Point and shoot 3d scanner

Wireless Handheld 3D Scanner | Artec Leo

Rethink what a 3D scanner can do.

Even more powerful with guaranteed accuracy? See how.

2020 Award Winner

2019 Highly Commended

2019 Gold Award Winner

2018 Innovation Award Winner

For every Leo sold worldwide, 1% is donated to Ukrainian NGO, LUkraine. Learn more

Wireless freedom. Smart data capture

Artec Leo is the only wireless and fully standalone professional 3D scanner designed to make scanning as easy and effortless as possible. With the new NVIDIA Jetson TX2 processor onboard, 5” HD built-in display and battery, it’s the ultimate all-in-one 3D scanning solution for fast, accurate, and high-quality data capture.

The all-new Leo runs at more than twice the power than it did before, and guarantees accuracy at every step of the way – you're set up for success from the start.

Download brochure

Artec Leo price

US $34,800 Please note that the prices displayed on our website are the Recommended Retail Prices. They do not include taxes, import fees or any other additional costs that may apply, depending on the location of your business. We suggest you contact an authorized Artec reseller in your city, state or country to check the specific prices in your region.

Artec Leo Premium Pack

US $48,050 Please note that the prices displayed on our website are the Recommended Retail Prices. They do not include taxes, import fees or any other additional costs that may apply, depending on the location of your business. We suggest you contact an authorized Artec reseller in your city, state or country to check the specific prices in your region.

What’s included

Technical specs

| Display | Built-in touch panel screen |

| Processing | On-board real time processing |

| Volume capture zone | 160,000 cm³ |

| 3D reconstruction rate, up to | 80 FPS |

| 3D resolution, up to | 0. 2 mm 2 mm |

| 3D point accuracy, up to | 0.1 mm |

| Color resolution | 2.3 mp |

| Structured-light source | VCSEL |

| Position sensors | Built-in 9 DoF inertial system |

| Multi-core processing | NVIDIA Jetson TX2 |

| Power source | In-built exchangeable battery |

| Connectivity | Wireless |

The 2022 Artec Leo remains at a stable and optimal temperature throughout the scanning process to bring your accuracy to the next level, while a calibration certificate and Leo Calibration Kit guarantee top quality is maintained every step of the way.

Find out more here

Up to

0.1 mm

point accuracy

Find out more here

Up to

0.2 mm

3D resolution

Up to

28 FPS

3D reconstruction rate in real time

Multi-core processing

With the fastest embedded AI supercomputer onboard, Leo gives you exceptional speed and power-efficiency.

Scan in sunlight

With Leo’s Class I Laser projector, a pattern invisible to the human eye is projected onto the surface of your object, so you can easily scan in sunlight.

Up to

3 mln points/s

Data acquisition speed in SD

Up to

35 mln points/s

Data acquisition speed in HD

With a 160,000 cm-cubed capture zone, Leo is truly versatile when it comes to size. It excels at capturing both medium-sized (20-50 cm) and large (50-200 cm) objects and surfaces. However, if paired with a powerful computer, it can take on even very large objects (200+ cm) or even entire spaces, such as rooms or crime scenes.

Examples

Typical objects for Leo:

- Gearboxes, castings

- Automotive parts

- Turbines, ship propellers, small boats

- Statues, and the human body

- Furniture and room interiors

- Crime scenes

Examples

Our bestselling 3D scanner. Fast, versatile, and accurate.

Fast, versatile, and accurate.

Scanner type

Handheld

Object size

Typical object sizes: XS: <90x60x60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

M, L

Accuracy

up to 0.1 mm

Resolution

up to 0.2 mm

Learn more

A metrological structured-light 3D scanner, set apart with its ability to render complex geometry, sharp edges, and thin ribs in high precision.

Scanner type

Handheld

Object size

Typical object sizes: XS: <90x60x60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

S

Accuracy

up to 0.05 mm

Resolution

up to 0.1 mm

Learn more

Powerful long-range laser 3D scanner with an inbuilt battery, for precise capture of large objects.

Scanner type

Long Range

Object size

Typical object sizes: XS: <90x60x60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

L, XL

Accuracy

up to 0. 0125°

0125°

Resolution

—

Learn more

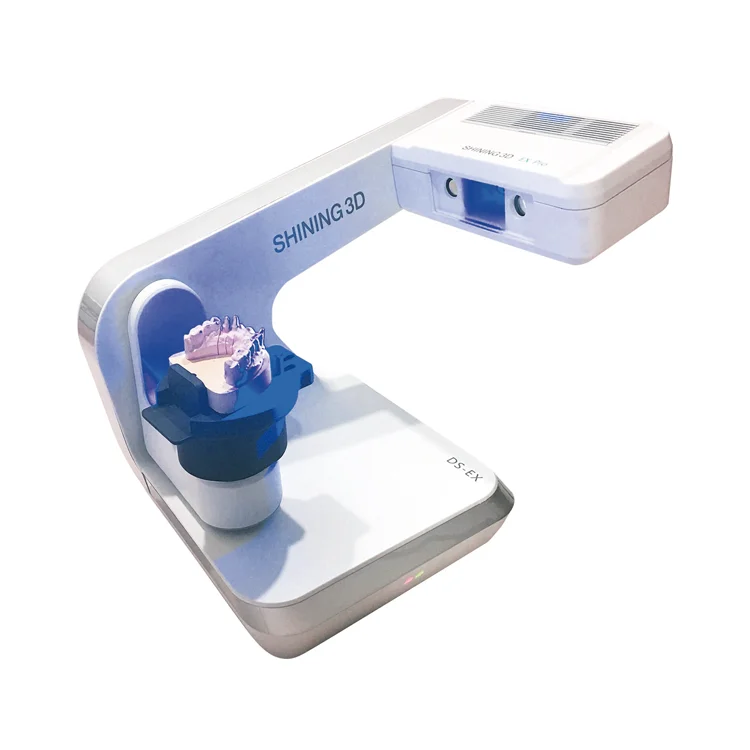

Metrology-grade desktop 3D scanner for quality control, inspection, jewelry, medical/dental components, etc.

Scanner type

Desktop

Object size

Typical object sizes: XS: <90x60x60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

XS

Accuracy

up to 0.01 mm

Resolution

up to 0.029 mm

Learn more

Photogrammetry kit with metrology-grade precision and volumetric accuracy for inspection, reverse engineering, and other industrial measurement applications.

Scanner type

Photogrammetry

Object size

Typical object sizes: XS: <90×60×60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

M, L, XL

Accuracy

up to 0.002 mm

Resolution

—

Learn more

One-click structured light 3D body scanner.

Scanner type

Booth

Object size

Typical object sizes: XS: <90x60x60 mm S: 5–20 cm M: 20–50 cm L: 50–200 cm XL: >200 cm

M

Accuracy

0.2 mm

Resolution

up to 2 mm

Learn more

Prehistory meets high tech as Artec Leo comes face-to-face with a dinosaur skull

Science and education

3D scanning for traffic accident reconstruction: How Origin Forensics uses Artec Leo

Science and education

Artec Leo and Ray join forces to fabricate replacement 15-meter pipe in an offshore vessel

Industrial design and manufacturing

Artec Leo helps Vorteq create the world’s fastest cycling skinsuits

Industrial design and manufacturing

How to boost the performance of an F3 race car with Artec Leo

Reverse engineering

Driving through the outback with Artec Leo: All the adventure, none of the diesel

Reverse engineering

See all cases

Industrial 3D Scanner | Space Spider

| Scanner type | Handheld | Handheld | Handheld | Handheld | Desktop |

| 3D point accuracy, up to | 0. 05 mm 05 mm | 0.1 mm | 0.1 mm | 0.1 mm | 0.01 mm |

| 3D resolution, up to | 0.1 mm | 0.2 mm | 0.5 mm | 0.2 mm | 0.029 mm |

| 3D accuracy over distance, up to | 0.05 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | — |

| HD Mode | N/A | Yes | No | Yes | N/A |

| Hybrid geometry and texture tracking | Yes | Yes | No | Yes | N/A |

| Data processing algorithms | Geometry and texture based | Geometry and texture based | Geometry based | Geometry and texture based | Geometry based |

| Working distance | 0.2 – 0.3 m | 0.4 – 1 m | 0.4 – 1 m | 0.35 – 1.2 m | — |

| Volume capture zone | 2,000 cm³ | 61,000 cm³ | 61,000 cm³ | 160,000 cm³ | 324 cm³ |

| Linear field of view, H×W @ closest range | 90 × 70 mm | 214 × 148 mm | 214 × 148 mm | 244 × 142 mm | — |

| Linear field of view, H×W @ furthest range | 180 × 140 mm | 536 × 371 mm | 536 × 371 mm | 838 × 488 mm | — |

| Angular field of view, H×W | 30 × 21° | 30 × 21° | 30 × 21° | 38. 5 × 23° 5 × 23° | — |

| Ability to capture texture | Yes | Yes | No | Yes | Yes |

| Texture resolution | 1.3 mp | 1.3 mp | — | 2.3 mp | 6.4 mp |

| Colors | 24 bpp | 24 bpp | — | 24 bpp | 24 bpp |

| 3D reconstruction rate for real-time fusion, up to | 7.5 fps | 16 fps | 16 fps | 22 fps | — |

| 3D reconstruction rate for 3D video recording, up to | 7.5 fps | 16 fps | 16 fps | 44 fps | — |

| 3D reconstruction rate for 3D video streaming, up to | — | — | — | 80 fps | — |

| Data acquisition speed, up to | 1 mln points/s | 18 mln points/s | 2 mln points/s | 35 mln points/s | 1 mln points/s |

| 3D exposure time | 0.0002 s | 0.0002 s | 0.0002 s | 0.0002 s | Customizable |

| 2D exposure time | 0. 0002 s 0002 s | 0.00035 s | 0.00035 s | 0.0002 s | Customizable |

| 3D light source | Blue LED | Flashbulb | Flashbulb | VCSEL | Blue LED |

| 2D light source | White 6 LED array | White 12 LED array | White 12 LED array | White 12 LED array | RGB LED |

| Position sensors | — | — | — | Built-in 9 DoF inertial system | — |

| Display/touchscreen | USB streaming through external computer | USB streaming through external computer | USB streaming through external computer | Integrated 5.5" half HD, CTP. Optional Wi-Fi/Ethernet video streaming to external device | USB streaming through external computer |

| Multi-core processing | On external computer | On external computer | On external computer | Embedded processors: NVIDIA® Jetson™ TX2 Quad-core ARM® Cortex®-A57 MPCore Processor NVIDIA Maxwell™ 1 TFLOPS GPU with 256 NVIDIA® CUDA® Cores | On external computer |

| Interface | 1 × USB 2. 0, USB 3.0 compatible 0, USB 3.0 compatible | 1 × USB 2.0, USB 3.0 compatible | 1 × USB 2.0, USB 3.0 compatible | Wi-Fi, Ethernet, SD card | USB 3.0 |

| Internal hard drive | — | — | — | 512 GB SSD | — |

| Supported OS | Windows 7, 8 or 10 x64 | Windows 7, 8 or 10 x64 | Windows 7, 8 or 10 x64 | Scanning: No computer required Data processing: Windows 7, 8, 10 x64 | Windows 10 x64 |

| Recommended computer requirements | Intel Core i7 or i9, 32 GB RAM, GPU with 2 GB VRAM | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with 8+ GB VRAM, CUDA 6.0+ | Intel Core i7 or i9, 32 GB RAM, GPU with 2 GB VRAM | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with 8+ GB VRAM, CUDA 6.0+ | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with at least 3 GB VRAM, CUDA 3.5+ |

| Minimum computer requirements | Intel Core i5, i7 or i9, 18 GB RAM, GPU with 2 GB VRAM | HD: Intel Core i7 or i9, 32 GB RAM, NVIDIA GPU with CUDA 6. 0+ and at least 2 GB VRAM 0+ and at least 2 GB VRAMSD: Intel Core i5, i7 or i9, 12 GB RAM, GPU with 2 GB VRAM | Intel Core i5, i7 or i9, 12 GB RAM, GPU with 2 GB VRAM | HD: Intel Core i7 or i9, 32 GB RAM, NVIDIA GPU with CUDA 6.0+ and at least 4 GB VRAM SD: Intel Core i5, i7 or i9, 32 GB RAM, GPU with 2 GB VRAMA computer is needed only for data processing. Scanning does not require a computer. | Intel Core i5, i7 or i9, 32GB RAM, GPU with 2 GB VRAM |

| 3D mesh | OBJ, PLY, WRL, STL, AOP, ASC, PTX, E57, XYZRGB |

| CAD | STEP, IGES, X_T |

| Measurements | CSV, DXF, XML |

| Power source | AC power or external battery pack | AC power or external battery pack | AC power or external battery pack | Built-in exchangeable battery, optional AC power | AC power |

| Dimensions, HxDxW | 190 × 140 × 130 mm | 262 × 158 × 63 mm | 262 × 158 × 63 mm | 231 × 162 × 230 mm | 290 x 290 x 340 mm |

| Weight | 0. 8 kg / 1.8 lb 8 kg / 1.8 lb | 0.9 kg / 2 lb | 0.9 kg / 2 lb | 2.6 kg / 5.7 lb | 12 kg / 26.7 lb |

3D scanners

Fundamentals 3D

reverse engineering

Geometry Control

The best on the topics

Automation of quality control

Author: Seeds PopaDYADYUK

Author: Semyon Popadiuk

Benefits of 3D Scanners | What tasks does 3D scanning solve | Criteria for choosing a 3D scanner | Professional 3D scanning for fast and efficient production solutions

Modern 3D scanners have a wide range of features and a variety of functionality. They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

Order a free test 3D-scan using the equipment of the world's leading manufacturers:

Leave a request

Advantages of 3D Scanners

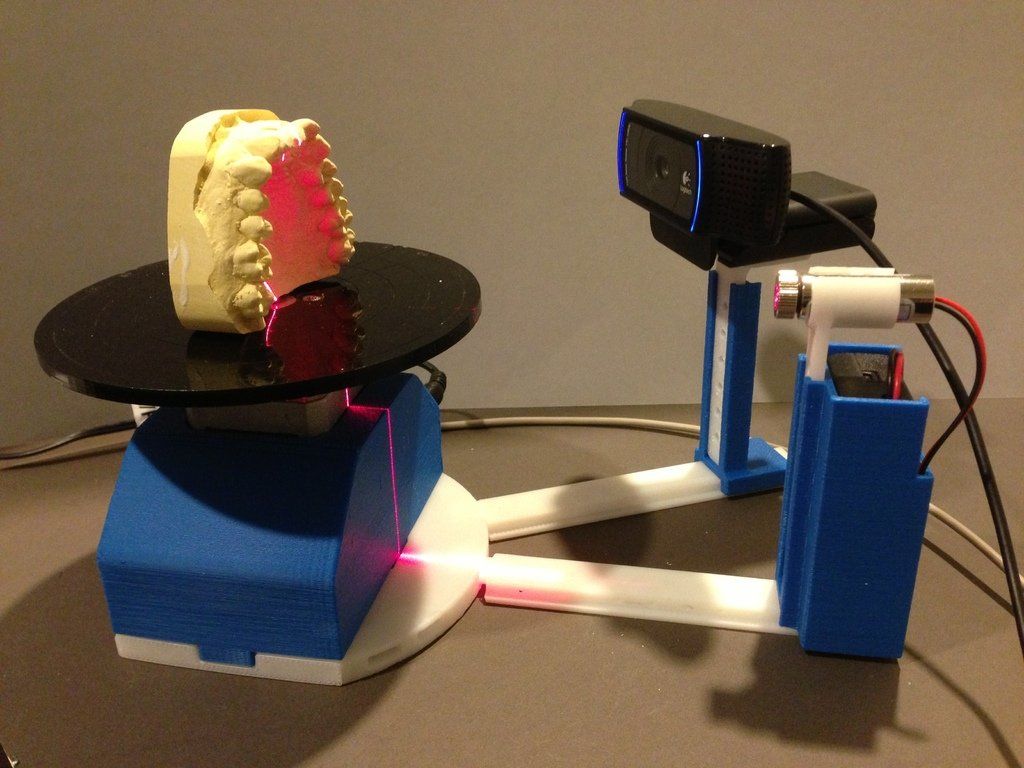

What is a 3D scanner? This is a device designed to quickly analyze a physical object and create its accurate 3D computer model. The principle of its operation is based on calculating the distance to the object using two cameras. In addition to the cameras, a backlight is used - LED or laser.

The principle of its operation is based on calculating the distance to the object using two cameras. In addition to the cameras, a backlight is used - LED or laser.

3D scanners are classified both according to their form of execution (stationary and portable) and according to the areas of use, mainly divided into professional and household.

3D scanners make it possible to significantly reduce the time and costs at the development stage, improve the quality of products and, ultimately, speed up the release of the product to the market. They can be used at any stage of product lifecycle management and will help to optimize the production process of enterprises in various industries, including:

- automotive,

- mechanical engineering,

- aerospace industry,

- oil and gas industry,

- shipbuilding,

- building and architecture,

- arts and culture,

- medicine,

- jewelry,

- science and education.

3D scanning devices remove many of the limitations of traditional measuring equipment. Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training.

Optical inspection systems, which include 3D scanners, are the best solution in terms of price and quality, as they provide:

- measurement speed,

- high precision digitization of objects of complex geometry,

- can work autonomously,

- are easy to operate.

Thanks to a 3D scanner, the work of a designer, technologist, and constructor is greatly facilitated: the performance of time-consuming complex measurements and the creation of a design from scratch are a thing of the past.

What tasks does 3D scanning solve

- Quality control: the ability to check any geometric parameters, including input and output control, metrological control of parts and production equipment.

- Reverse engineering of products for prompt receipt of project documentation and product upgrades.

- Design and simulation for the purpose of prototyping and evaluation of the appearance of products, modernization of production facilities and equipment.

- Digital archiving of any required assortment (eg discontinued parts). Models stored in digital libraries are available remotely from anywhere in the world.

3D scanner selection criteria

The main criterion is scanning accuracy . High-precision devices (10-30 microns) will help to get a phenomenal result: they are able to transfer the most complex surface geometry into 3D with minimal errors. Such 3D scanners are used in reverse engineering, quality control, medicine, and are used to digitize molds, device parts, etc. 3D scanners with an accuracy of 30–100 engineering.

3D scanners with an accuracy of 30–100 engineering.

ZG AtlaScan is the world's first 3D scanner with hole capture

When choosing a 3D scanner, you should also take into account resolution (detail) , i.e. the degree of discreteness that is available when digitizing an object. The highest level of detail allows you to display the smallest elements in the 3D model.

P the size of the scanned objects and, accordingly, the mobility of the 3D scanner directly depend on the type of device that you select. When digitizing parts and objects of small and medium parameters, hand-held scanners are usually used. Stationary scanners are suitable for capturing complex small and medium-sized products with small details. Scanning of large objects (buildings, structures, communications) is performed using ground-based laser devices (range finders).

When studying the functionality of 3D scanners, pay attention to such points as the conditions of use, scanning speed, the surface of the scanned object, and color.

Please note that the next step after scanning is to obtain and further work with the CAD model, and for this you will need specialized software.

Processing 3D Scan Data for Reverse Engineering in Geomagic Design X Software

Professional 3D scanning for fast and efficient production solutions

iQB offers cutting-edge solutions that successfully operate in leading enterprises around the world:

- Portable devices for metrological 3D measurements from ZG Technology (China). The line includes a wide range of instruments, from an affordable handheld 3D scanner to a powerful optical tracking measurement system, as well as photogrammetry and portable CMM. ZG's unique strengths include the world's first handheld MarvelScan solution with three cameras for markless laser scanning and tracker, and proprietary instant hole capture technology. ZG Technology 3D scanners provide measurement speed up to 1 million 350 thousand points per second and accuracy up to 0.

01 mm.

01 mm. - Stationary optical 3D-scanner of Russian production RangeVision PRO is an industrial solution for metrology, available to companies of any level. The device is designed to digitize objects from 1 mm to 5 m and offers the highest level of accuracy (up to 0.018 mm) and 3D resolution (up to 0.04 mm). This is the first domestic 3D scanner approved by the Federal Agency for Technical Regulation and Metrology as a type of measuring instrument.

- Creaform handheld 3D scanners for digitizing products ranging in size from a few centimeters to 6 meters. The Go!SCAN series devices (including the latest Go!SCAN SPARK) are based on structured illumination technology; HandySCAN 3D and MetraSCAN 3D are laser devices that are certified industrial grade metrology tools. The new generation MetraSCAN BLACK|Elite model is the fastest handheld 3D laser scanner on the market (1.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m. - Creaform also produces 3D scanners and software under the peel 3d brand, combining affordability, ease of use and high quality. The line is designed to solve the problems of reverse engineering and digitalization of objects in such areas as art, preservation of cultural values, consumer goods, science and education, human body scanning. Peel 3d devices are capable of measuring objects from 0.3 to 3 m with an accuracy of 0.1 mm.

RangeVision PRO Fixed Scanner Creates Yamaha R3 Sport Fairings with Improved Aerodynamics, High Strength and Lighter Weight

- Solutionix fixed optical 3D scanners for small objects (10-500 mm) with many small parts. Allow to receive an error less than 8 microns.

- FARO Focus 3D geodetic laser scanners perform fast and accurate scanning of large objects, complex structures, premises and landscapes. They operate in the range from 0.6 to 350 m, they are distinguished by increased accuracy, ease of operation and the ability to operate in the most difficult environmental conditions.

- EPiC budget 3D terrestrial laser scanners are based on the principles of simplicity, convenience and affordability. Their main advantages are super light weight, high shooting speed (from 30 to 90 seconds), 360-degree panoramic camera and the ability to control from a mobile device.

Many of the above scanners are included in the register of measuring instruments of the Russian Federation and have the appropriate certificates.

Robotic 3D scanning systems, such as Creaform MetraSCAN 3D-R, allow you to increase the speed and efficiency of quality control directly on the conveyor

A variety of 3D scanning devices on the market will allow you to choose exactly the model that is needed for solving specific problems. The price range is also wide: from simple devices costing up to $500 to high-precision professional 3D scanners costing tens and even hundreds of thousands of dollars.

Contact iQB Technologies experts! We will select the optimal solution that will optimize product development and production in your enterprise, design office or research center.

We remind you that the test scan is free!

We remind you that the test scan is free! Article published on May 25, 2017, updated on October 4, 2022

3D face scan with 3D scanner

Solve individual problems in medicine and cosmetics

Test scan

- Applications

- 3D Model Examples

- Scanning tips

- Hardware and software

- Where to buy?

In the field of modern technologies, the terms "personification", "individualization" are increasingly used. The solution of these problems becomes possible with the use of 3D scanners.

3D scanning is increasingly used by specialists in the field of medicine, health and beauty - cosmetologists, dentists, prosthetists, surgeons. In their work, they trust 3D scanners to solve problems such as the creation of individual prostheses, implants, surgical templates.

Also, 3D scanning of the face and body is used in the entertainment industry, in design and advertising to create souvenirs, individual packaging.

3D scanner transmits

the smallest details

The peel 3d line of 3D scanners was created to digitize various structures, including the human face, skin and its defects with an accuracy of 0.1 mm.

Applications

Plastic surgery

- 3D facial imaging for maxillofacial surgery

- plastic surgery modeling

Facial prosthetics

- creation of individual prostheses, surgical templates, implants

- visualization and modeling of the result of transplantation and prosthetics

Advertising, entertainment industry

- production of promotional items, including 3D printing

- 3D visualization of art objects

- creation of digital models for computer games and other programs

Souvenirs, designer accessories

- making figurines of real people for printing

- manufacture of personalized accessories and jewelery

- digitization of mini-copies of real objects, sculptures, busts

Project examples

Lincoln's face

human ear

Human face in high resolution

More cases in different industries

Test the scanner for free and see how it performs for your needs Test scan

Human Face Scanning Guidelines

Do you want to test the 3D scanner?

Order a scan in our office or make an appointment

for an online demo.

3D Face Scan Solutions

3D peel 3d scanner Face scanning is fast, easy and safe!

The compact peel 2, peel 2 CAD, Go!SCAN 20 scanners are professional solutions for digitizing objects up to 3 m with an accuracy of 0.1 mm and the ability to capture texture and color.

Go to catalog

Software Unleash your creativity with this powerful 3D modeling software!

The peel 3d software product allows you to solve all the main tasks when processing scanned data.

Go to catalog

Why order

solutions from iQB Technologies

Exclusive distributor of peel 3d in Russia

Professional

3D scanners at the price of budget counterparts

Free trial

3D scan of your part

Demo hall in Moscow: more than 10 scanners and 3D printers

Services for the implementation, maintenance and repair of 3D equipment

Training in the use of 3D scanners in prof. activities

activities

3D scanning services based on our own fleet of equipment

About

3D scanner applications

3D scanning technology continues to gain popularity, and today the 3D Scanner (3D Scanner) It is used not only in production, but also for scanning a person's face. 3D scan first (3D Scanning) faces used for biometric access control systems, but now the technology is in demand primarily in dentistry, plastic and maxillofacial surgery, and cosmetology.

Scanning a human face with the peel 3d 3D face scanner can be done almost under any angle, unlike complex measurement methods such as magnetic resonance imaging (MRI) and computed tomography (CT). This greatly simplifies the process of creating a 3D model.