metal, and wood from digital models.

You may design and print products for your workshop, office, and home, as well as construct entire objects and create replacement parts, all with the help of 3D printers. The best part is that it is generally accessible on the market so that anyone may get it.

Here are the top 3D printers to take into consideration, whether you're an expert or just starting started.

10 Best 3D Printers in the Philippines - Brands & Prices

Table of Contents

Best 3d Printer For Small Businesses

Anet ET4 PRO

What is a 3D Printer?

Additive manufacturing, also known as 3D printing, is the process of creating a three-dimensional object from a CAD model or digital 3D model. Materials can be combined, deposited, connected, or cemented using some computer-controlled procedures. For example, polymers, liquids, or powder grains can be fused, usually layer by layer.

The phrase "rapid prototyping" was more applicable at the time since 3D printing processes were seen as only being suited for the manufacture of functional or aesthetically pleasing prototypes. In 2019, 3D printing's accuracy, repeatability, and material variety have improved to the point that some 3D printing techniques are viewed as feasible as industrial production technologies. As a result, the terms 3D printing and additive manufacturing can be used interchangeably.

How Do 3D Printing Machines Work?

The additive manufacturing family includes 3D printers, which operate similarly to conventional inkjet printers but in three dimensions. To build a three-dimensional item from scratch, a mix of cutting-edge software, powder-like materials, and precise instruments is required.

Using 3D printing, a complete object is divided into thousands of minuscule slices, which are then assembled slice by slice. These minute layers adhere to one another to create a solid item. Due to the extremely complicated nature of each layer, 3D printers can include moving components like hinges and wheels into a single product.

How to Choose A 3D Printer?

Below is a rundown of the important tips to know in choosing a 3D printer.

Know what you want to print - The regularity of your printing, the location of the printed items, and the time commitment you're prepared to make should all be taken into account.

Identify your ideal 3D printer style - A printer known as a Fused Deposition Modeling (FDM) printer is utilized by many enthusiasts. To produce 3D-printed things, these printers expel heated materials and polymers, known as filament. Digital Light Processing (DLP), Stereolithography (SLA), and Selective Laser Sintering (SLS), which employs powder rather than resin, are some other printing techniques that use vats of liquid resin.

3D printer resolution - Microns are used to measure 3D printer resolution. The two most crucial elements for good printing are layer height and belt tension. Look for a printer with a higher micron count indicated in the specifications that is simple to modify.

Look for safety features - Generally speaking, 3D printers with safety features are well-designed. When you pause the job or the print is finished, some printers move the nozzle away from the object to prevent heat damage and excess filament from forming.

Look for high-quality features - Be on the lookout for items like heated glass beds, dual filament capability, and touchscreen user interfaces. A printer might be worth the expenditure based on something as simple as build volume or how much space you have to print.

Best Brands of 3D Printers here in the Philippines

With so wide variety of 3D printers on the market, you can surely take your time and choose the best one. When it comes to getting the best for your money, consider the quality features at a fair price The following 3D printer brands highlight the highest quality of the best 3D printer in the Philippines

Creality - Creality manufactures 3D printers that are reasonably priced and frequently have a huge print area. They created prints that were typically high quality and had incredible detail.

Anycubic - The AnyCubic has won over customers with the quality and use of their 3D printers. Their printer produced good prints for you, making it worth the cost.

Their printer produced good prints for you, making it worth the cost.

Elegoo - Elegoo has developed into a top supplier of many 3D printer solutions. The business works to make sure all of its products are of the highest caliber and have the best features that make 3D printing simple.

Kingroon - For the price, Kingroon produces an unquestionably good printer. They are sturdy and long-lasting, function admirably, and are ideal for everyone, whether a novice or an expert.

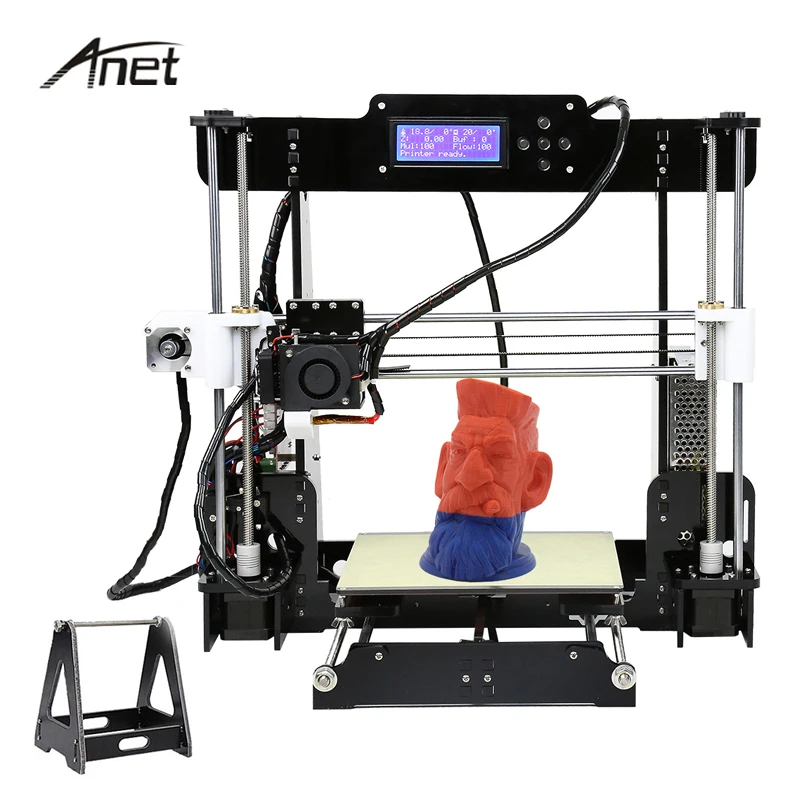

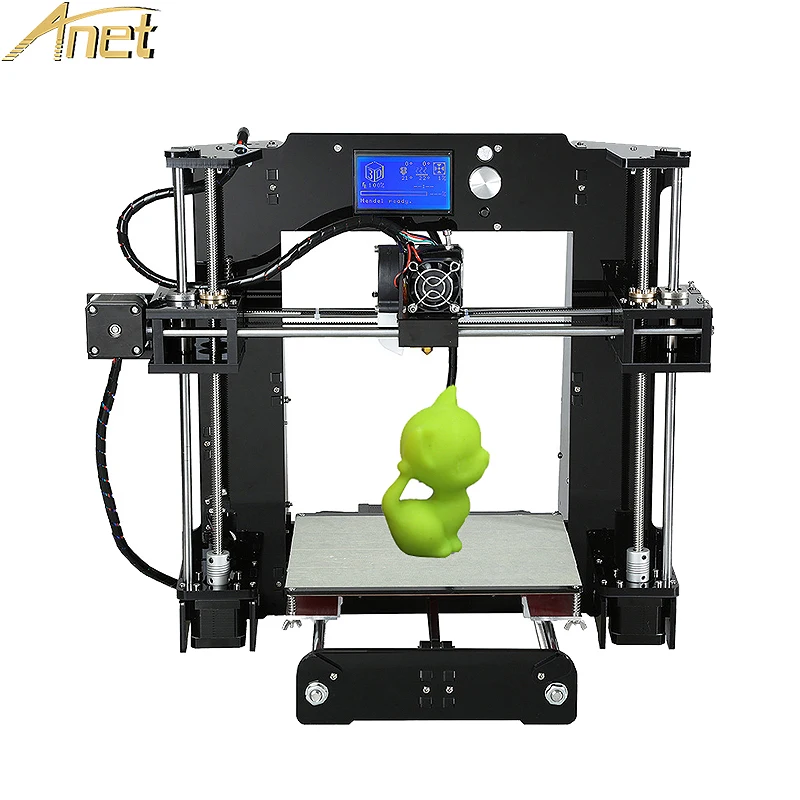

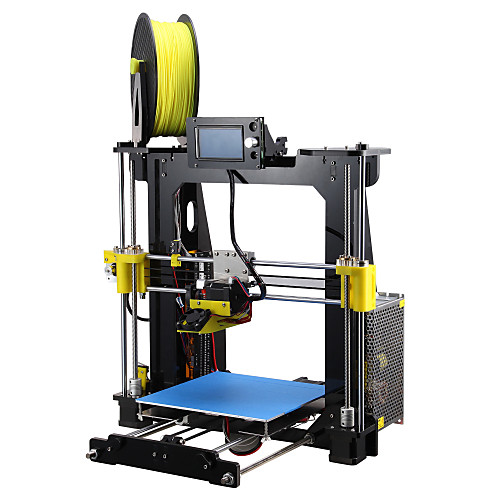

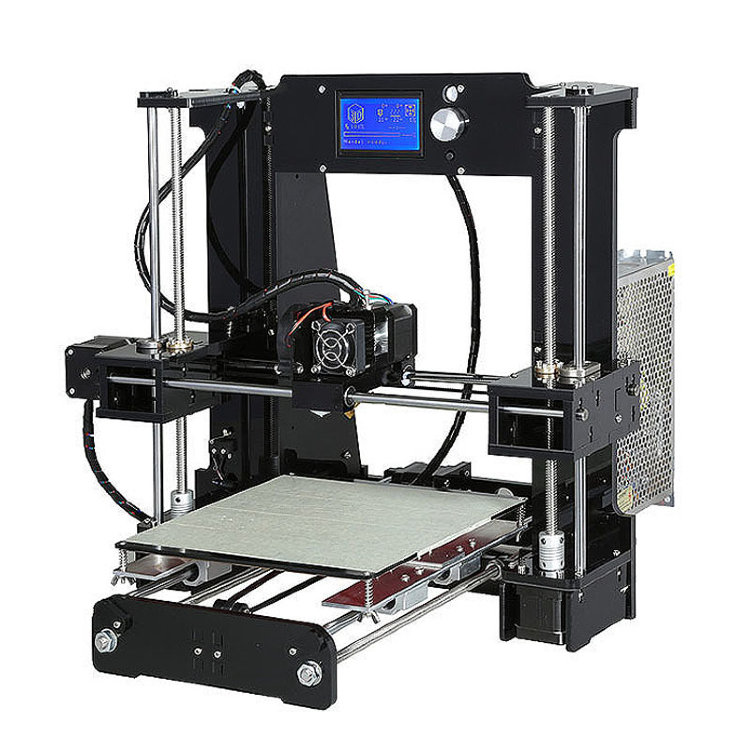

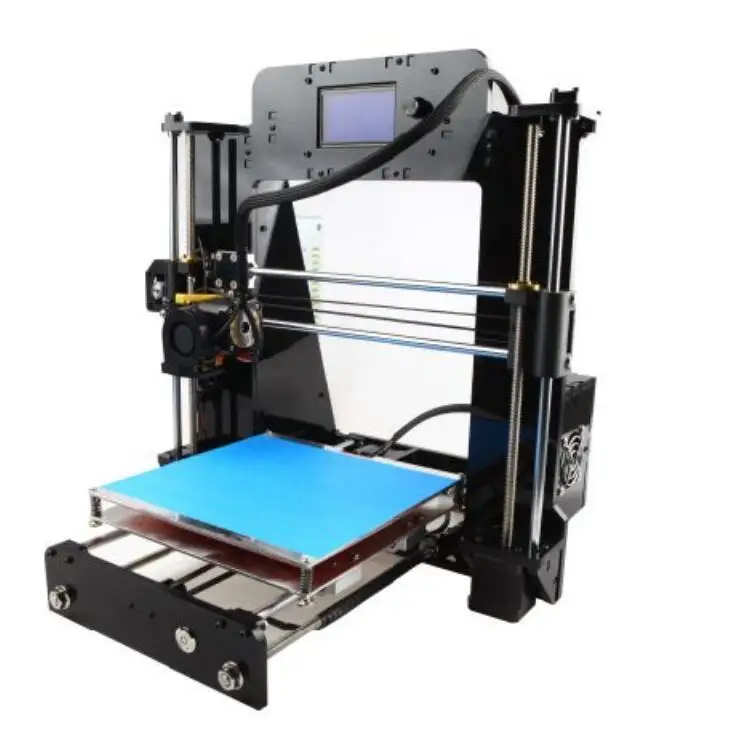

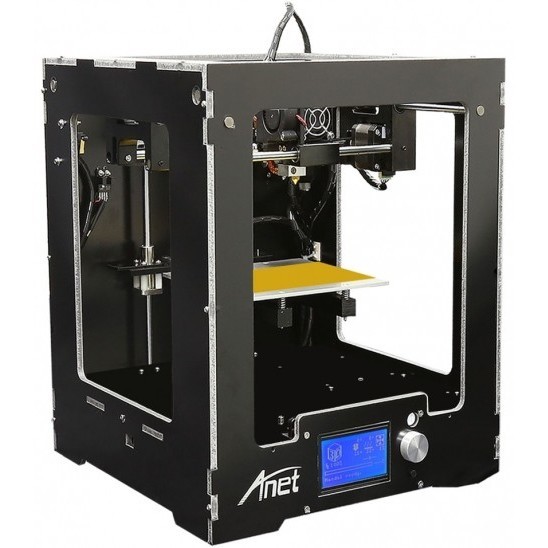

Anet - Anet is a contemporary maker of reasonably priced 3D printers that are ideal for small businesses, home and garage workshops, and training. It is a well-known Chinese manufacturer of affordable 3D printers that are utilized by both amateur and expert builders.

Price Range of 3D Printers here in the Philippines

The 3D printer price in the Philippines ranges from ₱10,000.00 to ₱30,000.00. The 3D printer for sale in the Philippines is in a very affordable range that you have to try and see for yourself!

Where to Buy 3D Printers here in the Philippines?

When shopping for the best 3D printer, you should check out Shopee and Lazada, two of the most popular online stores in the Philippines. They feature a wide range of rates for budget-conscious buyers and 3d printing service reviews from reliable customers, legitimate vendors, and 3d printing machine products.

They feature a wide range of rates for budget-conscious buyers and 3d printing service reviews from reliable customers, legitimate vendors, and 3d printing machine products.

Conclusion

Never has there been a better opportunity to enter the 3D printing industry or, for seasoned manufacturers, to improve. You may create models, toys, hooks, stands, replacement components, and more with the appropriate printer.

Be careful to think about the questions before deciding because there are many things to take into account before purchasing the finest 3D printer for you.

Related Articles- Best Printers

- Best Printers for Office

- Best Portable Printers

- Best Photo Printers

A top hotel in the Philippines will have a suite built with a concrete 3D printer.

News

Subscribe author

Subscribe

Don't want

3

Lewis Yakich, an experienced US developer, teamed up with renowned concrete 3D printing expert Andrey Rudenko to come up with the design of the hotel. The duo also worked tirelessly to figure out the right type of printer for the big project. Thanks in large part to Rudenko, the process of building the printed module took only two months. Rudenko even admits that their builds can be reproduced within a few weeks now.

The duo also worked tirelessly to figure out the right type of printer for the big project. Thanks in large part to Rudenko, the process of building the printed module took only two months. Rudenko even admits that their builds can be reproduced within a few weeks now.

After testing materials and blends for one month, the duo embarked on a revolutionary print.

The room designed for 3D printing will also have a printed Jacuzzi.

If you could stay in a hotel room built entirely with 3D printers, would you? Well, if you're planning a trip to the Philippines soon, you might just get the chance. In this country, the Lewis Grand Hotel has recently completed the construction of a new addition. A suite that was made almost entirely with a construction concrete printer.

In Angeles City (Pampanga), a 3D printed villa has appeared in the Lewis Grand Hotel. It has two bedrooms, a room with a jacuzzi (the jacuzzi was also 3D printed). The total area of the villa is approximately 120 square meters. The whole villa is approximately 10 by 12 meters in size, with high ceilings in the entire room - as much as 3 meters. This is a revolutionary number. The most impressive feature is the fact that he has a total number of hours to complete the printing of the entire issue - about 100. Add to this the time it took to install the plumbing, fittings and wiring.

The total area of the villa is approximately 120 square meters. The whole villa is approximately 10 by 12 meters in size, with high ceilings in the entire room - as much as 3 meters. This is a revolutionary number. The most impressive feature is the fact that he has a total number of hours to complete the printing of the entire issue - about 100. Add to this the time it took to install the plumbing, fittings and wiring.

“The Philippines is actually a great place to print with concrete because of the weather,” Yakich tells 3DPrint.com, “Nowadays everything is made of concrete. A 3D printer can do a lot of good in disaster areas, etc.'

Although construction has already finished at the Grand Lewis Hotel and the villa is ready, it is not known exactly when the hall will open to the public, and how much it will cost a night at the villa.

But it is known that this building made a splash and captured the attention of other enterprises in the Philippines. A construction pro like Yakich is in a position to secure a contract to build affordable housing in the country, something he plans to start in November. Considering how much money and time was spent on an addition to his chic Philippine hotel, such construction can be considered very effective. It seems likely that his next 3D printer construction contract won't be his last.

Follow author

Follow

Don't want

3

More interesting articles

6

Subscribe to the author

Subscribe

Don't want to

A new method called iCLIP was created with the participation of Professor DeSimon - co-founder and CEO ...

Read more

5

Follow the author

Subscribe

Don't want

Researchers from Peter the Great St. Petersburg Polytechnic University have developed an algorithm...

Petersburg Polytechnic University have developed an algorithm...

Read more

44

Subscribe to the author

Subscribe to the author

Don't want to

American startup Iro3D has shipped the first 3D printers for printing metal products using the se...

Read more (LFS)

Formlabs today is pleased to announce two new products that will usher in a new era of 3D printing for users: Form 3, our latest professional desktop printer available now, and Form 3L, the first affordable large-format stereolithographic 3D printer available for preview. order.

Both new printers are powered by Low Fracture Stereolithography (LFS)™ technology, which delivers very high print quality, lighter support structures and a platform for more complex materials and applications.

Formlabs 3D printers are ideal for a wide range of industries with stable performance and unsurpassed ease of use. The Form 3 and Form 3L continue this trend.

The Form 3 and Form 3L continue this trend.

New software features, such as the ability to send print jobs remotely and manage a shared print queue, open up new possibilities for working across teams and locations. We've focused on keeping things running smoothly for high-volume printing, and added comprehensive sensors and alarms, as well as user-replaceable components. Finally, Form 3L products allow you to seamlessly scale up to five times the print volume of our desktop 3D printers.

Buy Form 3 Pre-order Form 3L

We're excited to continue to make powerful industrial technology more accessible and provide unparalleled quality and reliability for printers to build product lines that can grow with your business. Read on to learn more about how LFS 3D printing works and why we needed to change the 3D printing process.

Formlabs made a name for itself in the industry seven years ago with the introduction of its first stereolithography desktop 3D printer that was powerful and affordable. Since then, we have sold over 50,000 printers with over 40 million designs.

Since then, we have sold over 50,000 printers with over 40 million designs.

Gillette's Razor Maker™ solution powered by Form 2 3D printers allows consumers to create and order custom razor handles.

The Form 2 printer makes industrial quality parts affordable by reducing equipment, material and labor costs. Thanks to this, a huge number of enterprises began to use stereolithography.

Formlabs maintains one of the largest materials research departments in the industry. Our product range includes 20 materials designed for specific applications and industries. This allows companies like Gillette to produce finished work items at affordable prices for end users. Today, Formlabs users know more than anyone how to expand 3D printer manufacturing from a single tool to a continuously running digital factory, turning a prototyping tool into a powerful business development tool.

For Form 3 and Form 3L printers, this approach has evolved naturally. They feature easy removal of support structures, increased accuracy and reliability, faster maintenance, and provide new opportunities for printing large models and materials of the future. Formlabs paved the way to make industrial-quality 3D printing not just affordable, but truly universal by building its own manufacturing platform that is robust and versatile enough to grow your business on.

Formlabs paved the way to make industrial-quality 3D printing not just affordable, but truly universal by building its own manufacturing platform that is robust and versatile enough to grow your business on.

“3D printing has long depended on the designer's understanding of the nuances of the printer's work to come. In addition, they had to know how to get the printer to produce quality models. As hardware evolved, fine-tuning knowledge faded into the background, and things got easier.

The Form 3 printer handles a range of tasks for you while producing quality parts. This is an example of the right approach to product design.”

—Nick Payton, Mechanical Engineer, RightHand Robotics

The first Formlabs 3D printers were much smaller and more affordable than existing industrial stereolithographic instruments. Inverted stereolithography technology, which is the basis of the Form 2 printer, reduces the size and cost of equipment, but at the same time, the part is subjected to significant forces during printing. This problem is solved by careful calibration, but the intensive process of separation of the printed layers creates restrictions on materials and volume of printing, and strong support structures are required for successful printing of parts.

This problem is solved by careful calibration, but the intensive process of separation of the printed layers creates restrictions on materials and volume of printing, and strong support structures are required for successful printing of parts.

Formlabs' development of Low Force Stereolithography (LFS) technology has revolutionized the approach to resin-based 3D printing and dramatically reduces the forces on models during printing.

Low forces in the LFS printing process allow the Form 3 printer to deliver consistently high model accuracy and surface quality.

LFS-based 3D printers use a flexible tank and linear illumination to achieve incredible surface quality and print accuracy. The lower press force allows for lightweight support structures that are easy to detach. In addition, the method itself opens up great opportunities for the further development of advanced materials ready for production.

“Making the supporting structures brittle was revolutionary.

It's impossible to convey how you feel when you first pick up a model to remove it, and it comes off with absolutely no effort. Now you don't have to worry about printing and cleaning models, and you can focus on designing and creating."

—Justin England, CEO, Delve

The Form 3 and Form 3L printers use a specially designed Light Processing Unit (LPU) with a lens and mirror system to produce accurate and reproducible models.

The Light Processing Unit (LPU) contains a system of lenses and mirrors to produce accurate models with reproducible results. The Form 3 printer has one LPU and the Form 3L has two.

Inside the LPU, a galvanometer positions a high-density laser beam in the y-direction, passes it through a spatial filter, and directs it into a deflecting and parabolic mirror so that the beam always remains perpendicular to the plane of the platform.

Learn more about Form 3 Order

“One of the great things about the Form 3 is how the lack of stress affects print quality and finish.

We like that we can reproduce all the subtleties of the design. I'm blown away by how detailed finished models can be. It's really impressive."

“The thinness of the support structure where it touches the model helps a lot. We save a lot of time by separating the model from the base. Modular optical units are pleasing in that they can be on hand and quickly changed. This helps us keep our operations running smoothly, which is a big advantage for us.”

- Sean Buxton, Principal Mechanical Engineer, Ximedica

Form 3 and Form 3L printers are designed to run smoothly. We wanted you to have more time to design and create. Built-in sensors detect and maintain ideal printing conditions and send alerts when action is required.

The Form 3 and Form 3L printers use the same convenient cartridge system as the Form 2, with an extensive library of over 20 specialty and general purpose media for a variety of applications.

The design of the system greatly facilitates maintenance for those rare occasions when problems occur. The light processing unit, rollers, and optical window can be replaced in-house, saving you the cost of sending the printer back to the manufacturer to have these parts replaced. And with improved error detection and handling, you can experiment with confidence.

Start printing from anywhere with the Remote Print solution.

The intuitive and redesigned user interface of our print preparation software, cloud management tools and printer touch screen makes it easy to operate the machine without any special training.

Our software is always free and packed with useful features that enable new ways to integrate 3D printing into workflows. Start printing on-the-go with Remote Print, manage an organized print queue in PreForm, and manage commands and permissions in the online Dashboard.

With Low Force Stereolithography (LFS)™ technology, the work area can be seamlessly enlarged by five times using the same powerful print engine.

The LPU's modular design, uniform linear illumination, and force-reducing elastic reservoir allow Low Force Stereolithography technology to seamlessly scale to a wider print area using the same powerful print engine.

The first affordable large-format Form 3L printer quickly prints large resin parts using two staggered LPUs that work simultaneously on an optimized print path.

Black Diamond designed helmet. On the left is the prototype printed on the Form 3L, on the right is the finished product.

For the first time, many companies have the opportunity to print large parts themselves, spending less time and money on it. When high performance is needed, the Form 3L increases the throughput of each device. For example, jewelers can print about 150 rings in one pass, and dental laboratories can make about 40 dental arches at a time.

Two staggered LPUs within the Form 3L move along an optimized laser path to work quickly through large builds.

The Form 3L's two stepped LPUs move along an optimized laser beam path to quickly cover a large area.

Both printers use the same convenient resin cartridge system as the Form 2. The Form 3L accepts two resin cartridges. This allows you to increase the capacity of materials and avoid interruptions when printing even the largest models.

Learn more about the Form 3L Book Now

The Form 3, Form 3L, and Form 2 printers use the same resin cartridges. Form 3 and Form 2 printers have the same platforms. Both of these models are compatible with Form Wash and Form Cure solutions. Learn more about the differences between Form 3 and Form 2 printers.

| Form 3 | Form 3L | Form 2 | 25-300 µm. 0.001-0.012 in. | *25-300 µm. *25-300 µm | 25-300 µm. 0.001" - 0.012" | ||

|---|---|---|---|---|---|---|---|

| XY resolution | 25 µm 0.001 in. | 25 µm 0.001 in. | n/a | ||||

| Laser spot size | 85 µm 0. 0033 in. 0033 in. | 85 µm 0.0033 in. | 140 µm 0.0055 in. | ||||

| Resin Cartridges | 1 | 2 | 1 |

Formlabs Stereolithographic 3D Printer Specifications Compare Form 3 and Form 2 Specifications

* Minor changes may be made to final Form 3L specifications.

Formlabs is committed to providing all types of businesses with the tools to access high quality workflow. Form 3 and Form 3L printers, which use advanced low-fracture stereolithography (LFS) technology, are a new step towards the unification of industrial desktop 3D printers and the deployment of 3D-based production at affordable prices.

Start with one printer and add more as demand increases, or start production on multiple printers at once to meet high volumes initially. No matter the size of your business or the phase of production you are focused on, Formlabs has the versatile hardware, software and materials you need to grow your business.