Nesting 3d printing

What is 3D nesting and why the 3D build will save you up to 60%?

If you are a professional who prints many parts in PA12/PA11 nylon or polypropylene PP with HP Multi Jet Fusion technology, nesting on the 3D build can help you to obtain savings of up to 60%.

How? Let's see it together

Technologies like Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) print large "builds" filled with hundreds of items: since each build costs the same amount to print regardless of how many parts are inside, the more parts that can be squeezed into a single build the better the value of the build.

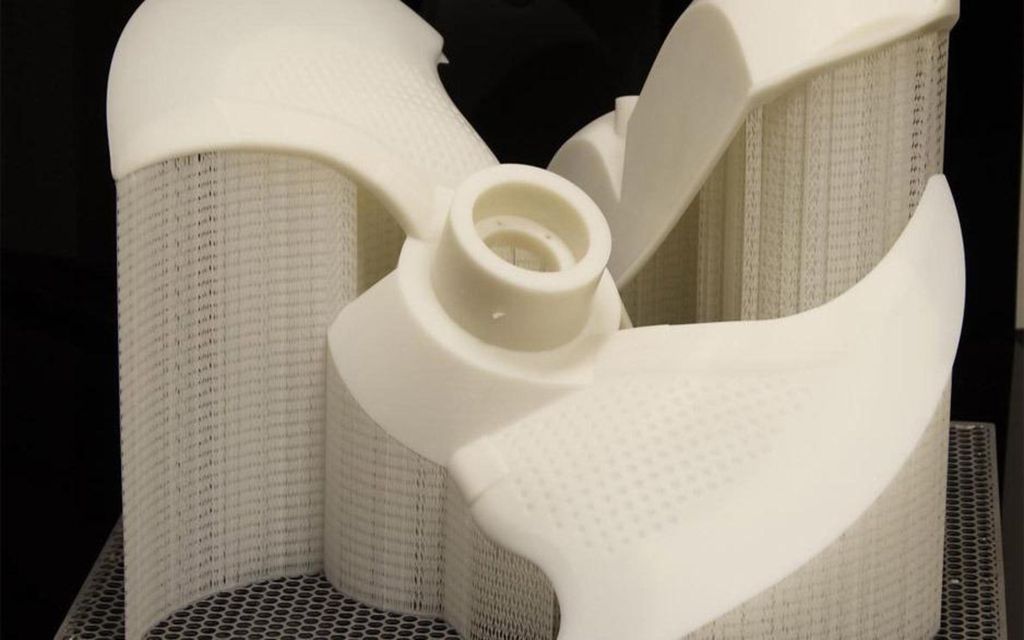

3D nesting in progress on the 3D build, still a lot of empty space to fill in this case.

Consequently, a 3D Nesting software translates and rotates automatically a collection of 3D parts inside the printing space (the 3D build) in order to minimize empty space and optimize the quality of the printed parts.

As it is easy to understand, even if it is possible to make builds of smaller dimensions, you can obtain top advantages from printing a 3D build only if you print enough parts to efficiently fill the build at is maximum size: if you are only printing a single part or a too small 3D build nesting will not be useful.

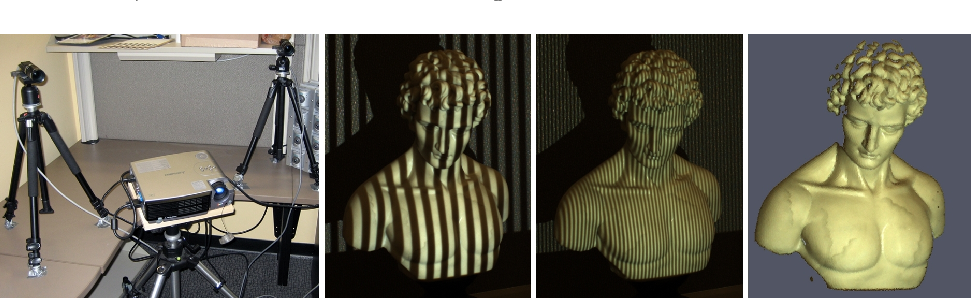

1. HP 5210 MJF 3D Printer, 2. Build unit, 3. Natural cooling station (it contains the 3D build), 4. Processing station

• 3D Build Nesting guidelinesThe 3D build nesting is easy because the guidelines are the same as for normal 3D printing that you find at this link and any of the nesting software that we suggest below will automatically avoid interlocking and trapped parts. In fact, these are errors that can be made only with manual 3D nesting that we do not recommend.

• 3D Nesting sizes and materials- 380x284x380mm (15x11.2x15 in) (X, Y, Z) on PA11 and PA12

- 370x274x370mm (14.5x10.8x14.5 in) (X, Y, Z) on Polypropylene PP

You can get more informations and suggestions at this link.

Although there are many software with which you can carry out a manual nesting (for example you could use any 3D CAD software) we tend to not to recommend them because the optimization is too complex to be done properly and without errors by hand. This is why we recommend the following automatic software:

This is why we recommend the following automatic software:

• Netfabb by Autodesk - instant free trial available

• Materialise Magics

• Fabpilot - instant free trial available

• Dimension 4 - instant free trial available

• 4D additive

• Polydevs

FINAL CONSIDERATIONS ABOUT PRINTING A BUILD FULL OF PARTS INSTEAD OF SEPARATED PARTS

If you make hundreds of parts in nylon pa11, pa12 or polypropylene PP with MJF technology 3D build printing is essential because it not only allows you to make huge savings but also allows you to perfectly control the inclination and positioning of the parts according to their importance.

The Role of Nesting in Polymer 3D Printing

03 July 2020

When running a 3D printing business, lowering the cost of printing is one of the first goals on the list. One way to achieve cost savings and optimise the use of your 3D printing fleet is through nesting, a common step during the data preparation process for 3D printing.

Today we’ll be taking a look at what nesting is, its benefits, as well some tips that will help you apply nesting more efficiently.

What is nesting in 3D printing?

In 3D printing, nesting is part of a build preparation stage that optimises the use of the build volume of a 3D printer.

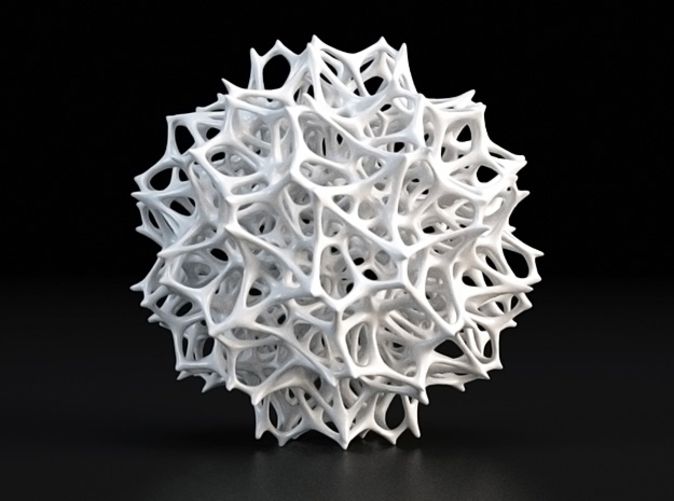

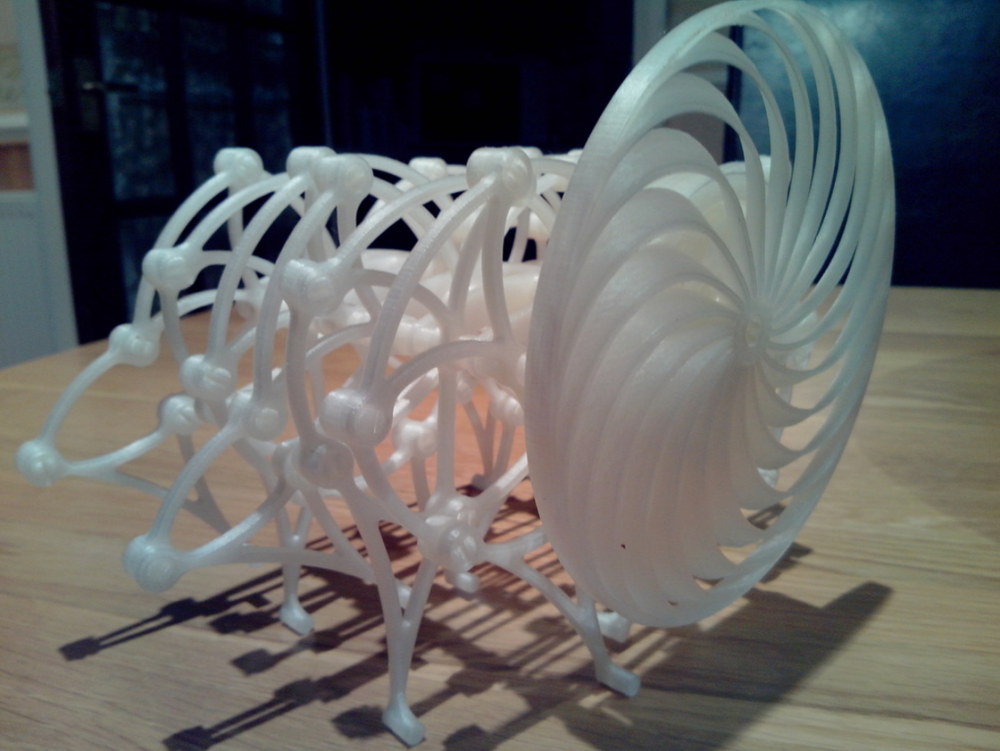

Nesting software sorts, orients and arranges 3D files to maximise space inside a 3D printerNesting can be compared to Tetris, a game where you need to arrange the falling blocks of different shapes to fill the line, whereas with nesting you try to pack as many parts as possible into one 3D printer to save costs and increase machine productivity.

Nesting is most commonly used with Powder Bed Fusion (PBF) technologies, like Selective Laser Sintering (SLS) and HP’s Multi Jet Fusion (MJF).

Automated or manual, nesting sorts, orients and arranges 3D files to maximise space inside a 3D printer, without interfering with no-build areas. Inefficient use of nesting can lead to material waste and printing errors.

Why should you use nesting in 3D printing?1. Optimise machine capacity

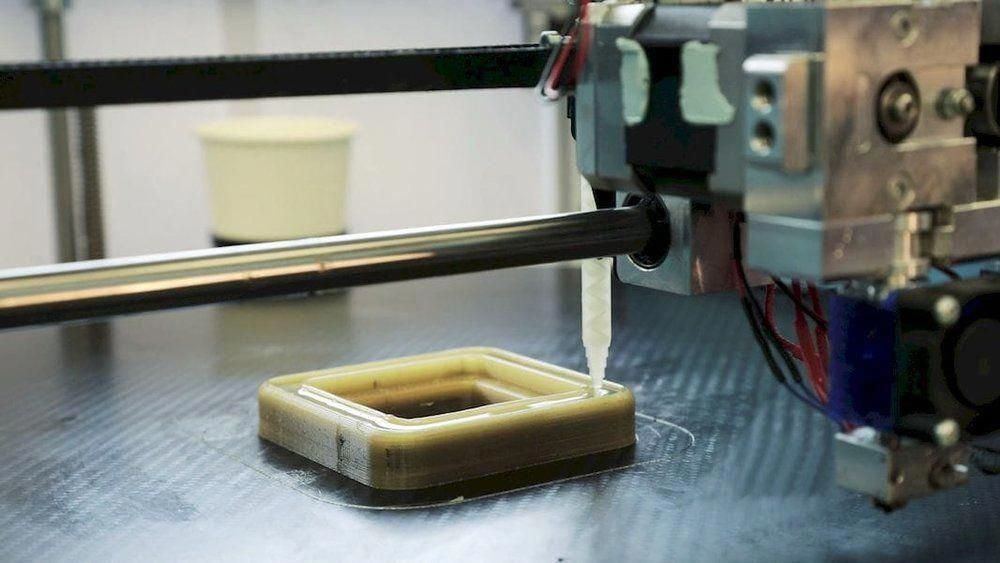

In PBF, the printing process involves the use of powdered polymers and a heat source. When one layer of powder is spread, a heat source traces the contours of the part defined by the software, fusing the material. The process is repeated until the parts are produced.

The finished parts remain in the 3D printing chamber, full of unfused, loose powder and need to be removed and cleaned.

The loose powder that surrounds the printed parts also works as a support material and can be partially recycled and reused.

Materials for PBF are expensive and can constitute a large portion of a part’s cost. To maximise the output of a PBF 3D printer, while introducing greater material efficiency, a company needs to take full advantage of its capacity.

Nesting has emerged as one of the solutions to enable higher packing density – which, essentially, means packing as many parts as possible in one build, for the optimal use of machine capability.

By packing in more parts, you can print the same amount in less time or more parts in the same build chamber.

2. Save materialIn PBF, you always have to use more powder than is required to print a part. The actual quantity is defined by how high your model is. The unused powder can be reused by mixing with fresh powder, but, in many cases, a lot of powder is wasted.

For example, one service provider has estimated that out of 500 kg of powder it buys per month, ‘25% becomes a part, 25% is waste and 50% is reused for refreshing the next build’.

By optimally nesting your parts and reducing the height of your build platform, you can save material, as well as speed up your production.

3. Reduce costs

When calculating the cost of a 3D printing part, one of the most important factors is the part’s bounding box, which refers to the rectangle space that contains your entire 3D model and determines the amount of space that the part will take up inside of the 3D printer.

By nesting your pieces optimally, you can fit more pieces into one bounding box. This will allow you to print more parts at a time, meaning, you produce faster and waste less powder – saving you unnecessary expense.

According to some estimates, nested models can provide around 30 per cent in savings. Designing parts with nesting in mind can further increase the savings up to 60 per cent.

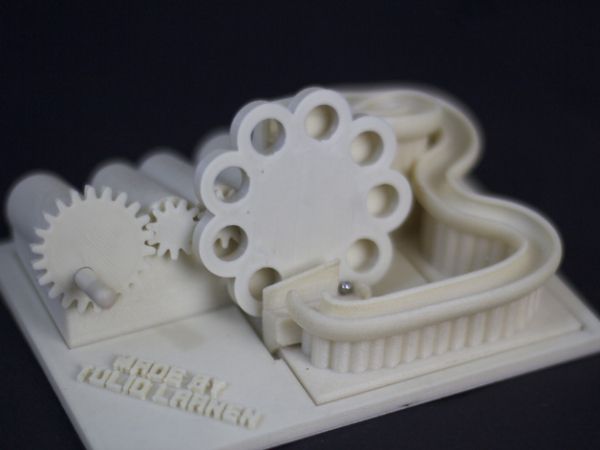

That said, not all parts will benefit from nesting. Sometimes it’s more economical to print parts in separate bounding boxes, as shown on the image below.

Today, the nesting capability can be found in most 3D printing data preparation solutions. Many such software solutions offer manual nesting, which tends to be time-consuming and requires skill to find the best possible combination of parts on the plate that minimises the space.

A rule of thumb is to start with the largest model and arrange the smaller parts around it, or, if possible, inside it.

Several tools on the market also offer automated nesting, like Materialise Magics and Netfabb, helping to speed up the nesting process.

Automated nesting tools can use one of the two types of part nesting: bounding box or geometry-based nesting.

Bounding box nesting takes the maximum X, Y and Z values of your part and forms a box around the part. Geometry-based nesting looks at the surface of the part and spaces based on actual part geometry.

The downside of the bounding box nesting is that it can be difficult to reach higher part densities with it. A good practice is to manually pre-nest parts before using software to run auto-nesting algorithms.

A good practice is to manually pre-nest parts before using software to run auto-nesting algorithms.

Whether in automated or manual nesting, it’s important to leave at least a 1.5mm gap between all of the components in your 3D file with SLS processes and a 5mm gap in MJF processes. This will prevent parts from fusing during the printing process.

Using nesting to achieve higher productivity with 3D printingNesting is a crucial step in data preparation for 3D printing. It helps to optimise machine capacity, reducing costs and printing time, while increasing machine productivity.

While nesting currently remains a largely manual operation, automated nesting software is evolving to enable 3D printing designers to optimise their builds through nesting faster.

Ultimately, considering nesting early in the design process will enable you to run a more profitable 3D printing business.

How to make money on 3D printing: all possible ways

Business on 3D printing: pros and cons, features, investments, earnings. All the obvious and non-obvious ways to make money on a 3D printer.

All the obvious and non-obvious ways to make money on a 3D printer.

Let's look at any presentation of a 3D printer and it immediately becomes clear: this invention is like a panacea with which you can print literally everything in the world. And if so, is there an option to build a profitable business on 3D printing? This is what the editors of the business magazine https://lindeal.com found out today. We figured out what 3D printers are, what moments are the most important for making money, how much investment such a business requires and what real financial return you should expect from it. We also found all possible and realistic ways to make money on 3D printing.

3D printers: what is it?

3D printer - a device for printing three-dimensional models using a variety of materials. Through multi-layer printing, a three-dimensional object is created, and not an image on paper, as in a conventional printer. This opens up a wide variety of uses for the equipment, from the manufacture of accessories and toys to the production of molds, complex parts and engineering structures.

If a picture or a text document is enough for a familiar printer, then to print a three-dimensional object, the first thing to do is to create its 3D model in the appropriate editor. Alternatively, you can download for free or buy a ready-made model at a low cost on the Internet.

How much investment does a 3D printing business require?

A popular consumable for a 3D printer is plastic: 1 kg of powder costs 7-15 dollars. The affordable price of raw materials makes it possible to obtain high-quality three-dimensional products at a low cost. For the production of exclusive products, more expensive plastic is used, which imitates wood, stone, metal, etc. But at first, 20-30 kg of standard plastic powder is enough for a beginner, which will cost $ 250-500.

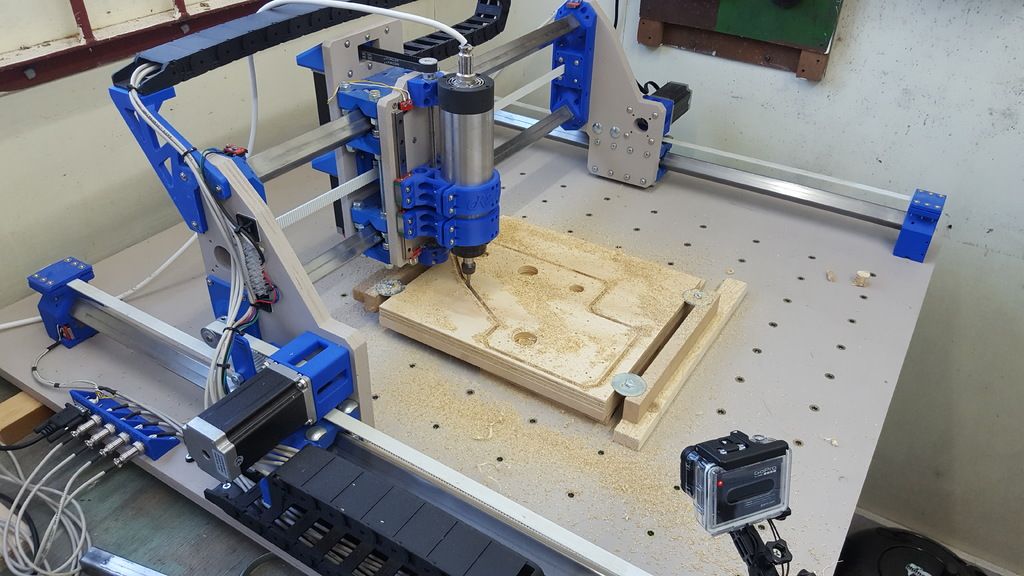

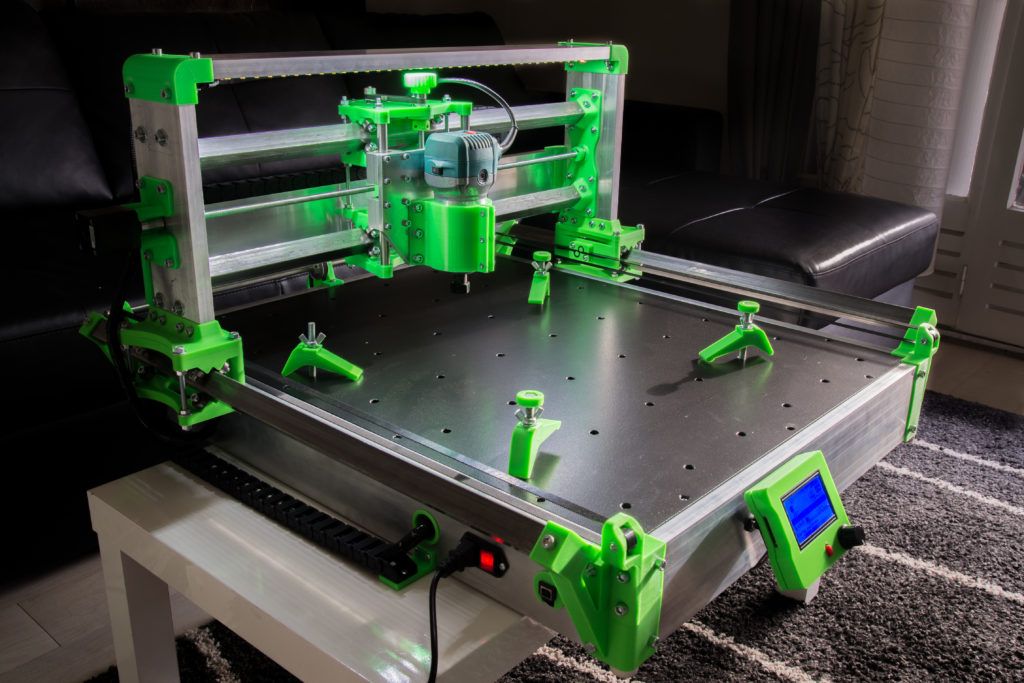

The main item of expenditure is the purchase of the 3D printer itself. The cost of basic high-quality reliable devices starts from $1000. There is an option to purchase a used model or self-assemble equipment, which costs about half the price. If you want to produce high-quality, expensive or rare products (auto parts, spare parts, food products), then it makes sense to purchase a professional printer, whose price is from $5,000.

If you want to produce high-quality, expensive or rare products (auto parts, spare parts, food products), then it makes sense to purchase a professional printer, whose price is from $5,000.

Since any business needs promotion and advertising, you should not forget about attracting an intelligent marketer, ordering advertising campaigns. For these purposes, every month it is worth allocating from 500 dollars. If you are going to work not at home, but rent a separate room for a 3D studio, then you need to add the cost of rent to the listed expenses. Thus, starting a 3D printing business costs, on average, $1,700.

Pros and cons of making money from 3D printing

Business Benefits:

- Low threshold for entry into a niche - to start a business, it is enough to purchase one budget printer.

- Simple implementation of the project.

- Small risks at the start.

- Possibility at first to combine with the main activity.

- Simple promotion - commercial accounts in social networks are enough.

Business weaknesses:

- Serious competition in developed cities.

- Comparatively low earnings and vague growth prospects in small towns.

- Even the most modern printer models are not able to print all the figures from complex sketches with high quality.

- Low cost devices provide single color printing only.

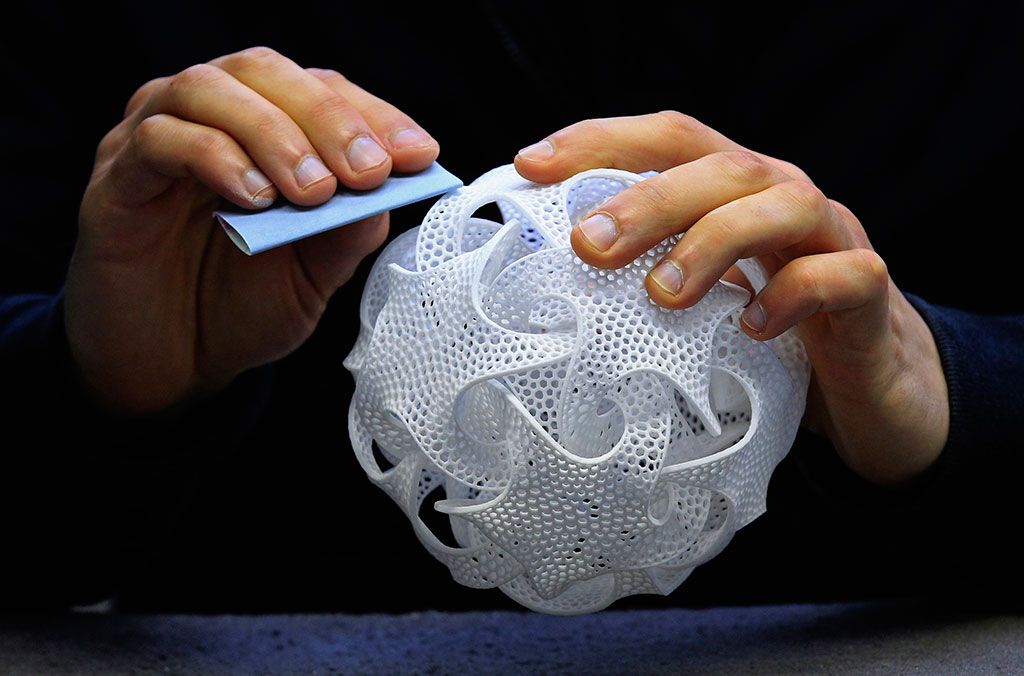

- Behind the printer, you have to refine the product: process with solvents, files, sandpaper, and also paint by hand.

For full-fledged work, you need not only specialized software, but also skills to work with it. It will not be superfluous for an entrepreneur to complete training in 3D modeling.

Ideas for making money with a 3D printer

Before starting a business, a businessman should decide which direction he will choose for himself. The first option: small-scale production of complex products with a high margin - to order, for retail. The second way is mass production of simple products for wholesale.

Printing toys and souvenirs

The easiest and most obvious way to make money is to make toys, jewelry and souvenirs to order. A 3D printer does not limit you in the design of models - you can make even the most complex design with a high degree of detail, either from your own drawings or from mock-ups from clients

Seal of Characters and Artifacts

Creating figurines of heroes of fictional universes from games, books, films, comics and anime is a profitable business. Fans are ready to buy a three-dimensional incarnation of their favorite "Persian" at a retail price ten times higher than the real cost.

Creation of architectural and engineering models, casting molds

Based on the finished drawing, using the printer, you can quickly create a three-dimensional model of a house, apartment, car, equipment, mold. In this case, you do not have to work with private retail customers - your customers will be manufacturing plants, engineering departments and developers. The only difficulty is to form a sufficient customer base for stable earnings.

The only difficulty is to form a sufficient customer base for stable earnings.

Manufacture of auto parts

The3D printer allows you to quickly create complex small parts for a variety of equipment. Auto parts are very popular these days. However, remember that in this case expensive plastic powder is required - raw materials will quickly pay off due to the high retail cost of products.

The next difficulty is that you will have to work on an individual order - that is, to design 3D models on your own. Please note that those parts that are difficult to find in retail will be in high demand - headlight washers, three-dimensional emblems, cases for mirrors and radio tape recorders, door handles, dashboard parts.

Printing copies of museum exhibits

A rather non-trivial way is to make 3D copies of museum exhibits, sculptures or architectural landmarks. The difficulty will be only with the formation of a permanent client base.

Creation of orthopedic goods

In this niche, small-scale local production for individual requests is especially valuable - insoles and orthoses made of rubber and plastic require personal settings and a level of rigidity.

Jewelry printing

3D printing significantly speeds up the production of custom-made jewelry. This is what the market lacks - personalized gold and silver products, bijouterie.

Getting 3D copies of people

Giving picturesque objects or photo shoots is a thing of the past. More and more people are attracted by the opportunity to present a three-dimensional small copy of a friend for a celebration. However, this option is not suitable for all businessmen, because the figurine will have to be painted manually, which requires both time and skills.

Food stamp

Among the most promising emerging trends is 3D food printing. In this case, instead of a plastic powder, hydrocolloids and a hydrogel are required that can reproduce bakery, dairy products, sugar and chocolates. There are printers working with frosting, chocolate, fruit paste and hummus to create figurines, lollipops and even pasta.

Beautiful 3D confectionery products, personalized sweet figurines as a gift, edible souvenirs of brands are very popular. In many countries, this attractive niche is not yet occupied - many are stopped by the high cost and rarity of raw materials.

In many countries, this attractive niche is not yet occupied - many are stopped by the high cost and rarity of raw materials.

Non-obvious ideas for making money on 3D printing

Consider other 3D printing business options:

- Working as a 3D designer. Create custom 3D mockups at the right price.

- Manufacture of 3D printers. The idea is to design an author's model of equipment for sale under his own brand. The idea, however, is quite difficult to implement, costly in terms of finances and time, because you need to develop something that the craftsmen from China did not think of.

- Manufacture of consumables for 3D printing and. The production of 3D printing filament is a fairly profitable, simple and quickly payback business. You will only need a Chinese machine and plastic powder.

- Sale of 3D printers . The obvious option is to open an online store, purchase machines from the manufacturer at dealer cost and sell at market value.

- Printer rental . If you do not want to learn all the intricacies of 3D printing and modeling, then you can earn money by renting the device.

- 3D printing training. To earn extra money from 3D printing, you can start educating beginners.

- Repair shop for 3D printers. Troubleshooters for 3D hardware will always be needed as long as it is in use - everything breaks down.

- 3D printing vlog . If you have a 3D printer and a good camera, this is enough to keep an educational blog on the same YouTube, earn money from training videos. To do this, of course, you already need to be a pro in 3D printing. Another option for the channel is a review of 3D printers.

- Investment in shares of printer manufacturers. This refers to earnings on the securities of joint-stock companies that produce 3D printing machines.

Since 3D printing is one of the promising and promising industries, it should be seriously considered for investment.

How much can you earn from 3D printing?

Net income from a 3D printing business starts at $1,000. However, in small towns and regions that are not closely familiar with technology, earnings can be reduced by almost half. In general, the business does not have an upper bar for profit - its size depends on the constituent factors:

- selected niche;

- cost of raw materials used;

- technical capabilities of printers;

- number of clients;

- ability to develop complex layouts to order;

- design skills for hand painting figurines.

As real experience shows, this business idea fully pays off within 1 year.

The editors of https://lindeal.com find the 3D printer to be a versatile piece of business equipment. The easiest and most obvious way to make money is to print unique things: fashion accessories, movie characters, jewelry, smartphone cases, souvenirs. You can also turn to such non-trivial methods as making copies of museum exhibits, human figures, or even three-dimensional edible products. However, for this business to really bring real income, you need to study local trends, the needs of the target audience and the products of competitors in order to bring to the market an offer that will really be in demand.

However, for this business to really bring real income, you need to study local trends, the needs of the target audience and the products of competitors in order to bring to the market an offer that will really be in demand.

- Material Information

- Julia Abdulbarova

- Material information

- Views: 119

-

Rating of the most expensive antiques: who makes money on antiques and how? Back

-

Top 20 things and brands that are most often counterfeited Forward

3D printing

business idea, how to open, investments, equipment, what you need to open + real cases

In three dimensions

3D printing is the latest business idea. It is becoming more and more in demand, the equipment for it is getting cheaper, and the demand is only increasing. A business based on 3D printing is a large number of ways to earn money and the independence of production. Now, when this idea is just taking root in Russia, it's time to start implementing it.

It is becoming more and more in demand, the equipment for it is getting cheaper, and the demand is only increasing. A business based on 3D printing is a large number of ways to earn money and the independence of production. Now, when this idea is just taking root in Russia, it's time to start implementing it.

3D benefit

A 3D printer is expensive equipment that allows you to create three-dimensional objects based on a 3D model created on a computer. Services of such printing are a huge range of opportunities for both the entrepreneur and the buyers. A person can come up with anything and contact your company for implementation. And you can offer exclusive items or parts that a customer would have to search several specialty stores to find.

Target audience - young people 20-30 years old, for whom the use of the latest technology is a trend, as well as older consumers who are familiar with the technology and understand its advantages. Unfortunately, such novelties do not inspire confidence in the most adult audience.

First steps

You should thoroughly prepare for the launch of the project:

- Register, preferably as an individual entrepreneur, if you do not plan to organize a whole network of 3D printing salons.

- Advertise your business to the maximum - on the Internet, social networks, since your audience is there. You can even create an online store.

- Rent a room. The advantage of such a business is that it does not need a lot of space.

- Buy equipment: the most important thing is the printer itself and plastic - consumables.

- Hire a modeling specialist or become one yourself.

Salon work

You can offer ready-made models, implement customer ideas, and provide modeling services. The better the printer, the more options. Ideally, it should support two types of plastic (ABS and PLA) so that you can print more environmentally friendly and safe models. Also useful is the ability to print in a wide range of colors and sizes.

In 3D printing, prefer creating exclusive products to prototyping, competing with a serial manufacturer. This is one of the conditions of demand in the market.

What can you do? Anything but small. Souvenirs and decorations of all kinds, in which exclusivity is highly valued, architectural models for students and not only, forms - both for soap makers or confectioners, and for a sandbox. You can offer a model of hand bones for a student, a necessary part for a sink, a medical prosthesis. They may come to you to make a unique shoehorn or print any strange object that your client has an idea for.

The printed product is to be worked out, unnecessary material removed, sometimes sanded. Do not forget to include in the price this unnecessary, but used consumable and the ink spent on it.

As a result

By spending resources on quality equipment, you will expand your opportunities, and hence the ways to earn income. You won't need a lot of space, but you will need good advertising and lots of ways to connect with customers.