Wasp 3d printing houses

Tecla house 3D-printed from locally sourced clay

James Parkes | Leave a comment

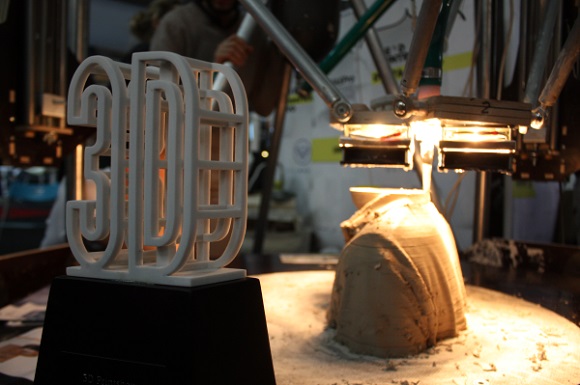

Bologna-based architecture studio Mario Cucinella Architects and 3D printing specialists WASP have collaborated to create a low-carbon housing prototype that is 3D printed using clay.

Named Tecla, a combination of the words technology and clay, the home was designed by Mario Cucinella Architects and was constructed and engineered by Wasp using clay sourced from a nearby riverbed.

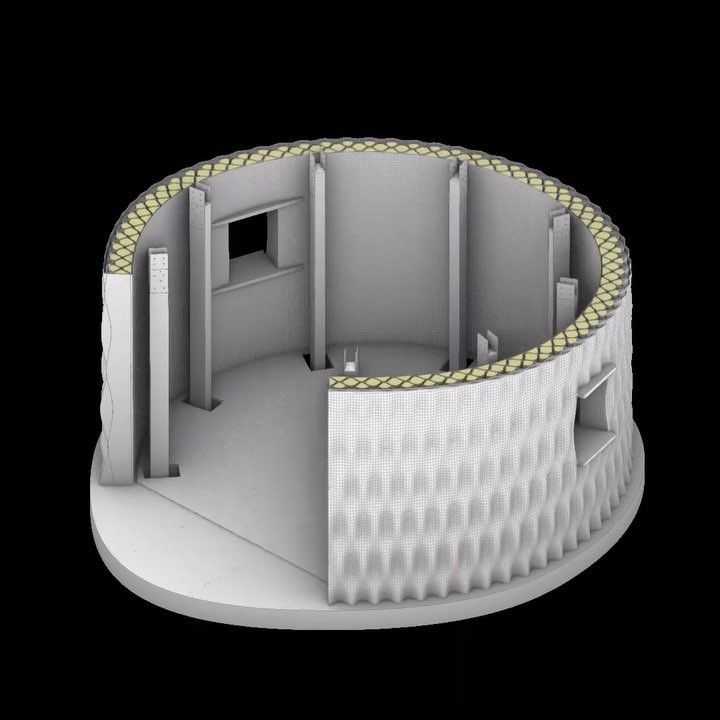

Top: Tecla was made by Mario Cucinella Architects and Wasp. Above: the prototype was printed using 350 layers of clayPrinted in Massa Lombarda, Italy, the home is formed of two connected dome-shaped volumes with a ribbed outer wall that is made up of 350 stacked layers of 3D-printed clay.

The clay is arranged in undulating layers that not only provide structural stability but also to act as a thermal barrier.

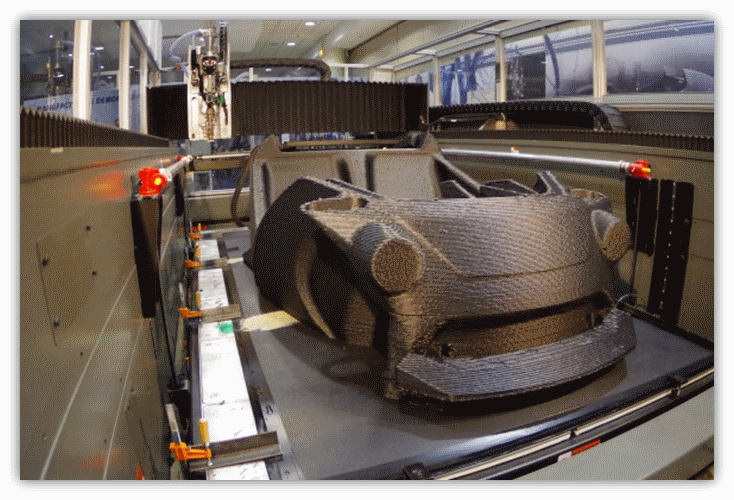

The prototype was constructed using a multilevelled, modular 3D printer that uses two synchronised arms, each with a 50-square metre printing area that can print modules simultaneously.

Mighty Buildings plans neighbourhood of 3D-printed homes for California

By using this technology, housing modules can be built within 200 hours while consuming an average of six kilowatts of energy and reducing typical construction waste almost entirely said the construction team.

The prototype has a ribbed exteriorAccording to the studio, the housing prototype combines ancient building techniques with modern technology to form recyclable, low-carbon, climate-adaptable housing.

"TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes and to the great global issue of the housing emergency that will have to be faced," said Mario Cucinella Architects.

"Particularly in the context of urgent crises generated, for example, by large migrations or natural disasters. "

"

The 60-square-metre structure is 4.2 metres in height and comprises a living space, kitchen and sleeping area and is fitted with services and a circular skylight on its roof.

Although mainly windowless, its entrance is marked by a glazed door within a large lancet arch.

A large lancet arch marks the entrance to the housing prototypeOn its roof, large circular skylights were fitted within its narrowest point allowing light to enter the space throughout the day.

Its interior has a similar organic aesthetic as the walls were left bare with a lancet archconnecting the different zones.

Furnishings were also partly printed using locally sourced earth to unite the space and were designed to be reused or recycled to align with the circular values of the prototype.

The prototype was developed as a response to climate emergency. Photograph is by ItaldronThe geometry of its envelope can be adapted and modified to work with different types of raw earth and respond to a variety of different climatic conditions.

"The aesthetics of this house are the result of a technical and material effort," said Cucinella. "It was not an aesthetic approach only. It is an honest form, a sincere form."

The prototypes can be constructed in 200 hours. Photograph is by ItaldronTecla was developed as part of an eco-sustainability research study that looked to bioclimatic principles and vernacular architecture and construction to produce low-carbon homes.

"TECLA shows that a beautiful, healthy, and sustainable home can be built by a machine, giving the essential information to the local raw material," said Wasp founder, Massimo Moretti.

Undulating curved layers provide structural stability. Photograph is courtesy of Wasp"We like to think that TECLA is the beginning of a new story," added Mario Cucinella Architects founder and creative director, Mario Cucinella.

"It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today. "

"

In 2019, WASP used its Crane Wasp 3D printer to create a small home constructed using soil and agricultural waste.

Elsewhere, 3Strands and ICON collaborated to build four 3D-printed homes using disaster-proof concrete.

Photography is by Iago Corazza unless stated otherwise.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Plus occasional news.

News about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

Mario Cucinella Architects and WASP built world's first 3D printed house made of local raw earth

Italian architecture studio Mario Cucinella Architects and Italy’s pioneering specialists in 3D printing WASP have built a 3D printed housing prototype made of local raw earth which combines a high-level technology use and local material.

The project, addressing to today's climate change and urgent needs that they bring, the team created a small-scale housing model that can be replicated in anywhere of the world by using a 3D printer and local soil.

Named TECLA, using a combination of two words "technology" and "clay", was printed in Massa Lombarda, Italy and the project represents and innovative and pioneering approach starting from design concept to construction, which was developed by Mario Cucinella Architects and WASP.

TECLA, inspired by one of Italo Calvino's "invisible cities" - the city in continuous construction, takes its name from a strong link between past and future by combining the matter and spirit of timeless ancient homes with the world of 21st-century technological production.

The project, printed with 200 hours using 7000 machine codes (G-code), was made of 350 stacked layers (one layer is 12 mm) of 3D-printed local clay, with 150 km of extrusion - which includes 60 cubic meters of natural materials.

As the team emphasized, this construction technique consumes an average of less than 6 kW of energy, which typically allows for the reduction of waste and scraps produced in traditional construction.

The layers can easily be perceived when users get closer to the structure - they also provide structural stability and stiffness, while the layers are used for thermal insulation in natural way.

The project was born from a research project as part of SOS - School of Sustainability, training center founded by Mario Cucinella, and the collaborative 3D printing technology of WASP and through the vision of Massimo Moretti, Founder of WASP.

The project can also be linked to Cucinella's previous lecture in WAF 2019.

Mario Cucinella had said: "We completely forgot the relationship with nature and the empathy with climate, because we build building that have no relation with climate at all. For too many years of technologies, architects forgot the knowledge and now the climate presents the bill: an increasing of pollution everywhere. "

"

"Buildings produce almost the 50% of the C02 emissions. Green Architecture will be a balanced hybrid of technological innovation and empathy with the climate. It throws a bridge towards the past, rediscovering and intimate complicity with nature."

"TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes at Km0 and to the great global issue of the housing emergency that will have to be faced - particularly in the context of urgent crises generated, for example, by large migrations or natural disasters," said the studio.

"We like to think that TECLA is the beginning of a new story. It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today," said Mario Cucinella.

"The aesthetics of this house are the result of a technical and material effort; it was not an aesthetic approach only. It is an honest form, a sincere form," added Cucinella.

"TECLA shows that a beautiful, healthy, and sustainable home can be built by a machine, giving the essential information to the local raw material. TECLA is the finger that points to the Moon. The Moon is the home, as a birthright, for everybody on the planet. From TECLA on, that's getting possible," said Massimo Moretti, founder of WASP.

TECLA is the finger that points to the Moon. The Moon is the home, as a birthright, for everybody on the planet. From TECLA on, that's getting possible," said Massimo Moretti, founder of WASP.

The project is also described as an innovative circular economy housing model that "brings together research on vernacular construction practices, the study of bioclimatic principles and the use of natural and local materials."

TECLA was developed as a nearly zero-emission project since it was entirely made of local material which allows for the reduction of waste and scraps during construction.

"This and the use of raw earth make TECLA a pioneering example of low-carbon housing," according to the studio.

For this project, Mario Cucinella Architects not only explored housing solutions in formal aesthetic terms, it also studied the building’s shape in relation to its climate and latitude.

In addition, the composition of the earth mixture responds to local climatic conditions and the filling of the envelope is parametrically optimised to balance thermal mass, insulation and ventilation according to the climate needs.

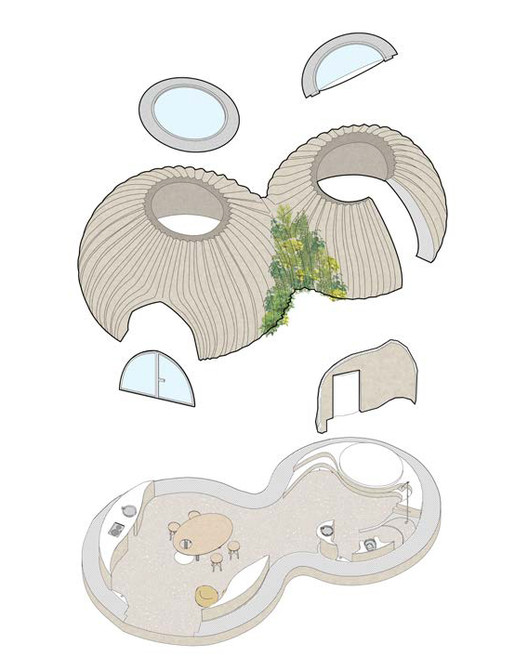

Covering approximately an area of 60 square meters, the house comprises a living zone with a kitchen and a night zone which includes services.

Inside of TECLA, the furnishings were partly printed in local earth and integrated into the raw-earth structure, and partly designed to be recycled or reused - reflect the philosophy of a circular house model.

The house is composed of two continuous elements that through a sinuous and uninterrupted sine curve culminate in two circular skylights that convey the ‘zenith light’.

The atypical shape, from the geometry to the external ridges, has enabled the structural balance of the construction - both during the 3D printing phase of the envelope and once the covering is completed - giving life to an organic and visually coherent design.

In this construction, WASP used "Crane WASP", the first in the world to be modular and multilevel, Crane WASP uses multiple 3D printers and work collaboratively.

Thanks to WASP' brand-new system Crane WASP, two printing arms were synchronized as part of a construction and the software were capable of optimizing movements, avoiding collisions and ensuring simultaneous operation.

Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

Sketch

TECLA module tool kit

Floor plan

Section

Axonometric section

The housing model is entirely Made in Italy: in addition to Mario Cucinella Architects and WASP, it sees the participation of Italian-only companies.

Read more about the construction of TECLA on WAC's previous coverage.

Project facts

Project name: TECLA

Architectural and Furniture Design: Mario Cucinella Architects, Bologna, Italy

Architectural and Furniture Design Team: Mario Cucinella Architects: Mario Cucinella (Founder and creative director), Irene Giglio (project manager), Augusto Barichello

Sustainability Research: SOS – School of Sustainability, Bologna, Italy (Postgraduate Training Center founded by Mario Cucinella): Lorenzo Porcelli, Stefano Rosso, Lori Zillante

Collaborative 3D Printing Technology Project: WASP, Massa Lombarda, Ravenna, Italy

Collaborative 3D Printing Technology Project Info: 200 printing hours, 7000 G-codes, 350/12 mm layers, 150 km of extrusion, 60 cubic meters of natural materials for less than 6 kW of average electricity consumption

Collaborative 3D Printing Technology Project team: Massimo Moretti (Founder), lapo Naldoni, Alberto Chiusoli, Francesco De Fabritis, Massimo Visonà

3d model/Images:

SOS – School of Sustainability, Bologna, Italy (Postgraduate Training Center founded by Mario Cucinella)

WASP, Massa Lombarda, Ravenna, Italy

Physical Model: WASP, Massa Lombarda, Ravenna

Landscape Design: Frassinago, Bologna, Italy

Structural Engineering: Milan Ingegneria, Milan, Italy

Lighting: Lucifero’s, Bologna, Italy

Construction: WASP, Massa Lombarda, Ravenna, Italy; TER Costruzioni, Bologna

Construction supervision: WASP, Massa Lombarda, Ravenna, Italy

Infilling blend optimization in 3D printing phase: Mapei, Milano

Infilling biomaterial: Rice House, Andorno Micca, Biella, Italy

Earthen floor: Primat, Occhieppo Inferiore, Biella, Italy

Doors and windows: Capoferri Serramenti, Adrara San Martino, Bergamo, Italy

Wood finishes: Imola Legno, Imola, Bologna, Italy

Table recycled wood: Saib, Caorso, Piacenza, Italy

Seating: Officine Tamborrino, Ostuni, Brindisi, Italy

Fabrics: Orange Fiber, Rovereto, Trento, Italy

Services (M&E): Cefla, Imola, Bologna, Italy

Completion date: 03/31/2021

Net area: 45m2

Gross area: 60m2

All images © Iago Corazza

All drawings © Mario Cucinella Architects

> via Mario Cucinella Architects

Print business cards print shop online in Osa

Filter

| On paper Majestic | ||

| New | On paper Majestic

| |

| Kraft paper | ||

| Recommended | On craft paper

| |

| On paper Touch cover | ||

| On paper Touch cover

| ||

| Laminated | ||

| With lamination

| ||

| Design paper | ||

| On design paper

| ||

| Lacquer business cards | ||

| Business cards with varnish

| ||

| With magnetic backing | ||

| With magnetic backing

| ||

| UV business card printing | ||

| UV business card printing

| ||

| Cheap business cards | ||

| cheap business cards

| ||

| On paper Tracing paper | ||

| On paper Tracing paper

| ||

| Embossed business cards | ||

| Recommended | Embossed business cards

| |

| On textured paper Linen | ||

| On textured paper Linen

| ||

| Plastic based | ||

| On a plastic basis

| ||

Print business cards with delivery to Osa

You can order printing of business cards online in your city of Osa with delivery. For the cost and delivery time, read on the "Delivery" page or check with our managers through the online chat on the site and by calling the toll-free phone number 8 (800) 707-66-81. Managers will also help you if you have any difficulties in the editor or at the registration stage.

make a business card online

Printing design in the city of Osa, order services

- Login

- Registration

- Home

- Artists

- Osa

- Design and engineering

- Print design

Print design

Found 8 designers

Average rating 3.93 based on 289 reviews and 1073 ratings 289

Print design - prices by agreement in... fully

PRO

Artyom Merkulov

Osa

Was 1 day ago

Work experience as a marketer in the company "Ledartis Design", graphic designer in the printing house "Contrast" (3 years), freelance (5 years). I cooperate with both large state. enterprises...

PRO

Maria Turlak

Osa

Was there 2 days ago

I will make a modern, high-quality, adaptive design or a turnkey project of your choice.

Services: design, adaptive layout, programming (WordPress), prototyping,. ..

..

PRO

Artur

Wasp

Last visit 3 days ago

I create logo design, corporate identity for printing and web resources. I draw illustrations for print and social networks

Milana Aleksandrovna Shvets

Wasp

Last visit

I draw digital art to order. I have been drawing for about 10 years, the experience is good. I draw quickly and efficiently, I can be entrusted with any work related to drawing. I myself am sociable and...

Ekaterina Andreevna Tomilova

Osa

Visited recently

Responsible, executive, I treat the quality of order fulfillment with high scrupulousness. Rewriting, copywriting, design of logos, flyers, textiles....

Apply for selection:

Add an application to find the Contractor in the category “Design of printing” in the city of OSA:

All fields are required for filling out

Valeriya CH

Osa

Was

logos

portraits

art

Infographics

text

Copywriting

Flyers

Vector

Sketches

Polina Alekseevna Lasheva

Wasp

Last Visit

Graphic designer, 3 years experience.

- logo development, full identity;

- business cards, brochures;

- magazines, books;

- guides, e-books;

Victoria

Wasp

Was recently

Creation of landings (single-page site / business card site), multi-page sites, online stores;

Design of social networks (Vkontakte, Instagram), design of newsletters;

Design...

What needs to be done?

Describe your task - the performers themselves will respond to your order

Order a service

Order a service

Submit a task and ask for prices

Graphic Designer (ETSY) Fri.)

from 07:00-19:00 (GMT London)

- Confident...

Graphic Designer for Printing

Write to whatsapp +79284555222 and I ask you to immediately send a link to the portfolio.

Thank you :)

Main duties

Hello friend! or a friend :)

in our team. ..

..

Designer (development of information stands)

For the STAND WORKSHOP project | MasterStendov.ru needs a DESIGNER.

PERMANENT and REMOTE work

RESPONSIBILITIES:

- development of stands design from scratch according to the technical...

Leaflet design

Develop a leaflet layout in A format 5

Budget: 500 ₽

Design a company presentation

It is necessary to design a company presentation (research and production complex). Budget 15t.r Volume 15-16 slides. There is TK. Also, you need to make a test slide,...

Budget: 15 000 ₽

It is required to design one letterhead

It is required to make a template design of the form. And to make three receipts (there is a text), you just need to enter everything through the cord and insert it into the completed form. 1) acceptance receipt (text...

Budget: 300 ₽

Development of packaging design layouts

We offer to consider an order for the development of clothing packaging design layouts: - Main label design 2 options - Hang tag design 2 options - Sew-in label design 2. ..

..

Offer and finish the design (fragment) of the gift box...

There is a gift box (~360*240) with a design and even printed in a printing house (not completely, it was suspended). We didn't like how the products are shown - all photos...

Budget: 3 000 ₽

Graphic Designer for Restaurant

We need a designer who can change the prices in the menu, as well as on a permanent basis (can be done remotely). We urgently need to change the prices in the menus of two establishments....

Layout of a children's book with illustrations

The illustrations are already there. We need a specialist who owns the Adobe InDesign program or any other professional book layout software Please, before answering the vacancy ...

- Perm

- Okhansk

- Ocher

- Solikamsk

- Suksun

- Vinskoye

- Usolye

- Ust-Kishert

- Tchaikovsky

- Frequent

- Cherdyn

- Chernorechensky

- Nigella

- Chusovoy

- Yurla

- Yusva

- Nyrob

- Nytva

- October

- Horde

How to order the service: Print design in the city of Osa?

To order the Printing Design service, you can Add an order and then the specialists will respond themselves, you can also choose a suitable designer from the catalog.

How much does the service cost: Print design in the city of Osa?

Prices for services: Printing design in the city of Osa can make prices by agreement, depending on the complexity or volume of work performed.

How to check a specialist in the category: Printing design in the city of Osa?

Before choosing a contractor in the category: Printing design in the city of Osa, you need to pay attention to the rating, the number of reviews, the correctness of filling out the profile, photos of work performed, the availability of documents. Contractors with PRO or TOP status monitor their reputation, work under a contract and try to provide services of high quality, on time!

How to leave feedback about the job: Printing design in the city of Osa?

To evaluate the work of Print Design, enter the profile of the selected specialist. Also, after completing the order, you will receive a notification with a proposal to evaluate the work of the designer.

Maintains a presentable appearance for a long time

Maintains a presentable appearance for a long time  4-0.7 mm thick.

4-0.7 mm thick.  275 mm thick like paper

275 mm thick like paper