Organic 3d printer

A Closer Look at 3D Printing Materials: Ceramics and Organic Material

Published on September 2, 2022 by Alexandrea P.

Over the years, additive manufacturing has grown exponentially. And currently there are many different 3D printing technologies that allow objects to be built depositing of layers one by one. At first, printing materials were scarce, but gradually and through research and development, it has been possible to expand the number and types of materials. The best known are certainly the polymers – PLA, ABS, resins, nylon, etc.. – and metals. However, today we want to draw your attention to about two lesser known but increasingly important material groups: ceramics and organic materials.

Ceramics

Ceramics

When we talk about ceramics, we often think of the more traditional ones like clay or porcelain. However, there are also more technical ceramics for advanced applications. Currently, there are two main groups of technical ceramics on the market today: oxides and non-oxides. The first group includes the metal oxides alumina, zirconia and silica, and the second group consists of materials such as silicon carbide, silicon boride or silicon nitride. The use of these materials is ideal for parts that require high temperature and wear resistance. A ceramic 3D printer can use different manufacturing processes, from powder bonding to stereolithography to extrusion. You can learn more about the different ceramic 3D printers on the market in our listing.

Photo Credits: 3D Ceram

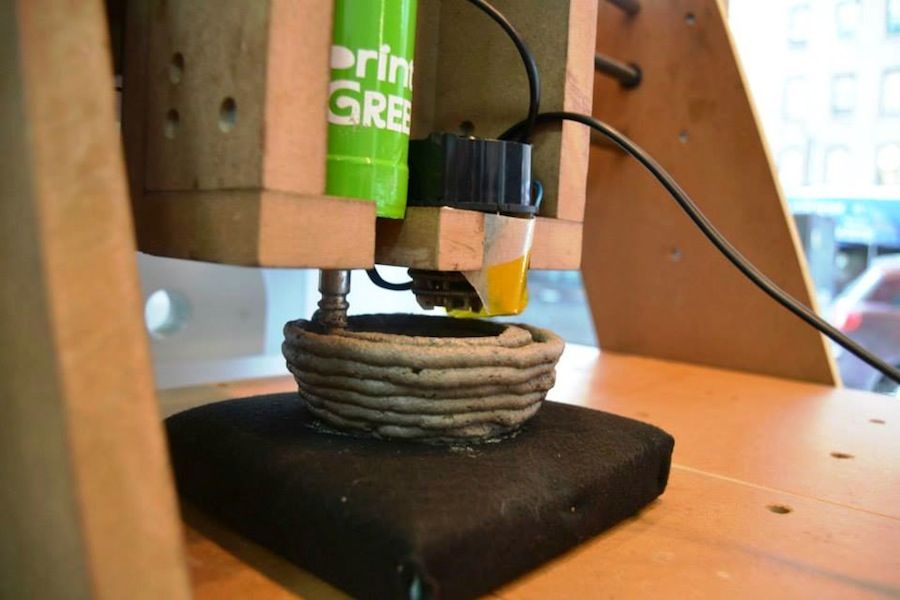

Sand

Sand can be considered as falling under this ceramic group. It is used to create complex parts that take advantage of the benefits of additive manufacturing, primarily for the manufacture of foundry molds. The use of this material reduces waste, saves energy and the manufacturing time is much shorter than other techniques. It can be used for mass production of finished products or for prototyping, with machines like ExOne’s S-Max Flex. In the video below, you can see an example where Sandhelden uses sand as the primary manufacturing resource in injection molding to create bathroom collections.

Concrete is another one of the ceramic materials we want to highlight. To make it, stone aggregates and water are mixed, creating a uniform mixture that is also compatible with 3D printing. Thus, additive manufacturing in the construction industry has become increasingly important. Using concrete as a building material is very economical, while printers range in price from $180,000 to over $1 million. Some of the printers you can find on the market include the Apis Cor House printer or the Crane from WASP. Speed is one of the advantages that characterize these machines: in 48 hours, you can erect the walls of a house!

Both of these ceramic materials are designed to be used with FDM/FFF 3D printers, and are available as filaments. There are two filaments on the market, the wood filament (LayWood) is composed of wood with plastic and the stone filament (LayBrick) is composed of minerals similar to chalk powder, it is a mixture of gypsum with plastic. What is amazing about these products is that their textures and smells are reminiscent of wood and stone. In the case of stone, smooth or rough surfaces can be obtained, depending on the variation of the extrusion temperature.

There are two filaments on the market, the wood filament (LayWood) is composed of wood with plastic and the stone filament (LayBrick) is composed of minerals similar to chalk powder, it is a mixture of gypsum with plastic. What is amazing about these products is that their textures and smells are reminiscent of wood and stone. In the case of stone, smooth or rough surfaces can be obtained, depending on the variation of the extrusion temperature.

Photo Credits: Forust

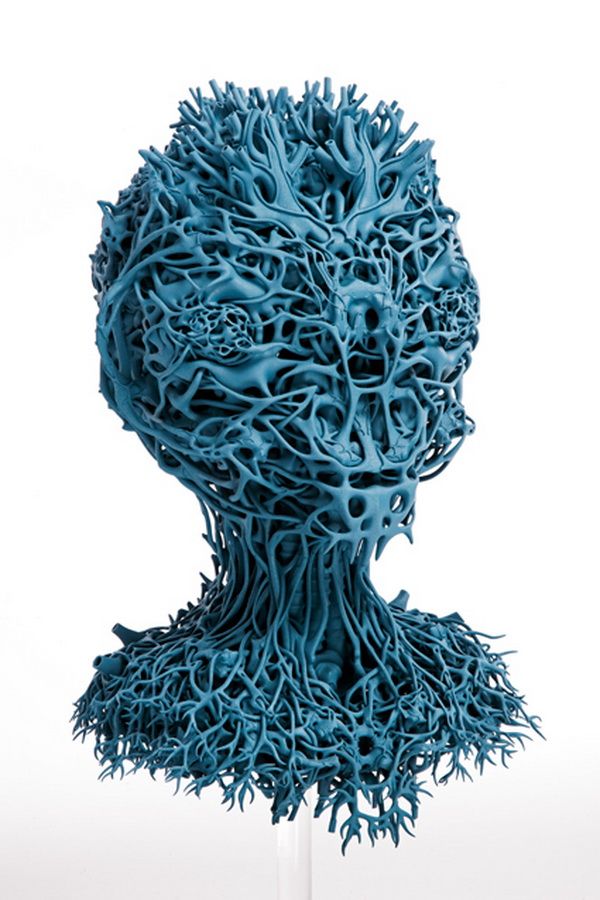

Organic MaterialsBiological Tissue

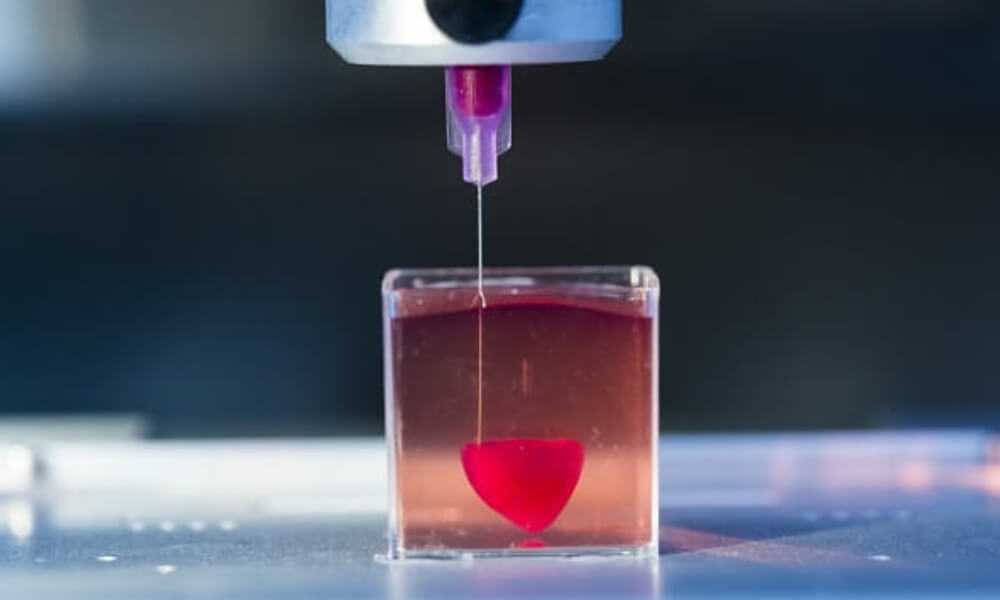

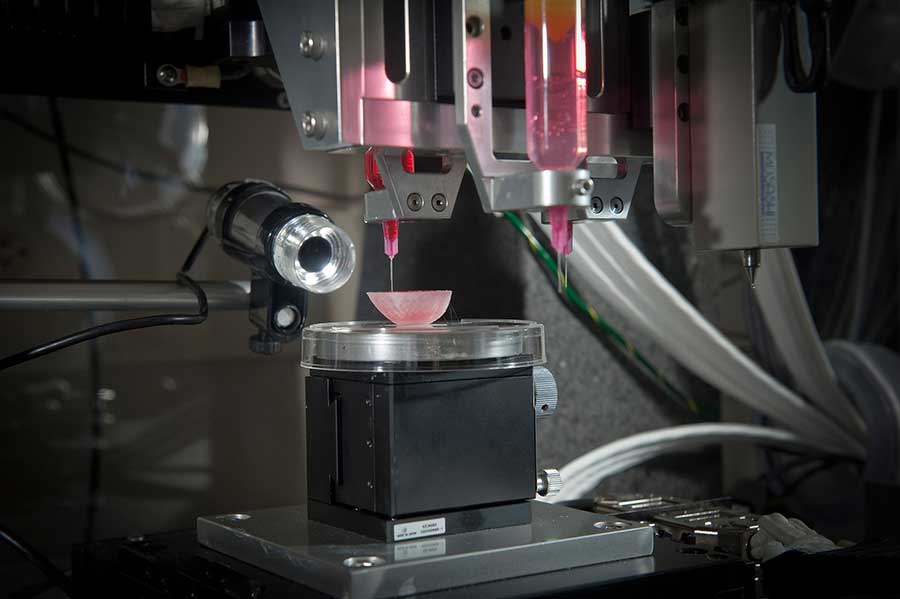

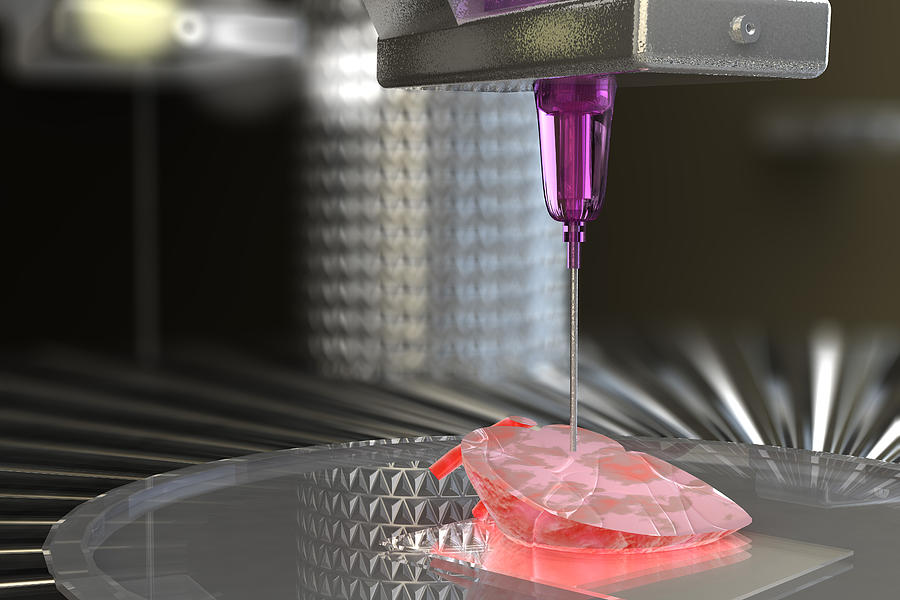

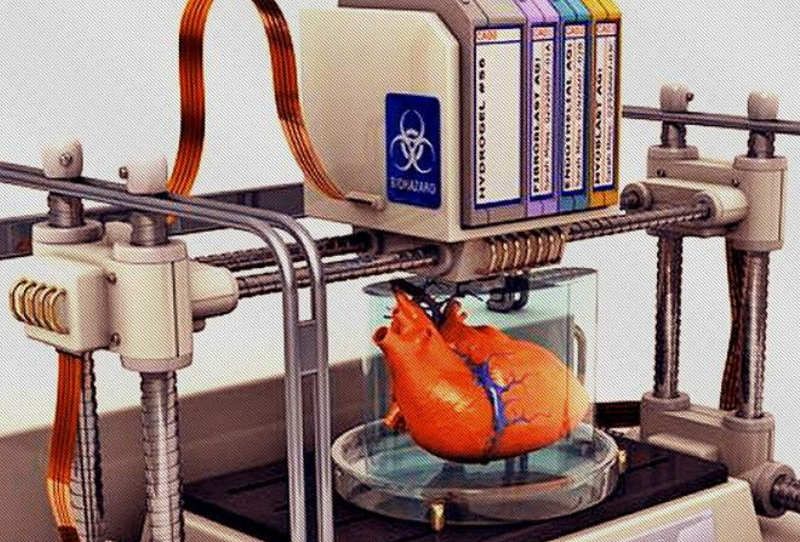

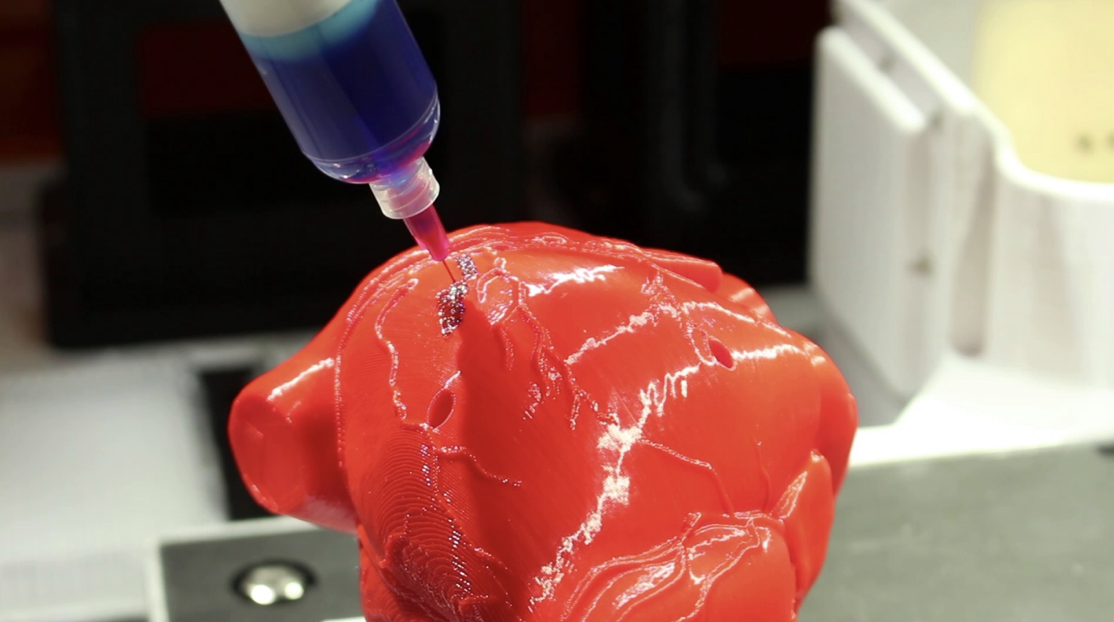

Having looked at ceramic materials, let’s now turn our attention to organic materials, starting with bioprinting. Bioprinting is the 3D printing of an ink composed of cells that can be used to obtain skin, tissue, tendons or even organs. The printing is usually done by depositing successive layers through a custom-made syringe. There is still a lot of progress to be made but the advances are real.

The BIO V1 3D bioprinter (photo credits: Regemat)

WaxThis organic material is primarily used for molding, whether for mechanical parts, artwork, dentistry or jewelry making. In terms of material, for example, M3 Hi-Cast is used with 3D Systems’ ProJet MJP 3600W and 3600W Max 3D printers. Note that Stratasys’ Solidscape company specializes in wax 3D printing machines, with models such as the 3Z Studio, 3Z Pro and MAX2. They work similarly to plastic FDM printers, but include a milling tool in each layer to make them uniform and level. Finally, 3D Systems offers the ProJet MJP 3600W, or Project MJP 2500W, ideal for jewelry making. Here’s a video:

In terms of material, for example, M3 Hi-Cast is used with 3D Systems’ ProJet MJP 3600W and 3600W Max 3D printers. Note that Stratasys’ Solidscape company specializes in wax 3D printing machines, with models such as the 3Z Studio, 3Z Pro and MAX2. They work similarly to plastic FDM printers, but include a milling tool in each layer to make them uniform and level. Finally, 3D Systems offers the ProJet MJP 3600W, or Project MJP 2500W, ideal for jewelry making. Here’s a video:

Food

Who would have ever thought that we could print food with 3D printers? Pasta, ice cream, chocolate, bacon, meat… 3D printing is revolutionizing the kitchen! And you may be wondering if there are food printers, the answer is yes. Among them are Foodini by Natural Machines, Brill 3D Culinary Studio, Mycuisini 2.0 or Choc Creator V2 Plus for chocolate printing.

The Foodini 3D printer (photo credits: Natural Machines)

What do you think about ceramic and organic materials? Do you use them for your 3D printing projects? Partagez votre avis dans les commentaires de l’article. Retrouvez toutes nos vidéos sur notre chaîne YouTube ou suivez-nous sur Facebook ou Twitter !

Bio printing - Bioprinting - Human tissue

3D bio printing of human tissue has been around since the early two-thousands. Nowadays scientists are in the midst of moving from printing tiny sheets of tissue to entire 3D organs. 3Dprinting.com will keep you informed of the latest developments in the bio printing industry.

Using AI and AM for Organoid Production

Living organs for medical experimentation are pretty hard to come by, on account of human beings actually using them on a day to... read more »

1 month ago

Bioprinting

Rabbit Gets Printed Cornea

Researchers from Hyderabad in India have successfully transplanted a 3D printed cornea onto a rabbit, which will pave the way for transplants onto. .. read more »

.. read more »

3 months ago

Bioprinting

3D Printed Lung Demos Gas Exchange in Animals

3D Systems and their collaborators at United Therapeutics have released an update on their 3D printed lungs at the LIFE ITSELF Conference in... read more »

5 months ago

3D Systems

Researchers Shape Matter with Sound

Researchers have figured out a way of fusing polymers using "sonochemical reactions". Unless you're a researcher in that field, or adjacent fields, it's... read more »

5 months ago

Bioprinting

3D Printed Living Ear Successfully Implanted on Patient

New York-based company 3DBio Therapeutics has announced the successful implant of a 3D printed ear onto a patient suffering from microtia, a condition... read more »

6 months ago

Bioprinting

Bioprinted Lymph Nodes Coming to an Immune System Near You?

It has been a while since we have covered anything in the domain of bioprinting. It’s not that we don’t like writing about... read more »

It’s not that we don’t like writing about... read more »

10 months ago

Bioprinting

Two Teams Win NASA’s Vascular Tissue Challenge Using 3D Printing

NASA started a competition in 2016 challenging entrants to “create thick, vascularized human organ tissue in an in-vitro environment to advance research and... read more »

1 year ago

Bioprinting

Benchtop Bioprinters: More Materials in Smaller Package

Last month, 3D Systems announced the acquisition of bioprinter manufacturer Allevi. It is the latest in a series of moves by the company... read more »

1 year ago

3D Systems

Industry Collaboration Highlights Path to 3D Printed Lungs

Earlier this year 3D Systems announced that they would be stepping up their efforts in the realm of bioprinting, in particular they intend. .. read more »

.. read more »

1 year ago

3D Systems

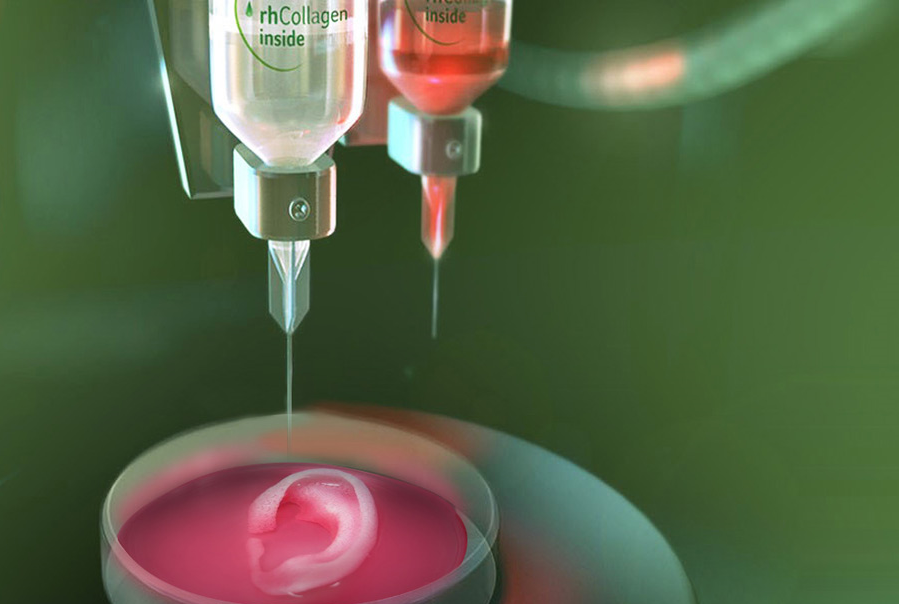

FRESH 2: Printing Heart Components From Collagen Bioinks

While many researchers have long been investigating a method for bioprinting a heart, this year has marked some stunning breakthroughs. Most notably scientists... read more »

3 years ago

Bioprinting

Mars Crew 3D Printing Skin & Bone Tissue in Space

While journeys through space require a lot of resources, there's only so much space missions can carry. This makes it especially difficult to... read more »

3 years ago

Aerospace

Ricoh Partners With Elixirgen Scientific to Develop 3D Bioprinted Products

Tokyo-headquartered digital technology company Ricoh has partnered with Baltimore-based stem cell research firm Elixirgen Scientific to develop new biomedical products and services that. .. read more »

.. read more »

3 years ago

Bioprinting

Aleph Objects & FluidForm Develop FRESH Bioprinting Tech

Aleph Objects, the makers of the LulzBot 3D printers is moving into a different sphere of additive manufacturing. In collaboration with Carnegie Melon... read more »

3 years ago

Bioprinting

SLA Organ Printing Yields Results Using Food Dye

Although the days of fully 3D printed organs are not here yet, every day medical researchers inch closer. Previously, Tel Aviv University developed... read more »

3 years ago

Bioprinting

Cryolithography Device Bioprints Organs Faster

With all the advances in bioprinting, there are distinct limitations most researchers are facing. Even with advanced organ recreations like a functional 3D... read more »

3 years ago

Bioprinting

3D Printed Heart Marks a Breakthrough in Bioprinting

In a landmark achievement, Tel Aviv University have 3D printed a small heart using human tissue. While the organ itself is smaller than one... read more »

While the organ itself is smaller than one... read more »

3 years ago

Bioprinting

3D Printed Bioreactor Can Grow Jawbones Using Ribs

Researchers at Rice, the University of Texas Health Science Center at Houston (UTHealth) and Baylor College of Medicine have developed a 3D printed... read more »

3 years ago

Bioprinting

Allevi Launches Bioink For Multi-layered Skin Printing

One of the most promising applications of bioprinting is that of printing skin for medical conditions and research. Researchers have long been trying... read more »

3 years ago

Bioprinting

Bioprinted Tubules Simulate Kidney Functions & Diseases

Harvard's Wyss Institute and their work with printed proximal bioprinted tubules help to reintroduce good molecules into the bloodstream. Aside from simulating the... read more »

Aside from simulating the... read more »

3 years ago

Bioprinting

Spinal Cord Implant Promotes Nerve Cell Growth

Researchers at UC San Diego School of Medicine and Institute of Engineering in Medicine have developed a spinal cord implant that could potentially revolutionize... read more »

3 years ago

Bioprinting

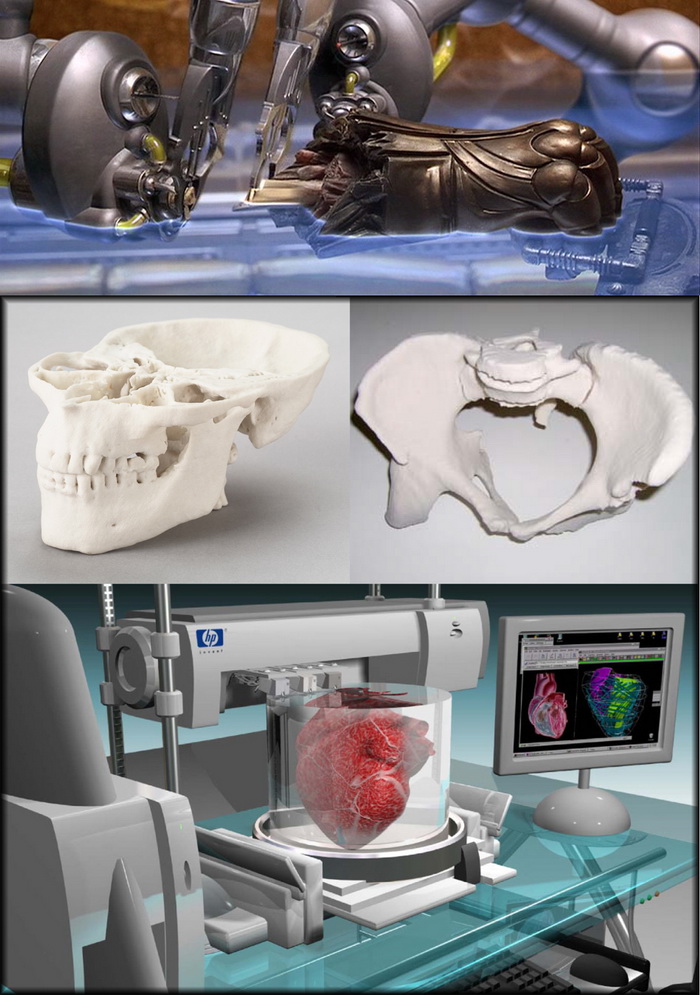

How bones, vessels and organs are printed using 3D printers / Habr

In the early days of rapid prototyping, it was widely believed that 3D printing would transform all manufacturing, spurring a consumer revolution that would bring a printer into every home. This has not yet happened, however, as has happened with many of the latest technologies, rapid prototyping has found its application in a completely different area - in medicine.

Article from the Gizmodo website.

The research and projects below are some of the most interesting examples of the use of bioprinting and the use of computer-controlled machines to assemble biological matter using organic inks and ultra-strong thermoplastics. The range of application of bioprinting is very wide - from the reconstruction of the main parts of the human skull to the printing of scaffolds - scaffolds on which stem cells can develop into new bones. Read the details below.

Skulls

Osteofab is a product of the company

Oxford Performance Materials. Initially, OPM entered the market by selling in its raw form a high-performance polymer often used in the manufacture of medical implants - a thermoplastic called polyetherketone ketone (PEKK), but over the past few years the company has become the first to master the use of this material, primarily in additive manufacturing . So, in February 2013, an American patient

installed FDA approved 3D skull implant. The casting and printing was carefully crafted to match the unique geometry of the patient's skull, of which 75% is now an implant.

The casting and printing was carefully crafted to match the unique geometry of the patient's skull, of which 75% is now an implant.

Leather

The main problem with creating new skin using printing is the difficulty of recreating a specific shade from the entire possible spectrum. Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story.

However, here are two of the most interesting: Scientist James Yoo of Wyke Forest University, with a grant funded by the US Department of Defense, is working on a machine that can print skin directly on burn victims. Another study is being carried out by scientists at the University of Liverpool, who are using carefully calibrated 3D scanners to obtain skin samples containing all of its finest nuances, which will allow more realistic implants to be printed later.

The research is still ongoing and the team plans to create a "skin sample database" of scanned samples that can be accessed from remote hospitals that do not have the cameras needed to scan a particular patient's skin. [ Gizmodo ; PhysOrg ]

Noses and ears

The creation of prosthetic ears, noses and chins is often a painful, expensive and time-consuming process for both the patient and the doctor himself. British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone.

These prostheses have the added bonus that when they wear out (which they eventually will), they can be reprinted at a very low financial cost. [

[

]

Prosthetic eyes

Fripp and a team at the University of Sheffield published the results of testing a similar process for making prosthetic eyes. Prosthetic eyes are expensive and, because they are hand-painted, can take months to make. Fripp Designs printers can produce 150 prosthetic eyes in an hour, and details such as iris color, size and number of blood vessels can be easily changed to suit the needs of the patient. [

PhysOrg]

Functional implants

As electronic devices — from drones to medical implants — get smaller, scientists are struggling to create batteries for them that are small enough, but with those could provide the necessary charge. However, a team of engineers from Harvard University is already printing microbatteries the size of a grain of sand using a 3D printer. Here's what the press release says:

“…researchers created an anode ink using nanoparticles of one lithium oxide compound, as well as a cathode ink made from nanoparticles of another kind of this compound. The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

Over time, they will be able to charge medical implants, which are held back due to charging problems. [ Harvard ]

Bones

3D printed implants such as the jaw have been around for several years. However, a small group of researchers is conducting an experiment whose goal is to print real bones. For example, scientist Kevin Scheiksheff of the University of Nottingham invented a bioprinter that creates matrices from polylactic acid and gelatin alginate, which are then coated with stem cells.

The implanted matrices will gradually dissolve and be replaced by new growing bone: it will take approximately three months for the bone to completely transform. [ Forbes ]

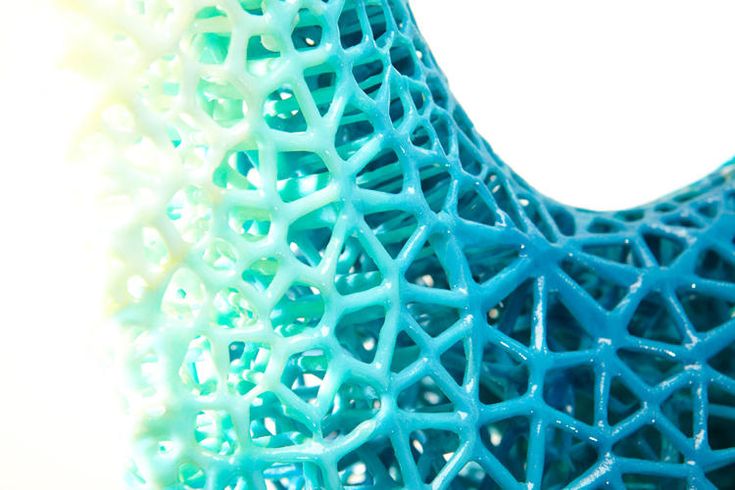

Blood vessels and cells

We can already print

organs , but there is a serious problem in creating a functioning circulatory system.

German scientist Günther Tovar, head of the Fraunhofer Institute for Interfacial Engineering and Biotechnology, is working on a project called BioRap. His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ Fraunhofer Institute ]

How do you see the future of 3D printing with living and substitute artificial materials for use in the human body? Will we soon be able to grow and replace full-fledged organs, such as the liver? Share your opinion in the comments.

When will we be able to print new organs on a 3D printer?

Photo: Alexander Ryumin / TASS In China alone, there are 1.5 million people on the waiting list, in the United States - 113 thousand, of which, on average, 20 people die a day without waiting for a donor. A new kidney - the most demanded organ - has to wait from three to five years. This problem can be solved by printing the necessary organs on special 3D printers.

A new kidney - the most demanded organ - has to wait from three to five years. This problem can be solved by printing the necessary organs on special 3D printers.

True, not earlier than the next ten years.

Bioprinting technology: how and why organs are printed today?

(Video: RBC)

The principle is about the same as in conventional 3D printing: we get a three-dimensional object on a special printer.

The first stage is preprinting : first, a digital model of the future organ or tissue is created. For this, images obtained on MRI or CT are used.

Then they print, layer by layer - this technology is called additive. Only instead of a conventional 3D printer, there is a special bioprinter, and instead of ink, there are biomaterials. These can be human stem cells, which in the body perform the role of any cells; porcine collagen protein or seaweed-based cell material.

If the cells are alive, they are biopsied and prepared in a bioreactor until they multiply by division to the required number. During printing, the bioprinter polymerizes the cellular structure - that is, binds it with the help of ultraviolet light, heating or cooling. Cell layers are connected using a hydrogel - organic or artificial.

During printing, the bioprinter polymerizes the cellular structure - that is, binds it with the help of ultraviolet light, heating or cooling. Cell layers are connected using a hydrogel - organic or artificial.

The resulting structure is then placed in a biological environment where it "ripens" before transplanting. This is the longest stage: it can last several weeks. During this time, the structure stabilizes, and the cells are ready to perform their functions.

Then the organ is transplanted and they monitor how it takes root.

Bioprinting: how living organs are printed on a 3D printer

(Video: RBC)

In addition to conventional additive bioprinters, there are other bioprinters. Some of them print collagen directly on an open wound: this way you can quickly build up new skin even in the field. In this case, the ripening (post-printing) step is skipped.

There are also printers that print in outer space, in zero gravity. In the future, they can be used on the ISS:

In the future, they can be used on the ISS:

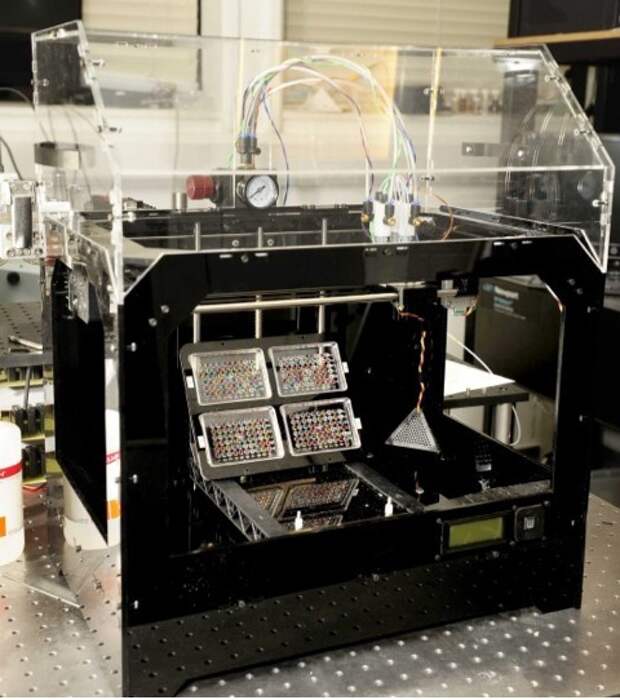

There are more than 100 companies worldwide that produce 3D bioprinters. 39% of them are in the USA, 35% are in Europe (of which more than half are in France and Germany), 17% are in Asia, 5% are in Latin America.

In Russia, bioprinters are produced by 3D Bioprinting Solutions, which is also engaged in research in the field of bioprinting.

The cheapest and most compact bioprinter — Tissue Scribe by American 3D Cultures, costs from $1.5 thousand

In second place - Australian Rastrum from Inventia for $5 thousand

Aether bioprinter from the USA can be bought from $9 thousand biosystems.

3D Bioplotter from the German EnvisionTEC costs from $100,000, and the Russian FABION (3D Bioprinting Solutions) is even more expensive.

Finally, the most expensive bioprinters — more than $200,000 — are NovoGen MMX from Organovo (USA) and NGB-R from Poietis (France).

In addition to the cost of the printer, the printing process itself is an additional 15-20% of the cost of the entire project. It will cost even more to obtain the necessary cell material.

So far, the most successful experience has been the transplantation of cartilage - the very ears of Chinese children.

Small artificial cell bones are printed on a printer and then coated with a layer. They are planned to be transplanted instead of a broken or damaged area, after which they completely regenerate in three months. In the future, they want to use the technology for spinal injuries.

The most promising direction is 3D printing of leather. Already in five years they promise that this can be done directly on a person, over or instead of the damaged area. Skin and other tissues are being printed from cells from cancer patients to test various therapies.

More complex organs, such as kidneys or hearts, have so far only been printed as prototypes or transplanted into mice, not humans.

In order for the organs to take root and function well in the human body, they take the patient's cells, and then they divide until they are enough for printing. There are entire institutes that create cell lines for bioprinting. But the problem is that cells have a division limit, after which they are no longer usable. Therefore, it is possible to print a model of the heart, but not life-size - that is, it is not suitable for transplantation into a person.

The second problem is that the printed organ must function in conjunction with the rest of the body : digest food, secrete hormones, deliver blood and oxygen. A complex system of cells, tissues, nerves and blood vessels is responsible for all this. So far, it has not been possible to reproduce it exactly.

Finally, bioprinting technologies are not yet regulated in any way. All research must go through all stages of testing, including on humans, and then obtaining patents.