3D printed titanium strength

New titanium alloy has highest specific strength of any 3D-printed metal

Materials

View 1 Image

Engineers at Monash University have developed a new 3D-printable titanium alloy with a unique microstructure that makes it ultra-strong. Not only is it stronger than most other forms of titanium, but it has the highest strength-to-weight ratio of any 3D-printed metal ever made.

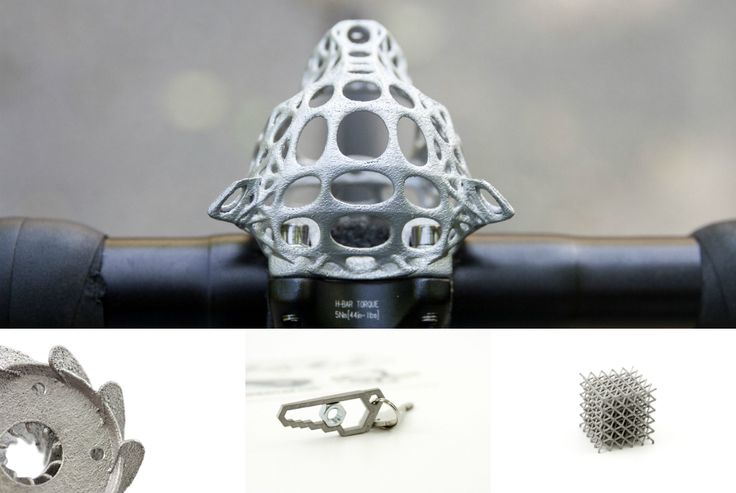

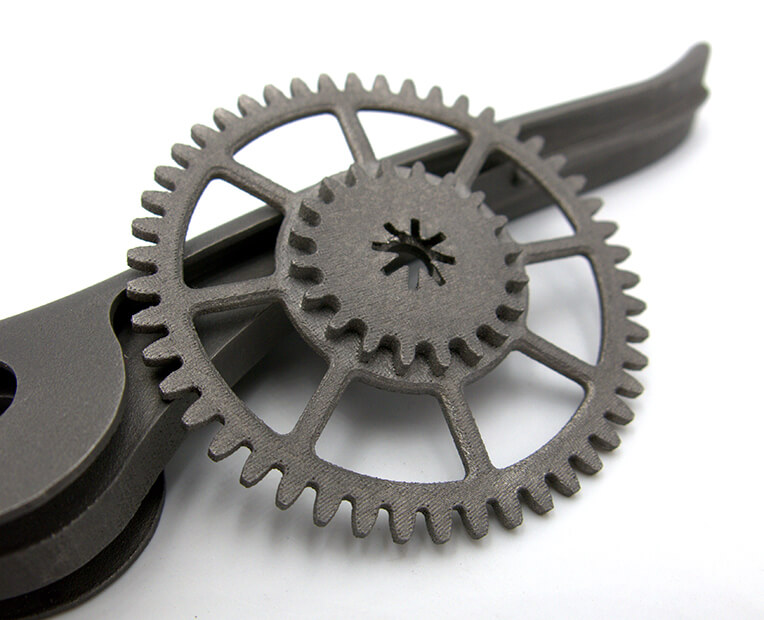

Titanium alloys are already prized in industry thanks to their strength and relatively light weight, which makes them perfect for aircraft and other vehicles. But there’s always room for improvement, and the new Monash alloy not only boasts greater strength, but because it’s 3D printed, it’s much easier to make into whatever shape is needed.

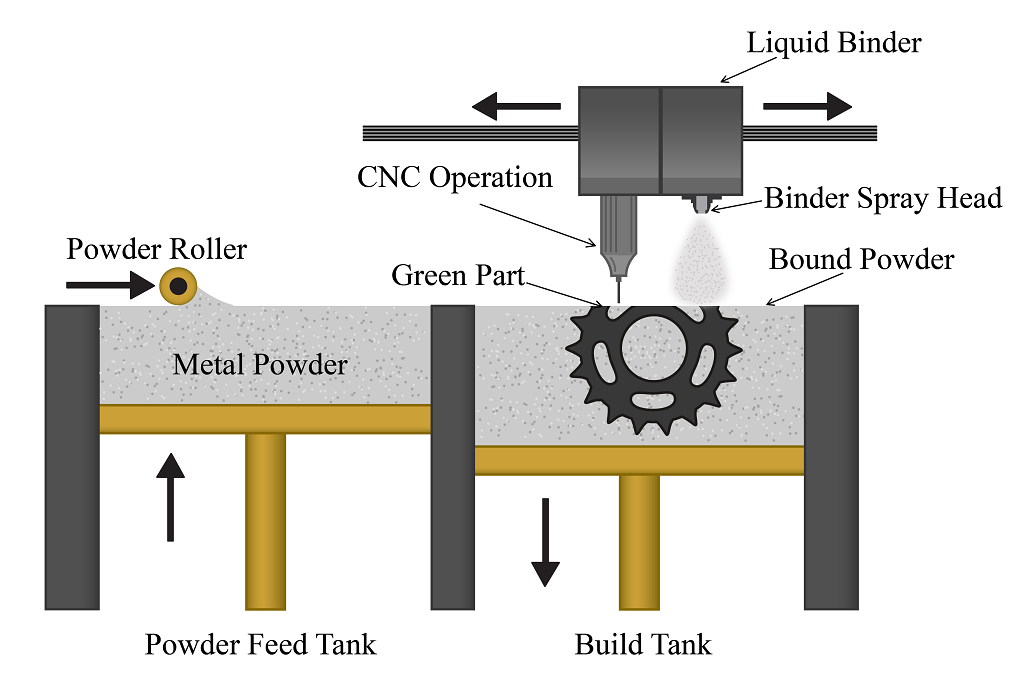

The team starts with a common 3D printing technique where a bed of powdered metal is melted by a laser, fusing it into a solid layer by layer. In this case, that powdered metal is the commonly used beta-titanium alloy. Next, the material undergoes heat treatment at temperatures between 480 and 520 °C (896 and 968 °F), which produces a microstructure that gives the alloy its incredible strength.

The treatment process causes particles of titanium to precipitate together in nanograins, which merge in “nanotwin” structures that each share a common side. The team says this is the first titanium alloy to exhibit this kind of structure, and it makes it much stronger than usual.

In tests, the team demonstrated that the new titanium alloy had both elongation and tensile strengths (stretching and tension, respectively) of over 1,600 MPa. For reference, most commercial titanium alloys top out at around 1,000 MPa. This is also the highest specific strength for any other 3D-printed metal alloy, the team says.

“Our findings offer a completely new approach to precipitation strengthening in commercial alloys that can be utilized to produce real components with complex shape for load-bearing application,” said Professor Aijun Huang, lead researcher on the study. “This application is still absent for any titanium alloys to date. The 3D printing plus simple heat treatment also means the process cost is greatly reduced compared to other materials with similar strength.”

The research was published in the journal Nature Materials.

Source: Monash University

Michael Irving

Michael has always been fascinated by space, technology, dinosaurs, and the weirder mysteries of the universe. With a Bachelor of Arts in Professional Writing and several years experience under his belt, he joined New Atlas as a staff writer in 2016.

3D Printing Progress by IDTechEx

3D Printing Progress

Oct 21, 2022

The Attempt to Achieve Standardization within the Graphene Industry

The true description of graphene is that of a single atomic layer of carbon atoms arranged in a hexagonal array. However, the nanocarbon material landscape is much more complicated than this simple statement, with single-layer, few-layer, multi-layer, graphene nanoplatelets (GNPs) and both graphene oxide (GO) and reduced graphene oxide (rGO) all to be considered as types of graphene.

However, the nanocarbon material landscape is much more complicated than this simple statement, with single-layer, few-layer, multi-layer, graphene nanoplatelets (GNPs) and both graphene oxide (GO) and reduced graphene oxide (rGO) all to be considered as types of graphene.

3D Printing Progress

Oct 20, 2022

IDTechEx Discuss Additive Manufacturing: So Much More Than the Printer

With so much focus being put on 3D printers, it can be easy to lose sight of the many other important sectors that make 3D printing, especially industrial additive manufacturing, possible. It takes an entire ecosystem, including materials, software, post-processing, quality assurance, services, specialized training, and more, for 3D printing to be utilized in high-value industries and applications

3D Printing Progress

Oct 5, 2022

Is Graphene Green?

Is Graphene Green? This question comes up an increasing amount. Green drivers and ESG investments are an obvious focus across the supply chain, but where does graphene fit into this discussion? IDTechEx explore the answer in this article.

Green drivers and ESG investments are an obvious focus across the supply chain, but where does graphene fit into this discussion? IDTechEx explore the answer in this article.

3D Printing Progress

Sep 8, 2022

3D Printing Webinar - Successes to Celebrate, Challenges to Tackle

Thursday 22 September 2022 - This webinar will discuss the sectors that 3D printing is currently having success in; analyze the barriers limiting additive manufacturing adoption in other industries; highlight the applications where 3D printing has high growth potential; and present IDTechEx's outlook for the AM market

3D Printing Progress

Sep 1, 2022

Webinar - The Graphene Market: What Will the Killer Application(s) Be?

Thursday 15 September 2022 - Overview of the broad graphene material family and different manufacturing processes; Graphene market status and outlook; Comparison to incumbent conductive carbon additives; A deep dive into 8 significant application areas with examples, pain points, and market outlook; and much more!

3D Printing Progress

Aug 2, 2022

The Dichotomy Influencing the 3D Printing Materials Market

Open vs closed materials systems: In this article, IDTechEx Technology Analyst Sona Dadhania discusses how the dichotomy between "open" materials systems and "closed" materials systems (also known as platforms or architectures) affects the growth and utilization of materials for additive manufacturing.

3D Printing Progress

Jul 5, 2022

Upcoming Webinar Discussing the 3D Printing Materials Market

Thursday 21 July 2022 - Exploring the Dynamics of the $29.5 Billion 3D Printing Materials Market. Benchmarking relevant materials/players; identifying growth drivers and trends to watch for different classes of AM materials; examining key market activity; IDTechEx's market outlook for the industry

3D Printing Progress

Jun 20, 2022

3D Printing Materials: A $29.5 Billion Opportunity Ripe for Innovation

The growth potential for AM materials differs from printing equipment, as operational legacy printers continue to consume materials. Therefore, this segment of the 3D printing value chain represents a tremendous opportunity.

3D Printing Progress

May 31, 2022

Still Waiting on a Commercial Need for Take-off: SWCNTs

Commercializing a new material is not easy. Single-walled carbon nanotubes (SWCNTs) are the higher-performance variants of the carbon nanotube family, but unlike their multi-walled counterpart, they are still hunting for their killer application.

Single-walled carbon nanotubes (SWCNTs) are the higher-performance variants of the carbon nanotube family, but unlike their multi-walled counterpart, they are still hunting for their killer application.

3D Printing Progress

May 3, 2022

Metal Additive Manufacturing: Don't Tell Me, Show Me

Since 3D Systems commercialized stereolithography 30 years ago, 3D printer manufacturers who invented their own proprietary technology predominantly followed the same business strategy: selling their printers to customers. Until recently, it was the norm for established and rising 3D printing players, both in metal and polymer additive manufacturing, to follow the same path.

production features and examples of parts

3D basics

Aerospace industry

Automotive industry

Medicine

Experts recommend

Author: Victor Naumov

Author: 0 Victor Naumov 90

Classification and groups of titanium alloys | Application of Ti6Al4V in additive manufacturing | Bugatti optimizes Bolide hypercar with bionic design and titanium 3D printing | Bracket for aircraft has become one third lighter | Thanks to the titanium prosthesis, the patient was able to return to normal life

Among the materials used in metal 3D printing, titanium and its alloys, especially Ti6Al4V, occupy a special place. Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Without going into details, the process is as follows. First, titanium tetrachloride (TiCl4) is obtained by chlorination in the presence of carbon monoxide at 1000 °C. After that, using magnesium or sodium, carbon monoxide is removed in an inert atmosphere at 800–850 °C. The result is pure titanium. Absolutely pure titanium is difficult to obtain due to its high reactivity, therefore samples with a purity of 9 are accepted on the market for it.9.9%. For this reason, titanium is mainly used in the form of an alloy with other elements.

Read more about additive manufacturing projects for Bugatti cars in the article

The main physical and chemical properties of this metal are high mechanical strength, low density and high corrosion resistance. For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

Can 3D printing help you optimize production in your organization? Order a free consultation from iQB Technologies experts!

Classification and groups of titanium alloys

Depending on the microstructure and phase composition, titanium alloys are divided into three groups: α, α + β, and β. What is microstructure and phase? Microstructure - the structure of the material, distinguishable under an optical or electron microscope. It can be used to determine the size, shape and orientation of individual crystals and granules that make up the material. It also largely determines its physicochemical properties. A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

Alloys are divided into groups depending on the elements included in their composition in addition to titanium. In alloys of the α group, α-stabilizers (aluminum, carbon, oxygen, nitrogen) predominate. Compared to other titanium alloys, these alloys have relatively low mechanical properties and high corrosion resistance. The most widely used of this group are Ti3Al2.5V and Ti5Al2.5V.

Group β alloys were developed to improve the mechanical properties of the material. They include β-stabilizers (iron, molybdenum, vanadium). These alloys include, among others, Ti10.2.3, Ti555.3 and Ti17.

Finally, there are alloys of the α + β group. They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

On the left is the equiaxed microstructure of the Ti6Al4V alloy (without heat treatment). On the right is a diagram of the phase composition of the Ti6Al4V alloy © 3dnatives.com

iQB Technologies Experts Recommend Article: Metal 3D Printing: Short Answers to Big Questions

Application of Ti6Al4V in additive manufacturing

Taking the market as a whole, Ti6Al4V alloy is the most widely used in 3D printing because of its high strength, low density, high corrosion resistance, and high biocompatibility. This set of properties makes it a valuable material in industries such as automotive, aerospace, medicine and biomedicine, dentistry, chemicals, defense and other areas.

Before starting 3D printing using Ti6Al4V, the alloy must be powdered. This is done using two main technologies: plasma and gas atomization.

Plasma atomization is used to produce highly pure metal powder (Ti6Al4V). The alloy in the form of a rod is fed into the atomizer tank and melted under the influence of the plasma torch. As it falls, the molten metal solidifies into spherical particles.

© 3dnatives.com

The most commonly used technology is gas atomization. The molten material is fed into the nozzle and atomized with an inert gas (argon or nitrogen). In the gas flow, the molten material solidifies and disintegrates into spherical particles, which accumulate at the bottom of the chamber.

See also: Russian manufacturer of SLM machines dispels myths about technology

The choice of technology for the production of metal powder (in this case, Ti6Al4V) is extremely important. The particle size and properties of the powder depend on it, which, in turn, determines the characteristics of the final product. There are three industrial Ti6Al4V alloys on the market today:

There are three industrial Ti6Al4V alloys on the market today:

-

TC4 conforming to GB/T 3620.1-2017;

-

Ti6Al4V class 5;

-

Ti6Al4V Grade 23 conforming to ASTM B348-13.

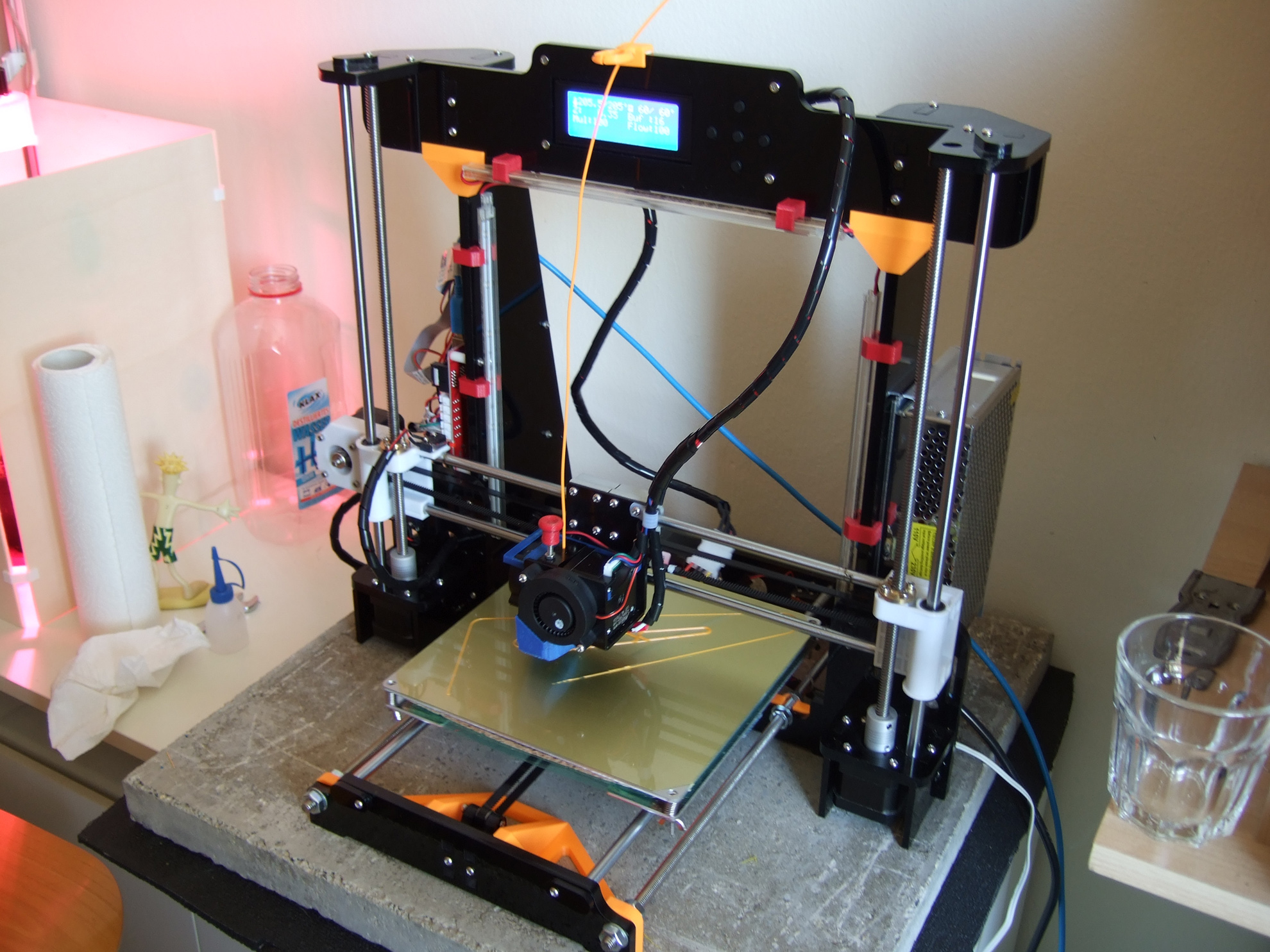

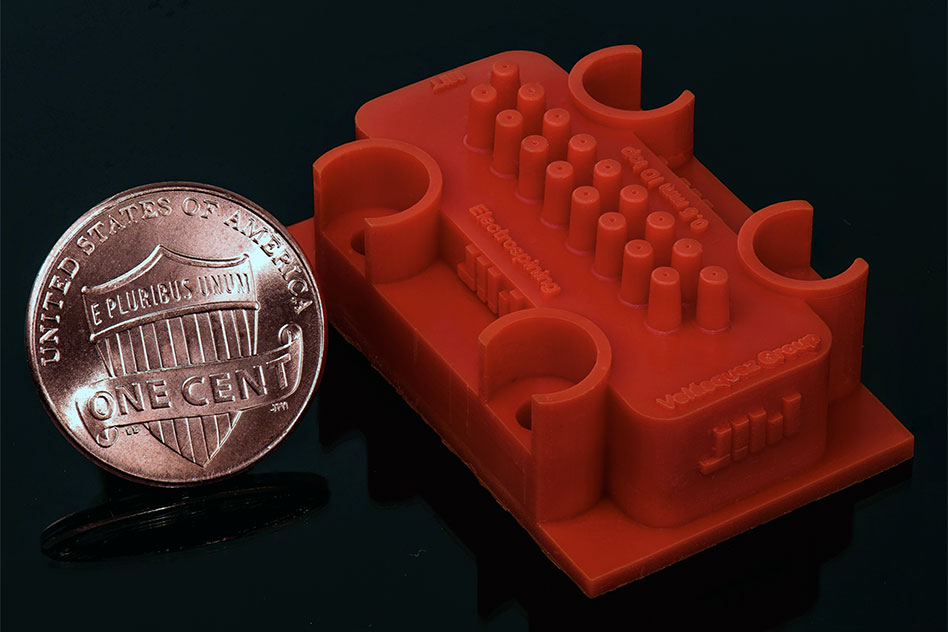

They differ from each other in particle size, which limits the minimum thickness of the printed layer. Most often, 3D printing using Ti6Al4V is carried out using DMLS or SLM technology. The choice of technology depends on the type of part and the desired characteristics.

Source: 3dnatives.com

Bugatti optimizes Bolide hypercar with bionic design and 3D printed titanium

© bugatti.com

Luxury car manufacturer Bugatti has been using additive technologies for years. New advances in 3D printing have been applied to the development of the Bolide hypercar, unveiled in October 2020. Bolide is equipped with an eight-liter W16 engine, weighs only 1240 kg and is capable of accelerating to more than 500 km/h.

Inspired by bone structure, the design team 3D-printed automotive components with a hollow structure with thin walls (up to 0.4 mm) and small ramifications. The use of bionic design has made it possible to give the parts exceptional rigidity and at the same time significantly reduce their weight.

Of the additively produced components for the Bugatti Bolide, the push rods stand out. Despite their light weight - only 100 g - they can withstand pressures up to 3.5 tons.

Another printed detail that Bugatti is particularly proud of is the hypercar's titanium rear fender mounting bracket. Weighing 600g, the bracket is capable of withstanding an aerodynamic downforce of up to 800kg, with a hollow design and a wall thickness of 0.7mm.

Bolide titanium rear fender mounting bracket © bugatti.com

Bugatti previously created a titanium brake caliper for the Chiron hypercar, the first to be 3D printed and the largest in automotive history. The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

Read more in the article: Bugatti did the impossible in 45 hours with a 3D printer

Bracket for the aircraft has become lighter by a third

The S-bracket is an aircraft lift actuator element printed from Ti6AI4V on an SLM 280 machine by ASCO Industries. Its elegant shape is the result of strict space requirements and high stresses on the seating surfaces. The original project involved the manufacture of a high-strength stainless steel bracket and complex machining.

S-shaped bracket - an element of the actuator of the aircraft lift system

The product design has been redesigned for additive manufacturing through topological optimization. Its goal was to minimize the mass while maintaining the necessary strength to withstand the aerodynamic loads specified in the project.

Results of application of selective laser melting:

-

31% weight reduction and overall assembly time reduction;

-

combining three parts into one;

-

decrease in the material utilization factor from 17 to 1.5;

-

significant reduction in machining time.

The result of the topological optimization of the bracket

Read more in the article: How to reduce the weight of an aircraft structural element by a third

Thanks to the titanium prosthesis, the patient was able to return to normal life

The biocompatibility of titanium alloys (such as Ti6Al4V ELI) makes them ideal for 3D printing prosthetic bones of the maxillofacial region, intervertebral discs, clavicles, knees, shoulder blades, hips, and various implants. In dentistry, these materials are used for the manufacture of one-piece implants, as well as metal bases for crowns and bridges made of titanium, cobalt-chromium and other alloys.

An 81-year-old patient suffered from a type 3B acetabular defect according to the Paprosky classification. Previous revision reconstructions in this patient had failed due to calyx loosening and displacement to the posterior cranial region.

For the operation, an aMace hip joint prosthesis was designed, individually made on a 3D printer in accordance with the defect. Thanks to this, the prosthesis helped to achieve the desired degree of recovery and fixation.

aMace custom prosthesis used for surgery

The aMace prosthesis (developed by Materialize) allows you to take into account all the medical features of the patient and the complex mechanical requirements for this important moving part of the human body. The complex porous structure of the back of the product, which allows bone ingrowth, is a feature that can be easily reproduced using 3D printing.

The prosthesis helped to restore the center of rotation to the desired location and orientation, and also provided sufficient support despite the limited amount of bone material (especially in the posterior cranial region).

So, the most important features of prostheses created using titanium 3D printing are:

-

excellent biocompatibility and ideal geometry, taking into account the individual characteristics of the patient;

-

no side effects and complications after surgery;

-

reducing the weight of the prosthesis, including due to the possibility of creating a hollow or porous structure;

-

faster to manufacture and economical solution compared to traditional methods.

Read more in the article: 3D-printed prostheses are transforming patients' lives

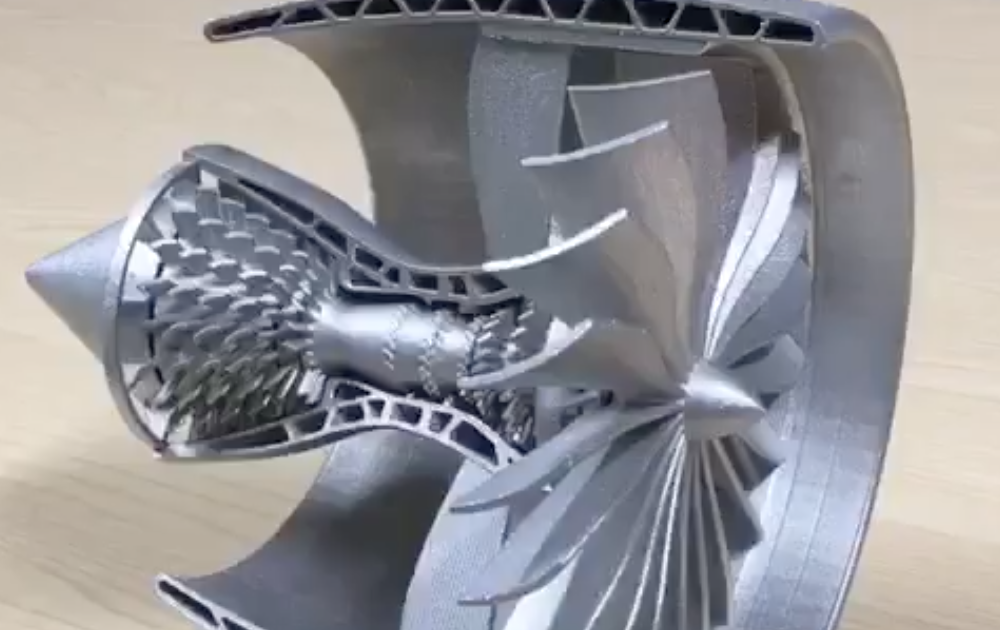

Intro photo of a business jet nose landing gear printed by Safran on an SLM 800 © slm-solutions.com

Article published on 11/26/2021, updated on 08/08/2022

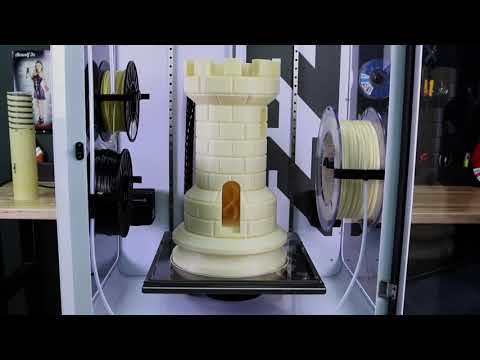

Just space! Huge titanium part in 6.5 days / Sudo Null IT News

This is the largest part to date produced on the SLM 280 additive machine with two 400 watt lasers. It was this machine that made it possible to print a product of this size in a relatively short time compared to traditional manufacturing technology.

It was this machine that made it possible to print a product of this size in a relatively short time compared to traditional manufacturing technology.

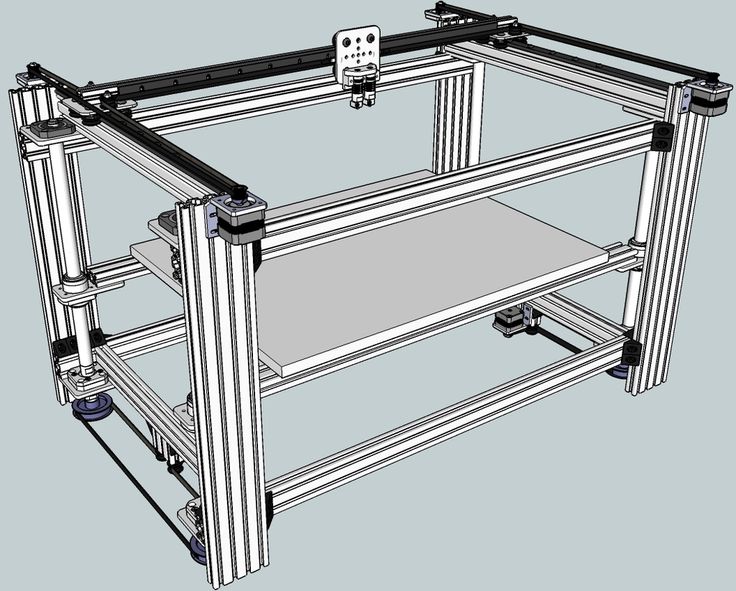

The standard size of the build platform in this class of 3D printers is 250mm x 250mm. However, the SLM 280 has an enlarged bed of 280mm x 280mm, which makes it possible to print larger items.

With developments in 3D printing of SLM metals (including titanium) for the needs of the aerospace industry, given the high strength and light weight of this metal, SLM Solutions has become one of the leading companies fulfilling orders for original equipment manufacturers. SLM Solutions has overcome the limitations of build chamber size and other challenges in manufacturing large titanium products and continues to improve its technology in this area. 9

Titanium powder 3D printing process residual stresses, which became a serious problem. “The geometry of the part was not particularly complex, but the difficulty was to make such a large product from titanium using additive technology,” the engineer noted.

This problem was solved by the system developed and patented by SLM Solutions, consisting of two lasers. Processing the product in the overlap zone simultaneously with two lasers made it possible not only to speed up the printing process, but also to produce a larger product. SLM Solutions tested the material in the overlap zone, which confirmed that there was no difference in material quality between the areas printed with one laser and the areas in the overlap zone, which were alternately exposed to two lasers. The SLM Solutions engineers went through several iterations to prepare the file and print some test samples to make sure the task was completed. The customer wanted a way to produce this product that would save cost, time and weight.

“This piece is notable for its size and the fact that it was produced from titanium in six and a half days without interruption in the printing process,” says Hansen. “The fact that the SLM 3D printer is able to operate for such a long time without requiring cleaning or other maintenance is extremely important in itself. ”

”

Although 3D printing technology usually attracts attention with its ability to reproduce unique geometries, this aerospace product was not particularly challenging in this respect. However, to obtain a titanium part of this size in such a short time would hardly be possible using conventional machining technology.

Traditional machining would take weeks to make

“Additive manufacturing is not constrained by the limitations of traditional machines and tools, so we can create more organic shapes, and the entire design and development cycle for critical aerospace products is greatly reduced.” Hansen explained.

Richard Grylls, Ph.D. in Metallurgy, Implementation Manager and CTO for SLM Solutions North America, commented: “Given the size of the product, the traditional machining process would take several weeks; this would require four or five readjustments. In other words, it would be a very costly process. It would take even more time to produce a product using casting technology, as tooling would be required, and the manufacturing process can take up to six months. In addition, traditional equipment has a high cost. We completed the task much faster, although the cost of the product was higher. However, given the time saved, the cost is justified for a mission-critical product of this size.”

It would take even more time to produce a product using casting technology, as tooling would be required, and the manufacturing process can take up to six months. In addition, traditional equipment has a high cost. We completed the task much faster, although the cost of the product was higher. However, given the time saved, the cost is justified for a mission-critical product of this size.”

Turbine blade printed on the SLM 280HL additive machine

SLM Solutions has achieved impressive results in terms of production speed, quality and density of the final product. Hansen noted that “meeting the stringent quality and material specifications for titanium in heavily regulated industries such as aerospace and automotive requires extensive material testing and parameter optimization to ensure that the customer gets exactly what they need. ".

Quality control requirements in the aerospace industry are quite extensive: to check the product for voids or porosity, a non-destructive testing method such as computed tomography is usually used, but the customer can choose to use destructive testing and cut the product.