3D printer cup

3d Printed Cup - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Cup best 3D printer models・Cults

Argentina T-shirt keychain

€3. 26

Key ring on Figurines Qatar 2022

€2.96

Egg Cup Karthago

Free

OFFICE PEN HOLDER

€1

Coffee Cup Hook

Free

football trophy

€6.95

Qatar logo keychain

€0.89

World Cup Home Pod Support

€3.85

Luna Sailor Moon Container (no holes)

Free

Business Pen Holder (or other tools!)

€0.81 -10% €0.73

Alloy wheels - OZ Racing - 19''

€0. 66

66

FIFA World Cup (With Green Ribbons)

€5.27

mate argentina national team messi 2022

€0.77

World Cup

€0.89

Messi 2022 Qatar Bust

€5.50

desk cup

€0.96

Christmas Cookie Cutter 4

€1.60 -10% €1.44

FLAT WORLD CUP

€11.54 -30% €8.08

Espresso ornament

€1.20

WORLD CUP 2022

Free

DIBU MARTINEZ/ ARGENTINA NATIONAL SOCCER TEAM/SCALONETA

€1. 73

73

Drill Bot Pencil Holder

€1.44 -30% €1.01

Soccer Cutters - World Cup 2022 - Argentina

€1.48

SecretLab Modular Can Holder

€1.72 -25% €1.28

WORLD CUP BRAZIL

€0.50

WORLD CUP ENGLAND

€0.50

WORLD CUP FRANCE

€0.50

WORLD CUP ARGENTINA

€0.50

WORLD CUP PORTUGAL

€0.50

Llavero de la Seleccion Mexicana de futbol / Keychain of the Mexican soccer team

€1

Qatar 2022 World Cup figurine box

€1. 78

78

faces mug

€1.44

PEN HOLDER, PENCIL CUP VERSION 3

€1.87

PEN HOLDER, PENCIL CUP VERSION 2

€1.87

Pen holder, pencil cup version 1

€1.87

Mobile phone tray for cup holder

Free

PORTA HANDY PICK UP CHEVROLET S10.

€11.84

CHEVROLET S10 CUP HOLDER

€14.80

Coozy O' Terror

Free

Viking Drinking Horn + Base

€4.81

Coffee Cup with Legs - Sitting on the edge

€1.87

Freezebee world cup with its base

Free

Double Cup Holder with Flaps, to Be Modified to Fit Your Car

Free

Saab 900 Double Cup Holder with Flaps for Larger Water Bottles Etc.

Free

Saab 900 Single Cup Holder with Flaps for Larger Water Bottles Etc.

Free

Coffee and tea cup holder

€0.75

NICO OTAMENDI, ARGENTINA NATIONAL SOCCER TEAM QUATAR2022

€1.59

Washing Machine Liquid Cup

Free

PLA mug and boiling water.

3D printing

Follow author

Follow

Don't want

19

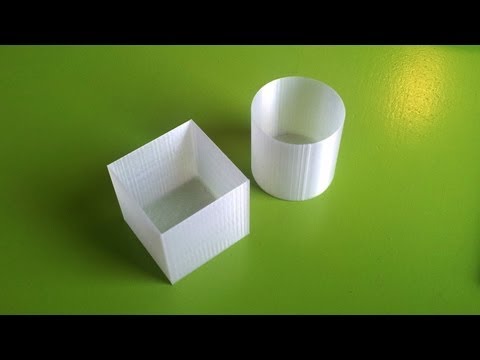

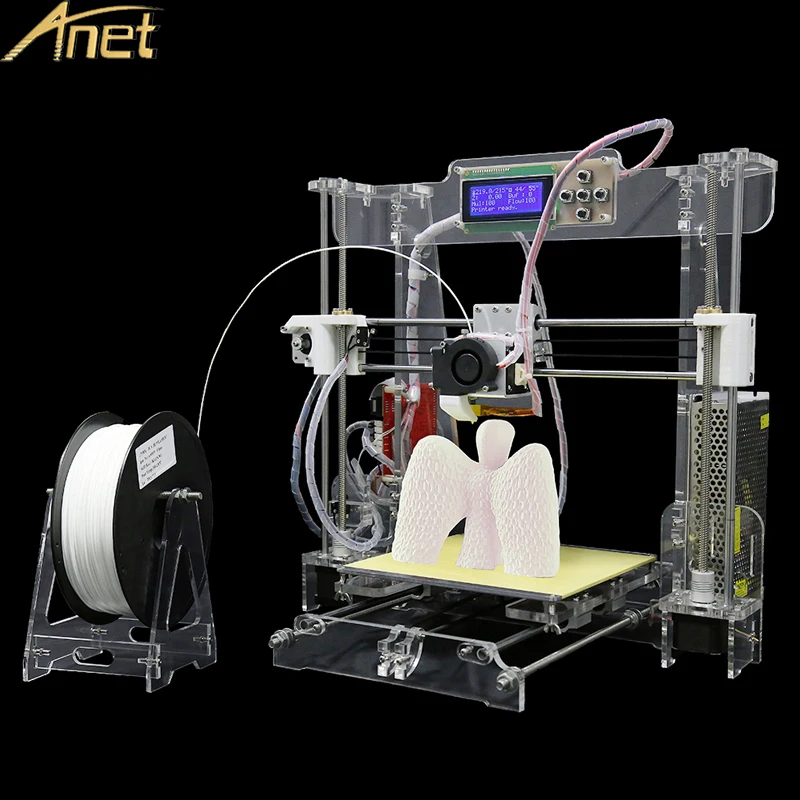

I once had a crazy idea to make a mug out of PLA plastic that wouldn't bend and hold hot coffee or tea. Earlier I saw a post about a pla cup and how it bends and softens when boiling water is in it. Based on what he saw, he decided to model a thick mug in the style of a thermos, i.e. 2 walls, and air between them, with the expectation that, apart from hot liquid, nothing will press on the inner walls, and since air prevails between the inner and outer walls, the outer walls will not heat up enough to wrinkle in the hands. So, for starters, a thermos mug was modeled, if you can call it that.

So, for starters, a thermos mug was modeled, if you can call it that.

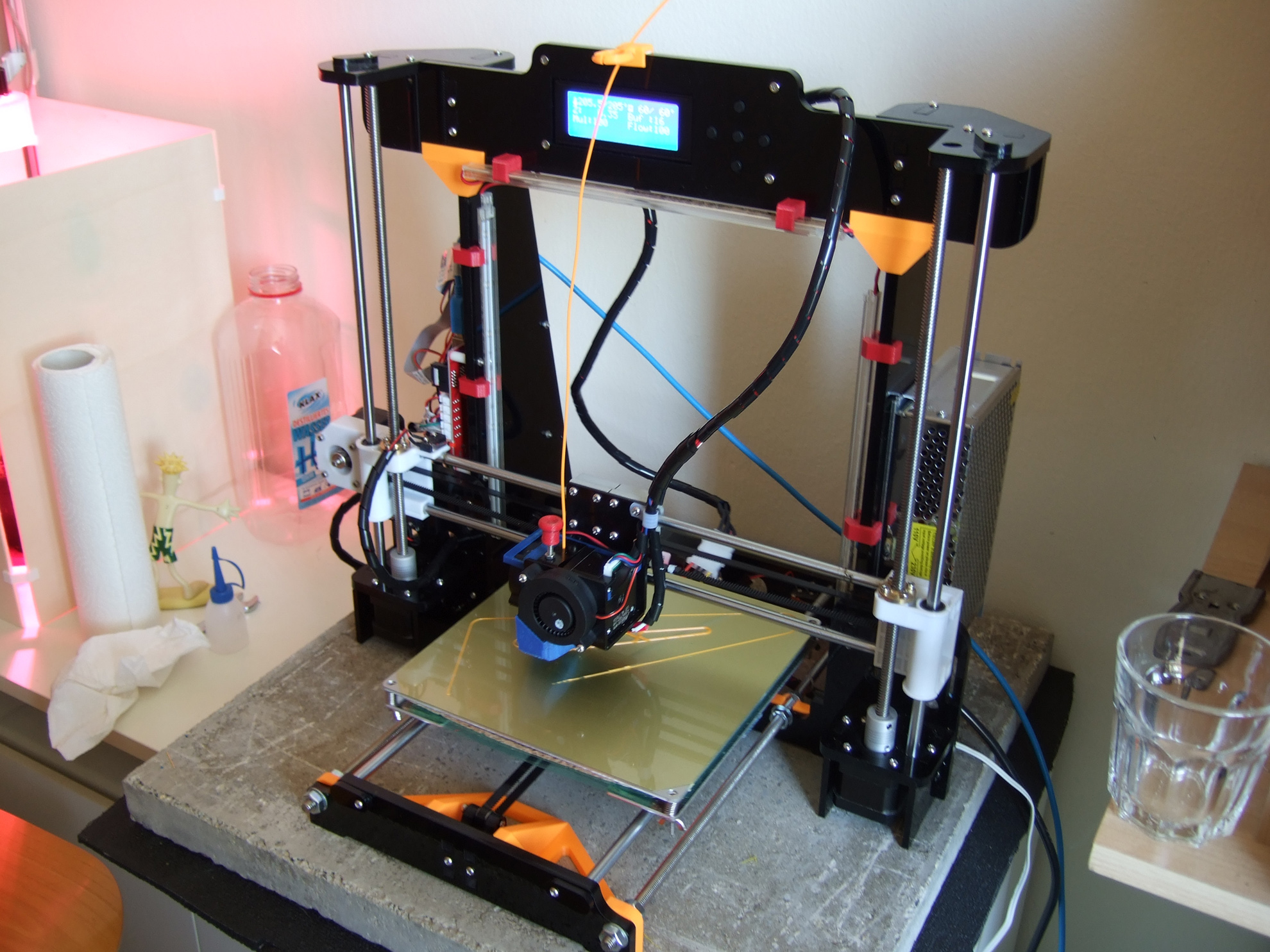

It consists of 2 parts, the thermos itself and the lid-mug, they are threaded and twisted. I modeled in a self-cad, it turned out pretty quickly and simply. Then I printed the lid on creatbot mini, natural pla plastic bestfilament (I considered the absence of dyes in plastic important), cura slicer.

print specifications:

0.4mm nozzle

0.2mm layer

1.6mm wall thickness

20% coverage

after 16 hours of printing, in other words the next day, I decided to immediately test the cap and poured into it boiling water. The result is as follows: the outer walls warmed up after 10 minutes, but not enough to be soft, the bottom warmed up faster and became a little soft, after which the boiling water cooled down.

then it turned out that I made a mistake with the thread and I had to print the cover of the mug again.

This is where the adventure began, or the problem was in the printer or in the plastic, or both, I didn’t fully figure it out, the plastic choked during printing very badly.

Perhaps because it is already old, and there was a problem of fluid leaks - cracks between the layers and fill lines. The solution was to dry out the coil and ream some of the Teflon tubing in the hot end. after which there was a small problem, in some places the distance between the lines in the horizontal plane, namely at the bottom is too large, as a result of which the bottom leaks. With the help of coffee, it was possible to find and show leaks

Here I got into the self-slicer, I remember exactly there is an opportunity to reduce the distance. (top/bottom line width)

After which the thermos was printed, the thread had to be worked out a little about 10 minutes of work with a file, and here it is the result.

well, a few links, suddenly someone will come in handy on Thingiverse - http://www.thingiverse.com/thing:2275179

Follow author

Follow

Don't want

19

More interesting articles

DrProg

Loading

11/08/2022

1176

9

Subscribe to the author

Subscribe

Don't want

We continue to reveal the incredible opportunities of enterprises from the Middle Kingdom, up to . ..

..

Read more

0

Subscribe to the author

Subscribe

Don't want

Ones Technology is a research and development center under the Ministry of Industry of Turkey. According to G...

Read more

Dima_pb

Loading

04.02.2016

75383

157

Follow author

Follow

Don't want to

Everyone knows about rollback, but few understand where to start to manage it properly....

Read more

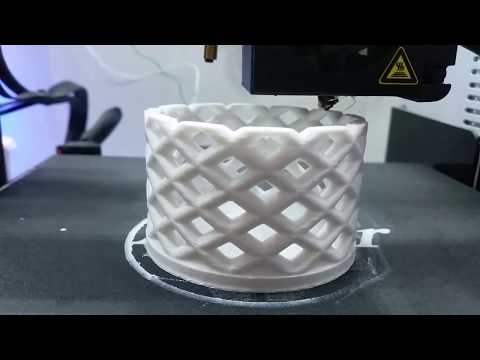

3D printing of a cup! Design Studio -Nervous System!

3D Printed Porcelain Cup

Nervous System design studio is well known for its amazing designs for a wide variety of purposes. A distinctive feature of most of them is the use of a 3D printer as a working tool, which works according to a 3D printing technique suitable for each specific situation, and, of course, close integration with 3D technologies. Nervous System's work includes both individual projects and larger commissions, some of which have received quite a lot of publicity. For example, for a long time, the design studio worked on the creation of 3D-printed sneakers in collaboration with New Balance.

Nervous System's work includes both individual projects and larger commissions, some of which have received quite a lot of publicity. For example, for a long time, the design studio worked on the creation of 3D-printed sneakers in collaboration with New Balance.

And the adorable 3D printed and 3D scanned dress debuted in March this year. In addition to these projects, the company has quite a few not less remarkable developments, such as various 3D printed accessories and decorative elements. This time Nervous System surprised us with the results of their experiments with a new 3D printing material called Porcelite from Tethon. Jessica Rosenkrantz, one of the founders of the design studio, described the problems that the developers had to face while working on the project, as well as the process of finding solutions to them.

How the cup was 3D printed

According to the designers, they became interested in the possibilities of Porcelite material immediately after its announcement on the Kickstarter crowdfunding site in February. With this ceramic mixture, the founders of Nervous System set out to create a set of porcelain cups that reflect the studio's creative choices. The design of the dishes was inspired by cellular structures, and the design of the products took into account the need for thermal insulation, in which the outer part of the cup remains cold, despite the high temperature of its contents.

With this ceramic mixture, the founders of Nervous System set out to create a set of porcelain cups that reflect the studio's creative choices. The design of the dishes was inspired by cellular structures, and the design of the products took into account the need for thermal insulation, in which the outer part of the cup remains cold, despite the high temperature of its contents.

This effect was achieved due to the construction with double walls, the air gap between which is responsible for the conservation and distribution of heat. “We planned to explore ceramic structures that require 3D printing technology. Products that are almost impossible to create using traditional manufacturing techniques, even by hand. We were also hooked on the double-walled idea, which we managed to beat in the end. The created set should not be exclusively of aesthetic value, but should also correspond to a given functional load,” says Rosencrantz.

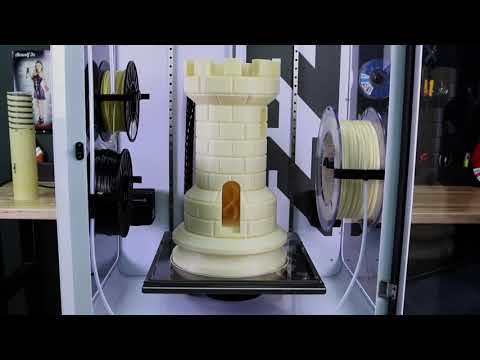

3D printed cups on SLA 3D printer

Since it was the first time the designers worked with Porcelite, it took them about a month to perfect the pieces. The main feature was the fact that this material is one of the few, if not the only, ceramic materials designed to work with SLA 3D printers. This circumstance can be safely called an advantage, since SLA technology allows for ultra-precise 3D printing with a high degree of detail, which provides creators with complete freedom in product design.

The main feature was the fact that this material is one of the few, if not the only, ceramic materials designed to work with SLA 3D printers. This circumstance can be safely called an advantage, since SLA technology allows for ultra-precise 3D printing with a high degree of detail, which provides creators with complete freedom in product design.

The developers used a Form 2 3D printer from Formlabs during the printing process, which had to be tormented with setting up for proper 3D printing with a new material. The first question that came up was the tendency of the substance to separate: Porcelite consists of two materials - a photopolymer and a ceramic powder, which quickly begin to separate from each other if not used at a particular moment. This problem was solved empirically due to the presence of an open printing mode in the 3D printer. This allows you to manually add the required amount of material to an empty cartridge. There was also the issue of adhesion, which the designers managed to get around by grinding the work surface.

Consumables

The original weight of Porcelite is significantly higher than the weight of the resins that the Form 2 is designed for, so the inclusion of supports in the structure was a must. However, as with standard materials, they were easy to remove once the 3D printing was complete. The main difficulty, familiar to every ceramic artist, was the process of firing finished products. Any ceramic mixture shrinks during drying and firing, on average about 12%. Porcelite was no exception, but it turned out that this material compresses even more - the shrinkage of the cups was 17.5%, which also presented some difficulties. Thanks to the preliminary irradiation of products in a UV oven for two hours, it was possible to avoid such unpleasant consequences of firing, such as cracking and deformation.

Still, there were some inaccuracies in the finished products. However, after applying several layers of glaze to the surface of the products, these shortcomings became almost invisible to the naked eye.