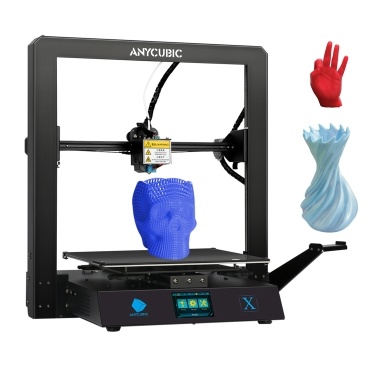

3D mobile cover printing online

Custom Mobile Cover Printing Online

Custom Mobile Covers and Cases Online at PRINTSHOPPY.COM

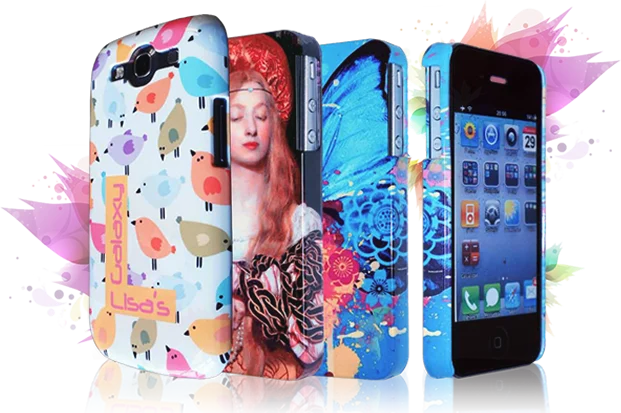

We, at printshoppy.com, have Customized Mobile Covers for most of the majorly available smartphones in India. Printshoppy will never compromise on three principles, i.e. material and print quality, value for money pricing and customer satisfaction.

For All Phone Cases, we use the best toughened polymer material which gives good protection for your Customized Mobile Cases. Whatever the Personalized Mobile Back Cover you opt, Printshoppy will leave you with utmost satisfaction. You can Buy Phone Case Online which were categorized with simple understandable navigation. Totally, Printshoppy created 400+ Customised Phone Case categories with 200+ design templates each.

Welcome to Printshoppy’s Customized Phone Cases Category

We hope you all know how vastly the transformational change of technology occurred in the field of mobile industry, isn’t it? On par with the technology, all the smartphone manufacturers are updating their Mobile Phone features starting from a featured phone to 4G Smartphone. Day by day, the number of smartphone users has increased significantly. Very soon, it wouldn't be a surprise to see, smartphones with IoT enabled.

Keeping everything aside, we, at Printshoppy.com, a Print E-Commerce company have come up with an innovative thought in making Customized Phone Cases. The following information will describe you that, how to pick the perfect Personalized Phone Case for your smart phone with your favorite photo or image. So, let’s go!!!

Best Selling Online Phone Cases in India

We have phone cases for about 350+ smartphone models. In which the best-selling online phone cases are from Xiaomi Redmi, Vivo, Honor, Oppo, Samsung, and Apple iPhone . At Printshoppy, we have custom mobile covers for majority of smartphone models available at very low price.

Design Your Own Mobile Back Covers Online India

You might ask, How to Design Mobile Covers Online? For every Customised Phone Case, printshoppy. com created 200+ templates with utter customization for all mobiles across India. As mentioned in the above three steps, Buying Phone Cases Online is easy. But still, if you need any assistance on how to buy Photo-Printed Customizable Back Covers, our customer support team are here to help you out at .

com created 200+ templates with utter customization for all mobiles across India. As mentioned in the above three steps, Buying Phone Cases Online is easy. But still, if you need any assistance on how to buy Photo-Printed Customizable Back Covers, our customer support team are here to help you out at .

How to print photo on mobile cover?

- Step 1: Choose your Customized mobile cover Brand/Model..

- Step 2: Upload Your Image or Photo to the selected mobile phone case.

- Step 3: Click on Finish Design and Buy phone cover Online.

Customized Mobile Covers: Mode of Payments

We have Customized Mobile Covers for all the smartphones across India. As well as, at Printshoppy accepts payments such as Credit/ debit card payment, net banking, cash on delivery, and PayTm.

Mobile Back Covers Online Delivery is available in Delhi, Mumbai, Bangalore, Gurgaon, Haryana, Pune, Maharashtra, Chennai, Hyderabad, Kochi, Kerala, Thiruvananthapuram, Ghaziabad, Thrissur, Kozhikode, Jaipur, Rajasthan, Indore, Noida, Ahmadabad, Gujarat, Kolkata, Surat, Malappuram, Nashik, Coimbatore, Aurangabad, Kollam, Faridabad, Puducherry, Kannur, Chandigarh, Vijayawada, and Raipur and all other major tier 2 and tier 3 towns.

Xiaomi Back Cover Printing|Custom Xiaomi Mobile Cover Online

Order your Case in 3 Steps

Mi Series

Mi 11 Lite NE 5G Mi 11X 5G Mi 11 Lite Mi 10 5G Mi 11X Pro 5G Mi 10T Pro 5G Mi 10T 5G Mi A2 Lite Mi 10i 5G Mi A3 Mi A2 Mi Mix 2 Mi 5 (2016) Mi 4i

Redmi 10 Series

Redmi 10A Sport Redmi 10 Prime 2022 Redmi 10A Redmi 10 Power Redmi 10 Redmi 10 Prime

Redmi 4 Series

Redmi 4A Redmi 4

Redmi 5 Series

Redmi 5 Redmi 5A

Redmi 6 Series

Redmi 6A Redmi 6 Pro Redmi 6

Redmi 7 Series

Redmi 7A Redmi 7

Redmi 8 Series

Redmi 8A Dual Redmi 8A Redmi 8

Redmi 9 Series

Redmi 9i Sport Redmi 9A Sport Redmi 9 Activ Redmi 9 Redmi 9 Power Redmi 9i Redmi 9 Prime Redmi 9A

Redmi K Series

Redmi K50i 5G Redmi K20 Pro Redmi K20

Redmi Note Series

Redmi Note 11 SE Redmi Note 11 Pro Plus 5G Redmi Note 11s Redmi Note 11 Redmi Note 11 Pro 5G Redmi Note 11T 5G Redmi Note 10 Lite Redmi Note 10T 5G Redmi Note 10s Redmi Note 10 Redmi Note 10 Pro Max Redmi Note 10 Pro Redmi Note 9 Redmi Note 9 Pro Redmi Note 9 Pro Max Redmi Note 8 Pro Redmi Note 7S Redmi Note 7 Pro Redmi Note 7 Redmi Note 6 Pro Redmi Note 8 Redmi Note 5 Redmi Note 5 Pro Redmi Note 4

Redmi S Series

Redmi S2

Redmi Y Series

Redmi Y3 Redmi Y2 Redmi Y1 Redmi Y1 Lite

Poco Series

Poco X4 GT 5G Poco F4 5G Poco M4 5G Poco X4 Pro 5G Poco M4 Pro 4G Poco M4 Pro 5G Poco C31 Poco F3 GT Poco M3 Pro 5G Poco M2 Reloaded Poco X3 Pro Poco M3 Poco C3 Poco X3 Poco M2 Poco M2 Pro Poco X2 Poco F1

Can't Find Your Model? Request Us

Pioneers and trailblazers.

Circular construction 3D printer - how did it all start? / Sudo Null IT News

Circular construction 3D printer - how did it all start? / Sudo Null IT News For thousands of years, people have been building without really understanding how to modernize the process into a simpler and cheaper one. Perhaps only agriculture can be called a more conservative industry than construction. But the current global market trends are relentless - innovation is needed to keep the industry, which in many countries is experiencing a significant crisis, afloat. One of the inventions designed to solve this problem was Apis Cor's mobile construction 3D printer. nine0004

The leading engineer of the company, Nikita Zherebtsov, told us about how this development was created.

3D printer: what a miracle, and what is it eaten with?

The idea of using 3D printers in construction is not fundamentally new, at the moment there are quite a lot of such systems. Why is this technology not well-known not only among a wide range of people, but also among engineers who have chosen construction as their industry?

The main problem with 3D printers is the limited number of applications. As a rule, they are stationary. That is, they ride on two parallel rails installed on a concrete surface, and on a flat surface, which is very important. If the surface is uneven, skew occurs, and all work goes down the drain. Simply put, such equipment has found its application only in large enterprises that have their own industrial zone, often with railway access roads. In the most demanded area of construction - the construction of houses - the use of such units was difficult. nine0013

As a rule, they are stationary. That is, they ride on two parallel rails installed on a concrete surface, and on a flat surface, which is very important. If the surface is uneven, skew occurs, and all work goes down the drain. Simply put, such equipment has found its application only in large enterprises that have their own industrial zone, often with railway access roads. In the most demanded area of construction - the construction of houses - the use of such units was difficult. nine0013

Secondly, a 3D printer can create, roughly speaking, a concrete box, the main walls of a building, and subsequently all the installation and finishing work has to be carried out by people. Adding to this a significant time (up to three weeks) and the considerable complexity of installing the printer itself, which also requires a team of professional installers, we get an interesting curiosity that is not very suitable for in-line construction.

This state of affairs continued until a group of promising young engineers arose who decided to breathe new life into an old idea, using enthusiasm, ingenuity and special approaches. The new mobile 3D printer was developed not by the technical department of a large company and not by the staff of the technological institute, but by Apis Cor, which in 2016 had three engineers at its disposal. nine0005

The new mobile 3D printer was developed not by the technical department of a large company and not by the staff of the technological institute, but by Apis Cor, which in 2016 had three engineers at its disposal. nine0005

“This is not just another project: We were pioneers and trailblazers”

Every day thousands of start-ups appear on the planet. Most of them pursue a fairly simple goal - to earn a decent existence. The goal is understandable and commendable, but civilization is moved forward by those who look wider. What inspired Nikita Zherebtsov to join the team and take part in the development of innovative technology?

— I have been in Apis Cor almost from the very beginning of the project, since 2016. The technology has already passed the first performance tests and it's time to build a working prototype, the company moved from Irkutsk to Moscow. Other engineers were developing the mechanical part of the equipment, and I spent my first months of work in the workshop - studying the existing developments and delving into the design features. nine0004

nine0004

— Have you worked on similar projects before?

— None at that time. I was not involved in the creation of industrial equipment. My area was auto and motorcycle technology. This is also why I was invited to Apis Cor. I had a decent experience in building structures, working with hydraulics, pneumatics and kinematic diagrams.

— How were the developments?

It was a complete startup. We had grandiose plans, and as soon as we thought about what was still to be done, we realized that the hours in the day were clearly not enough. Our assembly shop was located in the city of Stupino (Moscow region), we lived there in a large apartment that the company rented for us. Five adults 24 hours a day did not move further than 100 meters from each other, and thought only about work. We didn’t even have a hierarchy as such, we distributed tasks among ourselves. In a way, we were family, like-minded people. nine0004

- Such loads are like an obsession. What attracted you to this project?

What attracted you to this project?

Having immersed myself in the topic, I realized a simple fact: we are not doing another project with a standard set of technical tasks. It's much more. Building 3D printing technology is able to open a new era, radically change the industry and finally solve the problem of housing on earth. Architects will be able to work with forms and ideas that are impossible to realize using traditional building methods. We were pioneers and trailblazers. nine0004

New ideas and new challenges

Having studied the existing experience of 3D printing in construction, the developers began to look for new approaches in order to develop the optimal design configuration. Having noted many proposals, they chose a circular design: the machine prints a design of material layer by layer around itself.

- It seemed rational, but immediately a lot of problems arose, for example, with stabilization and feedback, a number of others. We set ourselves the task of creating a full-fledged CNC machine with high accuracy in prototype format. We almost did not use ready-made solutions. We developed all the mechanisms responsible for stabilization, lifting, structural rigidity, mixture supply and control system from scratch. Ready-made solutions for the circular design of the printer did not exist in nature. nine0004

We set ourselves the task of creating a full-fledged CNC machine with high accuracy in prototype format. We almost did not use ready-made solutions. We developed all the mechanisms responsible for stabilization, lifting, structural rigidity, mixture supply and control system from scratch. Ready-made solutions for the circular design of the printer did not exist in nature. nine0004

— What do you remember most in terms of difficulties?

— When X-Day — the printing of the first demo house was close, our plans were nearly thwarted by frost! It was the end of January - the beginning of February 2017, Stupino near Moscow, and the temperature during the day rarely rose above -25C. All equipment was ready for printing: actuators, electronics, program code. There was one question - where to conduct the test? In the production hall, the whole house simply would not fit. So we decided to erect a tent outside and print the building inside it. We had to separately insulate the water pipes that led water into the tent to the equipment. Otherwise, the mixture water would freeze in the pipes before reaching the equipment. To maintain at least a little plus temperature, we also had to fill all the seams in the tent with foam, install a heating system, and only after that we were finally able to save ourselves from the frost and successfully proceed to printing a demo house. The erection of the walls of the house with an area of 38 sq.m. took less than 20 machine hours in total. At the end of the printing of the building, for some time we still did not fully realize that by printing the entire house on the construction site without any additional assemblies and manipulations, we took construction 3D printing to a new level. nine0004

Otherwise, the mixture water would freeze in the pipes before reaching the equipment. To maintain at least a little plus temperature, we also had to fill all the seams in the tent with foam, install a heating system, and only after that we were finally able to save ourselves from the frost and successfully proceed to printing a demo house. The erection of the walls of the house with an area of 38 sq.m. took less than 20 machine hours in total. At the end of the printing of the building, for some time we still did not fully realize that by printing the entire house on the construction site without any additional assemblies and manipulations, we took construction 3D printing to a new level. nine0004

- Doing something completely new, what did you encounter besides conservatism?

- Basically, the problems were during the assembly of the prototype. We needed complex parts in a single copy, which greatly limited us in terms of suppliers. I had to resort to the services of small producers. This means that the quality of parts left much to be desired, and delivery delays were common. Moreover, this applied to both Russian and foreign suppliers. Everything was very tough in terms of deadlines - the word "deadline" literally got stuck in my teeth. Sometimes there was no time left to test nodes, a working solution was needed NOW. Because of this, it was necessary to immediately produce the assembly in its final form. From this, the responsibility of each engineer to the team was colossal. nine0004

This means that the quality of parts left much to be desired, and delivery delays were common. Moreover, this applied to both Russian and foreign suppliers. Everything was very tough in terms of deadlines - the word "deadline" literally got stuck in my teeth. Sometimes there was no time left to test nodes, a working solution was needed NOW. Because of this, it was necessary to immediately produce the assembly in its final form. From this, the responsibility of each engineer to the team was colossal. nine0004

— What helped you cope with the constant pressure?

— Absence of a rigid hierarchy inherent in large companies in a startup. Each member of the team can fully reveal himself, and this increases his effectiveness at times. An engineer is, first of all, a creative profession. And if you have the opportunity to implement your own ideas, to bring them to life, it is valuable. In large commercial or state enterprises, this is an unaffordable luxury - the risks are too great. nine0004

nine0004

- Last question: why did you become an engineer?

— I want to change the world around me and I want to change myself. Everyone chooses a path for themselves, and I am happy that I got into this company, where they gave me the opportunity to reach a new level, to do what I really want.

Engineering startup Roboprint develops a swarm of 3D printers

News

0005

5

As conceived by the authors, a complex of mobile additive manufacturing platforms will be able to build large-sized objects that are dozens of times larger than the systems themselves. For example, an airplane.

The Roboprint team is part of the Ventum Nova community of innovative projects of the National Research University MPEI. According to the press service of the university, the developed complex will be able to print parts of unlimited size for aerospace, automotive, shipbuilding, wind energy and other industries. nine0005

"Ventum Nova" on the basis of NRU "MPEI" allows student teams under the guidance of university experts to conduct scientific research, develop innovative projects in order to create technology companies and commercialize developments. One of such promising projects was Roboprint. The university provides all the necessary conditions for scientific activity: in our arsenal there is a unique educational and experimental thermal power plant, a full-scale renewable energy testing ground with wind, solar power plants and a geothermal complex, equipment from leading companies in the industry,” says Ivan Komarov, director of the Center for Innovative Development of NRU MPEI. . nine0005

One of such promising projects was Roboprint. The university provides all the necessary conditions for scientific activity: in our arsenal there is a unique educational and experimental thermal power plant, a full-scale renewable energy testing ground with wind, solar power plants and a geothermal complex, equipment from leading companies in the industry,” says Ivan Komarov, director of the Center for Innovative Development of NRU MPEI. . nine0005

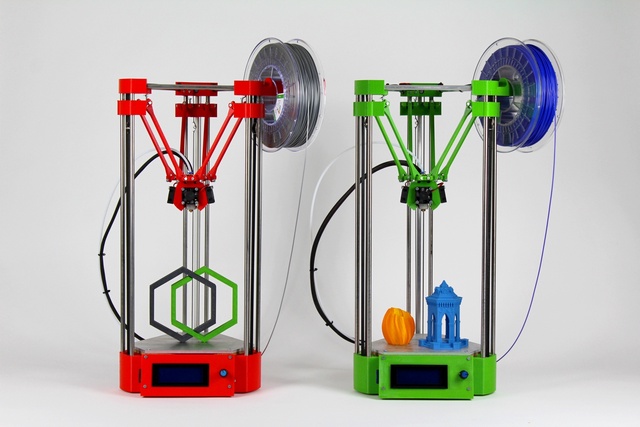

The project provides for multi-threaded 3D printing by a swarm of robots in an external space, that is, without size restrictions imposed by the useful volume of stationary additive systems. The use of a whole swarm of mobile 3D printers, in turn, should increase overall productivity.

Mobile platforms are equipped with radio navigation elements to help coordinate the actions of the swarm. The manufacturing process of a large part is divided into 3D printing of separate sections, each of which is responsible for a separate mobile 3D printer with a supply of consumables and an autonomous power supply. nine0005

nine0005

The process is not tied to specific molds/templates, which means production becomes flexible and easily reconfigurable. In addition, the use of additive technologies makes it possible to make parts not solid, but partially filled, reinforced with stiffeners and reinforcing threads, which allegedly allows the production of lighter analogues of cast products while maintaining mechanical properties. As one of the application examples, Roboprint proposes to place direct additive manufacturing of blades directly on the wind turbine construction site. A swarm of robots will be able to print one-piece parts without any templates and stencils on the construction site, eliminating the risk of damage to parts during transportation, and will make it easy to build wind farms even in the most remote corners of the planet. Apparently, if desired, you can even print white blades with black plastic, or it just seemed to us. nine0005

We can only add that large-format 3D printing in relation to the same wind turbines is really considered promising, but no one is making serious efforts to implement the idea of localized additive manufacturing of blades.