Origin 3d printers

Origin – Manufacture the impossible

Video Player is loading.

Current Time 0:00

Duration -:-

Loaded: 0%

Stream Type LIVE

Remaining Time -0:00

This is a modal window.

The media could not be loaded, either because the server or network failed or because the format is not supported.

Beginning of dialog window. Escape will cancel and close the window.

TextColorWhiteBlackRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentBackgroundColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentTransparentWindowColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyTransparentSemi-TransparentOpaque

Font Size50%75%100%125%150%175%200%300%400%Text Edge StyleNoneRaisedDepressedUniformDropshadowFont FamilyProportional Sans-SerifMonospace Sans-SerifProportional SerifMonospace SerifCasualScriptSmall Caps

End of dialog window.

We’ve joined forces with Stratasys to usher in the next era of additive manufacturing.

Featured In

THE LATEST NEWS

Exceptional Accuracy and Consistency

Programmable Photopolymerization (P³) precisely orchestrates light, temperature, and other conditions, automatically optimizing prints in real-time for the best possible results. Produce features less than 50µm in size with high-accuracy materials.

Big Build, Small Footprint

An optimized build volume (192mm x 108mm x 350mm), compact footprint (400mm x 450mm x 1100mm), and minimal power requirements enable manufacturers to efficiently maximize production capacity per sq ft.

Welcome to Open Additive Manufacturing

World-Class

Materials

Incorporate new application-specific materials from our open network of partners.

Commercial-Grade

Parts

Exceed injection molded strength, consistency, and durability at a competitive cost.

Additive Mass

Production

Seamlessly test, iterate, and scale production with our open approach and modular system.

World-Class Materials

Resilient elastomers, heat-resistant polymers, biocompatible formulations, and other high-performance materials from our open network of material partners.

Video Player is loading.

Current Time 0:00

Duration -:-

Loaded: 0%

Stream Type LIVE

Remaining Time -0:00

This is a modal window.

The media could not be loaded, either because the server or network failed or because the format is not supported.

Beginning of dialog window. Escape will cancel and close the window.

TextColorWhiteBlackRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentBackgroundColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentTransparentWindowColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyTransparentSemi-TransparentOpaque

Font Size50%75%100%125%150%175%200%300%400%Text Edge StyleNoneRaisedDepressedUniformDropshadowFont FamilyProportional Sans-SerifMonospace Sans-SerifProportional SerifMonospace SerifCasualScriptSmall Caps

End of dialog window.

Built for Volume

Materials engineered to be easy to handle, rapidly post-processed, and exhibit extended shelf life.

Priced for Scale

A cost-per-kilogram that starts low and drops as volume scales.

Lower Risk

Redundant sourcing of critical materials lowers the chance of supply interruptions.

Commercial-Grade Parts

Origin's production system uses Programmable Photopolymerization (P3) to turn materials into isotropic parts and products ready for end-use.

Hand Pump Thread AdapterDIMENSIONS

2.9" x 2.9" x 1.82"

TOTAL PRINT & POST-PROCESSING TIME

46 min

TOLERANCES

+/- 50µm

TENSILE STRENGTH

61 MPa

Additive Mass Production

High throughput, combined with unmatched part-to-part consistency, helps you expand production without delays, so you can launch faster and respond flexibly to shifts in demand while maintaining minimal inventory.

Video Player is loading.

Current Time 0:00

Duration -:-

Loaded: 0.00%

Stream Type LIVE

Remaining Time -0:00

This is a modal window.

The media could not be loaded, either because the server or network failed or because the format is not supported.

Beginning of dialog window. Escape will cancel and close the window.

TextColorWhiteBlackRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentBackgroundColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyOpaqueSemi-TransparentTransparentWindowColorBlackWhiteRedGreenBlueYellowMagentaCyanTransparencyTransparentSemi-TransparentOpaque

Font Size50%75%100%125%150%175%200%300%400%Text Edge StyleNoneRaisedDepressedUniformDropshadowFont FamilyProportional Sans-SerifMonospace Sans-SerifProportional SerifMonospace SerifCasualScriptSmall Caps

End of dialog window.

Smart Sensing

Computer vision and sensors monitor print progress to provide real, in-process QA, alerting you to potential issues to optimize production.

Massive Throughput

Print technology and materials optimized for speed and batch-processing that scales up at predictable and competitive costs.

Modular Hardware

Compact design and modular stacking with the best production capacity per square foot of available production space.

We’ve recently added to our network of material partners

THE LATEST NEWS

Origin – Manufacture the impossible

January 5, 2021

Press Release

Stratasys Completes Acquisition of Origin, Accelerating Expansion into Mass Production Additive Manufacturing — Origin’s resin based Programmable PhotoPolymerization (P3) technology addresses fast-growing demand for tooling and end-use parts across multiple applications

October 26, 2020

Press Release

Team Consisting of Stress Engineering Services, Origin, and nTopology have placed 1st in the USAF F-16 Approval Sprint Challenge for the Inaugural Rapid Sustainment Office Advanced Manufacturing Olympics — Working together remotely, the team designed, analyzed, tested and manufactured a solution for a difficult aerospace problem and was awarded $100K in prize money

October 15, 2020

Press Release

CASE STUDY: Origin Partners with nTopology and Stress Engineering Services to Redesign Fighter Aircraft Part for the U. S. Air Force — Producing a stronger, more durable hydraulic line clamp for the U.S. Air Force’s Fleet of F-16 Aircraft

S. Air Force — Producing a stronger, more durable hydraulic line clamp for the U.S. Air Force’s Fleet of F-16 Aircraft

September 30, 2020

via 3DPrint.com

Origin to 3D Print F-16 Parts for US Air Force’s AM Olympics — 3D printing startup Origin was selected to participate in the U.S. Air Force (USAF) Rapid Sustainment Office’s (RSO) inaugural Advanced Manufacturing Olympics (AM Olympics).

September 29, 2020

via TCT Magazine

Origin submits additively manufactured F-16 hydraulic line clamp for US Air Force technical challenge — The company worked alongside nTopology and Stress Engineering Services on the project.

September 25, 2020

Press Release

Origin Chosen to Participate in the 2020 USAF RSO Advanced Manufacturing Olympics — Working together remotely, Origin, Stress Engineering and nTopology produced a viable solution to a difficult aerospace problem in just three weeks, amid the pandemic

August 13, 2020

via AMFG

Expert Interview: Origin CEO Chris Prucha on Why The AM Industry Needs An Open Materials Ecosystem

July 30, 2020

via TDK Ventures

TDK Ventures invests in additive manufacturing space — TDK Corporation will provide its extensive experience in mass manufacturing and electronic materials to jointly explore new additive production markets.

June 25, 2020

via Enventys Partners

Case Study: Origin One Printer for End-Use Manufacturing — A unique opportunity for Enventys Partners to use cutting-edge technology in its Origin One printer to rapidly produce much-needed equipment

June 15, 2020

via 3DPrint.com

NP Swabs Prove 3D Printing’s Scalability and Speed-to-Market Advantages — A year ago, if you would have asked anyone in our industry what they thought might be a future killer application, it’s highly doubtful that anyone would have replied with, “nasopharyngeal swabs.” Until recently, it was a niche product and the entire market was serviced by a few dominant industry players.

June 13, 2020

via 3D Printing Media Network

The origin of Origin’s 3D printed nasal swabs — San Francisco company Origin is one of a handful of 3D printing companies that set out to develop and mass produce 3D printed nasopharyngeal testing swabs for COVID-19 diagnosis. This effort was a direct response to a lack of conventional swabs; stores of the traditional swabs, only produced by a select group of companies around the globe, were rapidly depleted as countries around the world ramped up COVID-19 testing.

June 12, 2020

via 3DPrint.com

3DHEALS 2020 Virtual Medical Summit: 3D-Printed Materials in Healthcare — Steve Kranz definitely offered some of the most interesting information regarding materials, and Origin’s recent transformation from software developer and 3D printer manufacturer to a ‘swab factory’ in response to the coronavirus pandemic. The San Francisco-headquartered company began manufacturing a variety of different 3D-printed swabs for testing purposes, as well as originally designing shields and other personal protection equipment, to include adapting snorkels to be transformed into N-95-style face masks.

June 12, 2020

via Henkel

Henkel and Origin collaborate to help meet demand for COVID-19 NP swabs — Henkel´s and Origin´s first FDA compliant, sterile, 3D printed nasopharyngeal test swab now shipping

June 6, 2020

via Yahoo! News

VIDEO: Bootstrapping gear for coronavirus tests: How companies innovated to solve a critical shortage — Origin, a California-based 3D printing company, was one of the four manufacturers whose swab prototype was clinically validated by Arnaout’s team.

June 4, 2020

via Additive Manufacturing Media

How Test Swabs Became 3D Printing's Production Win: The Cool Parts Show Special Episode — Nasopharyngeal swabs for COVID-19 testing are one of the best production cases for 3D printing we've seen, pandemic or otherwise.

May 14, 2020

via Forbes

How 3D Printing Test Swabs Will Help Fulfill America's Shortage — COVID-19 testing is of the utmost importance but there is a major shortage of testing swabs. The 3D printing industry has come together to tackle this problem head-on. HP, Origin, Carbon, Desktop Metal and more are working to ramp up swab production.

May 11, 2020

via Journal of Clinical Microbiology

Open Development and Clinical Validation Of Multiple 3D-Printed Nasopharyngeal Collection Swabs — Rapid Resolution of a Critical COVID-19 Testing Bottleneck

May 2, 2020

via Business Insider

Startups are making nasal swabs, clinical testing booths, and fever detection systems to fight the pandemic — Here are the 11 coolest pivots in tech since the coronavirus outbreak

April 24, 2020

via FastCompany

The race to 3D-print 4 million COVID-19 test swabs a week — 3D printing companies hope to help produce tens of millions of swabs for the American public. It’s a race against time.

It’s a race against time.

April 23, 2020

via NBC Bay Area

3D Printing Companies Shift to Produce Swabs for Coronavirus Testing — Tech companies are stepping up to help in the shortage of swabs needed to test for COVID-19.

April 23, 2020

Press Release

Stratasys and Origin Partner to Bring Millions of 3D-Printed Nasopharyngeal Swabs to Healthcare Providers for COVID-19 Testing — Stratasys and Origin are partnering to deliver millions of 3D-printed nasal swabs to healthcare providers and testing centers.

April 22, 2020

via The Washington Post

When these Boston doctors ran out of virus-testing swabs, they mobilized an army of 3-D printers — How one hospital and some manufacturers with 3-D printing capabilities came up with new designs and new supplies of swabs for coronavirus testing.

April 22, 2020

via ABC7News

3D printed swabs help solve COVID-19 testing kit shortage — San Francisco company Origin makes high-level 3D printers for automotive and footwear industries and for the federal government.

April 21, 2020

via CNBC

3D printing companies help boost production of coronavirus testing swabs — CNBC’s Josh Lipton reports on how coronavirus testing could be ramped up with the help of 3D printing testing swabs.

April 20, 2020

via BIDMC

BIDMC-led clinical trial identifies four novel 3D-printed swabs for use in COVID-19 testing — Large-scale production could reduce one obstacle to widespread COVID-19 testing.

April 13, 2020

via Crunchbase

From Making 3D Printers To Manufacturing COVID-19 Test Swabs, A Startup Pivots — Over the last two weeks, San Francisco-based Origin has quickly shifted its resources from being a 3D printer manufacturer to becoming a medical device manufacturer, and has started production to address the massive shortage of COVID-19 test kits.

April 13, 2020

Press Release

Origin 3D-Printed COVID-19 Test Swabs Clinical Trial and Validation Completed with Beth Israel Deaconess Medical Center — Company Ramps Production of Millions of Test Swabs in the Coming Weeks

April 9, 2020

via Fabbaloo

The Collaboration We Need: Consortium Propels 3D Printed COVID-19 Test Swabs — Validated manufacturers around the country are now poised to rapidly produce up to 4 million 3D printed swabs per week, starting today.

March 31, 2020

via BIDMC

BIDMC physician-scientists spearhead effort to address nationwide COVID-19 testing swab shortage — 3D-printable COVID-19 testing swabs could help address nationwide shortage in a multidisciplinary effort spearheaded by BIDMC physicians.

March 27, 2020

via Medical Design & Outsourcing

Software is enabling medical 3D printing innovation: Here’s how — The 3D printers themselves get a lot of attention, but for 3D-printing to become ubiquitous in the medtech space, software will have to play a key role.

February 14, 2020

via Digital Trends

This 3D-printed four-legged robot is ready to take on Spot — at a lower price — The finished pieces are comparable in quality to their CNC machined predecessors, although they can be printed for just one-quarter the cost.

February 7, 2020

via Additive Manufacturing Media

The Promise of Full Polymerization in Resin 3D Printing — Through hardware, software and material partnerships, the company is changing what is possible inside a photopolymerization printer.

January 15, 2020

via Additive Manufacturing Media

Production 3D Printing With Roots in Materials Development: The Origin Story — Production-oriented polymer AM machine uses the same platform with the same range of controls originally conceived for material development.

December 16, 2019

via Fotis Georgiadis

The Future Is Now: "Now we can 3D print materials that were traditionally unprintable" With Chris Prucha, CEO of Origin — We want openness to win because it will increase material diversity and increase innovation in the ecosystem.

November 22, 2019

via Fabbaloo

First Fire Safe 3D Printable Resin Produced — 3D printer manufacturer Origin announced a new Loctite resin that meets aerospace fire safety standards.

November 15, 2019

via TCT Magazine

Henkel and Origin unveil fire-resistant 3D printing photopolymer ahead of Formnext — "The development of our new fire-resistant material is a real breakthrough innovation. "

"

November 15, 2019

Press Release

Henkel launches first photoreactive 3D printing material meeting aerospace fire, smoke and toxicity safety standards — Open technology breakthrough in collaboration with Origin

November 12, 2019

Press Release

Origin Named to 2019 CNBC Upstart 100 List — CNBC Recognizes Origin as a Promising New Startup

October 17, 2019

via TCT Magazine

Origin Starts Shipping Origin One 3D Printer — "Shipping our first production printer, Origin One, is a huge milestone for the company."

October 17, 2019

via 3dprint.com

Origin to Begin Shipping New Industrial 3D Printer, the Origin One

October 17, 2019

Press Release

Origin Announces its 3D Printer, Origin One, is Now Shipping — Company’s Growing Momentum Spurs New Customers, the Appointment of a COO and New Office Space

October 15, 2019

Case Study

How Origin Was able to Produce 100 Parts in 24 hours at a Fraction of the Cost of Traditional Manufacturing

August 1, 2019

via Plastics Machinery Magazine

Origin Seeks Fast, Collaborative Process

July 11, 2019

via The Tech Blog Writer Podcast

[Audio] Meet Origin - 3D Printing For Mass Production

May 28, 2019

via TCT Magazine

Inside Origin One: innovation, collaboration and thermo polymerisation — "We’re relying on an ecosystem to build this. "

"

May 27, 2019

via Henkel

Healthcare Systems Manufacturer Reduces Per-part Cost 10x by Harnessing New Open Additive Ecosystem

May 21, 2019

via RAPID + TCT Conference

[Video] Unlocking Mass Additive Manufacturing with Origin’s Chris Prucha

May 20, 2019

via BASF Press Release

BASF 3D Printing Solutions and Origin collaborate with footwear manufacturer ECCO

May 20, 2019

Press Release

Origin to Unveil “Origin One” at RAPID; New Manufacturing-Grade 3D Printing System Enables Additive Mass Production — Leading footwear manufacturer ECCO is using Origin One’s programmable photopolymerization process and Open Material Network to cut production costs and get to market faster

May 15, 2019

via DSM Press Release

DSM and Origin announce partnership to enable new materials for Origin’s open additive manufacturing platform

May 15, 2019

via TCT Magazine

DSM joins Origin open materials network and introduces Somos PerFORM HW material

May 14, 2019

via Henkel

Additive Breakthroughs Enable Consumer-Grade Finishes That Rival Injection Molding

May 2, 2019

via TCT Magazine

RAPID + TCT Exhibitor Highlights — Visitors to RAPID + TCT can expect industry firsts. ..

..

February 27, 2019

via Fabbaloo

The Importance Of Materials Partnerships

February 11, 2019

via 3D Printing Industry

Big Ideas in Additive Manufacturing, Insights from am Experts at Ford, Origin and RadTech

February 6, 2019

via 3D Printing Industry

Henkel joins Origin’s Open Additive Manufacturing Platform to develop materials for mass production

February 4, 2019

via Henkel Press Release

Henkel and Origin to partner for additive manufacturing at scale

February 4, 2019

via TCT Magazine

Origin announces Henkel as second Open Material Network partner — "We believe our open network approach with Henkel and other strategic partners will fundamentally reshape manufacturing and global supply chains."

February 4, 2019

Press Release

Henkel Joins Origin’s Open Material Network to Enable New Chemistries for Additive Mass Production

December 31, 2018

via Engineering.com

3D Printing Predictions for 2019 — New Materials

December 13, 2018

via Engineering. com

com

Exclusive — Origin Discusses Its Unique Mass 3D Printing Process

November 8, 2018

via TCT Magazine

Origin launches Open Additive Manufacturing platform and announces BASF partnership — BASF will unveil new photopolymer materials at Formnext formulated on the Origin platform.

November 8, 2018

via Chemical & Engineering News

New 3-D printing company gets help from BASF — The firm, Origin, raised $10 million in its series A round

November 8, 2018

Press Release

Origin Comes Out of Stealth and Introduces Open Additive Manufacturing — A Completely New Approach to Additive Manufacturing

November 8, 2018

via Mike Maples, Jr.

Origin — Making 3D Printing ready for Mass Production

November 8, 2018

via DCM Ventures

Announcing our Investment in Origin

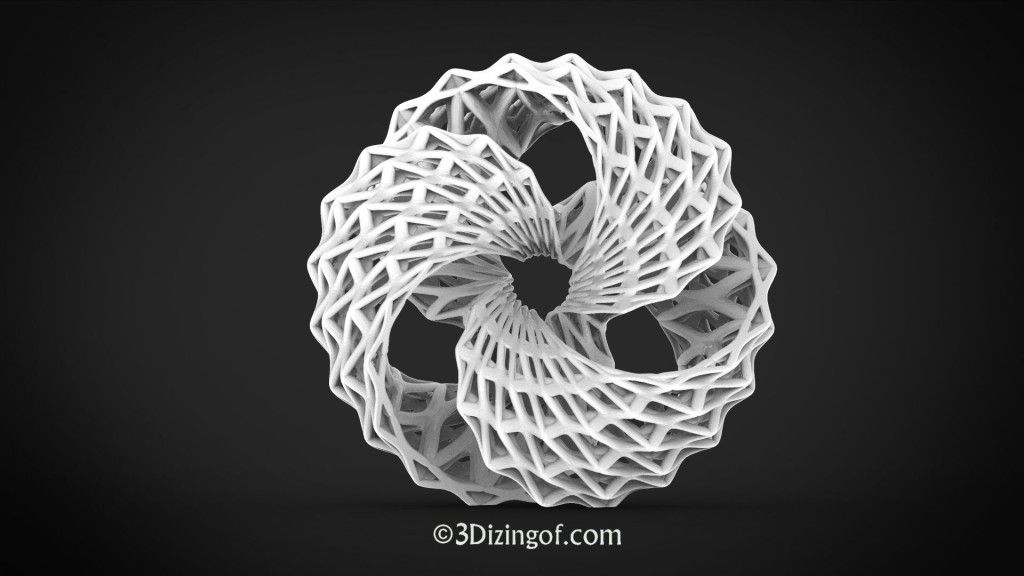

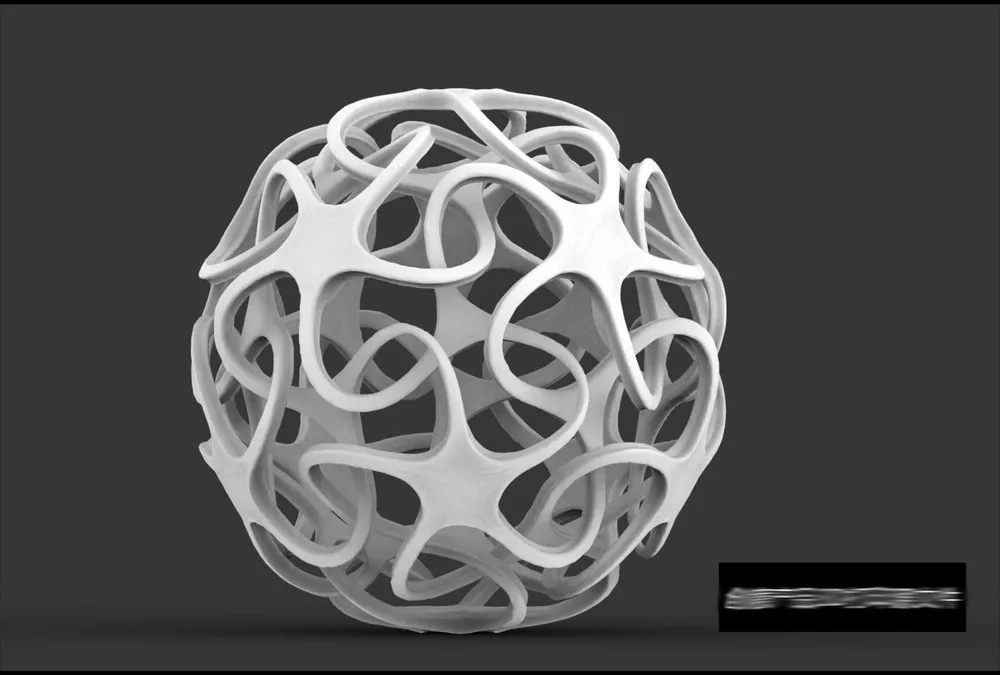

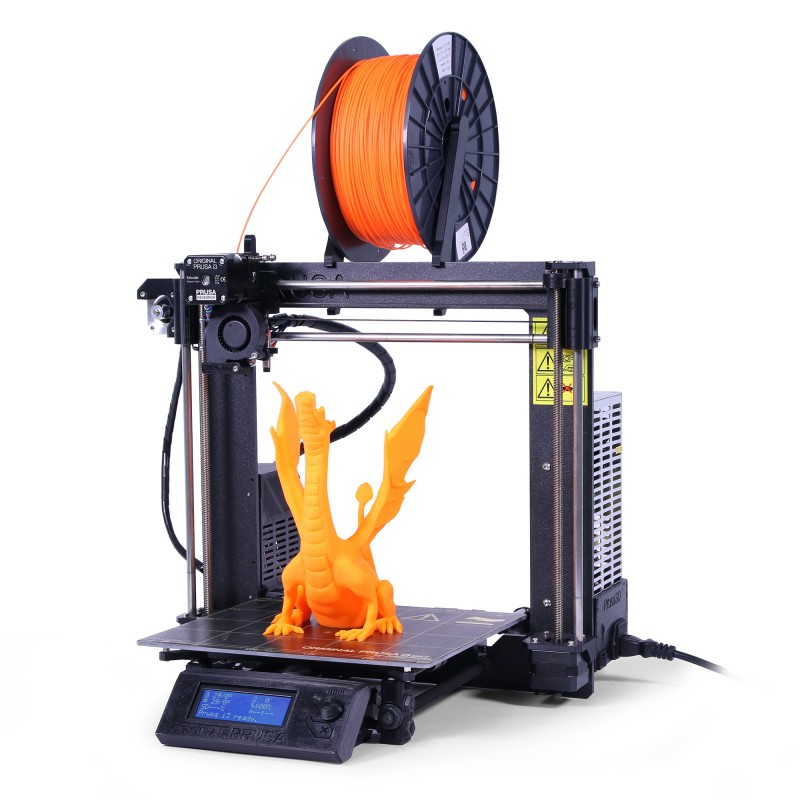

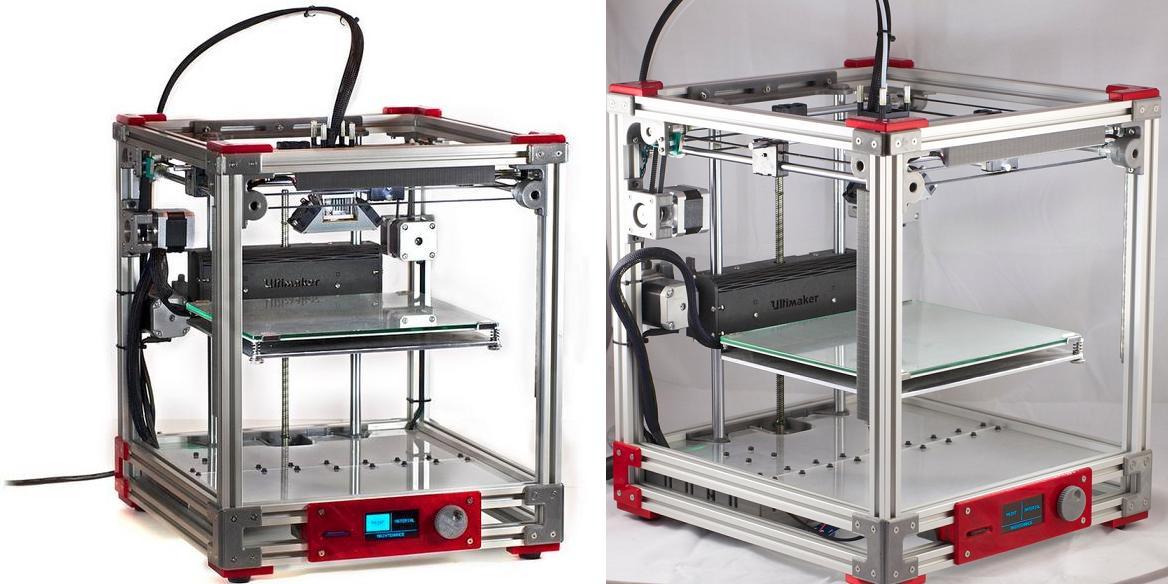

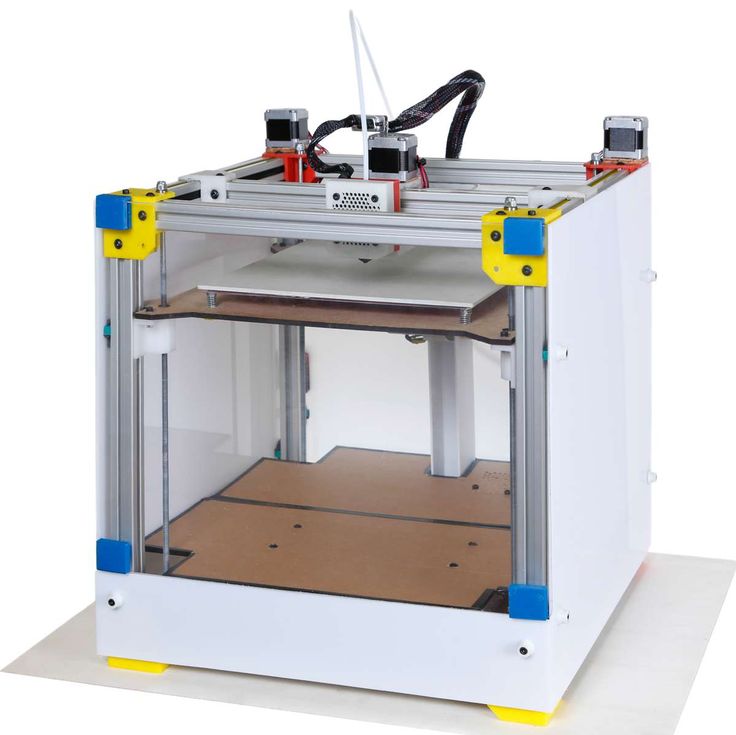

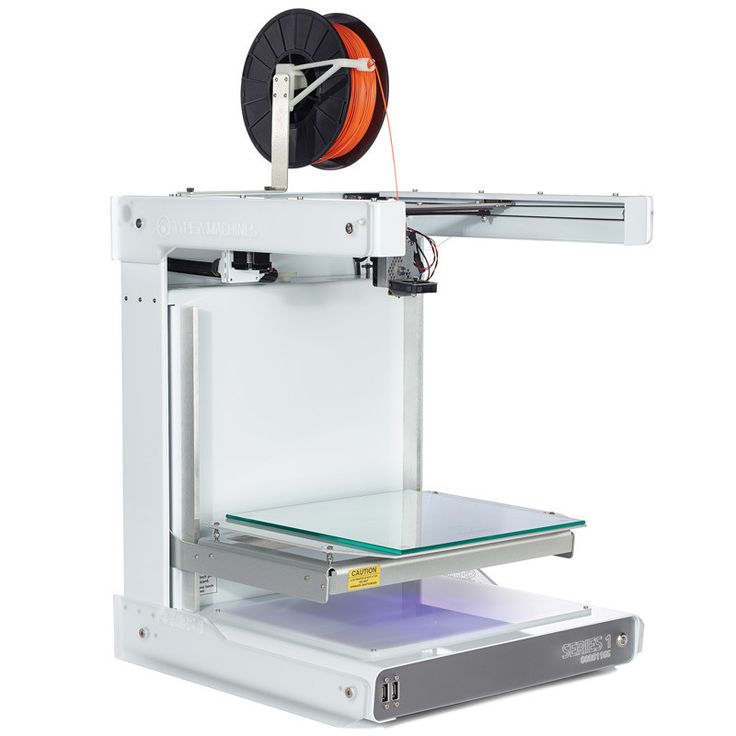

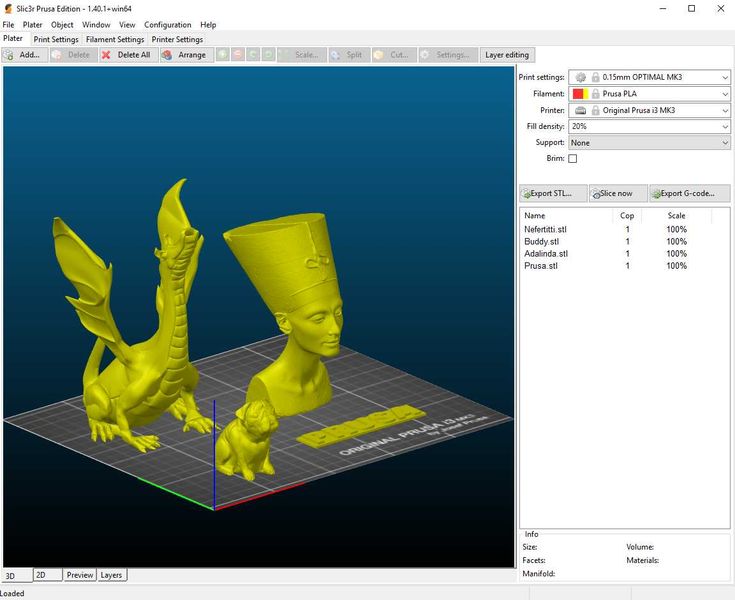

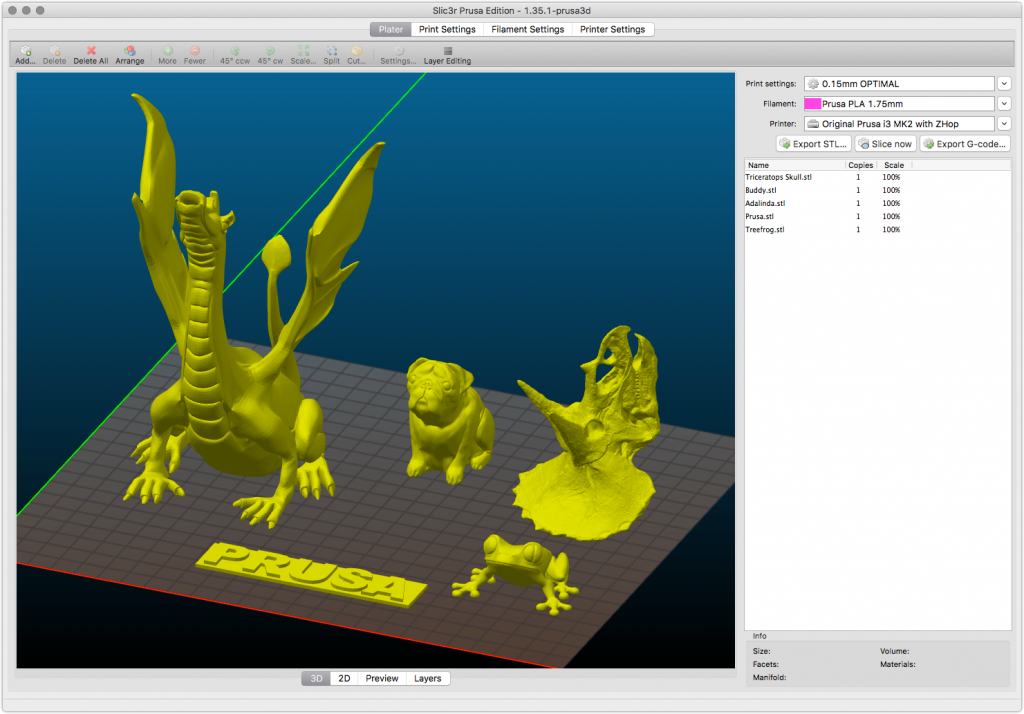

3D printer models

Looking for 3D printer models? The Internet is filled with sites that offer them for free. We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

We hope you can find what you are looking for.

- Yeggi

- Yobi 3D

- STLfinder

→ myminifactory.com

My Mini Factory is a 3D model depository operated by iMakr, an online store that sells 3D printers and accessories. It also has one of the biggest 3D printer shops in Central London. The site contains 3D models designed by professionals, and all models stored on it are checked for quality. You can also make a request for the desired model, which their designers will create and put in the public domain. Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites. nine0003

→ thingiverse. com

com

The most popular and famous site among 3D printer users, Thingiverse is owned by MakerBot Industries, the creator of the popular Replicator 3D printer series. The site allows users to store and share 3D model files that are used with 3D printers. It's a very popular site and has a large community of people hosting various categories of files on it. So if you're looking for "cool" printable stuff, Thingiverse is worth a visit. It is a portal designed to provide its users with ways to share their designs and to help print 3D creations. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be. nine0003

→ 3dshook.com

Another online community for 3D printing hobbyists showcasing interesting 3D printer accessories, electronics and most importantly 3D models. The site contains many very interesting models of cars and buildings, as well as various add-ons and spare parts for your 3D printer. A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself. nine0003

A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself. nine0003

→ youmagine.com

YouMagine catalog for Cube series consumer 3D printers manufactured by 3D Systems. The site mainly offers various ways to buy 3D printer supplies and files, but it also has a number of cool free items available, mostly in the Kids section. Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files. nine0003

→ 123dapp.com

Autodesk 123D is a suite of computer-aided design (CAD) and 3D modeling tools aimed specifically at hobbyists. Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it. nine0003

Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it. nine0003

→ cgtrader.com

Being primarily a place to buy and sell a variety of 3D models (not necessarily just those designed for 3D printers), CGTrader does offer a selection of free models that can be used on 3D printers. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the body will have better recommendations. nine0003

nine0003

→ cults3d.com

A French community and marketplace where developers can share or sell their creations. The site has a collection of high quality models that you can download. Users can follow the work of the designers they like and get instant updates when a new creation is posted on the site. The site's name, Cults, is a backwards spelling of St. Luc, the patron saint of artists. The site also supports English. This is a relatively new community, so the number of its users is not very large yet. nine0003

→ instructables.com

The Instructables website is a community where users can share their DIY projects. This also includes products obtained using 3D printers. The site also provides explanations and instructions describing how to build 3D elements, and some designers take the time to answer questions from site members. Instructables allows users to store and organize their 3D printing projects. This is done to help them work together in the future. You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it. nine0003

You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it. nine0003

→ pinshape.com

Pinshape, a marketplace for 3D models, is similar in style (layout, look, and ability to capture likes) to the well-known site Pinterest. You can buy models from designers, or download them for printing yourself if they are offered for free. Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself. nine0003

→ 3dfilemarket.com

A new and growing repository of 3D File Market models. All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers. nine0003

All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers. nine0003

Search engines for 3D models in various formats, including STL for a 3D printer. Use queries in English, these search services collect information about models from all over the Internet.

→ yeggi.com

Yeggi is a search engine that will browse major 3D printing sites to find files compatible with 3D printers. You can also browse some popular searches to get an idea of what the community is currently interested in. nine0003

nine0003

→ yobi3d.com

When in doubt, use yobi3D to search for files that match the desired 3D printer. This tool is useful if you want to search for one thing across all sites at once. A very convenient format filter, fast search, high-quality previews and stl models prepared for 3D printing for printing.

→ stlfinder.com

This is another STLfinder that surfs the web looking for 3D printing. To select files compatible with 3D printers, he goes through many 3D modeling sites. nine0003

"budget" metal powder 3D laser printer

News

metal powder compositions costing only half a Gelendvagen (we used to measure in Rolls-Royces).

One Click Metal is, in fact, a subsidiary of the well-known German engineering company Trumpf, which is also engaged in the production of industrial additive installations. The startup entered the market in 2019showcasing the first version of a PBF 3D printer of its own design called MPRINT at Formnext. The company is trying to find a specific niche, namely the production of low-cost additive systems for 3D printing with metal powders. Budget is a relative concept, but shortly before the premiere, One Click Metal CEO Bjorn Ullman estimated the cost at fifty thousand euros. In fact, the original 3D printers cost about that much, while the upgraded systems are offered for one and a half times more, but still much cheaper than most competitive offers ranging from a quarter to half a million dollars. nine0003

The company is trying to find a specific niche, namely the production of low-cost additive systems for 3D printing with metal powders. Budget is a relative concept, but shortly before the premiere, One Click Metal CEO Bjorn Ullman estimated the cost at fifty thousand euros. In fact, the original 3D printers cost about that much, while the upgraded systems are offered for one and a half times more, but still much cheaper than most competitive offers ranging from a quarter to half a million dollars. nine0003

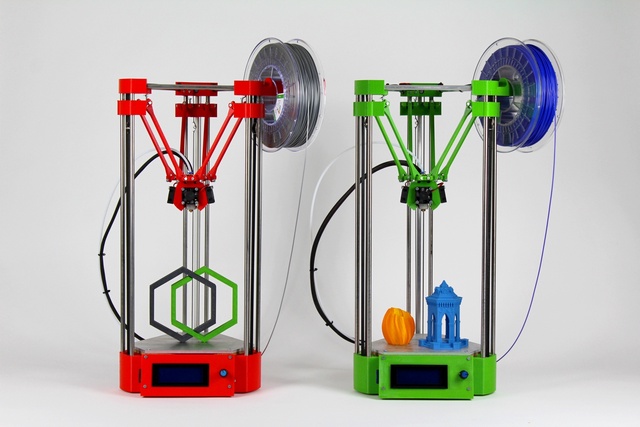

The updated MPRINT+ model differs from the original in a number of improvements aimed primarily at improving performance and resolution. The 3D printer is equipped with a more powerful 200-watt fiber laser compared to the 100-watt in the original version. With the positioning system, not everything is clear yet. The fact is that the original used a moving head with a diode laser from Trumpf - imagine your FDM 3D printer, but with an engraving laser nozzle on steroids. We have already seen something similar on the XM200 and XM300 3D printers of the American company Xact Metal. nine0003

nine0003

The new system allegedly uses a galvanometric scanning system that provides hatching speeds up to 3 m/s. Ullman at one time argued that a radical reduction in the cost of equipment became possible precisely due to the development of his own, relatively inexpensive scanner, so that a noticeable price jump can be fully explained by the transition to a more complex and expensive, but at the same time faster and more accurate galvanoscanner, if such the transition actually took place. Xact Metal, by the way, did just that, a year after the premiere, remaking the XM200 into the XM200S. nine0003

The spot diameter is 45 microns versus 100 microns for the original MPRINT, the layer thickness is set within 20-80 microns, the size of the construction area is 150x150x150 mm, and the density of finished products reaches 99.5%. Printing is carried out in a sealed chamber with a protective nitrogen atmosphere, which allows you to work with active metals and alloys.