Lpx 3d scanner

Technical support for Picza LPX-600RE 3D Laser Scanner

Application & Software Guides ( 1 )

Pixform Pro Training Guide (Spanish)

Pixform Pro Training Guide, espanol

2.01 MB

Driver ( 4 )

Windows 10

Windows 2000, Windows 7, Windows Vista, Windows XP

Windows 2000, XP, Vista, 7 (32bit) v121

Model : LPX-600 32 bit OS : Windows 7, Windows VISTA, Windows XP, Windows 2000

303. 50 KB

Windows 7, Windows Vista

Windows 7_Windows Vista Driver Installation

This document PDF outlines the procedures to install a Roland driver in Windows 7 and Windows Vista.

239.03 KB

Windows 7, Windows Vista, Windows XP

Windows XP, Vista, 7 (64bit) v091

Model : LPX-600 64 bit OS : Windows 7, Windows VISTA, Windows XP

58.00 KB

Firmware ( 1 )

LPX-600 Firmware ver 1. 20

20

Firmware version 1.20 for the LPX-600.

218.88 KB

Owner & User Manual ( 5 )

Pixform Pro II User Guide

Users guide for Pixform Pro II.

23.29 MB

User's Manual, Dr. Picza3 (English)

Users manual for Rolands Dr. Picza 3 scanning software

252.70 KB

User's Manual, LPX-600 (English)

Users manual LPX600

2. 97 MB

97 MB

User's Manual, LPX-600 (French)

Users manual for LPX600. francais

3.49 MB

User's Manual, LPX-600 (Spanish)

Users manual for LPX 600. espanol

1.58 MB

Product Info Guide ( 2 )

Setup & Install Guides ( 2 )

Roland Pixform Pro II Installation and Operation guide

Step by step installation for Roland Pixform Pro II software and operational instructions.

1.48 MB

Step 3: Roland Warranty Registration Page

Most Roland devices are supplied with a one year standard manufacturers warranty, but by registering your device within 60 days of purchase, your product could qualify for an extended warranty of up to 3 years.

60.53 KB

Software Updates ( 6 )

3D Editor Updater ver. 2.42

This software updater will update your 3D Editor program to version 2.42.

3. 01 MB

01 MB

Direct Control for Rapidform Updater ver. 1.56

This is a plug-in software which enables you to control the machine directly from RapidForm. You need to have RapidForm already installed. Download the exe file, and double-click setup.exe and follow the instructions as displayed for installation.

1.28 MB

Dr. Picza3 Updater ver. 4.70

Software updater for Dr. Picza3 version 4.70.

5.28 MB

LPX EZ Studio Updater ver. 3.02

3.02

This is a updater for LPX EZ Studio. You need to have a previous version installed in order to apply the update. Follow the instruction described in readme.txt in the extracted folder.

17.04 MB

LPX EZ Studio v3.01 Updater

This is a updating program for LPX EZ Studio. You need to have already a LPX EZ Studio installed. Download the exe file, and double-click to extract. Follow the instruction described in readme.txt in the extracted folder.

17.28 MB

LPX EZ Studio ver. 2.0A

Install for LPX EZ Studio software version 2. 0A. Please note you must have a USB hardware dongle key to operate this program.

0A. Please note you must have a USB hardware dongle key to operate this program.

10.48 MB

Knowledge Base Articles ( 9 )

Can't find the driver you need for your Roland?

HELP!! I can't find the driver I need for my Roland!

Cut Paths Are Being Clipped

The cut path is being clipped on one side of the print

How to install a Roland driver in Windows 7 and Windows Vista

How to install a Roland driver in Windows 7 and Windows Vista

I can't find a Windows 8/8. 1 driver!

1 driver!

HELP!! I can't find a Windows8 driver for my machine!!

Missing Software

HELP!! Ilost the software CDfor my machine!!

Roland Product End of Life Policy

Information about my legacy product

SL-CL cartridge vs. ESL4-CL cartridge

Can I use either of these cleaning cartridges interchangeably?

What are the system requirements for Pixform Pro II?

What are the system requirements for Pixform Pro II?

What is a Driver? What is a plugin?

All Roland devices with a USB, Parallel (LPT), or Serial (COM) port need a driver to communicate with a computer. For Roland products compatible with Apple Macintosh operating systems, a plugin is used with Adobe Illustrator. For Roland devices with an Ethernet port, the output software (e.g. - RIP)includes the driver as part of the application.

For Roland products compatible with Apple Macintosh operating systems, a plugin is used with Adobe Illustrator. For Roland devices with an Ethernet port, the output software (e.g. - RIP)includes the driver as part of the application.

ROLAND PICZA LPX-600 USER MANUAL Pdf Download

Table Of Contents

3-

page of 64

- Contents

- Table of Contents

- Bookmarks

Advertisement

Table of Contents

-

-

3

Table of Contents-

5

To Ensure Safe Use

-

-

9

Important Notes on Handling and Use -

10

About the Documentation -

11

1 Getting Started -

15

2 Preparing the Machine -

31

3 Creating 3D Data -

47

4 Editing Scanning Results - Using 3D Editor -

55

5 What to Do if -

59

6 Appendix

LPX-600

User's Manual

Thank you very much for purchasing this product.

To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read through this

manual completely and store it in a safe location.

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

The contents of this operation manual and the specifications of this product are subject to change without notice.

The operation manual and the product have been prepared and tested as much as possible. If you find any misprint or error, please

inform us.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur through use of this product,

regardless of any failure to perform on the part of this product.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur with respect to any article

made using this product.

Table of Contents

Previous Page

Next Page

Table of Contents

-

-

3

Table of Contents-

5

To Ensure Safe Use

-

-

9

Important Notes on Handling and Use -

10

About the Documentation -

11

1 Getting Started -

15

2 Preparing the Machine -

31

3 Creating 3D Data -

47

4 Editing Scanning Results - Using 3D Editor -

55

5 What to Do if -

59

6 Appendix

Related Manuals for Roland Picza LPX-600

- Scanner Roland PICZA LPX-60 User Manual

3d laser scanner (68 pages)

- Scanner Roland Picza LPX-1200 User Manual

3d laser scanner (64 pages)

- Scanner Roland Picza LPX-250 User Manual

3d laser scanner (49 pages)

- Scanner Roland Picza PIX-4 User Manual

3d scanner (31 pages)

- Scanner Roland Picza PIX-30 User Manual

3d scanner (33 pages)

- Scanner Roland Picza PIX-3 User's Manual Supplement

For macintosh users (8 pages)

Summary of Contents for Roland Picza LPX-600

90,000 select 3D scanner: types, advantages, solved tasks3D scanners

Fundamentals 3D

reverse engineering

Geometry Control

The best on the topics

Automation of quality control

Author: Seeds PopaDYADYUK

Author: Semyon Popadiuk

Benefits of 3D Scanners | What tasks does 3D scanning solve | Criteria for choosing a 3D scanner | Professional 3D scanning for fast and efficient production solutions

Modern 3D scanners have a wide range of features and a variety of functionality. They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

Order a free test 3D-scan using the equipment of the world's leading manufacturers:

Leave a request

Advantages of 3D Scanners

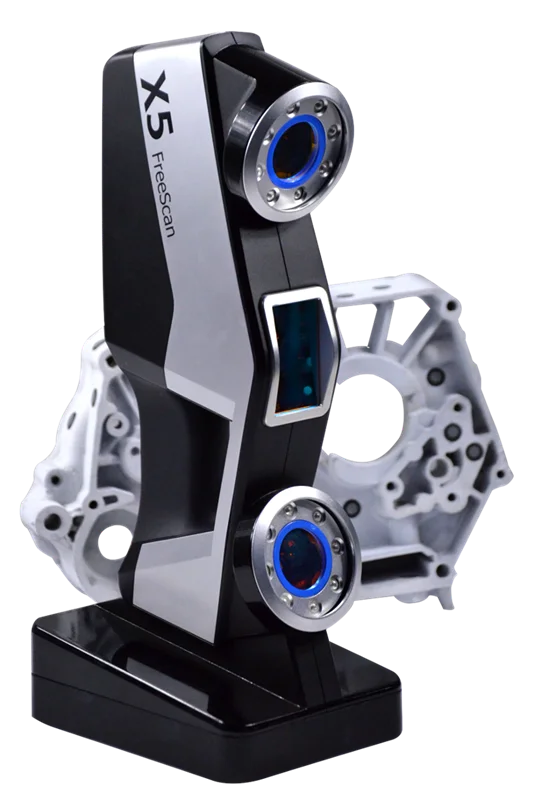

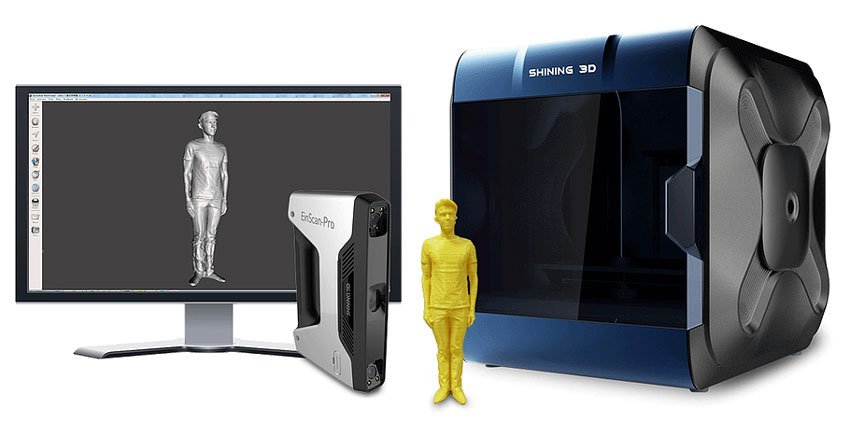

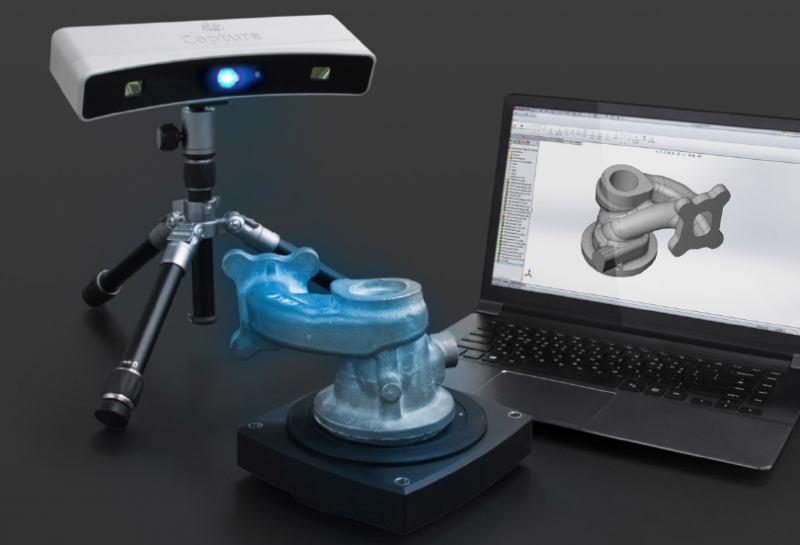

What is a 3D scanner? This is a device designed to quickly analyze a physical object and create its accurate 3D computer model. The principle of its operation is based on calculating the distance to the object using two cameras. In addition to the cameras, a backlight is used - LED or laser.

3D scanners are classified both according to their form of execution (stationary and portable) and according to the areas of use, mainly divided into professional and household.

3D scanners make it possible to significantly reduce the time and costs at the development stage, improve the quality of products and, ultimately, speed up the release of the product to the market. They can be used at any stage of product lifecycle management and will help to optimize the production process of enterprises in various industries, including:

- automotive,

- mechanical engineering,

- aerospace industry,

- oil and gas industry,

- shipbuilding,

- building and architecture,

- arts and culture,

- medicine,

- jewelry,

- science and education.

3D scanning devices remove many of the limitations of traditional measuring equipment. Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training.

Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training.

Optical inspection systems, which include 3D scanners, are the best solution in terms of price and quality, as they provide:

- measurement speed,

- high precision digitization of objects of complex geometry,

- can work autonomously,

- are easy to operate.

Thanks to a 3D scanner, the work of a designer, technologist, and constructor is greatly facilitated: the performance of time-consuming complex measurements and the creation of a design from scratch are a thing of the past.

What tasks does 3D scanning solve

- Quality control: the ability to check any geometric parameters, including input and output control, metrological control of parts and production equipment.

- Reverse engineering of products for prompt receipt of project documentation and product upgrades.

- Design and simulation for the purpose of prototyping and evaluation of the appearance of products, modernization of production facilities and equipment.

- Digital archiving of any required assortment (eg discontinued parts). Models stored in digital libraries are available remotely from anywhere in the world.

3D scanner selection criteria

The main criterion is scanning accuracy . High-precision devices (10-30 microns) will help to get a phenomenal result: they are able to transfer the most complex surface geometry into 3D with minimal errors. Such 3D scanners are used in reverse engineering, quality control, medicine, and are used to digitize molds, device parts, etc. 3D scanners with an accuracy of 30–100 engineering.

ZG AtlaScan is the world's first 3D scanner with hole capture

When choosing a 3D scanner, you should also take into account resolution (detail) , i. e. the degree of discreteness that is available when digitizing an object. The highest level of detail allows you to display the smallest elements in the 3D model.

e. the degree of discreteness that is available when digitizing an object. The highest level of detail allows you to display the smallest elements in the 3D model.

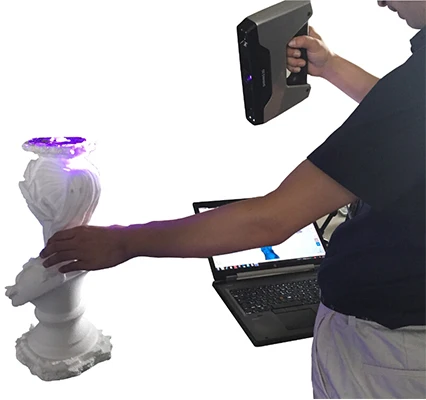

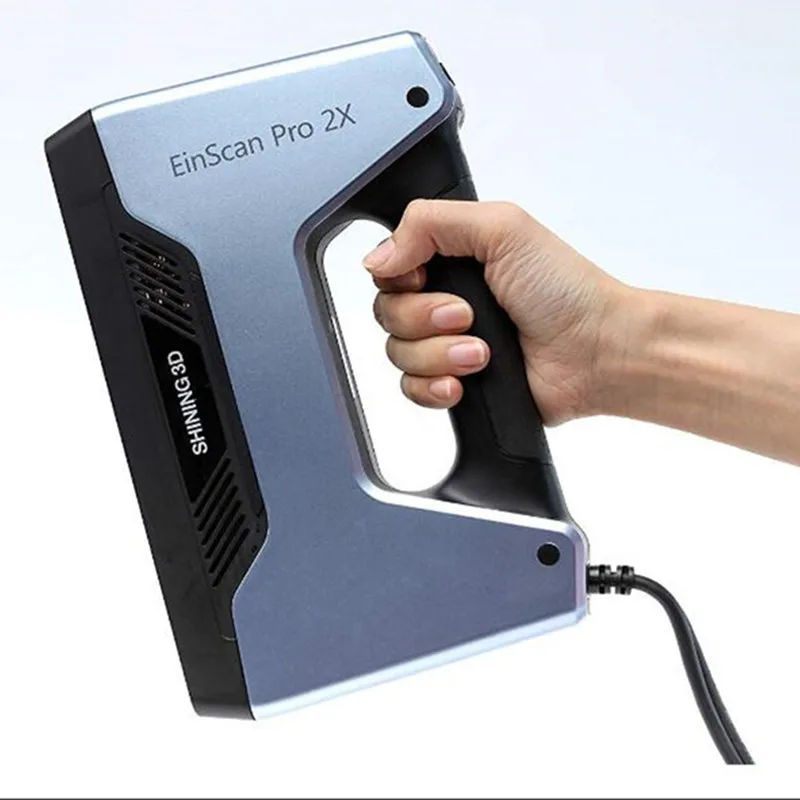

Р the size of the scanned objects and, accordingly, the mobility of the 3D scanner directly depend on the type of device that you select. When digitizing parts and objects of small and medium parameters, hand-held scanners are usually used. Stationary scanners are suitable for capturing complex small and medium-sized products with small details. Scanning of large objects (buildings, structures, communications) is performed using ground-based laser devices (range finders).

When studying the functionality of 3D scanners, pay attention to such points as the conditions of use, scanning speed, the surface of the scanned object, and color.

Please note that the next step after scanning is to obtain and further work with the CAD model, and for this you will need specialized software.

Processing 3D Scan Data for Reverse Engineering in Geomagic Design X Software

Professional 3D scanning for fast and efficient production solutions

iQB offers cutting-edge solutions that successfully operate in leading enterprises around the world:

- Portable devices for metrological 3D measurements from ZG Technology (China). The line includes a wide range of instruments, from an affordable handheld 3D scanner to a powerful optical tracking measurement system, as well as photogrammetry and portable CMM. ZG's unique strengths include the world's first handheld MarvelScan solution with three cameras for markless laser scanning and tracker, and proprietary instant hole capture technology. ZG Technology 3D scanners provide measurement speed up to 1 million 350 thousand points per second and accuracy up to 0.01 mm.

- Stationary Russian-made RangeVision PRO 3D optical scanner is an industrial solution for metrology, available to companies of any level.

The device is designed to digitize objects from 1 mm to 5 m and offers the highest level of accuracy (up to 0.018 mm) and 3D resolution (up to 0.04 mm). This is the first domestic 3D scanner approved by the Federal Agency for Technical Regulation and Metrology as a type of measuring instrument.

The device is designed to digitize objects from 1 mm to 5 m and offers the highest level of accuracy (up to 0.018 mm) and 3D resolution (up to 0.04 mm). This is the first domestic 3D scanner approved by the Federal Agency for Technical Regulation and Metrology as a type of measuring instrument. - Creaform handheld 3D scanners for digitizing products ranging in size from a few centimeters to 6 meters. The Go!SCAN series devices (including the latest Go!SCAN SPARK) are based on structured illumination technology; HandySCAN 3D and MetraSCAN 3D are laser devices that are certified industrial grade metrology tools. The new generation MetraSCAN BLACK|Elite model is the fastest handheld 3D laser scanner on the market (1.8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc.

m.

m. - Creaform also produces 3D scanners and software under the peel 3d brand, combining affordability, ease of use and high quality. The line is designed to solve the problems of reverse engineering and digitalization of objects in such areas as art, preservation of cultural values, consumer goods, science and education, human body scanning. Peel 3d devices are capable of measuring objects from 0.3 to 3 m with an accuracy of 0.1 mm.

RangeVision PRO Fixed Scanner Creates Yamaha R3 Sport Fairings with Improved Aerodynamics, High Strength and Lighter Weight

- Solutionix fixed optical 3D scanners for small objects (10-500 mm) with many small parts. Allow to receive an error less than 8 microns.

- FARO Focus 3D geodetic laser scanners perform fast and accurate scanning of large objects, complex structures, premises and landscapes. They operate in the range from 0.6 to 350 m, they are distinguished by increased accuracy, ease of operation and the ability to operate in the most difficult environmental conditions.

- EPiC budget 3D terrestrial laser scanners are based on the principles of simplicity, convenience and affordability.

Their main advantages are super light weight, high shooting speed (from 30 to 90 seconds), 360-degree panoramic camera and the ability to control from a mobile device.

Their main advantages are super light weight, high shooting speed (from 30 to 90 seconds), 360-degree panoramic camera and the ability to control from a mobile device.

Many of the above scanners are included in the register of measuring instruments of the Russian Federation and have the appropriate certificates.

Robotic 3D scanning systems, such as Creaform MetraSCAN 3D-R, allow you to increase the speed and efficiency of quality control directly on the conveyor

A variety of 3D scanning devices on the market will allow you to choose exactly the model that is needed for solving specific problems. The price range is also wide: from simple devices costing up to $500 to high-precision professional 3D scanners costing tens and even hundreds of thousands of dollars.

Contact iQB Technologies experts! We will select the optimal solution that will optimize product development and production in your enterprise, design office or research center.

We remind you that the test scan is free!

We remind you that the test scan is free! Article published on May 25, 2017, updated on October 12, 2022

ULK Group of Companies

Corporate Communications

Pachina Yulia Borisovna, General Director of the Ustyany Publishing House

+7 921 486-95-23, [email protected]

Archives of publications, photo

Anna Silina, Chief editor of the newspaper "Ustyanskiye Vesti"

+7 931 402-07-98, [email protected]

On November 1, a large-scale modernization of sawmill production began in the Velsky timber industry complex.

The first area of work is the sorting of round timber, where the 3D scanner will be replaced. Instead of the German equipment, which has worked at the plant for 4 years, a new log meter from the domestic manufacturer Avtomatika-Vektor will be installed.

According to the director of the enterprise Evgeny Tolstoy, it has a number of advantages:

- If the breakdown of the old scanner could stop production indefinitely, then this will not happen with the new one. "Vector" is not only reliable and easy to manage, but also displays the necessary forms of reports. And any operator of the sorting section will be able to eliminate any error or hitch.

"Vector" is not only reliable and easy to manage, but also displays the necessary forms of reports. And any operator of the sorting section will be able to eliminate any error or hitch.

Together with the scanner, the software will also be replaced, which will allow determining the diameter of raw materials with a maximum error of 0.5 mm, so that sorting will become 100 percent accurate.

Specialists of the supplier company have already arrived at the plant to install and launch a new scanner and train personnel.

According to Yevgeny Tolstoy, after upgrading the equipment, the enterprise will be able to handle 3,000 cubic meters of round timber per day without any problems.

The biggest changes during the shutdown will affect the sawmill: 25% of all mechanical components of the sawmill line will be replaced and automation will be diagnosed. This analysis is necessary for making decisions on the subsequent replacement and modernization of sawmill equipment, which, by the way, will occur during the next scheduled shutdown of production.

The changes will also affect the bunkers for storing wood chips and sawdust, they are planned to be built entirely of concrete and larger.

In addition, cosmetic repairs will be carried out in all the premises of the sawmill. At large stages, contractors will be involved, the repair of the mechanical parts of the line and painting work will be carried out by the staff of the workshop.

The next unit to be changed during the shutdown will be the drying complex. Here they will perform maintenance of all equipment and put into operation new drying modes.

A small modernization will also take place in the boiler room with equipment maintenance and a trial run of a second boiler with a capacity of 9MW.

Least of all, the suspension of production will affect the relatively new division of VLK - the shop for sorting dry sawn timber. A line and software check is planned here.

Work on the modernization of the plant has already begun - a group of German engineers from SAB is checking and analyzing the sorting and sawmill lines.

Velsk timber industry complex

High quality tree planting material is ready for wintering and is on the hardening grounds. Today there is an active preparation of equipment for the winter, as well as the preparation of an agricultural plan for sowing for 2019year. It should be reminded that the Seed Center positively assesses the success of this year: the total amount of seedlings grown during the year exceeds 8.17 million seedlings of pine and spruce. The plans for 2019 are to plant and sell even more high-quality forest planting material.

Ustyansky seed-growing complex

The machine will be located on the territory of the UTK boiler house in Oktyabrsky. It will shred wood waste from the sawmill, as well as logging residues from logging sites, such as tree tops, branches, stumps, crooked trunks, various bushes, etc. Recycled chipper waste will be used as fuel for the boiler house.

Ustyanskaya thermal power company

During his stay on the territory of the timber industry complex, a lot of work has been done.

On the first day, while working at the facilities of the complex, Vladimir Fedorovich focused special attention on the territory of the terminal, which will begin to operate at full capacity from the beginning of 2019 and cope with the loading and unloading of large volumes of roundwood and wood chips. In this regard, priorities were set for the facilities under construction and the deadlines for the implementation of the main work were set.

The head of the terminal, Natalya Molchanova, took all the instructions of the general director of the holding "on a pencil" and promised to cope with the tasks set on time. VLK director Yevgeny Tolstoy will control the process.

Velsk timber industry complex

The fifth complex, consisting of three pairs of new John Deere 1270 G harvesters and John Deere 1510 G forwarders, has already started work. The complex is staffed by both experienced loggers and young employees who have only recently come to work in the ULK Group of Companies.

It should be reminded that by the end of the year it is planned to put into operation five logging complexes equipped with new equipment. At the moment, two of them have already been launched: this is the fifth complex in the Ustyansk LPH and the fifth complex in the Plesetsk LPH.

Ustyansky logging complex

Good afternoon, dear colleagues!

We are glad to announce that the ULK Group of Companies has been and remains the largest timber holding in Russia in terms of the scale of harvesting and production of sawn timber.

From December 1, 2018, the work of the Pomor sawmill company in Arkhangelsk will be completely stopped. The difficult decision to close the Solombala plant was made because it is unprofitable due to outdated equipment. In addition, the PLC pellet production was built by the previous owners of the enterprise without the necessary permits, in violation of technology and in close proximity to the housing stock. After the launch of the pellet plant, the local population began to receive regular complaints about its work to the City Prosecutor's Office, Rosprirodnadzor and other authorities, and 9October 2018, the court ruled to close the pellet plant.

Production from Solombala will be transported to a new site in the Pestovsky district of the Novgorod region (on the territory of the Pestovsky timber processing complex), part of the equipment will be dismantled and also delivered to the village. Karpogory, which is located 200 kilometers from the city of Arkhangelsk.

Place of implementation of a new investment project for wood processing in the village. Karpogory was not chosen by chance, because it has advantages in terms of railway logistics management.

In this regard, we inform you that the position of the company is still stable, the holding is in continuous development.

We also inform you that all the plants that are part of the ULK Group of Companies have been reaching full capacity since 2019, namely: Ustyansky timber industry complex - 1.5 million cubic meters of raw materials at the entrance, Pestovsky and Velsky timber processing complex - 600 thousand cubic meters of raw materials each at the entrance. In addition, the volume of pellet production in 2019 will amount to 330 thousand cubic meters, and from 2020 it will double.

In addition, the volume of pellet production in 2019 will amount to 330 thousand cubic meters, and from 2020 it will double.

In view of the closure of the line at the Pomeranian sawmill company, we offer our European customers products from other plants of the Group of Companies, and also find the best delivery methods.

We assure you that the Group of Companies is still a responsible employer and taxpayer, the initiator of a number of social projects aimed at improving the well-being of not only residents of the Arkhangelsk region, but also neighboring regions.

Looking forward to further constructive cooperation,

Group of companies "ULK"

Dear colleagues,

Due to a lot of rumors circulating around the name of the ULK group, I would like to clarify some moments.

Starting from the 1 st of December, 2018 the production of the Pomor Timber Company in Arkhangelsk will be stopped completely. The reason to that difficult decision we’ve made is that the pellet factory was built by former owners without the necessary permitting documents, in violation of technology and very close to the residential area. After the launch of the pellet factory, lots of complaints from the local people started to come to the Prosecutor’s office and other authorities, which ended up with the Court’s decision on 9 th of October to shut down the pellet factory. The future running of the sawmill at this site is also impractical – the equipment is outdated and the enterprise itself is unprofitable.

After the launch of the pellet factory, lots of complaints from the local people started to come to the Prosecutor’s office and other authorities, which ended up with the Court’s decision on 9 th of October to shut down the pellet factory. The future running of the sawmill at this site is also impractical – the equipment is outdated and the enterprise itself is unprofitable.

The pellet factory will be transported from Solombala to Pestovskiy area of the Novgorod region (to the Pestovskiy Timber Complex site), part of the timber equipment will also be disassembled and transported to Karpogory village, which is 200 kilometers away from Arkhangelsk. Karpogory, as a site of the implementation of the new wood processing investment project had been chosen also because of the convenient railway transport approach.

Also we would like to let you know, that all of the sawmills of the ULK Group will start production with the full capacity in 2019: Ustyanskiy – 1.5 million CBM of logs, Pestovo and Velsk – 600 thousand CBM of logs each. Besides, the production volumes of pellets will be 330 thousand tones in 2019 and this volume will be doubled in 2020.

Besides, the production volumes of pellets will be 330 thousand tones in 2019 and this volume will be doubled in 2020.

In a view of closing the production line at the Pomor, we by no means do not refuse to fulfill our obligations we have to supply the goods to our European partners. To substitute the volumes, we may offer the product of the other sawmills of the ULK Group. The best way to ship the goods will be discussed to each client individually.

I hope that unverified information from the unreliable sources will not affect our further cooperation in any way. ULK Group, as before, is one of the largest forest holdings in Russia, responsible employer and taxpayer, initiator of a number of social projects.

Looking forward to further constructive cooperation, Group of companies ULK

The language laboratory of the Bereznitsa gymnasium received new furniture. These are modern desks designed for one person and comfortable chairs. The classroom will have a special arrangement of desks, which, coupled with swivel chairs, will allow students to freely communicate with classmates, which is very important for the development of a spoken foreign language.

In addition, the language lab will hold German classes, as well as English classes.

Social projects ULC

In the Pestovsky timber industry complex, preparations are underway for scheduled preventive maintenance of the sawmill No. 1, the dry sorting shop and the drying tunnels.

Alexei Samoilov, director of the Pestovsky LPK, said that after the work was completed, the plant would steadily process at least 50,000 cubic meters of sawlogs per month.

At present, a list of measures has been prepared for mechanical, electrical parts, automated control systems. The activities, which are led by the chief engineer Dmitry Prusov, must be completed in November of this year.

Pestovsky timber complex

It will operate flights from the right bank to the left bank of the Northern Dvina River.

The need to purchase a boat arose during the off-season in case of fulfilling production tasks and providing emergency assistance to the population.

According to Sergey Zenin, director of the Vinogradovsky timber industry enterprise, in the new vessel, the air cushion "dampens" wave and rock vibrations, so staying on board will be as calm and comfortable as possible. In addition, the cabin of the ship is equipped with a heating system that will prevent passengers from freezing on a long journey in severe frost.

Now the issue of purchasing a second boat of the same type is being decided.

Social projects ULC

A division of the ULK Group of Companies, the Avtomatika-Vektor Velsky Timber Complex (Arkhangelsk Region), will install a new 3D scanner on the sorting line.

In order to implement the project for the modernization of equipment and workshops, the company will suspend sawmill production from November 1 this year. After installing the 3D scanner, Avtomatika-Vektor will be able to process 2,000 m3 of round timber per day.

Forest complex of Siberia, November 1, 2018

In Pinezhsky timber industry enterprise (Ustyansky logging complex, Arkhangelsk region), shipment of round timber from the new terminal will be carried out in November 2018, the official website of the ULK Group of Companies reports.

Currently, work is underway on the territory of laying slabs, arranging timber loading fronts, as well as building an overpass. The territory of the terminal will be fenced along the perimeter with a new fence with a lighting line and video surveillance cameras.

The ULK Group of Companies includes enterprises engaged in harvesting, hauling, deep processing of wood and disposal of sawmill waste, the activities of the enterprises form a closed production chain. The total number of employees of the Group is currently 5.29thousand

Lesprom Network, November 1, 2018

A new Liebherr LH 40 caterpillar loader has arrived at the terminal of the Vinogradovsky timber industry enterprise (Ustyansky logging complex, Arkhangelsk region), the official website of the ULK Group of Companies reports.

The equipment will be involved in the loading and unloading of timber trucks and the formation of stacks of round timber. At the moment, the machine has been serviced.