Non toxic 3d printer resin

It Turns Out There Are Non-Toxic 3D Printer Resins « Fabbaloo

I’ve become aware of at least one provider of apparently non-toxic 3D printer resins.

Toxic resin is the norm in resin 3D printers. The components in the resin are virtually always toxic, requiring 3D printer operators to wear protective gear when working with the resin.

This includes safety glasses, nitrile gloves, and sleeves to ensure skin does not come in contact with the resin. It also requires a very careful workflow, as prints move between printer, wash station and UV curing stations. Each step is a potential spot where resin can be mishandled and “dirty” surfaces or tools.

Honestly, a truly safe workflow is quite a burden and I am pretty sure that many resin 3D printer operators don’t always follow proper safety precautions. I’ve even seen videos where people freely pick up wet prints with bare hands.

The problem is that the toxins enter the body through the skin only gradually. Thus, after multiple exposures the body will sudden reach a threshold level and react. Thereafter, the exposed person will often develop symptoms whenever near resin, even from airborne smells. In other words, you don’t know it’s bad until it is. Therefore we’ve always strongly advised anyone operating a resin 3D printer to take all precautions.

All of this is caused by the toxic resins, which by the way are often totally safe AFTER they’ve been fully cured. Some are even food safe — after they’ve been cured.

I wondered if there was a non toxic resin that could be used to short circuit all these issues, and couldn’t find any.

The closest I could find were “water washable” resins. These are pretty much just as toxic, but they remove the additional issue of washing prints in similarly toxic IPA. Instead of IPA, you wash in water.

The problem with these solvents is that they become corrupted with, you guessed it, toxic resin. To “clean” them, you must leave the dirty solvents out in the sun, where the dissolved photopolymer resin will eventually cure and settle out. Water washable resin is slightly safer, but just as much trouble to use when you consider the entire workflow.

Water washable resin is slightly safer, but just as much trouble to use when you consider the entire workflow.

Then it was brought to my attention that there could be a truly safe 3D printer resin, made by, Carima, which just happens to be the oldest Korean 3D printer company.

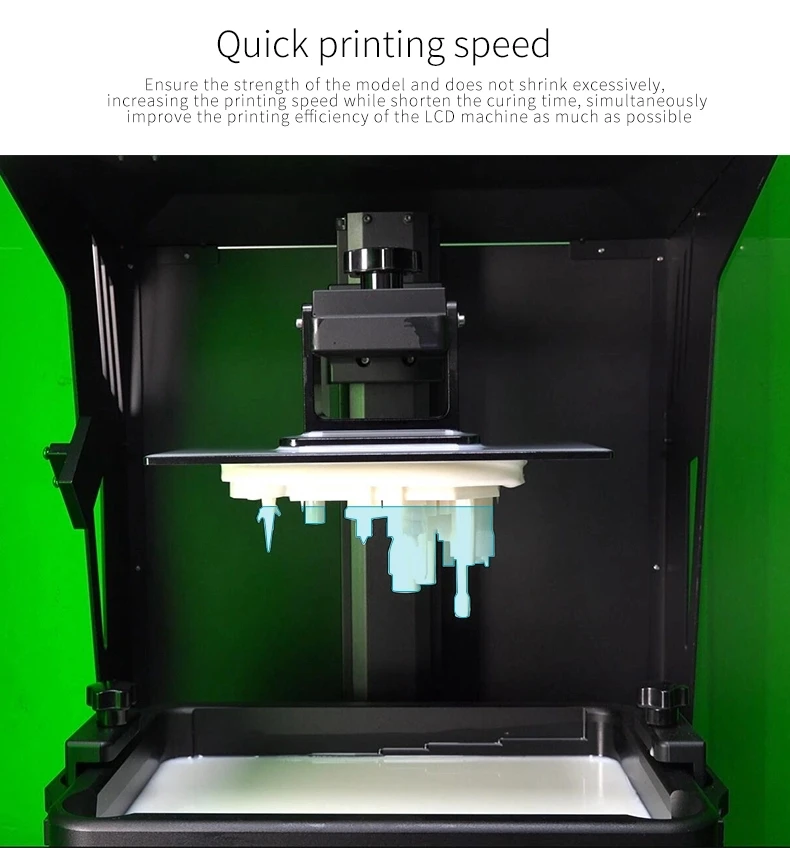

They produce several different models of DLP-powered resin 3D printers, targeted at the dental, jewelry, ceramic and healthcare industries. Along with the hardware, they also provide a wide range of resins for specific applications.

Hidden in their list of resins is “Nontoxic CMYK” resin. They explain:

“Carima’s CMYK resin, consisting of five colors, is a non-toxic mixable material, allowing users to freely combine colors. The liquid resin has been tested and classified as non-irritant and no harmful chemical substances were detected, which makes it suitable for educational use and children’s toys.”

The emphasis is mine, and I point out the words, “liquid resin”. Not cured. Liquid. Non-toxic.

Not cured. Liquid. Non-toxic.

They provide this chart illustrating the toxicity, as measured in mg of toxic chemicals per kg:

And this chart comparing the material to common substances that you would normally encounter:

You might be surprised that caffeine is so toxic. It’s so dangerous that years ago scientist Dr. Bernard Cohen challenged Ralph Nader to eat the same amount of caffeine as he would eat plutonium. The truth is all about HOW MUCH of the toxin is absorbed, and that’s what we’re talking about with the Carima resins.

However, the chart suggests that you’d need to absorb 26X as much volume of CMYK resin as caffeine to get a toxic dose, and many of you consume some amount of caffeine every day. I’m wondering where standard toxic resin would sit on this chart. [Aside: If you’re interested in the topic of common toxic substances, try searching for “banana radioactive” for a surprise.]

The resins have toxins, but so does everything else! It’s the level of toxicity that’s in question here.

As far as I can tell, these particular resins could be the least toxic one could use in a 3D printer that are commercially available.

But there’s more!

This family of non-toxic resins is actually intended for color mixing. The “CYMK” name is the standard color mixing method in the print industry: cyan, yellow, magenta, and black. With those four colors, it’s possible to reproduce any color you want, so long as you have the right mixing ratio. In the 3D print world, however, there is no “white paper background”, so the family also includes white and clear options.

Those six mixable resins should enable creative 3D printer operators to come up with very unique colors. You can even mix them “without stirring” to obtain wild multicolor resin 3D prints.

These resins are available for purchase from Carima resellers worldwide. I poked around and found a typical price to be about €60 per half liter, or about US$124 per kg. But remember, to get full color capability you need all six, and that would set you back about US$370 for a half liter of each.

I’m very curious about these resins and hope to give them a test in the near future.

Via Carima

Chasing The Elusive Safe 3D Printer Resin « Fabbaloo

Water-washable 3D printer resin [Source: ELEGOO]I’ve been on a bit of a quest to find some truly safe 3D printer resin, and I’m not sure there’s actually such a product.

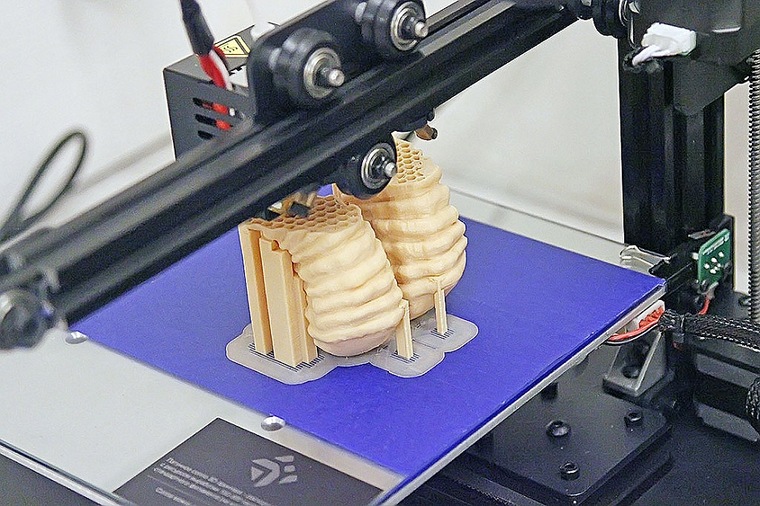

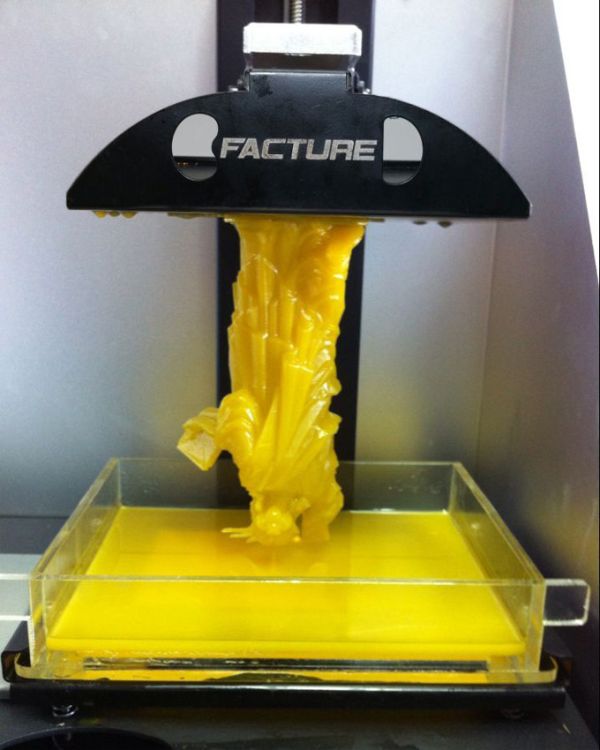

Resin 3D printers, whether by laser, LCD or DLP, can produce some of the highest-quality 3D prints. With the current low prices of such equipment, there’s quite a market for resin, and this has resulted in reasonably good prices (at times) as well some a widened choice of materials.

You can find all kinds of different 3D printer resins these days: strong, flexible, clear, colorful, heat-resistant, biocompatible, and many more options.

But one thing that seems a bit elusive is a resin that is actually safe.

Don’t get me wrong, ALL 3D printer resins can be USED safely if you follow the procedures and don’t mess up. But often mess-ups do happen, either accidentally or otherwise.

There are several aspects of resin 3D printing that concern me for this type of application, and I’m hoping to find something that counteracts all three.

Resin Odor

Most photopolymer resins emit a rather horrible odor. Sometimes these are successfully captured by the machine, and sometimes not. The less expensive desktop resin 3D printers often require you to manually pour the resin into the tank, thus exposing it to the air.

That smell is actually your nose detecting loose particles in the air. The more you smell, the more particles are present. In a sense, you are a kind of pollution detector.

If these particles are truly airborne, then you could potentially breathe them, thus exposing your lung tissue to whatever they might be. It’s for this reason that it’s strongly recommended you perform the 3D printing in a ventilated location. Our lab has an air exchanger that does just that.

Resin On Skin

Photopolymer resins are typically quite toxic. Sometimes very toxic. Thus you really shouldn’t be allowing them to touch any exposed portion of your body: skin, eyes or whatever.

Sometimes very toxic. Thus you really shouldn’t be allowing them to touch any exposed portion of your body: skin, eyes or whatever.

If you accidentally do so, it’s quite possible that not much may happen immediately. That’s because your body may gradually grow a negative reaction upon repeated exposure to the chemical. Then, at some undetermined future point an exposure will result in a bad reaction, which could be blisters, breathing problems or worse. The best idea is to never let the photopolymer resins touch you.

This is why it’s strongly recommended you always use nitrile gloves when handling resin. You should also wear goggles and probably a lab coat, too.

Flammable IPA

Cleaning completed resin 3D prints is frequently done with IPA, or isopropyl alcohol. This commonly used solvent is able to dissolve the inevitable leftover resin drips that are on the solid surface of the 3D print when it emerges from the 3D printer. If you don’t remove them, subsequent curing will solidify the drip and you’ve spoiled the part.

The IPA washes away the resin, and this is usually done in a pair of wash tanks, each filled with IPA. The first tank is the “dirty” tank that takes the bulk of the resin away. The second tank is the “final clean” tank, and it gets rid of any residue from the first tank.

This process works well, except for two things. The dirty IPA is quite dangerous because the alcohol can open pores of the skin, and that could allow dissolved photopolymer resin a more direct route into your body if exposed to skin.

Secondly, and probably more importantly, the IPA is extremely flammable. Caution must be used when handling and storing these large tanks of flammable liquid to avoid a severe fire.

Using 3D Printer Resin Safely

These factors together pose a problem in setting up a 3D printer. While you could easily overcome all of these challenges in a workshop or factory, they are more difficult in a consumer setting.

With the introduction of low-cost resin 3D printers, I fear that many operators are actually using these devices at home, and face all of the risks mentioned above.

While some may certainly take appropriate precautions, I’m sure many don’t. I think it’s just a matter of time before we start seeing an increasing number of people with toxic reactions or house fires.

Is there anything we can do about this?

Water Washable 3D Printer Resin

Polyjuice, a water-washable 3D printer resin [Source: Filaments.ca]There may be. I’ve recently heard of some alternative resins that might be able to get at this problem.

One type of resin is the “water washable” resin. The most popular type I’ve seen comes from Elegoo, which produces the ELEGOO Water Washable 3D Printer Rapid Resin. This substance is different in that you don’t use IPA to clean it after 3D printing. Instead you simply wash the print in warm water!

This means you can do away with the large vats of flammable IPA, and that should significantly reduce risks to safety. These materials also don’t emit nearly as much odor as traditional resins.

However, the ELEGOO product is not quite complete: it’s still toxic, and you cannot touch it. You still must wear gloves, provide ventilation and the rest. Even the dirty water cannot be dumped down the drain: it still contains dissolved resin, and you must let the water sit in the sun to solidify the residual resin before you sift out these solids and dump the water.

You still must wear gloves, provide ventilation and the rest. Even the dirty water cannot be dumped down the drain: it still contains dissolved resin, and you must let the water sit in the sun to solidify the residual resin before you sift out these solids and dump the water.

There’s more problems with some of these water-washable resins: they can be expensive at times, and some report brittle 3D prints. Those factors could constrain their usage.

Non-Toxic Resin

3dresyn non-toxic 3D printer eco-resin [Source: 3dresyn]Some photopolymer resins are billed as non-toxic. That sounds pretty good, as the parts made from these materials are intended for use in or on the human body, like dental appliances, for example.

However, the non-toxicity refers to the prints made from the resin, not the resin itself. For example, Formlabs’ biocompatible materials contain this statement:

“Samples printed with BioMed Clear Resin has been evaluated in accordance with ISO 10993-1:2018 and ISO 7405:2018, and has passed the requirements for the following biocompatibility risks:”

It goes on to explain the samples will not be cytotoxic, irritant, sensitizer, genotoxic and are non-toxic. But it’s samples, not resin. Thus you still have to wear the gloves and goggles.

But it’s samples, not resin. Thus you still have to wear the gloves and goggles.

Eco-Resin

eSun’s eco-resins [Source: eSun]Some resins are billed as eco-friendly, and perhaps they could overcome some of these difficulties.

Well, actually not. While the eco-resins are made from natural sources, like soybeans or corn, they still can be toxic and still require IPA baths. But you can feel eco-good when using them.

Is There A Truly Safe 3D Printer Resin?

What I looked for was a resin that is:

- Biocompatible while in resin form

- Does not emit odors

- Does not require IPA for cleaning

- Eco-friendly

After considerable searching online, I don’t think such a resin actually exists. You can find resins that do one or two of the above, but not one that does them all.

Perhaps it has something to do with the chemicals required to intiate polymerization? I’m definitely no chemist, so perhaps more knowledgeable readers could add a comment on this. If this is the case, there might never be a truly safe 3D printer resin on the market.

If this is the case, there might never be a truly safe 3D printer resin on the market.

But if it is possible, I suspect it could become quite popular for hobbyists using resin 3D printers in less than optimal operating conditions. If you know of such a beast, please let us know!

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A Biocompatible)

114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

Photopolymer resin 3D Ink.

Materials for 3D printer in stock

Materials for 3D printer in stock When buying a 3D printer DISCOUNT on plastics and polymers up to 10%

There are no products matching your request.

If you are looking for a versatile, non-toxic, practical resin for DLP printing, we recommend that you buy 3D Ink Resin, which comes in two products, UV Resin and UV Resin Clear. Both varieties of this consumable are ideal for prototyping master models for further production of casting molds - when they are burned, there is no ash left. In addition, when using the Clear version, you can also experiment with dye inhibitors. You can order 3D Ink photopolymer resin inexpensively with delivery across Russia on the website of our online store. nine0053

Read more…

On our website you will find a huge selection of quality consumables for 3D equipment and 3D printers. Pay attention to the prices in our online store - almost all products are in an affordable price category and differ significantly downward compared to the market value. Low prices are formed on our website through cooperation with official dealers. We offer reliable products from trusted manufacturers, without overpricing them. The company offers a huge range of top brands. For example, 3D Ink photopolymer resin is being developed by a well-known brand in the field of FDM consumables and photopolymer printing. The site presents 2 types of such photopolymers. nine0053

Low prices are formed on our website through cooperation with official dealers. We offer reliable products from trusted manufacturers, without overpricing them. The company offers a huge range of top brands. For example, 3D Ink photopolymer resin is being developed by a well-known brand in the field of FDM consumables and photopolymer printing. The site presents 2 types of such photopolymers. nine0053

UV Resin

UV Resin is a versatile consumable for 3D printing. Under the influence of light rays instantly hardens. Used for printers from the manufacturer MCh with stereolithography printing technology. 3D equipment working with SLA - allow you to get the highest accuracy in detail. Some personal 3D printers can be as accurate as 5 microns.

Important! Photopolymers are very sensitive to the effects of light rays, so they need to be stored in a special protected place. Otherwise, the filament will harden. nine0053

Finished models made of UV Resin after the end of the 3D printing process have high strength characteristics, moisture resistance and have a long shelf life.