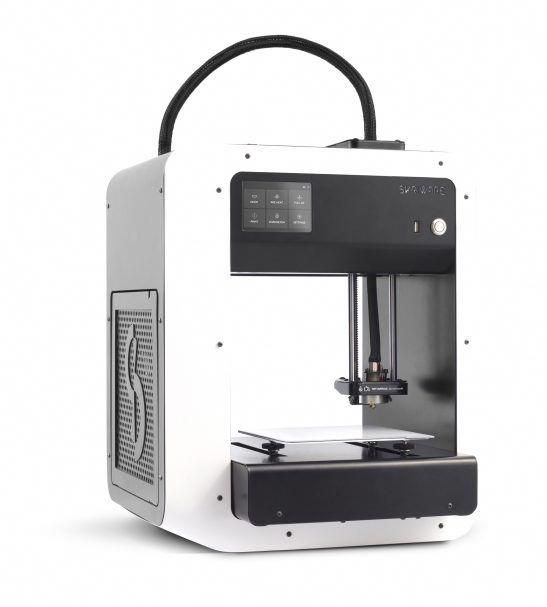

Airwolf 3d printer review

Airwolf HD 3D Printer Review 2022

4

See Price

Let’s say that you’re looking for a real workhorse 3D printer. You need something big enough to print large models without having to manually assemble it from parts, but you also want it to print quickly. Well, you’re in luck: we’ve actually found a 3D printer that claims to do both.

Enter the Airwolf HD printer. This is a high-end product with a price tag to match, but it may be just what your business needs. We’ll be taking a look at its strengths and weaknesses to help you decide if it’s a good choice, and more importantly, if it’s really as impressive as it seems.

| Filament Diameter | 3mm |

| Extruders | 1, optional 2nd |

| Supported Materials | ABS, PLA, Nylon, Wood, Stone, 11 others |

| Connectivity | USB, SD card |

| Printing Speed | Up to 400mm/s |

| Build Volume | 12 x 8 x 12” |

Table of ContentsShow

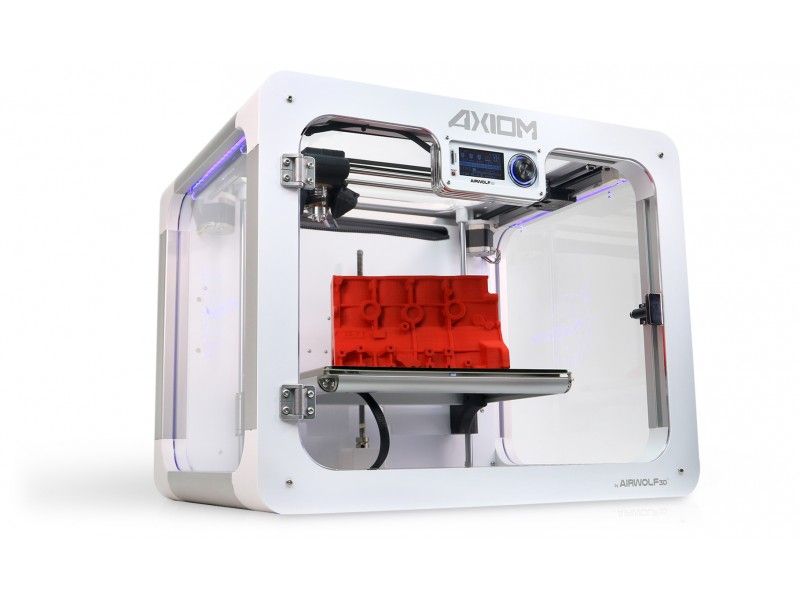

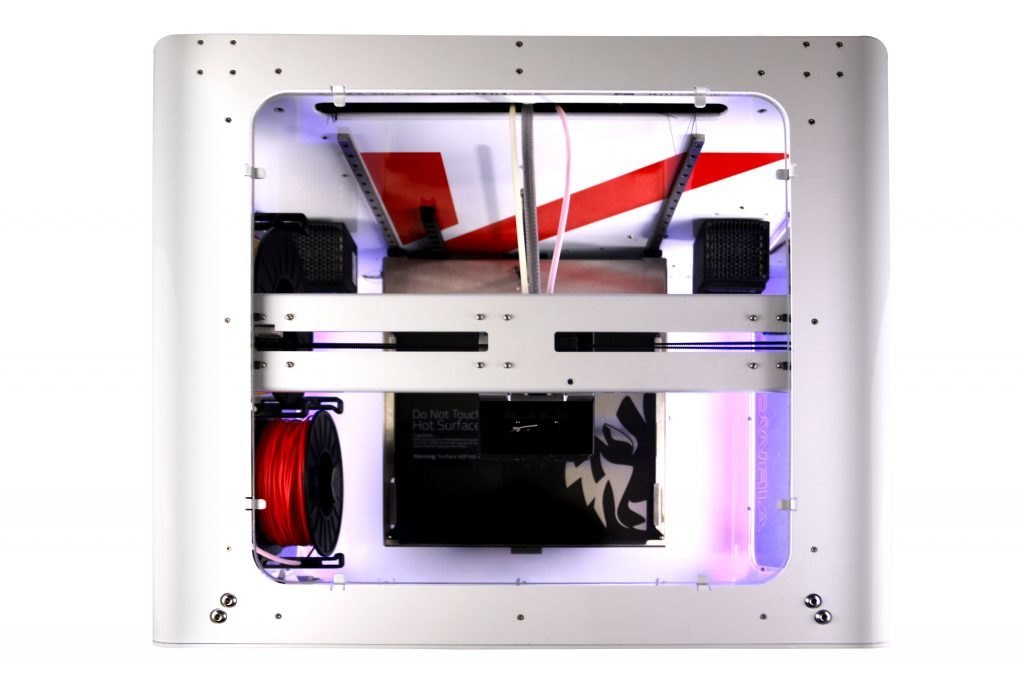

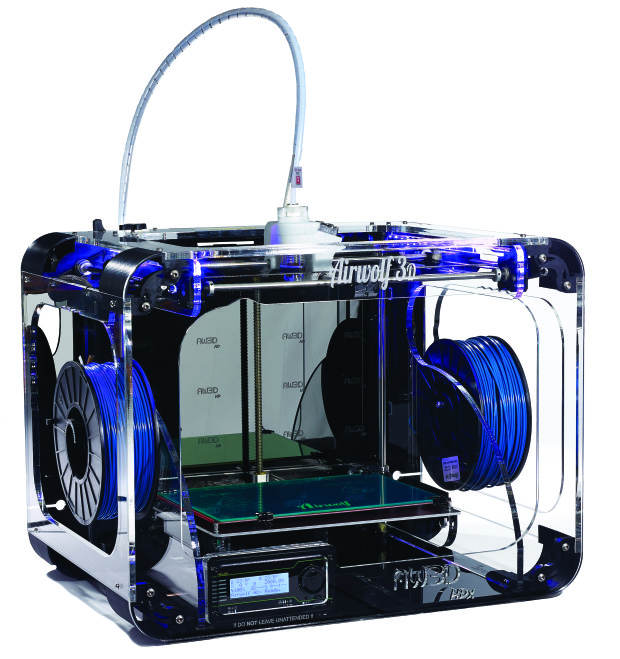

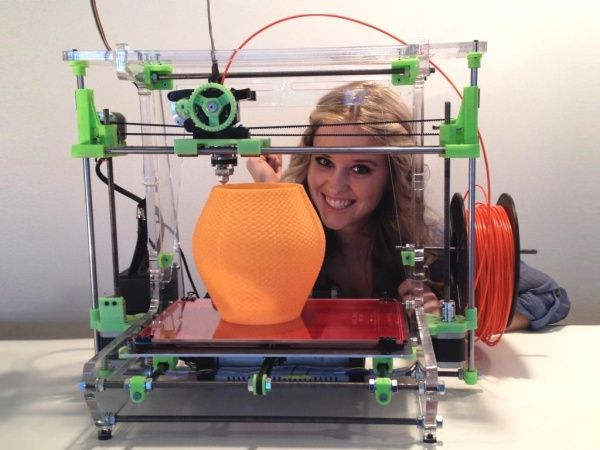

Design

Well, it definitely looks professional. The Airwolf HD 3D printer is futuristic, with a fully transparent outer casing. This is 6mm thick acrylic, however, with adds a considerable heft. Considering that this product already takes up more space than most of its rivals, you’re definitely going to require a dedicated printing area.

You’ll notice the dual filament reels, one on either side. However, these both feed into the same extruder, and cannot be used to print with multiple materials simultaneously. A second extruder kit is accessible, but predictably, costs more money. The Airwolf HD is faster than most anyway, so there’s really no need.

We’re always pleased to see a printer with an onboard controller, but the lack of WiFi connectivity is a surprise, particularly given this printer’s price point. Still, it’s clear Airwolf put a lot of thought into this printer’s design: it’s sturdy, created with high-quality components, and seems built to last.

Printing

With most premium 3D printers hovering around the 200mm/s mark, the Airwolf HD stands well ahead of the pack. It can print at a blistering 400mm per second, but understandably, this has a pronounced effect on the quality of your prints. Generally, you’ll want to stick to lower speeds for any model where appearance is important.

It can print at a blistering 400mm per second, but understandably, this has a pronounced effect on the quality of your prints. Generally, you’ll want to stick to lower speeds for any model where appearance is important.

Don’t get the wrong idea: even at high speeds, the Airwolf HD creates passable models. However, they’ll usually require some post-processing to really make them look good. The main issues are layer definition and edges: both pose significant problems for any high-speed FFF printer, so the HD is far from alone in this.

At the very least, this printer supports a wide range of materials. All the usual suspects (ABS, PLA, Nylon, are accounted for, but you’re also able to print with wood, stone, and bronze-based filaments, among others. This greatly increases the versatility of the printer.

Features

Rather than show off flashy but ultimately rarely-used features, most of this product’s advanced functionality could easily pass undiscovered. Take the heated bed, for instance: it’s rarely remarked upon in premium models because it’s taken for granted so often. Still, in this case, it helps ensure your prints aren’t warped before they even really get started.

Still, in this case, it helps ensure your prints aren’t warped before they even really get started.

There’s also a special anti-jam nozzle, and you can even swap it out for a higher resolution one if you’d like. This is temperature-controlled too, so there’s no need to worry about accidentally ruining your print or filament. When combined with the fully-enclosed design, this ensures you’ll waste as little material as possible.

There are a couple of other features. You can slice models directly from the printer using the small LCD screen, but that’s not all. With a minimum layer thickness of 0.6mm, if you go slowly, there’s no reason why you shouldn’t be able to build some truly magnificent and detailed models.

Price

The price really is the Airwolf HD’s biggest stumbling block. This printer was initially released in 2014, but it still holds quite a significant price tag. Currently, this product retails for around $3000, so it’s all but inaccessible to hobbyists, small companies, startups, or anyone other than medium-to-large businesses.

There is one silver lining, though: with the Airwolf HD, you don’t have to use a proprietary filament. In fact, since so many materials are supported, you’re free to use almost any 3mm filament you’d like. This (and the printer’s anti-waste temperature control) helps keep waste down, which keeps profits up.

The big question is whether you can justify this high initial fee for the promise of lower running costs later. Again, this comes down to whether or not you really need this level of speed or this high a build volume. If so, go for it, but if not, there may be something reasonably priced that will meet your needs.

Support

The Airwolf support page provides tutorials and walkthroughs for some of the most common tasks. Best of all, specific guides are available for every printer the company has ever made. If your problem isn’t addressed here, you can also submit a support ticket (and check your ticket’s progress) on the same page.

So what other support is available? Well, there’s a one-year warranty which guarantees a replacement free-of-charge if have any defective parts. There’s a nasty sting in the tail, though: even if it wasn’t your fault, you have to pay for shipping to and from the repair center. Remember: this printer weighs 40lbs.

There’s a nasty sting in the tail, though: even if it wasn’t your fault, you have to pay for shipping to and from the repair center. Remember: this printer weighs 40lbs.

This is flat out unreasonable. Sure, if the printer cost a few hundred dollars, perhaps it would be justified, but we’re talking about a high-end model here. The expectation seems to be that since businesses buy these products, they’ll pay in order to get their workflow back on track as soon as possible.

3D Printer Reviews, Feedback and Customer Testimonials for Airwolf 3D

You can definitely use me as a business reference. The EVO 3D printer is the best tool I have with only the Ultimaker 2+ at a distant second.

Nate / Cable Save

Your technical support staff is the best I have ever worked with. The support is phenomenal.

Eddie M. / Sun Valley High School

You took the team further and faster than anyone could have done. Thanks to you and Eric for not only making a great product, but supporting it in a way no other provider could.

Thanks to you and Eric for not only making a great product, but supporting it in a way no other provider could.

Derek K. / AEP

Airwolf is awesome. I bought a printer from them a really long time ago and I have always received great service. I had an issue once and they got my machine dialed in and working like new again and upgraded some parts for me for cheap. I think they genuinely really care about their customers…More

Dillon C. / Orange County, CA

The Axiom Dual Extruder 3D printer is perfect for our needs. Whenever I contact anyone at Airwolf it is a pleasure. They are knowledgeable and friendly. They get the job done and it feels like they even wanted to do it. It is good to find a company that likes…more

Jonathan J. / Linden, TX

Purchased an Axiome Direct Drive unit and was Very Pleased with the simple but Extremely strong structure and robust printer head, I recently upgraded the unit to a heated bed model and purchased all the upgrade parts from Airwolf, they were very inexpensive…More

Greg M. / Santa Clarita, CA

/ Santa Clarita, CA

I have had a good experience with the Airwolf 3D printer. I purchased an Axiom and have upgraded to the dual. Real good quality of print—and that is at a lower setting. Many materials. Modular construction for upgradeability…More

Gogoosh F. / Carlsbad, CA

Awesome sales and support as usual. Had an issue with heat cartridge and support took care of it immediately. Issued a technical ticket beforehand and Blake in support was able to diagnose the issue 100% before arriving at the shop. I drive all the way up from Carlsbad…More

Matthew Y. / Carlsbad, CA

We use their dual direct drive at our school. The students love being able to 3D print. Fairly easy to use once you get the hang of it!

AirWolf is helpful when things go awry.

Kristi K. / Newport Beach, CA

Great experience. Very helpful. Cool printer rental program too! Great help with tech questions. Everyone is always so polite as well.

Very helpful. Cool printer rental program too! Great help with tech questions. Everyone is always so polite as well.

Matthew I. / Huntington Beach, CA

Awesome products! Great customer service! They did a full training tutorial for my company and were very helpful with all of our questions! Looking forward To seeing the new EVO metal 3D printer coming out hopefully soon!

Alex R. / Trabuco Canyon, CA

Best 3d printers! Reliable and consistent prints.We’ve used hdx and axiom.They print in many filaments and print fast.

Angela K. / Los Angeles, CA

Being responsible for spending the precious little money my school district has for my budget, it was important for me to purchase 3D printers that would meet our needs. Equally as important was the customer service that comes after the sale…More

John Horton / Education

I have been using an Airwolf 3d printer for 6 years now. We purchased the first one from them because we were happy that they were made in the USA. Also, the were local to us. We have the 7th one that…More

We purchased the first one from them because we were happy that they were made in the USA. Also, the were local to us. We have the 7th one that…More

Sue Pantoja / Orange County, CA

We’ve been using Axioms since they first came out in 2015, and they have always been our go-to machine for challenging jobs. We recently upgraded to Axiom Dual Direct Drive and we couldn’t be happier. They offer reliable and repeatable…More

Jesse Jackson / University of California, Irvine

We’ve been with Airwolf from the beginning.They truly value their partnerships with education.If something goes wrong, they are quick to address it. Great products and people all the way around. Our MIT project this past summer…More

Ed Hernandez / Tustin High School

I bought the Axiom Dual direct drive printer in Feb 2018. Within a week, it was on my doorstep. In that time, I have printed non-stop on it without problems. Thats not saying the printer is without limitations. I have been using the APEX…More

In that time, I have printed non-stop on it without problems. Thats not saying the printer is without limitations. I have been using the APEX…More

Robert Goodnight

I’ve used two different Airwolf 3D printers – an XL and an AXIOMe – for several years now.Very reliable and accurate machines.I’m literally using either one or the other almost every day with student projects or making edge-lit LED…More

Mark Bush / Century High School

We recently added a few EVOs to the lab and they are, by far, the best value in the range of the entry level professionaldesktop fused filament deposition based 3D printers available on the US market today. Airwolf 3D not…More

Mickey Micic / Cerritos College

They have been immensely helpful in a myriad of ways from instruction to equipment donations and everything in between. We could not be where we are today without their help and as we continue our endeavors we will always appreciate…More

William Amos / Closed Loop Plastics

Great product, supportive team, and an easy-to-use interface!

John Stevens / Educator

Students in my Gateway to Technology class have been inspired by being able to print their designs with the AirWolf! We have been printing custom hall passes for the teachers and many other projects. Currently the ASB director broke…More

Currently the ASB director broke…More

Joeseph Ismay / Educator

They provide great service. Technicians are knowledgeable and friendly. Quick turnaround whenever I take my machine in for service.

Tinh Tran

Amazing company. Wonderful staff and printers. Reliable printers mine has been running since I purchased it.

Jeffrey Derouso

I have used Multiple 3D machines and I am very happy with my recent purchase of the Airwolf Axiom, The auto leveling bed and self cleaning brushes really make life simple.

Kyle Mooney

I am a teacher in Southern Cali.I received an AW3D HDL for my class.I absolutely love it & have received the very best customer service when questions about use arise.Best company ever!

RoseZetta Cummings / Educator

The best quality 3D printers, very friendly staff and the best service.

Arturo Alvarez

View All Google Reviews

Please Share Your Thoughts

If we are getting it right, let us know! If your experience was less than stellar, we need to know that right away. Your private message will go straight to one of the co-founders within 24 hours. We would love to hear from you.

What is the most durable material for 3D printing?

3DPrintStory 3D printing process What is the most durable material for 3D printing?

While the 3D printing process seems like a great alternative to traditional manufacturing methods, the parts produced can be fragile and unusable. As a rule, this is the result of using standard materials that are not designed for strength and durability. But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

In this article, we'll take a look at the three most durable types of 3D printing materials. However, before that, we will take a closer look at what strength means in terms of filament materials.

What is strength and how do we evaluate it?

The strength of a material can be measured and evaluated in different ways. In this article, we will mainly use tensile strength (stress before something breaks). We will list the tensile strength of each 3D printing material in pounds or pounds per square inch (PSI).

Despite the obvious number of pounds the material can support, there is still a margin of error depending on how the part was printed. We've compiled research from a variety of sources to make sure these three materials are the strongest.

You must also understand that the material itself is not the only factor that affects the strength of the finished product. The design itself, post-processing and the 3D printing process also affect the strength of the part.

The design itself, post-processing and the 3D printing process also affect the strength of the part.

Polycarbonate

Polycarbonate (PC) is considered by many manufacturers and reviewers to be the strongest 3D printing filament available. In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

Some Numbers

Airwolf 3D has come to the conclusion after many filament tests that polycarbonate is the best choice of durable filaments for desktop 3D printers. They were able to hang up to 685 pounds on a polycarbonate printed hook and found that this material had a tensile strength of 9800 psi. In contrast, the same part printed in PLA could only support 285 pounds.

Using a similar test, MatterHackers studied the tear strength of this type of thread, as well as a number of other materials. They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

Finally, renowned 3D printing YouTuber Thomas Sunladerer reviewed several polycarbonate materials and gave very positive feedback on the strength of the material.

3D printing with polycarbonate

It is worth noting that the quality of 3D printing with polycarbonate is not very good. Compared to other materials, protrusions and small details may not turn out as well as using the same PLA.

According to Rigid.Ink, polycarbonate is mostly sold in clear. This 3D printing material has excellent heat resistance as well as impact resistance. But note that you will have to print at high temperatures. As mentioned above, it is better to use an enclosed 3D printer and a solid metal hotend.

Pros of polycarbonate : extra strong, excellent thermal and impact resistance.

Cons of polycarbonate : does not cope well with protrusions and small details of a 3D model, requires a body and an all-metal hot end, a limited number of colors.

Nylon

Next on our list of durable 3D printing materials is nylon. This material is considered by many to be the most reliable for desktop 3D printers. Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Some numbers

A hook printed with nylon (910) thread had a breaking strength of 7,000 psi, while the same ABS hook only had a tenacity of 4,700 psi, according to Airwolf 3D. Airwolf 3D also noted that the nylon-filament-printed clip holds 485 pounds.

MatterHackers posted similar results and noticed that a hook printed with their NylonX material can hold an average of 364 pounds before it breaks. Rigid.Ink also reviewed some nylon threads and gave them a four out of five rating for strength and a five for durability. For comparison: the strength and durability of PLA is three conventional units.

Nylon 3D printing

Nylon is slightly easier to print than polycarbonate, but it's still not PLA. Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon pros: impact resistance, fatigue resistance, heat resistance, easier to print than polycarbonate.

Nylon 9 cons0042 : hygroscopic, warping, very high hot end temperature required.

Composites

Finally, composite threads, although not essentially one material, can be extremely strong. Composites are threads with certain additives that affect the properties of the material, including to increase strength. The names of these threads usually have the words "pro", "reinforced" (reinforced) or "infused" (infused), since they are usually a mixture of different materials.

For this reason, it is impossible to assess where the composite fibers are compared to the two previous materials. Some composites, such as Carbonyte, can compete with nylon threads for strength, while some composites are less durable.

It all depends on what the composite thread consists of. Durable is usually a high strength material such as nylon impregnated with another high strength material such as carbon fiber or glass.

Speaking of carbon fiber, this is also a very strong filament that is sometimes used for 3D printed bicycles. However, some composite fibers are stronger than many pure carbon fibers, so they are not in the top three, but deserve special mention as composite fibers.

Some numbers

We will use carbon fiber nylon and glass fiber nylon threads as examples. MatterHackers has determined that hooks printed on these materials can hold an average of 349and 268 pounds respectively.

Rigid.Ink gave the fiberglass nylon filament four out of five ratings for strength and five for durability. They also gave the carbon fiber nylon a five out of five rating for both strength and durability. In comparison, PLA and ABS were in the top three for strength.

3D printing with composites

Composites vary in the way they are 3D printed, but they are generally relatively similar to their base material. Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Advantages of composites : This is a combination of several materials to achieve the best possible properties, durable.

Cons of composites: Expensive, requires high 3D printing temperatures.

From affordable to industrial: A roundup of the best 3D printers of 2018

If ten years ago the word "print" was applicable only to text, now innovative technologies have made it possible to print full-fledged shoes, sweets and entire houses.

3D printing is actively used in the aerospace, aviation and automotive industries, where 3D printers can quickly create prototypes for field testing, as well as accelerate the production of various parts.

The 3D technology industry has seen a significant evolution in recent times and we've rounded up the new 2018 printers for you, ranging from industrial printers to affordable machines that even kids can use.

Best 3D Printer 2018

According to specialist publication All3DP, the Ultimaker 3 is the undisputed leader in 3D printing. It is designed for professional designers and small businesses that need a machine with exceptional build quality and reliability.

The Ultimaker 3 uses layer-by-layer filament fusing technology that can work with virtually any material and produce high quality parts.

In addition, the device is optimized to create a whole farm of such 3D printers. Cura Connect makes it easy to set up a network of multiple Ultimaker 3.

Best Industrial 3D Printer

Airwolf 3D's EVO Additive Manufacturing Center was unveiled at CES 2019 in Las Vegas. EVO AMC is a fifth generation product of 3D printers, which is positioned as a full-fledged center for additive manufacturing. Thus, a 3D printer allows you to "grow" products according to CAD models of computer-aided design systems, which facilitates the manufacture of complex geometric parts.

EVO AMC uses high temperature printing based on Tri-Heat technology. This allows precise temperature control to produce stronger parts. At the same time, the printer supports the use of more than 40 different materials, ranging from water-soluble Hydrofill to metal.

In addition to the large build chamber, the 3D printer is equipped with print security systems. For example, thanks to PartSave technology, in the event of a power outage, the unit will continue printing immediately after power is supplied. Also, if the printer runs out of media or a filament jam occurs, special FailSafe technology ensures that the unit continues to work exactly where the print was interrupted.

Best SLA 3D Printer

Stereolithography - SLA printing - a technology that uses a liquid photopolymer, which under the influence of ultraviolet light becomes solid. Most often, SLA 3D printers are used in dentistry and jewelry.

The best printer in this category is the Formlabs Form 2. In addition to being supported by $3M on Kickstarter, this SLA 3D printer's main selling point is its ease of use.

In addition to being supported by $3M on Kickstarter, this SLA 3D printer's main selling point is its ease of use.

The Formlabs Form 2 is a wireless 3D printer that connects to a computer using Wi-Fi and also has a touch screen. In addition, the unit is equipped with an automated resin filling system and a special heated tank. The only drawback is that after printing, some objects require additional polishing.

Best 3D printer for beginners

If you have been afraid to start 3D printing because of the rumors about the toxicity of materials, you can safely choose the Tiertime UP mini 2. The fact is that it is equipped with a built-in air filter that provides maintaining a safe and healthy work environment. In addition, the unit is equipped with a touch screen and Wi-Fi connectivity. But what really makes this 3D printer stand out is its special safety features that protect the mechanism from power failures, ensuring that printing continues even after a sudden interruption.