Hewlett packard designjet 3d printer

HP Industrial 3D Printers - Leading The Commercial 3D Printing Revolution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

Integrity.

Production ready

and reliable

Together, we can take revolutionary designs seamlessly from prototype to production grade.

Ability meets

agility

Let’s implement production processes that allow you to rapidly develop unique solutions while remaining flexible.

Reimagining

realities

Now we have the power to customize like never before and produce wherever, whenever your product is needed.

The possibilities are endless

Partnership makes anything

possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Bastian Solutions & Fast Radius, Heygears, Avular, Breezm, Volkswagen and Cupra Racing

- Data courtesy of GoProto and Ropes Edge

- Data courtesy of Gimatic

- Data courtesy of SmileDirectClub

- Data courtesy of Volkswagen

- Data courtesy of Invent Medical

- Data courtesy of Cobra Golf

- Data courtesy Addit.ion

- Data courtesy of Hopkins, J., Lobete, A., Remacha, C.

- Data courtesy of Lumenium

- Data courtesy of Breezm

Industrial 3D Printer – HP Jet Fusion 5200 Series 3D Printing Solution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Expand and scale into volume production with HP industrial 3D printers

Enhanced manufacturing predictability

Breakthrough productivity and automation

Expand into new applications and markets

See how the HP industrial 3D printer works

Explore the complete HP Jet Fusion 5200 Series Industrial 3D Printing Solution

HP 3D High Reusability PP

1enabled by BASF

Chemical resistant,2 weldable, low moisture absorption, functional parts

Data courtesy3

HP 3D High Reusability PA 11

4Ductile,5 quality parts

Data courtesy6

HP 3D High Reusability PA 12

7Strong, low cost,8 quality parts

Data courtesy9

HP 3D High Reusability PA 12 GB

10Stiff, dimensionally stable, quality parts

Data courtesy11

BASF Ultrasint® TPU01

Flexible, functional parts.

HP Jet Fusion 5200 Series 3D Automatic

Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

HP 3D API

12Streamlined data access and automation across industrial management systems.

HP 3D Center

13Dashboard view into production data and remote monitoring for greater efficiency and agility.

Learn

Watch

HP 3D Process Control

14Dimensional accuracy and repeatability—faster—for manufacturing predictability.

HP SmartStream 3D Build Manager

Quickly and easily prepare your jobs for printing with all the elements you need.

Download

Autodesk® Netfabb® with HP Workspace

Provides advanced software for the additive manufacturing of production quality parts.

HP Build Processor

The industry standard software for professional 3D Printing, to unlock the full potential to manage every step in your production process.

Siemens NX AM

Combine design, optimization, simulation, preparation of print jobs, and inspection processes all in a single managed environment and with minimal steps.

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

HP 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

HP 3D Professional Services

Expert guidance to help you and your customers identify viable strategic opportunities, optimize design for breakthrough applications, and streamline manufacturing processes.

Data courtesy15

HP 3D as a Service

Pay based on usage: Gain new levels of cost predictability and the flexibility to scale your business as you grow.

HP Integrated Financial Solutions

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

Data courtesy16

Expand your offering with quality white applications

Achieve consistent white - part after part, with the HP Jet Fusion 5420W 3D Printing Solution that delivers enhanced manufacturing predictability and outstanding part quality at the right cost.

Disclaimers

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Based on internal HP testing, May 2020.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use. - Based on internal HP testing, May 2020, with tests for mechanical property retention, dimensional stability, and weight change after 7- and 30-day immersion with acids, bases, organic solvents, and aqueous solutions. Due to the material characteristics, extra tuning is required in part design and printing, compared to other rigid HP 3D Printing materials.

- HP 3D High Reusability PA 11 image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy. - Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

- HP 3D High Reusability PA 12 image is data courtesy of Addit.ion

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

- HP 3D High Reusability PA 12 GB image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- BASF Ultrasint® TPU01 image is data courtesy of Kupol.

- Supported industrial management systems for HP Jet Fusion 5200 / 4200 Series 3D Printing Solutions : 3D Control Systems, AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required. Supported industrial management systems for HP Jet Fusion 5420W 3D Printing Solution : 3D Control Systems, AMFG, LINK3D. Access to additional data modules available only for the HP Jet Fusion 5420W 3D Printing Solution.

Additional purchases required.

Additional purchases required. - Available only for the HP Jet Fusion 5420W 3D Printing Solution and HP Jet Fusion 5200/4200 Series 3D Printing Solutions. Compatible software. Additional purchase required.

- Available only for the HP Jet Fusion 5200 Series 3D Printing Solution. This software is sold as an HP 3D Solution Service. For more information visit https://h30195.www2.hp.com/v2/GetDocument.aspx?docname=4AA7-7931EEW

- Data courtesy of Meidai

- Data courtesy of Invent Medical

Overview of 3D printer manufacturers

3D printing appeared in the late 1980s, but 2020 became a breakthrough year for the technology. The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The prospects and pace of development of the sector in recent years have significantly increased its investment attractiveness, however, there are certain risks that should not be discounted. nine0003

nine0003

Vadim Kizimov

private investor

Author profile

Buy

Buy

Buy

Buy

Service in partnership with Investment mi.koff Quotes are updated every 15 minutes

Brief overview of technology

3D printing is the process of converting a model developed on a computer into a real three-dimensional object. Printing occurs due to the successive layering of thin layers of material. These are mainly thermoplastics of various types, but ceramic, biocompatible and other composite mixtures can also be used. That is why this technology is called additive. nine0003

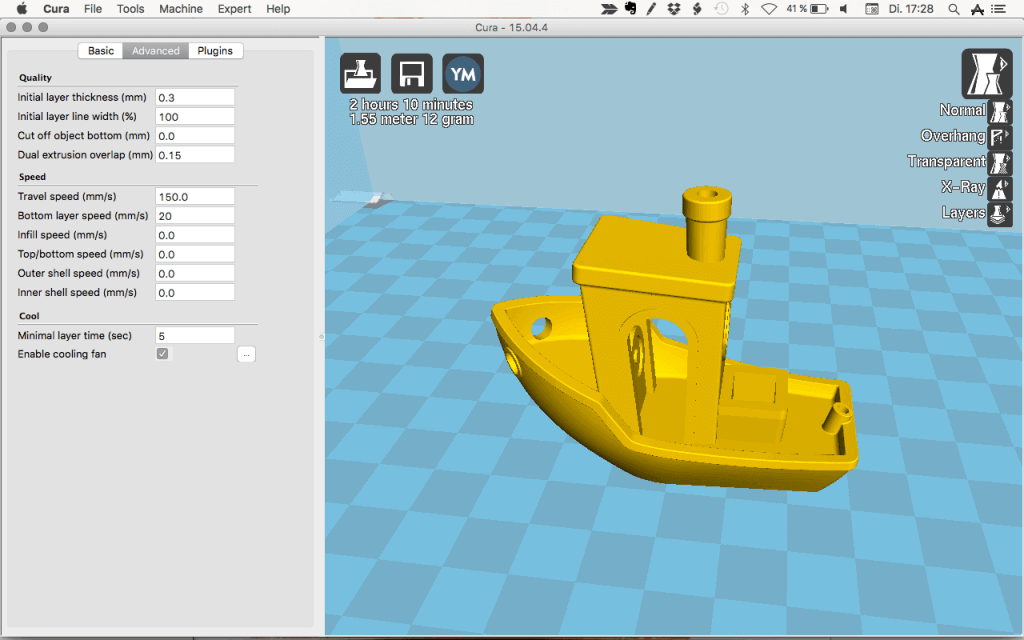

3D printing technologies differ depending on the materials and equipment used, but the general scheme of the process is always the same:

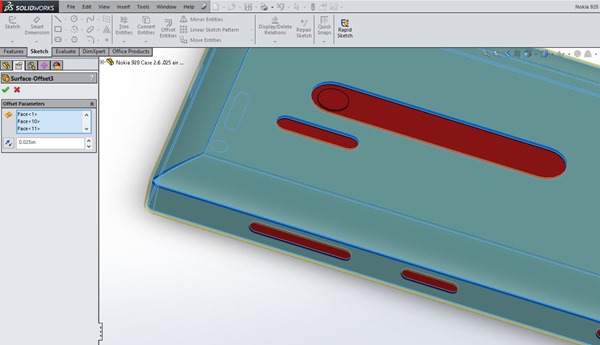

- A virtual model of the object is created on the computer, and in order to make a model, you do not need to have 3D modeling skills. A special scanner photographs a real object from different angles, creating a digital copy of it.

- The program is slicing - splitting the model into many thin horizontal layers.

- The template is loaded onto the 3D printer, the device reads the diagram and prints it layer by layer in volumetric form.

Applications

Using a 3D printer, you can copy any object or create your own. The possibilities for additive printing are almost limitless. Now the technology has already found application in various industries:

- health care: the creation of orthopedic orthoses, dentistry, transplantology, the manufacture of prostheses;

- industrial production: parts of machine tools and equipment; nine0031

- space, aviation and automotive industry;

- robotics;

- construction: models of buildings or individual structural elements;

- food production: figured chocolate, jellies and other desserts;

- household items: from smartphone cases and collectible figurines to shoes and interior items;

- jewelry.

At the moment, additive technologies are most in demand in medicine — 3D printing makes it possible to create consumables, prostheses, orthoses, mouth guards, and even absolutely accurate models of human organs — and in industrial production when creating parts and equipment elements. nine0003

But the scope of 3D printing is constantly expanding, opening up new opportunities for both large companies and small start-ups.

Industry Prospects

At the moment, 3D printing does not yet allow you to get fast and large-scale results, but the technology has proven itself in areas that require precision and uniqueness.

The increased availability of equipment and the absence of the need for long training of personnel to work with 3D printers also played a role. Over the past six years, the number of global and specific industries that use 3D printing technology has increased, and this market is truly limitless:

- large companies or organizations may refuse to purchase the necessary consumables or parts, producing them on their own in the volumes they need;

- The role of additive printing in medicine has already been discussed above, and there are also broad development prospects here;

- 3D solutions lower the barrier to entry for new players.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity. nine0031

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity. nine0031

At the end of 2021, the additive printing market was worth $15 billion, calculations were based on the cost of 3D printing and the production of printers and components. In the coming years, the expert agency Business Insights predicts an annual growth of the segment by more than 24%. At this pace, by the beginning of 2029, the size of the 3D printing market will grow at least five and a half times.

Technology deficiencies and risks of companies

Despite the prospects for the development of 3D technologies, 3D printing cannot yet be unequivocally called a profitable industry. There are a number of difficulties that do not allow you to fully rely on additive technologies. nine0003

nine0003

Still high cost of equipment. Cheap 3D printers can print small objects. To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

Poor performance. This drawback should be considered in conjunction with the previous one: now the speed and cost of 3D printers do not allow them to be used in mass production, making a tangible profit. nine0003

Insufficient strength of manufactured parts. The layered structure is more brittle in the direction of the layers than the monolith and cannot withstand heavy loads.

Lack of stability. The use of additive technologies on an industrial scale requires equipment and materials that can provide higher production reliability. At the moment, 3D printing is most often used for prototyping, quality control, or for the production of single parts. nine0003

The need for post-processing , which increases the cost and time of production of each unit.

Unpredictability. Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

3D printing companies on the St. Petersburg Stock Exchange

There are quite a few companies associated with 3D printing on the St. Petersburg Stock Exchange, and it is not their main activity. This industry is so young that at the moment it does not even have a benchmark significant index. nine0003

But the global trend of increasing demand for additive technologies in various areas of life can open up new prospects for industry pioneers.

Proto Labs (NYSE: PRLB). Capitalization - 2.56 billion Proto Labs was founded in 1999 in Minnesota, and by 2022 it already has more than ten branches in seven countries of the world. The company specializes in the creation of prototypes and finished parts for individual orders. In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity. nine0003

In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity. nine0003

Since 2014, Proto Labs has been using additive technology for manufacturing parts. In total, the company operates in four areas:

- Injection molding, revenue growth +4% year-on-year.

- CNC machining, +41%.

- 3D printing, +17%.

- Sheet metal production, +24%.

While 3D printing still only accounted for 14.8% of the company's revenue as of the end of 2021, the technology's growth trends could bring more tangible profits in the future. nine0003 Source: Tinkoff Investments Source: Tinkoff Investments

3D Systems Corp (NYSE: DDD). Capitalization - 1.88 billion. The company was founded in 1986, headquarters - in Rock Hill, South Carolina.

3D Systems manufactures and sells equipment, software and materials for additive manufacturing. Most often, the company's products are used in the aerospace, automotive, semiconductor and healthcare industries.

In 2021, 3D Systems announced two separate acquisitions. The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications. nine0003

After the announcement of the results for the fourth quarter of 2021, the company's quotes increased by 15%. This positive reaction was driven by double-digit revenue growth of 13.1% yoy, excluding sales of part of the business. In addition, 3D Systems reduced its net loss by almost three times, and the revenue forecast for 2022 was increased by 10%.

Source: Tinkoff Investments Source: Tinkoff Investments Align Technology (NYSE: ALGN). Capitalization - 32.4 billion American company Align Technology is a manufacturer of medical equipment for dentistry and orthodontics. The patented Invisalign bite treatment system is based on the use of transparent removable orthodontic caps, which are printed on a 3D printer individually for each client. nine0003

nine0003

The company is headquartered in Silicon Valley and has a rapidly growing branch network covering Russia, Mexico, Costa Rica, the Netherlands, Australia and Japan.

Digital orthodontics is rapidly evolving, and Align Technology is not going to give up just yet. The percentage structure of revenue for 2021 is distributed as follows: 80% - sales of Invisalign products, 20% - sales of intraoral scanners and other dental equipment.

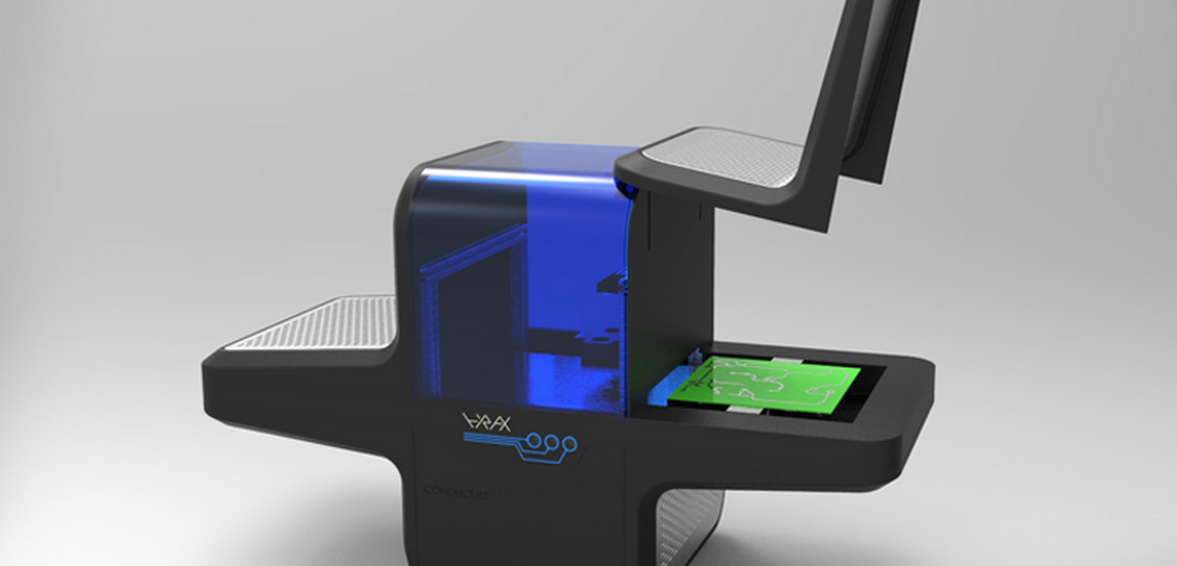

Source: Tinkoff Investments Source: Tinkoff InvestmentsHP Inc. (NYSE: HPQ). Capitalization - 39.7 billion. The company does not specialize in the production of 3D printers, but is still one of the leaders in the additive printing market.

In 2014, HP developed Multi Jet Fusion 3D powder printing technology to lower the price and speed of industrial 3D printers, and two years later, the first HP Multi Jet Fusion models went on sale.

In 2017, Hewlett Packard introduced the world's first 3D lab for testing various types of additive printing raw materials. And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products. nine0003

And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products. nine0003

HP Metal Jet Printer delivers 50 times the performance and significantly lower cost of finished parts than other technologies.

On April 7, 2022, investors were shocked by the news that Warren Buffett had bought $4.2 billion worth of shares in the company. Immediately after the announcement of the deal, HP shares grew by 14.75%.

Compare companies by multiples, growth rates, and R&D spending.

Source: Tinkoff Investments Source: Tinkoff InvestmentsCompany multiples

| Capitalization, billion dollars | P/E | Forecast P/E | P/S | Debt to equity | |

|---|---|---|---|---|---|

| PRLB | 2.56 | 38.00 | 28.00 | 2.81 | 0.01 |

| ALGN | 32.40 | 41.00 | 32.00 | 8.18 | 0.04 |

| DDD | 1. 88 88 | 5.30 | 5.00 | 2.88 | 0.60 |

| HPQ | 39.70 | 6.80 | 8.70 | 0.69 | −3.58 |

Capitalization, billion dollars

PRLB

2.56

ALGN

32.4

DDD 9008

0002 HPQ

39,7,000

Algn

32

HPQ

8.7

PRLB

2.81

Algn

8,18

DDD

2.88

HPQ

0.69

DEBT TO equity

PRLB

0.01

Algn

0.04

DDD

0.6

HPQ

−3.58

Power growth rate, million dollars

| 8888 | 2019 | 2020 | 2021 |

|---|---|---|---|

| PRLB | 458 (+2.69%) | 434 (−5.24%) | 488 (+12.44%) |

| ALGN | 2406 (+22%) | 2471 (+3%) | nine0183 3952 (+60%)|

| DDD | 636 (−8%) | 557 (−12%) | 615 (+10. 4%) 4%) |

| HPQ | 58,760 (+1.3%) | 56,630 (−3.62%) | 63,000 (+11.25%) |

2019

458 (+2.69%)

2020

434 (−5.24%)

200003

488 (+12.44%)

2019

2406 (+2222 %)

2020

2471 (+3%)

2021

3952 (+60%)

2019

636 (−8%)

2020

557 (−12%)

2021

615 (+10.4%)

2019

58 760 (+1.3%)

2020

56 630 (−3.62%)

2021

63 000 (+11.25%)

Help growth, million dollars

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 63 | 50 | 35 |

| ALGN | 442 | 1775 | 772 |

| DDD | −69 | −149 | 322 |

| HPQ | 3152 | 2884 | 6503 |

2019

63

2020

50

2021

35

2019

442

2020

1775

2021

772

2019

−69

2020

−149

2021

322

2019

3152

2020

2884

2021

6503

R&D costs, as a percentage of revenue

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | nine0183 7.8.5% | 9.0% | |

| ALGN | 6.5% | 7.1% | 6.3% |

| DDD | 13.1% | 13.3% | 11.2% |

| HPQ | 2.6% | 2.6% | 3.0% |

2019

7.2

2020

8.5

2019

6.5

20200003

7.1

2021

6.3

2019

13.1

2020

13.3

2021

11,2,2

2019

9000

2020 9,0003

2.6

Summarizing the data, several conclusions can be drawn:

- All companies are profitable, with the exception of DDD, which received a one-time profit in 2021 through the sale of non-core assets.

- ALGN and PRLB have the lowest leverage. nine0031

- All companies are growing.

- DDD has the highest R&D spending and the lowest revenue growth rate. Investors should pay attention to this.

What's the bottom line

Modern 3D printers can significantly reduce time and costs when solving geometry control and reverse engineering problems in the automotive, aviation, mechanical engineering, shipbuilding, jewelry and medicine industries.

However, in any industry, especially in a start-up one, it is necessary to carefully select companies for investment, since you can always get on a promising, at first glance, start-up, whose management, carried away by development costs, will not be able to turn a profit. nine0003

Innovations from HP and Ford - Wasteless 3D printing of automotive parts

It's no secret that 3D printing is actively used in the production of automotive parts. This technology is actively used by many manufacturers. It did not bypass the world-famous American concern Ford Motor, which purchased a huge batch of 3D printers from Hewlett-Packard. With their help, some minor parts for passenger cars are produced at Ford factories. 3D printing technology has made it possible not only to speed up the process of creating spare parts for vehicles, but also to significantly reduce the cost of manufacturing parts. nine0003

Interesting to know: In the 3D printing industry, various types of plastic are usually used (depending on the 3D printing technology).

The negative impact of 3D printing on the environment

During the operation of 3D printers from HP, Ford found that there was a fairly large amount of waste plastic powder and various parts. In this connection, the problem arose that if you do not come up with a high-quality way to dispose of waste from 3D printing, then the accumulated garbage will negatively affect the ecology of the planet. Even if we take into account the fact that the automaker produces only small parts, for which it is inappropriate to connect expensive industrial equipment, as well as various means for employees. Fortunately, both manufacturers (HP and Ford) quickly realized that the annual increase in 3D printing waste would quickly lead to a huge accumulation of garbage and bring the Earth closer to an environmental disaster. nine0003

Important: Many companies monitor the environmental state of the planet. Therefore, various technologies are regularly introduced into production that reduce the negative impact on the Earth's ecology. Do not think that only Greenpeace is engaged in such activities.

Do not think that only Greenpeace is engaged in such activities.

What Ford and HP have done to get rid of 3D printing waste

All 3D printed waste is recycled by Ford Motor Company. This company is called Lavergne. Its core business is the production of high quality resin from recycled plastics. In this case, special round-shaped plastic granules are made from waste. Further, these products are again sent to the Ford concern, where they are used for injection molding various parts. In addition, this solution was also introduced into production by the largest American company Smile Direct Club, which manufactures products for dentistry. nine0003

Interesting to know: We make plastic circular is Lavergne's main advertising slogan, which literally translates to "We make plastic circular". Although many interpret this slogan as "We make the plastic cycle." At the same time, both statements equally well describe the activities of this brand.

2%

2%