Most expensive 3d printers

The Five Most Expensive 3D Printers on the Market Today

Electronics

ByGarrett Parker Posted on Updated on

What began as a novelty in the technology world has rapidly advanced to a new way of manufacturing a variety of goods. 3D printing is taking the world by storm and it’s now used to create parts for jets, automobiles, shoes, and even homes that people can live in. The first 3D printer prototypes were smaller and we were amazed watching them slowly create objects through a computer program, but when we viewed one at the local fair some years back, we didn’t imagine what they would be capable of. Some of the 3D printers used privately and commercially range from small in size to very large. This technology is fascinating, and in researching them, we were curious about how much they cost. We thought you’d enjoy what we found out so we’re sharing the five most expensive 3D printers in 2018.

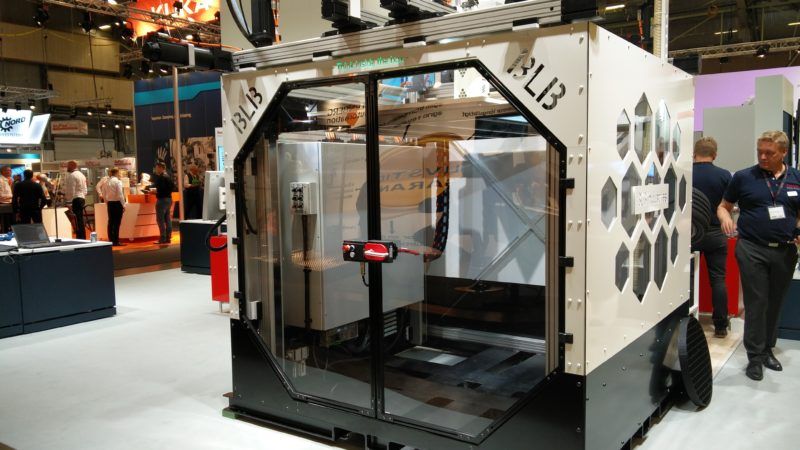

5. The Box – $310,000

Th Box is a 3D printer that is available for purchase if you have the $310,000 it retails for. The Box was created by two Swedish students who were working on a hobbyist project. Jacob Lundin and Cim Bergdahl were the pair responsible for the concept of the Box and deserve the credit for its development. They joined with others who had an interest in furthering the development of their project and formed BLB industries which manufactures this unique 3D printer that is among thee fastest and largest in the entire world, and it works through a Fused Granular Fabrication process. This 3D printer is fifth on our list because although it’s quite expensive, there are four more that are even higher in price.

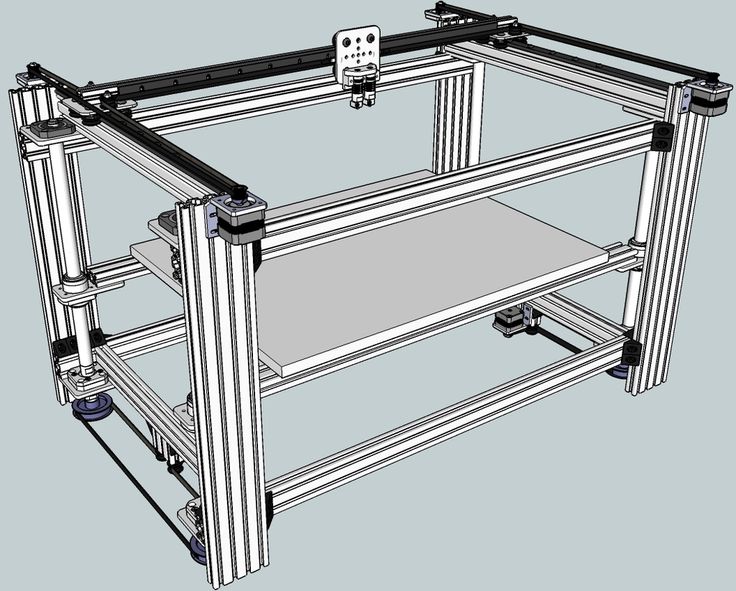

4. 3D Platform Excel – $450,000-1,200,000

The 3D Platform Excel is the fourth most expensive printer in the world. You may notice that there is a broad price range and this is because this machine is customizable and although the base size is 13 x 328 x 13 feet, we learned that there is an infinite range of length dimensions possible. This 3D printer is unique, and although the base model is not the largest, there is a full potential for manufacturing it in a size that would place it in the lead. There are other customizable features available for the tech savvy who have specific projects in mind. This printer uses the Fused Deposition Modeling process. The company that manufactures this printer is 3D Platform and they offer several large 3D printers.

This 3D printer is unique, and although the base model is not the largest, there is a full potential for manufacturing it in a size that would place it in the lead. There are other customizable features available for the tech savvy who have specific projects in mind. This printer uses the Fused Deposition Modeling process. The company that manufactures this printer is 3D Platform and they offer several large 3D printers.

3. Optomec LENS 850-R – $1,200,000

The Optomec company manufactures and sells the LENS 850-R 3D system. It’s the third most expensive printer in the world. It operates through the Laser Engineered Net Shaping process, also referred to as LENS, hence the name of the printer model. It’s available for sale for $1.2 million. The unique LENS process builds a print layer by layer and it melts metal powder through a high power laser. This printer has the capacity to build objects from scratch as well as making repairs to existing items that are damaged.

2.

SonicLayer 7200 – $2,500,00

SonicLayer 7200 – $2,500,00Fabrisonic is the company that manufactures and sells the SonicLayer 7200. It’s tied for the most expensive position with a price tag of $2.5 million. This printer has been described as a CNC mill. It’s a complicated machine that has tremendous potential and capacities. It uses the Ultrasonic Additive Manufacturing process, also known as UAM. Ultrasonic waves are used to bond metal layers together, so it doesn’t require high temperatures to operate.

1. Imprimere’s Model 2156 – $2,500,000

The most expensive 3D printer in the world is in a tying position with the SonicLayer 7200. It’s the Imprimere’s Model 2156. The Im company manufactures and sells it commercially. This 3D printer uses the Concrete Deposition process and is used in the construction business and holds promise for revolutionizing the industry through a more consistent fully automated building process that reduces costs. This amazing technology is used to or printing with concrete as well as for grinding, milling and 3D scanning. It also has the capability of traveling on tracks for up to 70 meters. It’s an exciting and innovative development in 3D technology that holds promise for changing the way that buildings are constructed.

It also has the capability of traveling on tracks for up to 70 meters. It’s an exciting and innovative development in 3D technology that holds promise for changing the way that buildings are constructed.

Final thoughts

It’s truly amazing how far 3D technology has come. The things that were once believed to be speculative and based on futuristic fantasy are now becoming realities that are useful in real life applications. Having accomplished this level of advancement, it makes one wonder what we’re going to see next?

Garrett Parker

Garrett by trade is a personal finance freelance writer and journalist. With over 10 years experience he's covered businesses, CEOs, and investments. However he does like to take on other topics involving some of his personal interests like automobiles, future technologies, and anything else that could change the world.

Similar Posts

Electronics

SPUD: The Spontaneous Pop Up Display

ByGarrett Parker

In today’s world, being able to stay up to date on news, family and friends, and work while on the go is absolutely essential. Great advances in technology have allowed people to stay connected while…

Great advances in technology have allowed people to stay connected while…

Read More SPUD: The Spontaneous Pop Up DisplayContinue

The Complete Comparison – Printing It 3D

It wasn’t too long ago that 3D printers were costly and only used by commercial businesses. However, as the technology has become more popular and mainstream, the cost of 3D printers has come down significantly, making it even more challenging for enthusiasts to decide between cheap and expensive 3D printers.

Cheap 3D printers are most suitable for beginners or those who don’t need the best possible prints. On the other hand, expensive models are ideal for anyone looking for printed objects with intricate details and incredible precision.

Read on for more insights into the differences between cheap and costly 3D printers. I’ll walk you through the pros and cons and help you choose the best model for your needs.

Cheap 3D Printers Pros and Cons

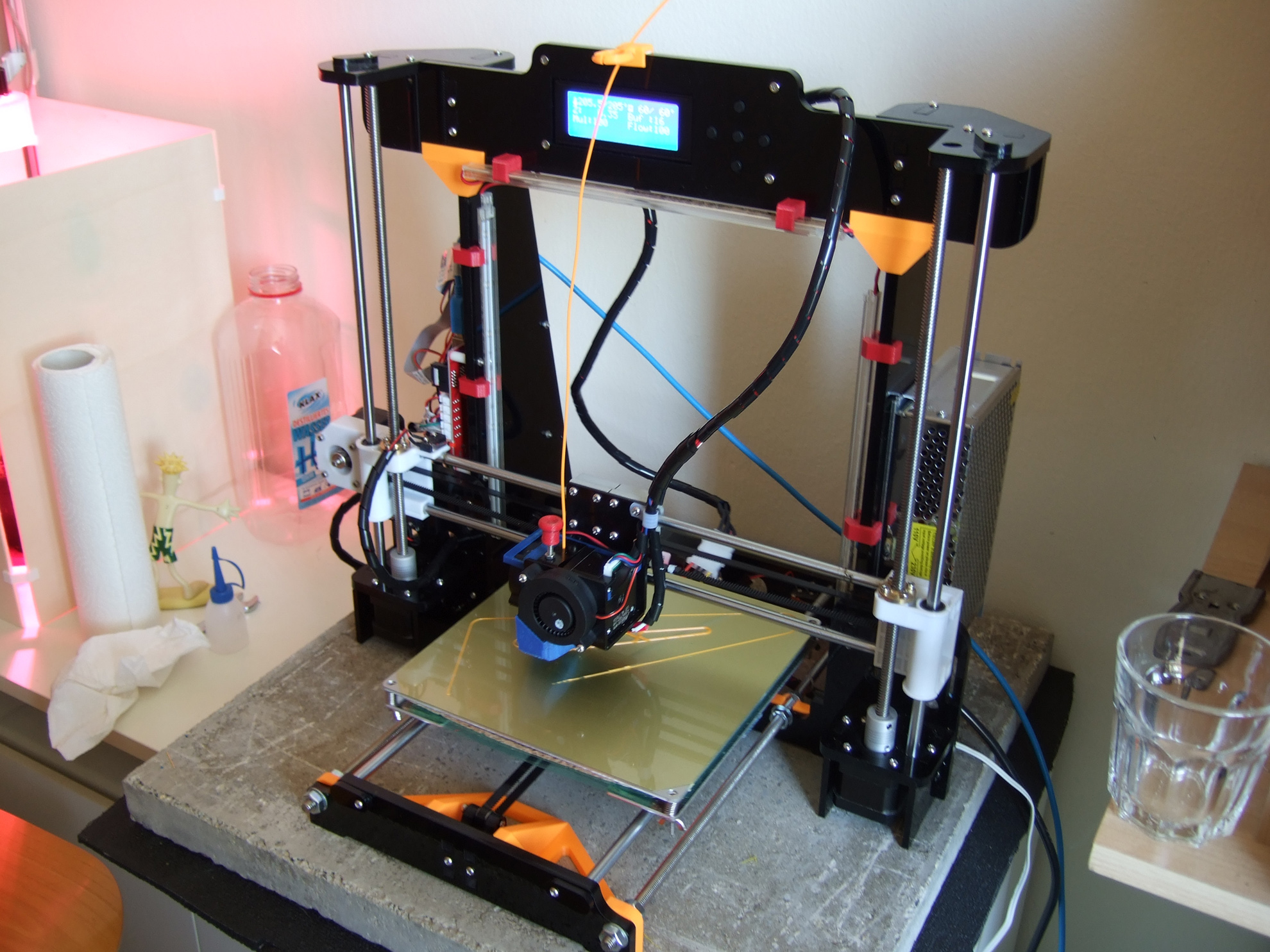

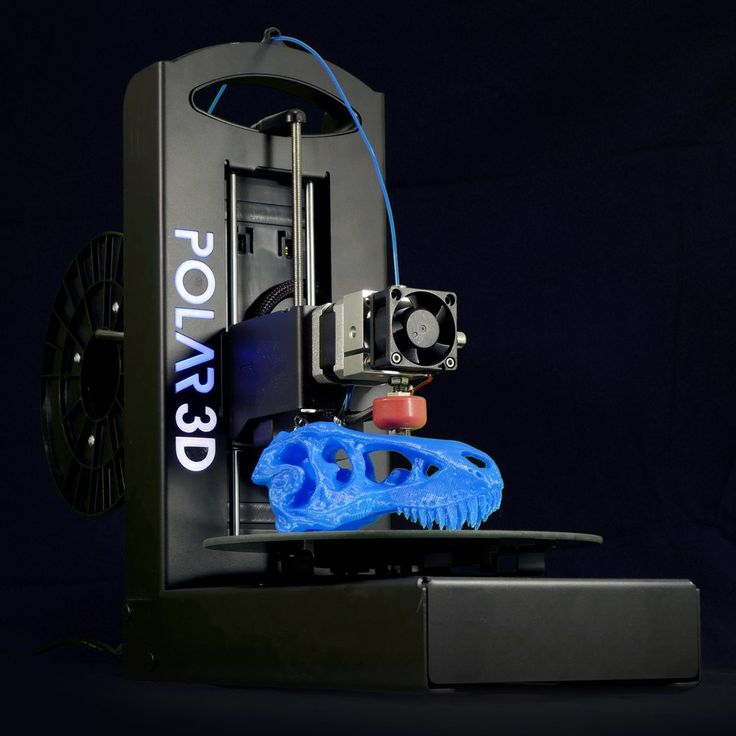

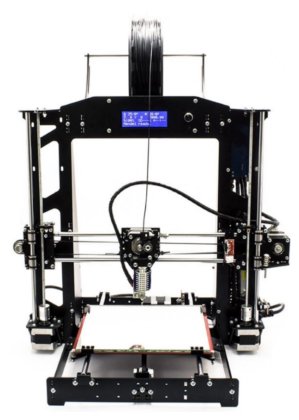

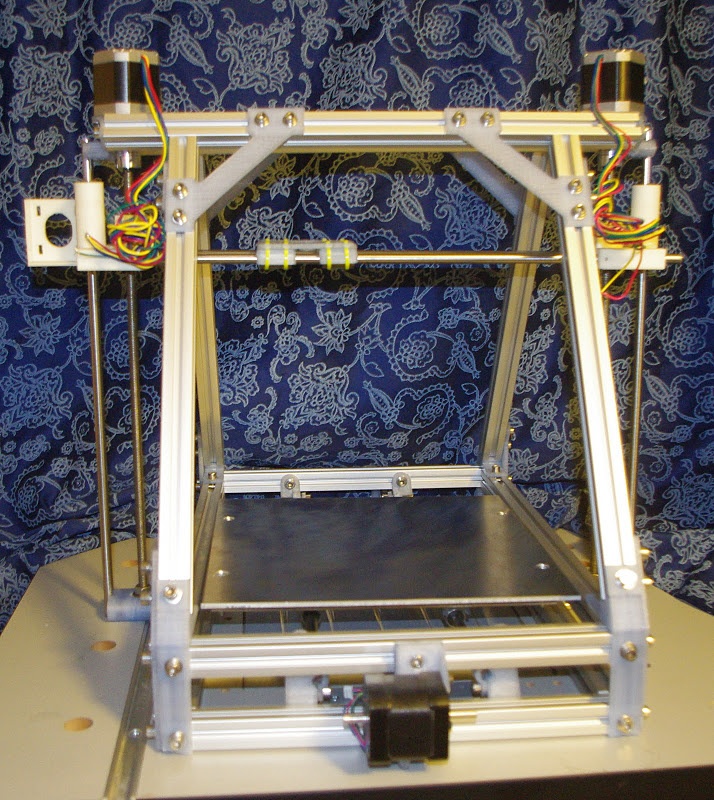

Suppose you’re starting with your first foray into the world of additive manufacturing. In that case, a cheap 3D printer such as a fused deposition modeling (FDM) or fused filament fabrication (FFF) printer is a great place to start.

In that case, a cheap 3D printer such as a fused deposition modeling (FDM) or fused filament fabrication (FFF) printer is a great place to start.

However, these printers are not perfect and do have some drawbacks. Here’s a rundown of some of the pros and cons of 3D printers:

Pros

- Inexpensive: Generally speaking, cheap 3D printers are significantly less expensive than their industrial counterparts. That makes them much more accessible to hobbyists and small businesses who may not budget for a more expensive model.

- Easy to use: Another advantage of these printers is that they are generally straightforward to use. They tend to be less complex than more expensive models and often come with user-friendly software.

- Great for beginners: As mentioned earlier, cheap printers are an excellent option for learning additive manufacturing. They are easy to use and relatively low-cost, so you can learn the basics of printing without making a significant investment.

- Wide variety of printers available at different price points: You can find a cheap printer to suit just about any budget, which is great if you’re working with limited funds.

Cons

- Lower quality prints: One of the most significant disadvantages of cheap printers is that they tend to produce lower quality prints. That is because they often have smaller build volumes and use lower-quality materials.

- Limited print settings: Cheap printers also typically have fewer print settings than more expensive models, which can be a disadvantage if you wish to fine-tune your prints.

- Inferior build quality: Many cheap printers suffer from poor build quality, meaning that they may not be as durable or reliable as more expensive models.

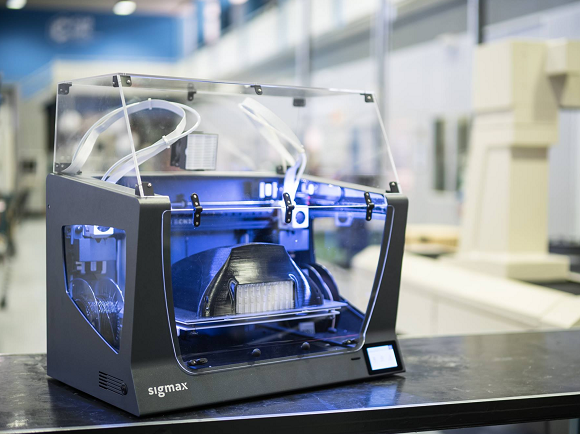

Expensive 3D Printers Pros and Cons

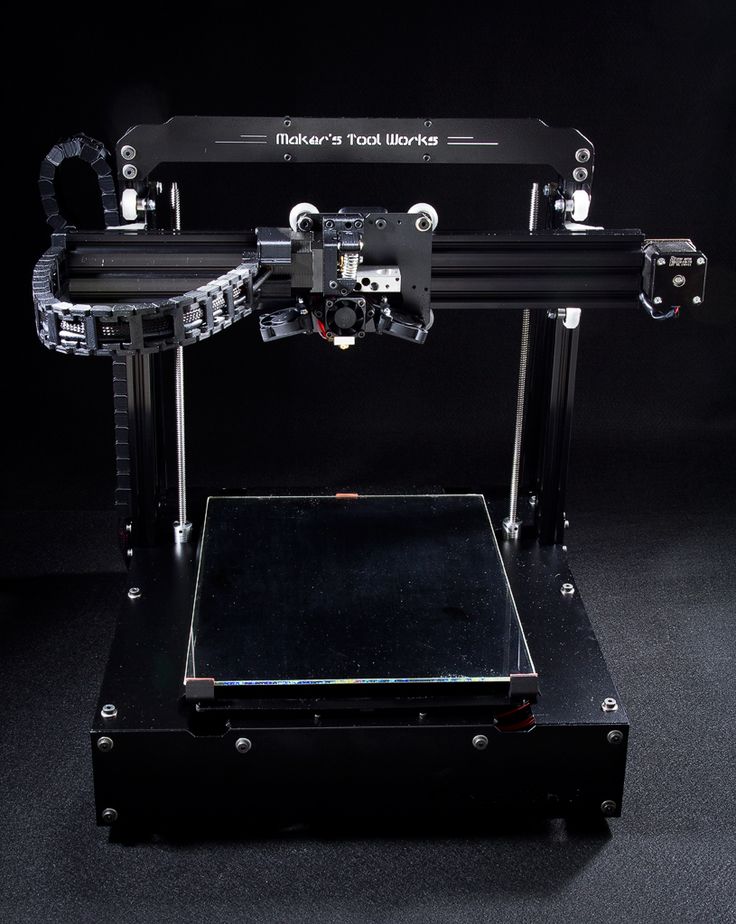

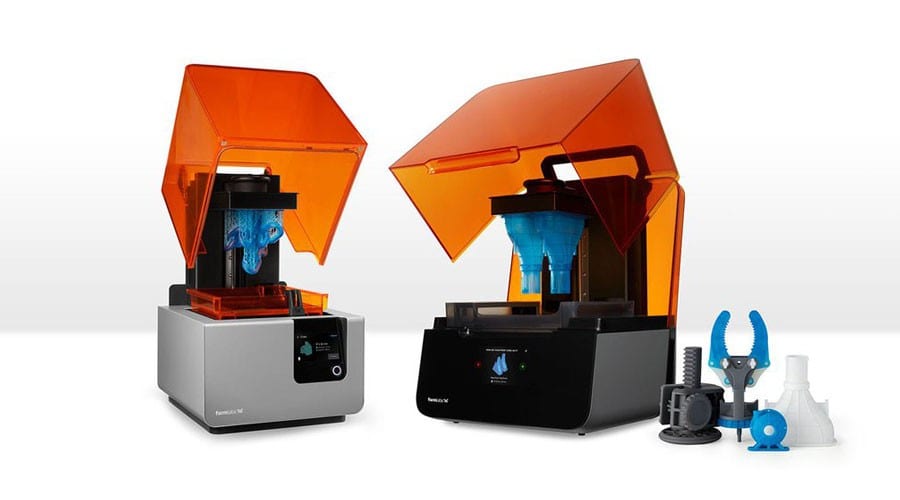

If you’re looking for the best possible print quality and don’t mind spending a bit more money, a costly printer (such as a stereolithography printer) is a good option. However, these printers have some drawbacks that you should be aware of before making your purchase. Let’s look at some of the pros and cons of these printers:

However, these printers have some drawbacks that you should be aware of before making your purchase. Let’s look at some of the pros and cons of these printers:

Pros

- Superior print quality: One of the most significant advantages of expensive printers is that they produce outstanding print quality. That is because they use higher-quality materials.

- More reliable: These printers are generally more reliable than their cheaper counterparts. They often have better build quality and use more durable materials.

- More print settings: Expensive printers also offer a more comprehensive range of print settings, which allows you to fine-tune your prints for the best possible results.

Cons

- High cost: Arguably, the main disadvantage of expensive printers is their high cost. Cost can be a barrier for many people interested in 3D printing.

- Complex to use: These printers tend to be more complicated than cheap models and often require more experience to operate effectively.

- Requires more maintenance: Expensive printers also require more maintenance than affordable models, which can be a hassle.

Head to Head Comparison

In a nutshell, here’s a table summary of how cheap vs. expensive 3D printers stack up against each other based on a few selected factors:

| Cheap 3D Printers | Expensive 3D Printers | |

| Quality | Typically lower | Typically higher |

| Print Size | Typically smaller | Typically larger |

| Accuracy | Typically lower | Typically higher |

| Precision | Typically lower | Typically higher |

| Tolerance | Typically higher | Typically lower |

So, let’s compare the two in more detail:

Quality Comparison

There is a clear relationship between price and quality.

Specifically, expensive printers tend to produce higher-quality prints than their cheaper counterparts.

However, there are some instances where a costly printer may create lower-quality objects. This quality difference can be due to several factors, such as improper maintenance or incorrect settings. Besides, your skill level and experience can also play a role in the quality of your prints.

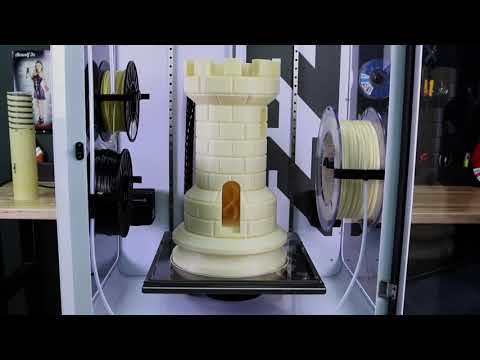

Here’s a typical example of an expensive printer printing better than a cheaper one:

Print Size Comparison

One of the main factors determining how much you can print with a given printer is its build volume. Build volume is the maximum size of the object that the printer can create in a single session.

As you might expect, expensive printers tend to have larger build volumes than cheap printers. That means you can usually print bigger objects with a more costly printer than a cheap one.

However, it’s important to note that build volume is not the only factor determining print size. The type of printer and the material you’re using also play a role in this.

Accuracy Comparison

Accuracy is another critical factor to consider when choosing a 3D printer. Accuracy refers to how close the printer can get to the desired dimensions of your object.

In general, expensive printers are more accurate than cheap ones. That’s because they use higher-quality materials and have better build quality.

However, there are some instances where a cheap printer can be just as accurate as an expensive one. However, these errors are usually due to user errors or incorrect settings.

Precision Comparison

Precision is similar to accuracy, but it refers to the printer’s ability to print fine details. That means that precision determines how small a feature the printer can recreate.

That means that precision determines how small a feature the printer can recreate.

Again, expensive printers tend to be more precise than cheap ones.

However, there are some instances where a cheap printer can be just as exact as an expensive one. Again, this could arise from user error or incorrect settings.

Tolerance Comparison

Tolerance is the final factor to consider when choosing a printer. Tolerance refers to how much the printer will deviate from the intended model. The smaller the tolerance, the more accurate your prints will be.

However, there is a tradeoff between accuracy and speed. Printers with smaller tolerances tend to be slower, as they have to account for a smaller margin of error. That means that if you need your prints quickly, you may have to sacrifice some accuracy.

Cheap Vs. Expensive 3D Printers: Which Is Better?

Now that we’ve compared the pros and cons of cheap and costly printers, it’s time to answer the question: which is better?

A cheap 3D printer should be better for you if you need simple, everyday prints. On the other hand, you’ll need to invest in an expensive printer if you need high-quality, precise 3D printed models.

On the other hand, you’ll need to invest in an expensive printer if you need high-quality, precise 3D printed models.

However, it’s essential to keep in mind that your skill level and experience with additive manufacturing can also play a role in the quality of your prints. So if you’re starting, don’t be afraid to experiment with different cheaper printers first.

That said, here are two printers I’d recommend, depending on your budget:

- Recommended affordable 3D printer: Monoprice Select Mini (from Amazon.com): The Monoprice Select Mini is a superb cheap printer that’s perfect for beginners. Despite the small build volume, it’s easy to use and affordable.

- Recommended expensive printer: Snapmaker 3D Printer (from Amazon.com): The Snapmaker is an excellent choice if you need a high-quality printer. It’s easy to use and comes with a wide range of features, making it perfect for those who need precise prints.

Conclusion

So, in summary:

- Cheap printers are better for simple, everyday 3D printed objects.

- Expensive printers are better for high-quality, detailed models.

- Your skill level and experience will impact your 3D printer choice and the success of your 3D print projects.

- Before buying an expensive printer, it would be best to build your skills and experience by using cheaper printers first.

The most expensive 3D printers in the world

- home

- News AT

- World

- The most expensive 3D printers in the world

Various technologies do not stand still, they are constantly developing. This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

3D printers are unique in terms of the variety of different 3D printing methods, materials used and their applications. You can spend as little as $100 to get a reliable 3D printer to make a huge variety of parts from affordable plastic material. On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

It can be noted that the size of the 3D printer does not determine how expensive the 3D printer will be. Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Some of the most expensive printers are not even for sale. Carbon 3D's 3D printers are available for rent only, which allows them to be used by many users. Others use their 3D printers on a project-by-project basis, such as the Vulcan construction printer from homebuilder Icon 3.

Others use their 3D printers on a project-by-project basis, such as the Vulcan construction printer from homebuilder Icon 3.

Stargate, the world's largest metal 3D printer built by Relativity Space to 3D print rockets, it's not for sale, but if it was, it would definitely be on our list. Many of the most exciting technologies in 3D printing can only be used for custom 3D printing, not for purchase. (Source: Relativity Space)

Let's look at the criteria that affect the cost of a modern industrial 3D printer.

Features 3 D -printers affecting their price:

- The uniqueness of technology when creating

- How automated the processes in 3D printer

- The size of the working chamber

- Functions allowing quality control

- Self -software software

- Numerous controls and adjustments

- Controlled environment inside the working chamber (use of inert gas, possibility of heating/cooling the working platform)

Let's break down these features:

Features that drive up the price of 3D printers include printer technology-specific software, real-time 3D printing control systems, and anything that automates processes that sometimes are performed manually in cheaper systems (layer leveling, subsequent post-processing or powder sieving) or processes that require knowledge of metallurgy or polymers.

Production technology that requires a vacuum chamber in a 3D printer, filling the working chamber with an inert gas, or printers that are certified for use in clean rooms and have these characteristics are significantly reflected in the final price of this equipment.

The materials used in the 3D printing process also have a significant impact on the final cost of a 3D printer. Many 3D printers only work with proprietary materials that have been developed by the manufacturer for that 3D printer. They can be metal powder, special resins filled with carbon fiber particles, and unique polymer powders. At this point in time, it is possible to 3D print anything from pure gold to advanced engineering plastics on 3D printers, even in the harsh environment of space.

There are 3D printers that can 3D print multiple materials in one job, and there are multicolor 3D printers that are also in the higher price segment.

THE MOST EXPENSIVE 3 D -PRINTERS

The 3D printer manufacturers discussed below are reluctant to publish exact prices for their products. This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

E-Plus3D EP-M450H

3D printer EP-M450H LPBF (Source: E-Plus 3D)

E-PLUS3D produces industrial metal 3D printers with a large camer of the building for additive manufacturing for various industries in the country. These 3D printers are used in the aerospace, automotive, electronics, and engineering industries to produce not only large-sized parts such as heavy-duty molds, but also mass-produced parts.

The EP-M450H Metal 3D Printer is the company's largest 3D printer with a build chamber of 456 x 456 x 1080 mm, producing 99.9% density metal parts from a wide range of materials at a speed of 55 cm³ per hour.

XJet Carmel 1400C

Israeli company XJet has developed a unique ceramic 3D printing technology. NanoParticle Jetting (NPJ) technology allows the production of metal and ceramic parts with a high level of detail, smooth surface roughness and geometric accuracy. The high cost of this 3D printer is not only due to the technology itself, patented materials that make this printer a serious investment, but also to the advanced automation of the 3D printer itself, which makes it easy to use.

Carmel 1400C, equipped with one of the largest 1400 cm² work platform in the industry, which allows you to simultaneously produce several ceramic parts.

SLM Solutions NXG Xll 600

Large Metal 3D Printer NXG XII 600 (Source: SLM Solutions) range of printers, but its NXG Xll 600 is what the company says is a revolution in industrial additive manufacturing. The NXG XII 600 was designed for high-volume additive manufacturing and features the industry's first 12 1,000W lasers with a 600x600x600 build chamber. Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

In addition to lasers, the NXG Xll 600 has all the benefits that SLM Solutions customers have been asking for over the years, including automatic start-up, laser focusing, closed powder feed and material screening, and other latest developments.

UpNano NanoOne Bio

The Austrian company UpNano has developed a two-photon 3D printer using hydrogel-based bio-ink, which allows direct printing of 3D structures containing living cells, both at the meso- and microscale. The NanoOne Bio printer is based on the NanoOne line of laser printers capable of creating structures of 12 orders. The new hydrogel is the only commercially available resin that allows live cells to be embedded directly from culture plates into 3D printed structures for biological applications.

UpNano claims that the combination of X Hydrobio INX U200 and NanoOne Bio opens up new possibilities in biomedical research and development, both in industry and academia, allowing pharmaceutical companies and research institutes to create cell models that mimic natural growth conditions in the body person.

Black Buffalo 3D

Black Buffalo's new 1G construction printer (Source: Black Buffalo)

Black Buffalo 3D, an American company based in South Korea, officially unveiled its Nexcon 1G earlier this year, which is a 3D printer for building houses and other large concrete objects. The printer can create a 92.9 square meter structure in less than 20 hours. It uses Black Buffalo's patented cementitious material, the company calls it ink, that can be dyed to a chosen color and is also customizable to 3D print locally according to the temperature, humidity and altitude conditions of the area.

The Nexcon 1G is a modular 3D construction printer that can be extended along the X, Y and Z axes to scale up (or down) a project up to three stories high. The 1G printer is unique in that users can reposition the base rails and move the printer to a new printable area without having to remove the X or Z axis.

Optomec LENS 860

Energy Deposition (DED), which allows the recovery of large titanium components, such as those used in aircraft engines. Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

The LENS 860 machining systems are ideal for the fabrication, repair or coating of medium to large metal parts.

ExOne S-Max Pro

While many ExOne printers (now owned by Desktop Metal), they are still very affordable given that high volume 3D printers can cost quite a few zeros.

3D printers are used to 3D print complex and detailed sand molds and cores for foundries producing large metal parts for industrial use. The S-Max Pro features a 1,260 liter build chamber for fast 3D printing of sand molds and cores. A new automated print head enables fast 3D printing, while improved sand compaction ensures the density and strength of complex sand mold designs. As the most advanced system in the ExOne family of sand 3D printers, the S-Max Pro is focused on continuous 24/7 production and offers Industry 4.0 integration with cloud connectivity and real-time machine monitoring.

In conclusion, I would like to know the opinion of Russian industrialists and users of industrial 3D printers: Is it possible to integrate these 3D printers into the Russian industry? Do Russian developers of this equipment need to produce the same expensive 3D printers in Russia?

Share article:

top 10 rating according to the KP version

A 3D printer opens up incredible opportunities for a person. The first prototype of such a device was born in the distant 1984 year. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top 10 rating according to KP

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ru Our rating opens with a model from the world's largest manufacturer of 3D printers. Ender 3 features include an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

Pros and cons

Possibility of using different types of plastic, high quality of parts, reliable design

A small display that displays only basic information

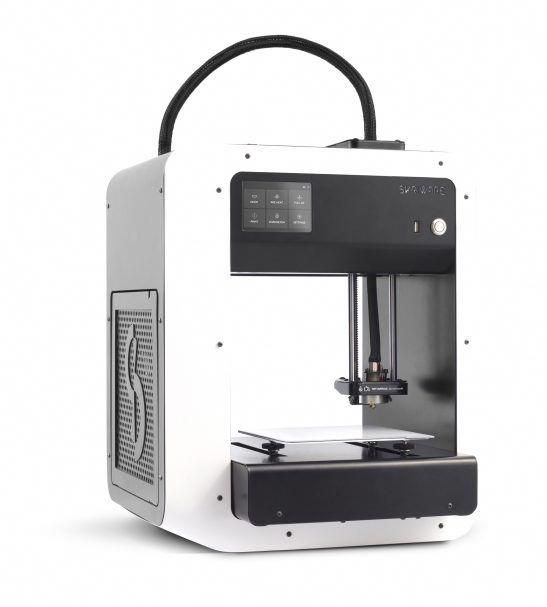

2. FlashForge Adventurer 3

FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3. FlyingBear Ghost 5

FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. Pros and cons Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ru The budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Applications | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing rate

Small work surface, slightly inferior to competitors in some parameters

900bic8 Anycubic8 5. Photon Scu0bic8 Anycubic8 5. S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Duplicator Mini i3. Photo: market-yandex.ru Miniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

PLASS AND MINSS

Good price

LOW THE WORKS and Protection of the Working Service, High probability of problems with a working reel

.

Artillery Genius. Photo: market-yandex.ruThe base of the device consists of an aluminum case, in which all the electronics are hidden. An aluminum portal is also attached to it. The latter is also a guide for the moving parts of the printer. At the top of the portal is a plastic jumper to which the spool holder and filament sensor are attached. As for the control screen, its functionality is seriously curtailed. However, it is sufficient for simple tasks, but it is impossible to configure the printer.

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ruThis model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

FDM Method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software).