Eclipson 3d printed plane

Eclipson - 3D printed airplanes

3D PRINTED AIRPLANES

WITH 3D PRINTED RETRACTS!

MUSTANG P-51D

GET IT

2nd GENERATION

Welcome to the second generation of 3D printed airplanes! Our planes are the lightest of the market.

All our airplanes have been tested and modified if necessary to be adapted to the mechanical properties of new revolutionary filaments such as LW-PLA from Colorfabb. We guarantee you that despite the huge weight reduction our models are still strong enough to make any kind of aerobatics maneuvers

(more than ± 10G) or hard landing (read more)

DOWNLOAD FILES

AND PRINT IT

The process is simple:

1º Buy and download STL files /G-codes and cura profiles.

2º Add the G-codes into your printer and build your plane!

We provide you all the information that you will need.

Before buying an airplane you can download a test part.

Download a free model!

LEARNING FROM

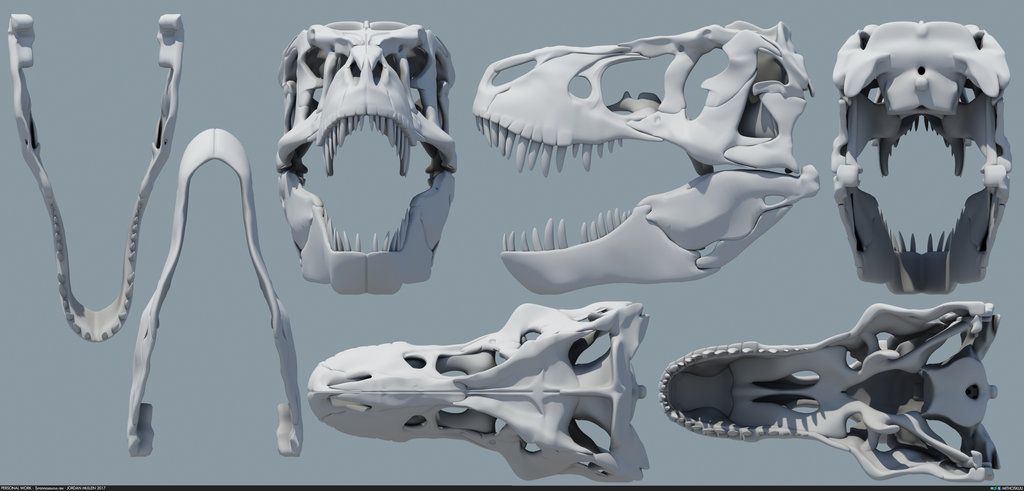

NATURE

We are totally aware about the design freedom that 3D printing technology gives us, but this freedom should be used in a clever way otherwise you are not taking advantage of this incredible way to manufacture things!.

We are convinced that biomimicry is a great approach to take advantage of this freedom in order to develop low-weight, strong and efficient airplanes. (read more)

DESIGNED TO BE PRINTED

Every small detail has been designed taking into account that it will be 3D printed since the conceptual design phase allowing us to design complex shapes such as winglets which are much more difficult and expensive to build with traditional manufacturing technologies. But our models were also designed to be electric RC planes, this is very important to reduce weight even more.

ENGINEERING PROJECTS

Physics and aerodynamics affect in the same way an Airbus A350 than a small RC airplane. That is why we take each airplane project as an engineering project.

Stress analysis to ensure an acceptable strength and aerodynamics analysis to ensure that the airplane will be stable and efficient are just two of many examples. (read more)

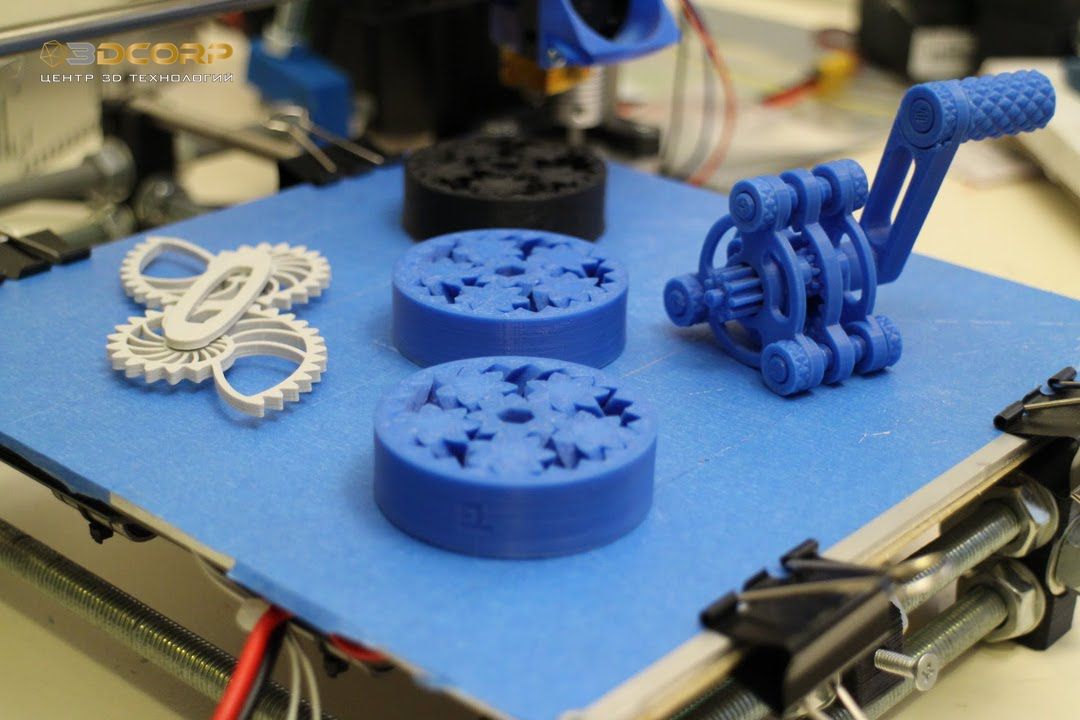

LOW COST

Nowadays you can print functional

parts for complex mechanisms like a radio control airplane even with a low cost 3D printer without losing performances compared with traditional RC planes.

All our models have been tested with Anet A8, which is one of the cheapest printers of the market.

in addition to this, the main electronics components have been standardized, this mean that you can use the same electronic in any of our models reducing even more the price.

YOU CRASH IT

YOU PRINT IT AGAIN

Crashing is part of this hobby, but now you have a factory at home! The great advantage of a 3D printed airplane is that in case you crash it you can print the damaged parts again, which saves a lot of money!. The electronic elements which are more expensive rarely suffer any damage during a crash.

The electronic elements which are more expensive rarely suffer any damage during a crash.

Critical parts are designed to be detachable allowing you to replace them.

Airplanes| Eclipson - 3d Printed airplanes

MUSTANG P-51D

-Span 1,1m

-Flying weight 850g

-7 Channels

-Min. printing vol. 210x210X200(Z)

€37

MXS-R v2

-Span 1,45 m

-Flying weight 1400g

-5 Channels

-Min. printing vol. 210x210x205(Z)

€42

MODEL B

-Span 1,2m

-Flying weight 590g

-5 Channels

-Min. printing vol. 150x150X190(Z)

€27

MODEL A XL

-Span 1,4m

-Flying weight 900g

-7 Channels

-Min. printing vol. 200x200X190(Z)

€25

E-VTOL-1

-Span 1,1 m

-Flying weight 800g

-5 Channels

-Min. printing vol.170x170x190(Z)

€27

MODEL S

-Span 1,8 m

-Flying weight 750g

-7 Channels

-Min. printing vol.170x170x200(Z)

printing vol.170x170x200(Z)

€33

-Span 1,25 m

-Flying weight 1100g

-5 Channels

-Min. printing vol. 200x200X195(Z)

PITTS S12

€39

MODEL R

-Span 1 m

-Flying weight 640g

-5 Channels

-Min. printing vol. 160x160x190(Z)

€30

-Span 1,35 m

-Flying weight 650g

-6 Channels

-Min. printing vol. 210x210X185(Z)

V2

€35

MODEL V2

-Span 1,4 m

-Flying weight 500g

-4 Channels

-Min. printing vol. 200x200x190(Z)

€27

EWW-180

-Span 1,75 m

-Flying weight 850g

-3 Channels

-Min. printing vol. 210x210X190(Z)

€33

MODEL A

-Span 1m

-Flying weight 490g

-5 Channels

-Min. printing vol. 150x150X190(Z)

€18

EBW-140

-Span 1,4m

-Flying weight 480g

-3 Channels

-Min. printing vol. 180x180X195(Z)

printing vol. 180x180X195(Z)

€17

MODEL C

-Span 1,1m

-Flying weight 560g

-5 Channels

-Min. printing vol. 150x150X190(Z)

€27

EWW-180 EDF

-Span 1,75 m

-Flying weight 850g

-3 Channels

-Min. printing vol. 210x210X190(Z)

€33

EGW-80

-Span 0,8 m

-Flying weight 480g

-3 Channels

-Min. printing vol. 210x210x180(Z)

€22

EGW-80 EDF

-Span 0,8 m

-Flying weight 490g

-4 Channels

-Min. printing vol. 210x210x180(Z)

€27

MODEL D2

-Span 1,2 m

-Flying weight 500g

-3 Channels

-Min. printing vol. 160x160x190(Z)

€25

MODEL T

-Span 1,16 m

-Flying weight 600g

-4 or 5 Channels

-Min. printing vol. 210x210x180(Z)

€16

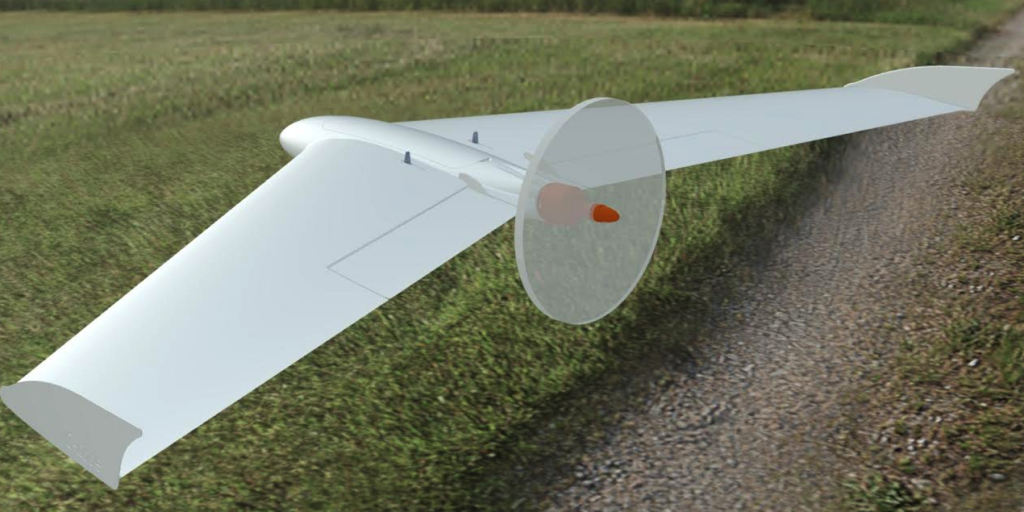

PRANDTL V2

-Span 1,6 m

-Flying weight 470g

-3 Channels

-Min. printing vol. 180x180x195(Z)

printing vol. 180x180x195(Z)

€17

STREAM V2

-Span 1,1 m

-Flying weight 550g

-3 Channels

-Min. printing vol. 160x160x190(Z)

Coming

soon

EBW-160 R/C

-Span 1,6 m

-Flying weight 680g

-3 Channels

-Min. printing vol. 210x210x180(Z)

€18

EBW-160 UAV

-Span 1,6 m

-Flying weight 760g

-3 Channels

-Min. printing vol. 210x210x180(Z)

€27

MODEL Z

-Span 1,2 m

-Flying weight 500g

-4 Channels

-Min. printing vol. 150x150x185(Z)

€19

✈️ Best Aircraft & Aircraft 3D Printing 3D Files ・Cults

✈️ Best Aircraft & Aircraft 3D Printing 3D Files

Climb with this collection of 3D files perfectly optimized for 3D printing. You can print beautiful airplane models to decorate your home or even do some modeling. As a result of 3D printing and connecting various parts, your aircraft can even fly for real. This is a great way to show your child how an airplane works and talk about the different models: CESSNA, Airbus, Boeing, etc.

This is a great way to show your child how an airplane works and talk about the different models: CESSNA, Airbus, Boeing, etc.

RC plane - Eclipson model A free version by Eclipson

Free

F5 Tiger 1/64 easy to print scale model

Free

Free RC Airplane

Free

Pilot Baby - 3D printed reproduction of a vintage RC sport model.

Free

Build your own aircraft engine

Free

RAF WW II Spitfire

Free

Plane

Free

Easy to print T-38 Talon aircraft scale model (esc: 1/64)

Free

RC airplane Wing - Eclipson Model Y

Free

F117 Nighthawk

Free

MD80 AIRCRAFT SCALE MODEL

Free

RC plane fuselage - Eclipson model Z

Free

Airbus A220-100 - 1:144 - Free

Free

Zlin Z-242 frame model (esc: 1/64) (No 3D print, CNC routing)

Free

Cessna 172 Skyhawk 1:72

2 €

Turboprop Engine

Free

Ultimate Biplane 10-300S

Free

Easy to print Cessna Citation SII 1/64 aircraft scale model

Free

Porco Rosso Savoia S.

21 Aircraft

21 Aircraft Free

Aero Commander 500S

Free

Model plane

Free

SOFIA, the Stratospheric Observatory for Infrared Astronomy

Free

Das Liddle Stik RC Airplane

Free

Antonov An-225

Free

Aircraft

Free

Easy to print Aero L-39 Albatros aircraft scale model

Free

Lancer B1 Bomber

Free

PIPE ECHAPEMENT SPITFIRE

Free

WW II RAF Spitfire Sliced

Free

A02 C-3D aircraft

Free

P-51D Mustang - Sally AURI

Free

First Take Off of a fully printed (FDM) sailplane.

Free

Ercoupe Golden Age Aircraft

Free

RAF Mosquito WW II

Free

Le Rhone spinning radial dummy engine for RC planes

Free

Little Jet Plane

Free

RAF Lightning

Free

Floonda - free 3d printed Freestyle Glider 1335mm Wingspan (Vasemode)

Free

Transport Aircraft Toy Puzzle

Free

Mobile device Barron Red

2.44 €

Speedy "Red Mini Wing" RC Plane

Free

"Red Swan" the biggest fully printed Flying Wing

Free

Antonov An-32

Free

Antonov An-124

Free

Touristic plane

Free

EL-39 - RC half-scale jet for 120 mm EDF

17. 35 €

35 €

Skewer Fighter Jet (F-86 Saber)

Free

Bi Plane

Free

Hawker Tempest V WW2 Fighter

Airbus A220-100 - 1:144 - Free

Airbus A220-100 - 1:144 - Free

Aichi D3A2

Here is our selection of best 3D aircraft files , all these great machines from the Cults and 3D file libraries are perfectly 3D printable for .

This collection includes free 3D files of all types of aircraft. There are many aircraft models of the most prestigious brands, such as Boeing , Airbus , Cessna or Antonov .

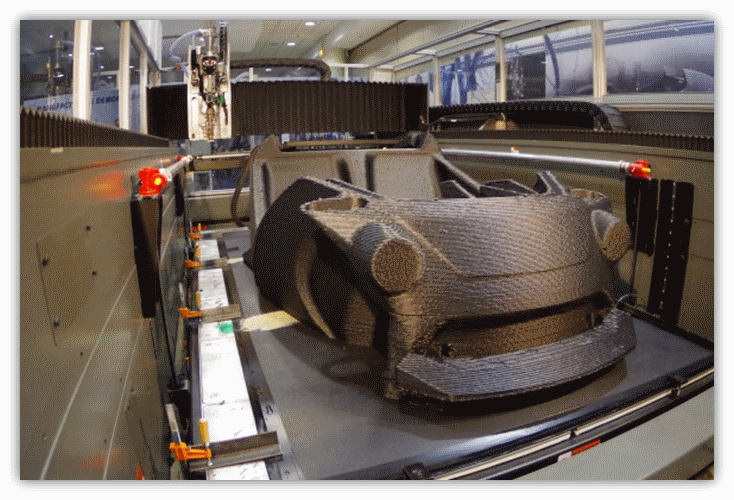

Professional 3D printing of has gained a lot of development in the world of aeronautics mainly for very specific applications. For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

Of course, you won't find real aircraft parts here, but you will find lots of 3D aircraft models . For lovers of modeling, you can 3D print your own airplane or glider!

Aircraft 3D printing: An engineer's story Boeing

Each Boeing 787 passenger aircraft has about 30 3D printed parts. Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Boeing spokesman Bernardo Malfitano spoke at the EAA AirVenture Oshkosh forum of aviation enthusiasts and spoke about how 3D printing is being used in the aircraft industry today.

Mechanic, tester, aircraft builder and pilot

Bernardo Malfitano has been with Boeing since 2007. In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

According to the expert, all popular 3D printing methods are now used in the aerospace industry: laser stereolithography (SLA), deposition method (FDM), selective laser sintering (SLS) and direct metal deposition (DMD). Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Where are printed parts on airplanes?

Air ducts are the part of the aircraft where 3D printed parts are most widely used today. In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

Power units. There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser sintering or metal deposition. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. And in the F-15K Slam Eagle military aircraft, casings for turbines were made using volumetric printing. This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

Interior details . Shelves, brackets and various fixtures in passenger aircraft cabins are often printed in plastic. For example, the popular Boeing A350 has over 500 of these parts on board.

Small parts. End caps, parts of seats and instrument cases - all this can also be made using the 3D printing method. In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

Advantages of 3D printing for aircraft construction

Additive technologies attract aircraft designers not only because they are economical. They make it possible to optimize the shape at the model stage and significantly reduce the weight of the product. So, by replacing the cast metal bracket with a plastic one printed on a 3D printer, the designers managed to reduce its weight from 918 grams to 326. Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

Parts with mesh and honeycomb structure are lighter than monolithic ones, but at the same time they do not lose strength. Each new sample introduced in the aircraft industry undergoes multi-stage tests, especially if it is a functional part.

Is it possible to print the entire aircraft?

If additive technologies are so good for 3D printing, is it possible to print an entire airplane? Bernardo Malfitano is sure that now it is impossible.

Today, 3D printing is successfully used to make drone bodies and working models of aircraft. At the Berlin Air Show in 2016, visitors saw the Airbus Thor, a remote-controlled aircraft about 2 meters long. All of its parts were 3D printed.

But to create the hulls of large aircraft - passenger liners, cargo planes, fighter jets - modern 3D printing technologies are not reliable enough.

Malfitano explained that the US has statutory manufacturing standards. The aircraft industry is governed by 14 CFR Part 25 (“Airworthiness Standards: Transport Category Aircraft”). It says that the structure of the materials must be strong, and the details must be reliable, which must be confirmed by certain tests. Meanwhile, testing parts created by 3D printing often reveals defects and inhomogeneities.

The second factor is the price. Aircraft manufacturing is mass production, so it is now more profitable to use traditional techniques at most nodes.

Bernardo Malfitano's entire presentation can be viewed here.

Learn more