Best 3d printer hotends

The Best 3D Printer Hot Ends Buyer's Guide 2022

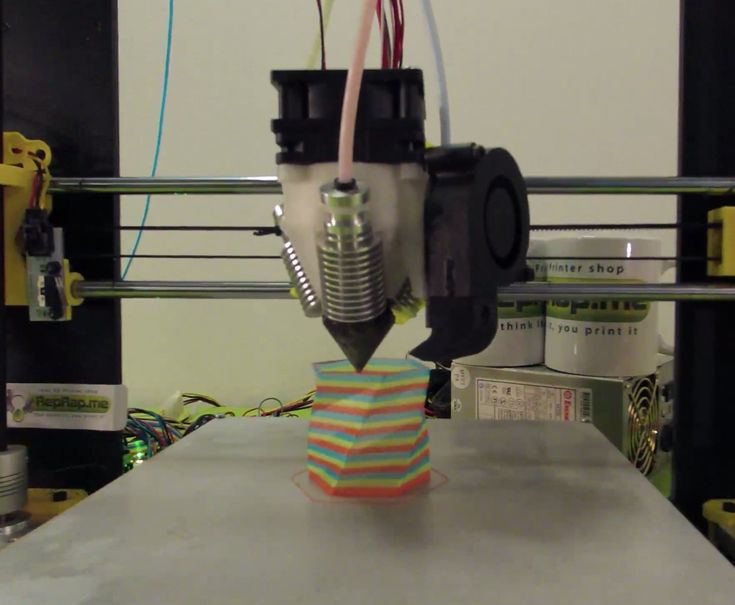

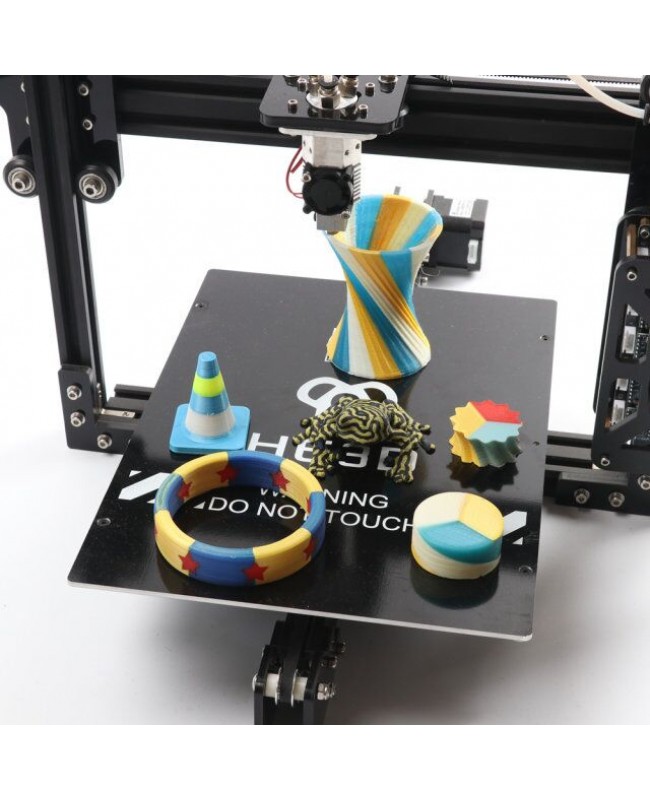

A 3D printer hot end makes up part of the extruder, probably the single most important part of an FDM 3D printer. The hot end melts plastic filaments that are then deposited on the print bed to create your 3D model.

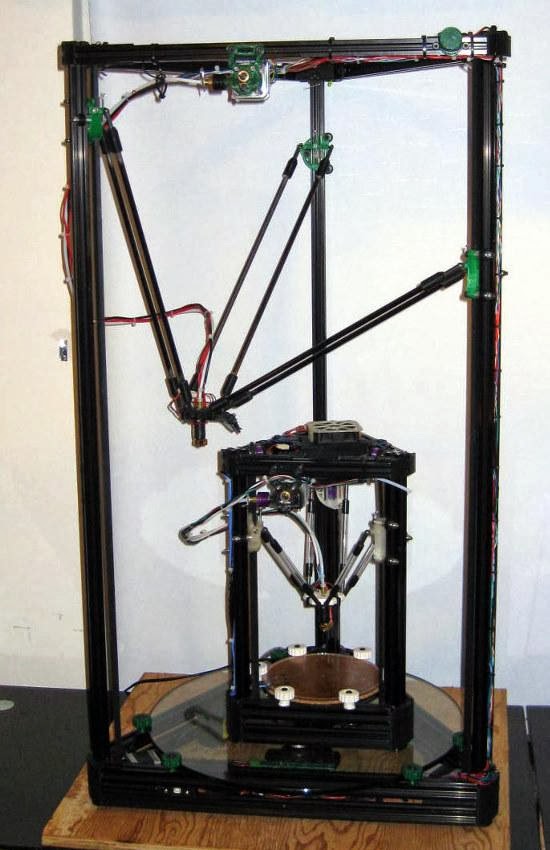

In a direct drive extruder set up, the hot end is directly below the cold end for direct access. In a Bowden extruder however, the hot end is separate from the cold end, which is mounted on the printer’s frame and is commonly seen in delta 3D printers.

Investing in a good quality hot end is one of the best investments you can make in 3D printing, as they are so integral to print quality and efficiency. A sign of a good hot end is that there are many copies or clones – though we strongly recommend spending the extra $20 and picking up the real deal, ensuring a great 3D printing experience.

- We also have a guide to all the parts of a 3D printer.

How a 3D Printer hot end affects 3D printing:

- Reliability: A good hot end reduces the likelihood of prints failing and helps prevent filament clogging.

- The materials you can use: Some hot ends are made of fully metal parts and therefore can handle higher temperatures. This allows you to print with tougher filaments such as Nylon or PETG. Always check what temperature your hot end can manage.

- 3D printing speed: a lightweight hot end can mean a faster 3D printer with less chance of overshooting.

- Print quality: hot ends are key for precise, crisp finishes on prints. A hot end that effectively melts filament to deposit it at the perfect temperature reduces chances of warping.

- Nozzle size: some hot ends are compatible with different 3D printer nozzle sizes, which affect accuracy and speed.

Top 5 Best 3D Printer Hot Ends / Extruders

| Name | Price | Best place to buy: | Other purchase option: |

|---|---|---|---|

| E3D V6 | $61 | Amazon here | Matterhackers here |

| E3D Lite6 | $37 | Amazon here | Matterhackers here |

| Micro Swiss MK10 All Metal Hot End | $63 | Amazon here | |

| Diabase Flexion Single Extruder | $150 | Amazon here | |

| Diabase Flexion Dual Extruder | $250 | Amazon here | |

| E3D Titan Aero | $140 | Amazon here |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

Choosing the Best Hot End for You

When considering buying a hot end, consider:

- What materials you want to print with – some hot ends can reach 400C and can melt and print with anything, while others can only print PLA. Metal hot ends can reach higher temperatures than PEEK hot ends, and are therefore compatible with more materials. You’ll need a high-quality hot end for tougher materials such as Nylon, and should consider a special extruder for flexible filaments.

- How much you are willing to invest – saving money on a cheaper hot end can cost you more money in the long run if they keep breaking and need to be replaced. We have picked hot ends with a reputation for reliability and durability which we recommend below.

- What 3D printer do you currently have – only buy a hot end compatible with your 3D printer or that is easily modifiable to fit with it.

The best hot ends, such as those made by E3D, are compatible with almost every 3D printer.

The best hot ends, such as those made by E3D, are compatible with almost every 3D printer. - Size of filament you want to print with – many hot ends are compatible with both 1.75mm and 3mm filament, but make sure you don’t buy the wrong size for you.

Metal vs PEEK / PTFE Hot Ends

Hot ends are usually either made of PEEK, PTFE or metal. Metal hot ends are more versatile and can reach higher temperatures, and are therefore compatible with more filament material types. They are also considered more reliable, so for any maker looking for reliable printing and the option to print materials beyond the standard ABS or PLA, we recommend a metal 3D printer hot end.

PEEK is good enough for standard filaments such as ABS or PLA, but for tougher filaments it is not best suited.

The materials you can print doesn’t just depend on the hot end, however. Other factors such as whether your 3D printer has a heated bed affect whether you can print ABS, PETG, Nylon and several other filaments.

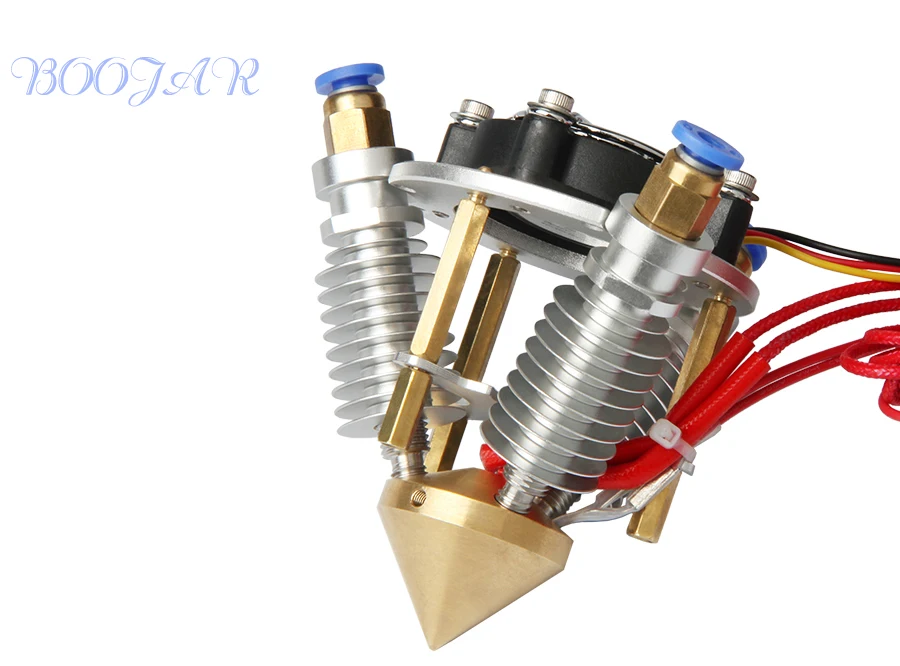

Parts of a 3D Printer Hot End

- Nozzle – lets filament out, and on to the print bed to form the model. The size of your nozzle affects precision, as smaller nozzles can print more precise details. However, there is a trade-off: you can either print more quickly with a larger nozzle but at lower quality, or more slowly at a higher quality with a smaller nozzle. The standard nozzle size is 0.4mm, but varies. They can easily be switched out if you want to print with a larger or smaller nozzle. A smaller nozzle is important for 3D printing miniatures.

- Heat Block – keeps the heater cartridge and thermistor in place, and connects the heat break and nozzle together. This part produces the heat which melts filament so it can be extruded.

- Thermistor – monitors the heater block’s temperature.

- Heat Break – connects the heat block to the heat sink, and is where the filament moves from normal temperature to the high temperatures that will melt it.

- Heat Sink – cools down the cold side of the break, usually with a fan to help cool it.

5 of the Best 3D Printer Hot Ends

E3D V6 — best overall 3D printer hot end

- Price: $62 — Available on Amazon here / Available on Matterhackers here

Considered the best hot end around by makers and 3D printer companies alike, the E3D V6 is a customizable all-metal hot end that works great even with tougher filaments like Nylon. As with all E3D hot ends, parts can easily be replaced and switched out.

It comes as a DIY kit that you will need to assemble yourself, unless you’d prefer to pay more to have it ship assembled. Building it yourself gives you the flexibility you need, as you may want to turn it into a direct or Bowden extruder, or change it to take either 1.75mm or 3mm filaments.

E3D hot ends are extremely versatile, and compatible with almost any FDM 3D printer you can think of. It’s built to be lightweight and precise, meaning you can print with no overshooting at good speeds. Overall, we highly recommend the E3D V6 as one of the best 3D printer hot ends.

It’s built to be lightweight and precise, meaning you can print with no overshooting at good speeds. Overall, we highly recommend the E3D V6 as one of the best 3D printer hot ends.

E3D Lite6 – best 3D printer hot end for beginners

- Price: $37 — Available on Amazon here / Available on Matterhackers here

The E3D V6’s baby brother, the Lite6 is one of the best hot ends for beginners to 3D printing. It’s only compatible with 1.75mm filament, so for the minority of makers who prefer 3mm this won’t work for you.

For the lower price, you lose some of the benefits of the E3D V6. Instead of being fully metal, a small number of parts are PTFE-lined, so the Lite6 can’t take on the same high temperatures as the E3D V6. For that reason, it is mostly limited to standard filaments such as ABS and PLA.

Being less customizable than the V6 shouldn’t be a problem for beginners, and it is easier to assemble and mount than its bigger brother. Overall, we recommend it for newer makers and those who want to save time, prefer a less complex hot end, and want to save some money.

Micro Swiss MK10 All-Metal Hot End

- Price: $63/£37 — Available on Amazon here

This all-metal hot end is similar in price to the E3D V6 and is a great upgrade on the standard MK10 hot ends ever-present on printers such as the Creality CR-10, Flashforge, Qidi Tech and Dremel 3D printers.

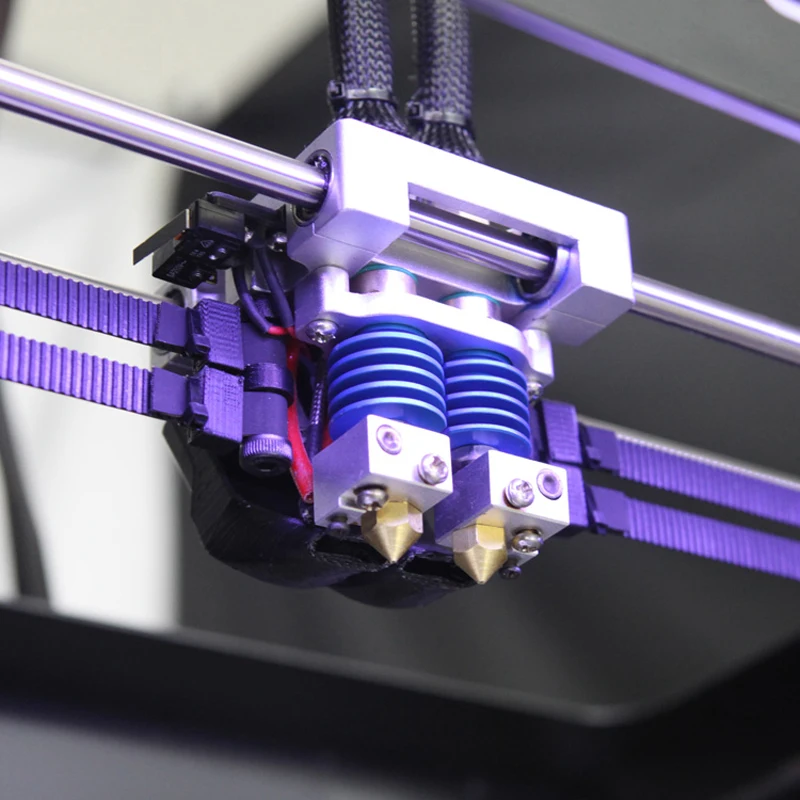

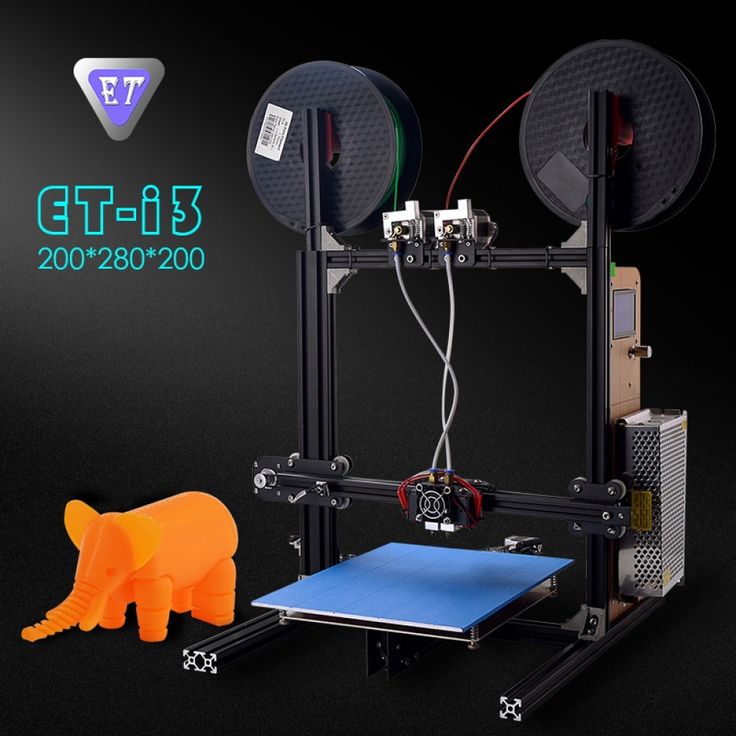

The Micro Swiss MK10 is compatible with a variety of different nozzle sizes, and can be used with dual extruder 3D printers as well as single extruders. In effect, the MK10 all-metal upgrade replaces some PTFE parts with metal ones to improve printing conditions and results.

Unlke E3D hot ends, you don’t get every part to your hot end, just the necessary parts to replace the non-metal parts of existing standard MK10 hot ends.

Diabase Flexion Extruder — best 3D printer hot end for flexible filament

- Price: $149 single, $249 dual extruder

- Single extruder version available on Amazon here

- Dual extruder version available on Amazon here

The Diabase Flexion is specifically designed for printing flexible filaments, and is by far the most effective hot end for flexibles – able to print at higher speeds and with less clogging and errors.

Designed to prevent errors that can occur often with flexible filament printing due to clogging or the squeezing of flexible materials into positions or areas where they are not supposed to go. The specially-designed feeder can more effectively grip flexible filament to travel through to be printed without issue and avoid jams.

Coming in both dual extruder and single kits, but only compatible with 1.75mm filaments, this is the ideal hot end we recommend if you want to avoid the stress of filament jams. Overall, for flexible filaments, you can’t get much better.

E3D Titan Aero

- Price: around $140 — Available on Amazon here

Designed for direct drive extruders and with the heat sink attached to the hot end, the Titan Aero is a hybrid hot end built for efficiency.

Since the heat sink is attached to the hot end, there is a far shorter distance to travel from the heater block to the extruder. This makes it great for fast printing, and the E3D Titan Aero also has great grip to prevent filament jams, and is designed to be extremely easy to clean. It’s also compatible with both 1.75mm and 3mm filament.

It’s also compatible with both 1.75mm and 3mm filament.

Though minor, it is important to remember that the attached heat sink will add a small amount of weight to the hot end, so it will struggle to reach the precision of the E3D V6 at the same faster speeds.

Related articles:

- Ender 3 hot ends – best options

- 3D printer nozzles – the best and tips and tricks

- 3D printer nozzle size – the pros and cons of smaller and larger nozzles

- Best 3D printer extruders

- Best dual extruder 3D printers

Best 3D Printer Hotends & All-Metal Hotends to Get – 3D Printerly

In your 3D printer, several parts perform functions to make sure the printer runs smoothly. Arguably, the most important component of all of is the hotend.

Why? The hotend is the part that melts the filament into thin straight lines and deposits it on the print bed. It affects everything from the printing temperature to the speed to even the quality of the printed object.

So, to get the best out of your 3D printer, it’s a great idea to invest in a quality hot end.

In this article, I’m going to help you do just that. I have put together a list of some of the best 3D printer hotends on the market. I also added some of the things to look for before buying.

Using our criteria, I’ve checked out the all-metal hot ends available on the market. After evaluating them, I’ve come up with a list of the six best all-metal hotends.

Price: Around $60 | Material: Aluminum (Cooling block, Heat block), Titanium (Heat break) | Temperature Range: 260°C+ | Compatibility: Creality printers / 1.75mm filament

The Micro Swiss all-metal Hotend kit is an excellent replacement for non-metal parts stock hot end. It is built with premium materials like titanium and aluminum to ensure top-notch service and little wear.

Furthermore, it is also easy to install, requiring no modification at all to the firmware.

The Micro Swiss Hotend comes with aluminum cooling and heating blocks, a brass-plated wear-resistant nozzle, and a Grade 5 titanium heat break. The nozzle is replaceable, and the printer supports nozzle sizes from 0.2mm to 1.2mm.

The titanium heat break is where this hot end shines. Titanium offers up to three times less thermal conductivity than conventional stainless steel. It helps the hotend in creating a more defined melt zone.

It is said that this hotend can hit temperatures of 260°C without any changes, then it requires a firmware flash by changing the configuration.h file to reach higher temperatures, but you only want to do this if your printer has the capabilities.

Some have mentioned that low-cost 3D printers have the bare minimum when it comes to the wiring and the circuit which can overload in some cases.

The hotend circuitry should be the same as the heated bed circuitry which draws a lot more power, so the power to the hotend should be safer, as long as the wires are up to par.

Another thing to keep in mind is how the accuracy of your thermistor reduces as you go into those higher temperatures, but for most materials, you don’t need to go so high regardless.

Even for Polycarbonate, you can get low temperature versions like the Easy PC CPE Filament from Filament.ca that requires around 240-260°C and a bed of 95°C.

User Experience

The Micro Swiss hotend is easy to install and even comes with tools in the box for that. Its superior build quality and ease of installation have already made it a favorite of users.

There is no need for firmware modifications to make it work. The hotend is plug-and-play. Many users describe this as an excellent piece of kit which provides amazing results from day 1.

One user who had clogging issues with their Ender 5 Pro tried many solutions to no avail. Once they bit the bullet and got themselves the Micro-Swiss All-Metal Hotend Kit, they could finally print without problems.

The Hotend itself feels like a premium product which is fairly expensive, but the results show how worthy it is.

Another user described it as a “first class upgrade for my Ender 3 Pro” due to having a significant improvement on their 3D prints.

If you are experiencing issues like heat-creep, many people have solved it by getting themseves this hotend.

Some people have complained about a leaking nozzle or heat creep, but this usually comes down to not following the right installation instructions.

To reduce clogging, Micro-Swiss say to have a maximum retraction of 1.5mm at 35mm/s.

Pros of the Micro Swiss All-Metal Hotend Kit

- Comes with a wear-resistant nozzle.

- Can print high-temperature materials.

- Doesn’t require a heat tube replacement.

Cons of the Micro Swiss All-Metal Hotend Kit

- Tends to clog when printing with low-temperature filaments.

- There have been reports of nozzle leakage.

- It’s a bit expensive considering electronics aren’t in the box.

Final Thoughts

The Micro Swiss all-metal hot end ticks all the right boxes when it comes to design and materials. But when buying such a premium hotend, the issues and long-term viability should give any buyer pause.

But when buying such a premium hotend, the issues and long-term viability should give any buyer pause.

If you want to transform your 3D printing experience, whether on your Ender 3, Ender 5, or other compatible 3D printer, get yourself the Micro-Swiss All-Metal Hotend Kit today.

Price: Around $60 | Material: Aluminum (Cooling block, Heating block), Stainless Steel (Heating break) | Temperature range: 300°C | Compatibility: Almost all printers / 1.75mm & 3.0mm filaments

The E3D V6 all-metal hot end is the gold standard for all-metal hotends in 3D printing. Its reliability and versatility have made it a favorite among 3D printing enthusiasts for years.

It’s used widely in 3D printing with various printers and materials.

Another reason this hot end is so popular is its modularity. The E3D V6 comes with an extensive support ecosystem of different parts for different printing scenarios. You can easily swap out parts and configure the hot end for any printing scenario.

You can easily swap out parts and configure the hot end for any printing scenario.

The E3D V6 is a machined metal build. It comes with an Aluminum heat sink and heater block break. The Heat break, however, is made out of stainless steel. The nozzle is made out of brass, but it can be easily replaced with a wide variety of options.

It can be fit on many 3D printers, but in some cases, you’ll need a modification and a mount for 3D printers like the Creality CR-6 SE and Di Vinci Pro 1.0. There are plenty of custom carriages you can find on Thingiverse for your 3D printer.

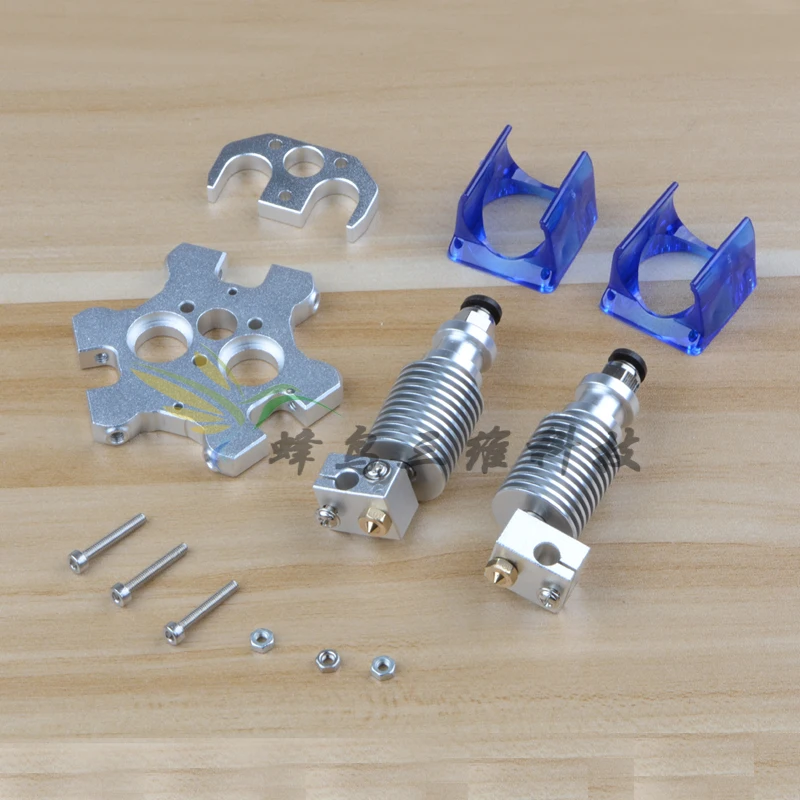

The kit itself comes with many separate parts that you put together:

Metal parts

- 1 x Aluminium Heatsink (Contains brass embedded bowden coupling ring pre-fitted in top)

- 1 x Stainless Steel Heatbreak

- 1 x Brass Nozzle (0.4mm)

- 1 x Aluminium Heater Block

Electronics

- 1 x 100K Semitec NTC thermistor

- 1 x 24v Heater Cartridge

- 1 x 24v 30x30x10mm fan

- 1 x High Temperature Fiberglass Wire – for Thermistor (150mm)

- 2 x 0.

75mm Ferrules – for Solder-Free Wire Joins

75mm Ferrules – for Solder-Free Wire Joins

Fixings

- 4 x Plastfast 30 3.0 x 16 screws to attach the fan to the fan duct

- 1 x M3x3 socket dome screw and M3 washer to clamp thermistor

- 1 x M3x10 socket dome screw to clamp the heater block around the heater cartridge

- 1 x Fan Duct (Injection Moulded PC)

User Experience

The E3D V6 All-Metal Hotend is a genuinely great hot end. It can be a little tricky to set up for first time users, but there are plenty of resources online for help.

To install, all you have to do is find the correct mounting for your printer on Thingiverse and follow directions.

However, for some unsupported printers, there still have to be some additional firmware modifications for the hot end to function properly.

This isn’t a deal-breaker as thermistors are replaceable.

One user who implemented this hotend and used it for around 50 hours said that it’s the best money they spent on their 3D printer. Since installing it, they haven’t had a single clog while using materials like PLA, ABS, and PETG.

Since installing it, they haven’t had a single clog while using materials like PLA, ABS, and PETG.

There are a few reviews where the kit came with a faulty thermistor, but this can easily be replaced through their customer service or getting a set of your own.

Pros

- A great ecosystem of parts

- Superior build quality

Cons

- It has a complex installation process for some printers.

- There have been problems with its thermistors after delivery.

Final Thoughts

This hotend is hands down one of the best in its class. It combines effective design with a decent price, you’d be hard-pressed to find one with as much accessory support as this.

Get yourself the E3D V6 All-Metal Hotend from Amazon today.

Price: Around $140 | Material: Aluminum (Cooling block, Heating block), Stainless Steel (Heating break) | Temperature Range: 300°C | Compatibility: Almost all printers / 1. 75mm & 3.0mm filaments

75mm & 3.0mm filaments

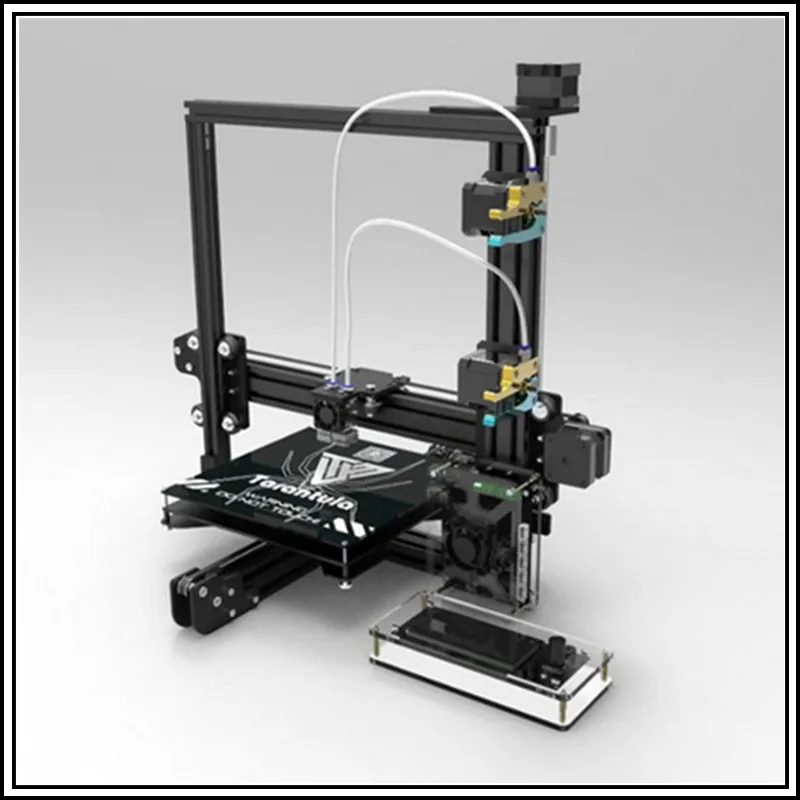

The E3D titan aero differs from all the hot ends on this list in the sense that it’s technically an extruder – hot end combo. It combines the design of the E3D V6 hot end with a Titan extruder to create a smaller, more compact extrusion system.

It’s a Direct Drive setup which means it has a much shorter filament path than Bowden, leading to less jamming or bending. This is perfect for flexible filaments or simply improving the quality of normal filament in many cases.

The Titan Aero’s compact design means it occupies less space than standard hotend/extruder combinations.

This design means it takes up less build volume on the Z-axis.

The Titan Aero is built on the bones of the E3D V6 system, so this means it inherits the modularity of the previous system. Most of the aftermarket accessories compatible with both the V6 hotend and the Titan extruder should work with it.

Most of the aftermarket accessories compatible with both the V6 hotend and the Titan extruder should work with it.

One of the key attributes of this extruder is how lightweight, reliable, and versatile it is performance-wise. It has the Titan 3:1 gearing ratio along with the compact and poweful motor, for low weight and pushing power.

User Experience

The Titan comes with quite a bit of assembly required. There are videos and resources available online to guide users through the installation process.

Even with these resources, the process can be a little complex for inexperienced users.

The stock materials in the Titan limit the maximum printing temperatures. To print at higher temperatures with better materials, you’ll have to swap out these components.

As you may know, there are many knockoff versions of different 3D printers, and even hotends. One user had an E3D V6 knockoff and then changed over to the real thing, which led them to noticing a “tremendous difference in print quality”.

One user who has a 3D printing service implemented this in their operation and found it to be a great addition to print plenty of hours throughout the day.

The pankcake stepper motor is nice and compact, but you can even go with a Genuine E3D Slimline Motor to get an even more compact stepper.

Depending on what 3D printer you have, you can find an applicable mount on Thingiverse, which you’ll want to print out of ABS or PETG for the higher heat resistance.

Pros of the E3D Titan Aero

- Great space-saving design.

- Has a wide selection of accessories.

Cons of the E3D Titan Aero

- It is expensive.

- Assembly can be a bit complicated.

Final Thoughts

The Titan Aero offers a proven high-quality extruder and hotend design in a compact package. If you’re looking to revamp your extruder setup, this is the one for you.

But, if you’re already using a Titan extruder or a V6 nozzle, then this upgrade might not change much for you.

Get the E3D Titan Aero from Amazon.

Price: Around $85 | Material: High Strength Copper, Hardened Steel and Brass Alloy | Temperature Range: 500°C | Compatibility: All printers compatible with V6 / 1.75mm Filaments

The Phaetus Dragon is a premium all-metal hot end made for printing at high temperatures. It provides efficient thermal performance with consistent filament flow at high speeds.

This is due to the insulation provided by its heat break and the low inner roughness of its nozzle.

The Phaetus Dragon diverges from conventional hot end design by connecting the heat block to the heat sink with four stainless steel tubes. The heat transfer between these parts is lowered considerably with this design.

It also gives the hot end additional structural rigidity, which makes one-handed nozzle changes possible.

Nozzle replacement is made easier due to the internal frame structure, so it can be done without needing to hold the heat block.

User Experience

Setting up the Phaetus Dragon is very easy due to its compact design. Although the Phaetus Dragon does not come with electronic parts in the box, it’s compatible with accessories used for the V6.

During printing, the hotend performs as advertised, spitting out filament consistently at high temperatures. However, users have reported clogging issues on the hot end. The clogging issues have been attributed to the improper mounting of the hotend.

Despite all these, when it comes to print quality, the Dragon consistently produces high-quality results.

If you do use a temperature of above 250°C for a long time, you’ll want to take the silicone sock off the hotend to prevent damage.

Pros of the Phaetus Dragon Hotend

- Fast heating and heat dissipation due to the copper build.

- High filament flow rate.

- High-temperature resistance.

Cons of the Phaetus Dragon Hotend

- Electronics do not come in the box.

- It clogs when printing with some materials.

- It is expensive.

Final Thoughts

The Dragon hotend is one of the best hotends on the market right now. If you’re looking for top-quality thermal performance at high printing speeds, then this hotend is for you.

You can find the Phaetus Dragon Hotend from Amazon.

Price: Around $160| Material: Copper Alloy (Heater Block), Copper Heat sink), Stainless Steel (Heat Break) | Temperature range: 450°C | Compatibility: Almost all printers / 1.75mm Filaments

The Mosquito Hotend is one of the more modern products on this list, but it is already proving to be one of the best.

It brings a new radical hot end design to the table. Instead of the traditional heat break, it builds everything off a single metal frame.

This gives it thermal and mechanical advantages over conventional hotends.

Why is this important? Since the heat break isn’t required to connect the parts, a more efficient copper heat sink can replace the traditional stainless steel heat break. It also makes installation easier since there are fewer parts.

It also makes installation easier since there are fewer parts.

Compared to a normal hotend, the heat break conducts 85% less heat into the heat sink compared to a normal heat break. You don’t need a large heat sink due to the reduction in heat transmission.

Also, with fewer moving parts in a compact design like that, the durability is increased.

It is an adaptable piece of kit that has four different mounting options, machined adapters, and plenty of options to mount to the 3D printer of your choice. You’ll find adapters on Thingiverse as usual.

They say how it’s especially ideal for 3D printers that support multi-extrusion setups.

When you get the Mosquito Hotend, it comes as a package:

- Mosquito Magnum Hotend

- Cooling Fan – 12v

- Mounting Kit – 9 screws, 2 washers, zip-tie

- 3 Hex Keys

Installing the Mosquito Hotend is very easy due to its design. You’ll need to get a special adapter if your printer’s mount is not supported. It’s as close as you can get to an actual plug-and-play hotend.

It’s as close as you can get to an actual plug-and-play hotend.

Replacing parts like the nozzle is even easier as you can do them one-handed.

Getting new accessories for the Mosquito hot end is no problem, as the hotend is compatible with the V6 range of products. When it comes to print quality, the mosquito hot end is no slouch.

It churns out great quality prints at elevated temperatures justifying its price tag.

Pros of the Mosquito Hotend

- Great design

- Wide range of compatible accessories

- High printing temperature range

Cons of the Mosquito Hotend

- Fairly expensive

- It does not come with electronics in the box

Final Thoughts

The Mosquito Hotend brings a new game-changing design built with top-notch materials to create a great product. It might be a little costly for some, but if you’re looking to upgrade to the best, then it doesn’t get any better than this.

Check out the Mosquito Hotend on Amazon for a real improvement in your 3D printing.

Price: Around $25 | Material: Aluminum, Stainless Steel, and Brass | Temperature Range: 260°C | Compatibility: Select Creality Printers. / 1.75mm Filaments

The Sovol Creality hotend is a budget option for those looking to replace their stock hot ends cheaply. It comes with a fully assembled hotend extruder array and 0.4mm nozzles. This is one of the cheapest all-metal hot ends on the market.

You’ll probably find this to be one of the most popular hotends out there due to it’s price, effective output, and ease of use.

This happens to a 100% Creality Original, where they have silver and golden versions. It comes with the top quality Capricorn PTFE tubing which has good lubricity, as well as high temperature resistance so it won’t give up on you so easily.

Many people have seen 3D print quality improvements just from the PTFE tubing alone.

This hotend kit is very easy to plug into your 3D printer.

User Experience

The hotend comes fully assembled with a threaded connection for easy installation.

The experience with the Sovol Creality Hotend are mostly positive, with one user stating how they had some feeding and retraction issues with their Ender 3 Pro. Once they installed the new hotend with the PTFE tubing, they got great results.

It’s a pretty standard replacement for your Creality 3D printers, and you can expect grat performance like thousands of other users sout there.

When it comes to the thermal performance, this hot end performs how you’d expect a budget hotend to, poorly. The print temperature maxes out around 260℃. This makes it unsuitable for high-temperature applications.

Some users have complained about getting substandard products different from the specifications shown, so be careful to get yours from a trusted vendor.

Make sure that you have the right voltage for your unit since it is a 24V unit. If you run into some issues where your 3D printer doesn’t heat up as well, check your power supply and your controller.

If your power supply is set to run at 220V, people say changing it to the 110V input gets it working as it should. In terms of the controller, you won’t get the right heating if you have a 12V controller, so check your power supply is 12V.

Pros of the Sovol Creality Extruder Hotend

- Comes with its electronics in the box.

- It is cheap.

- Comes fully assembled

- Easy to install into your 3D printer

Cons of the Sovol Creality Extruder Hotend

- The printing temperature range is low compared to other hotends

Final Thoughts

If you’re looking for a hot end to replace or upgrade what you have without breaking the bank, then this is for you. Just beware, you get what you pay for, nothing more and a little bit less.

Hotend Buying Guide

Quality hot ends can seriously change your printing activities for the better, but they can also be costly.

With an increasing amount of clones of famous brands on the market, it’s best to know what to look out for to avoid wasting money on substandard products.

To help in making your purchase decisions, let’s look at some of the things that make up a quality hot end:

Material And Build Quality

The type of materials used in the construction of the hot end is very important. It determines the mechanical properties of the hot end like durability, wear-resistance, and thermal conductivity.

The material can also influence the type of filaments used and the maximum print temperature.

When discussing materials, there are two main camps – All metal and PTFE hot ends. In this article, there is more of a focus on All-Metals hot ends. All-metal hotends can be built from brass, steel, or even aluminum.

The build quality is also a crucial property. Machined hot ends with modular, simple, and compact designs often fare better since there are fewer moving parts. They rarely suffer from flaws like clogs or creep because of their design.

Temperature

The print temperature required is also a factor to consider when picking a hot end. When printing materials that need high temperatures like PEEK, it’s best to go for sturdier all-metal hotends.

When printing materials that need high temperatures like PEEK, it’s best to go for sturdier all-metal hotends.

These hot ends can resist the thermal stresses encountered efficiently.

Accessories

Accessories cover all the functioning parts of the hot end ranging from the heating block to the nozzle. For the best results, it’s best to use hotends with a modular design. You can change components on these hotends as the situation requires.

These accessories include nozzles, thermistors, etc.

Also, with components like heater cartridges and thermal probes that fail frequently, the importance of quality accessories cannot be understated. If they fail, it’s crucial to know you can easily find replacements.

Compatibility

All hotends are not universally compatible with all printers. There are usually differences that pop up due to differences in firmware, printer configuration, etc.

A mark of a good hotend is it is compatible with a wide range of printers without requiring much in the way of modifications.

Tips For Buying A Great All-Metal Hotend

Factoring in all the advice given above, I’ve come up with some tips to help guide you when purchasing your hot end. These tips are a checklist of sorts to follow before making a decision.

Let’s take a look at them:

- Always double check to see if the nozzle is compatible with your 3D printer.

- If there are a lot of knockoffs, then the hot end is a great product. Just be careful not to buy a fake.

- Always check if the hot end you are using can handle the material you want to use. Not all hotends can handle abrasive, flexible, or high-temperature filaments.

- When printing for food or medical applications, never get a brass nozzle. Stick with non-toxic metals like steel or aluminum.

Advantages And Disadvantages of All-Metal Hotends

Earlier in the article, I mentioned that there are many types of hotends like all-metal, PTFE, and PEEK. But throughout this list, I’ve focused on all-metal hotends to the detriment of all others.

This is because all-metal hotends offer certain advantages that other brands do not. Let’s take a look at some of these advantages:

- All-metal hotends can print at higher temperatures.

- They can handle a wider range of filaments better.

- The PTFE liner no longer has to be replaced regularly.

Although all metal hotends are better performance-wise than their peers, there are still some areas where these other hot ends take the cake over them. Some of these disadvantages are:

- They are more expensive than other hotends

- They produce slightly worse results at lower temperatures.

- Jamming and clogging are more likely to happen

Top 5 extruders for 3D printer Anet A8

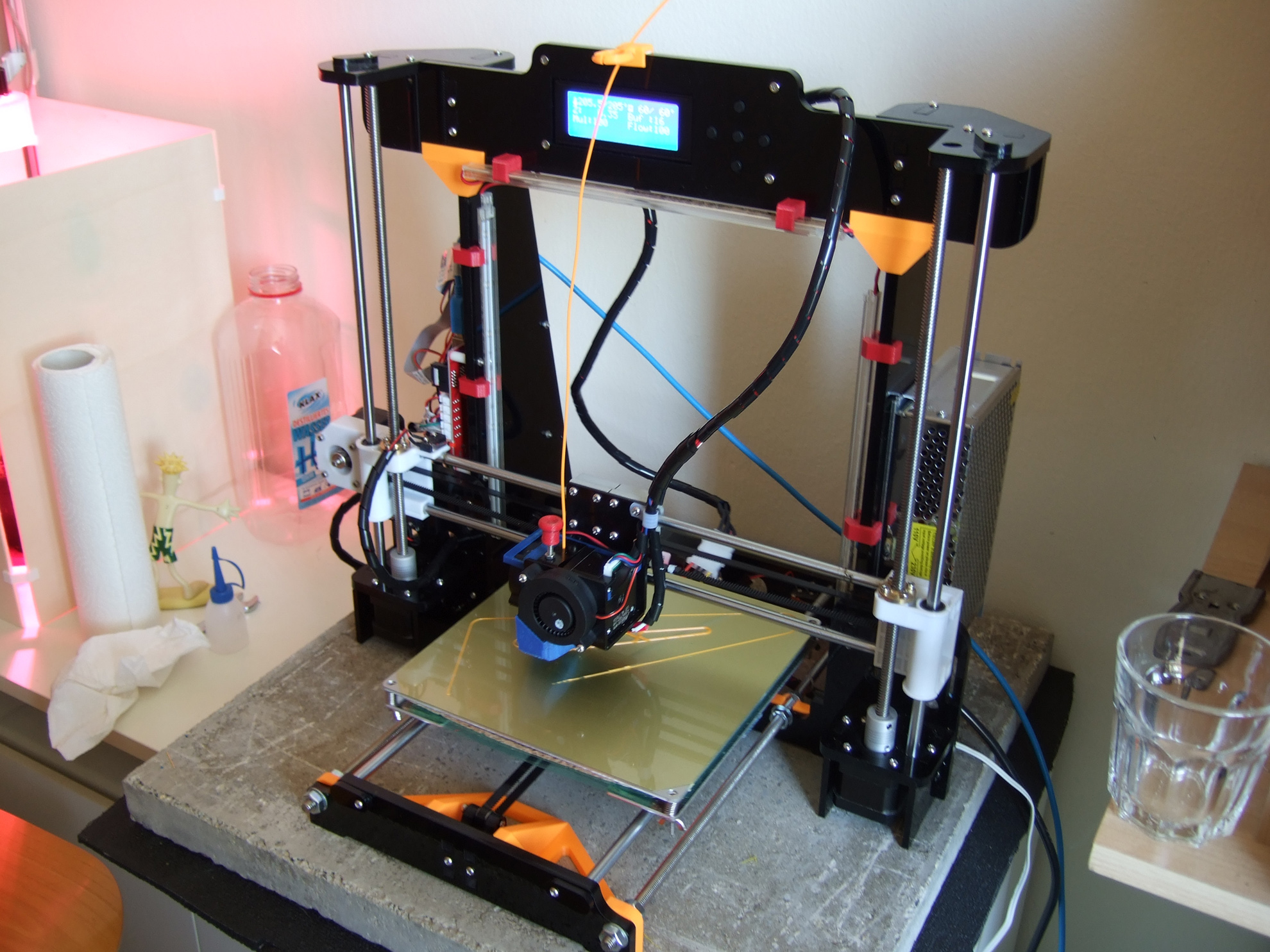

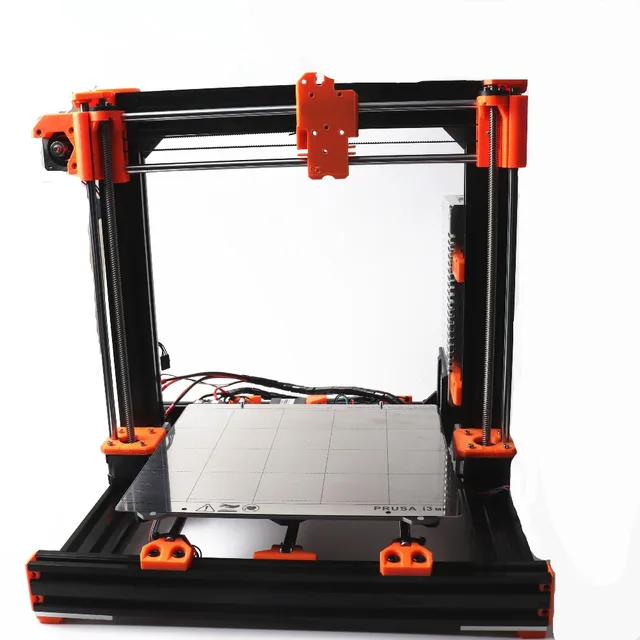

The Anet A8 is a very popular 3D printer due to its affordability and wide customization options. This is certainly an interesting project that you can assemble yourself or buy as a set. Thanks to its affordable price and clear design, Anet A8 has long been the "people's 3D printer" and a great option to get acquainted with the intricacies of 3D printing.

Due to the extensive modification options, 3D printing results on the Anet A8 can vary greatly. And some modifications simply turn this model into an analogue of expensive 3D printers in terms of 3D printing quality. There are a lot of modifications on the Internet, and in this article we will touch on the modifications of one node - the extruder. Believe me, there are a lot of modifications to the Anet A8 extruder and they are worth discussing.

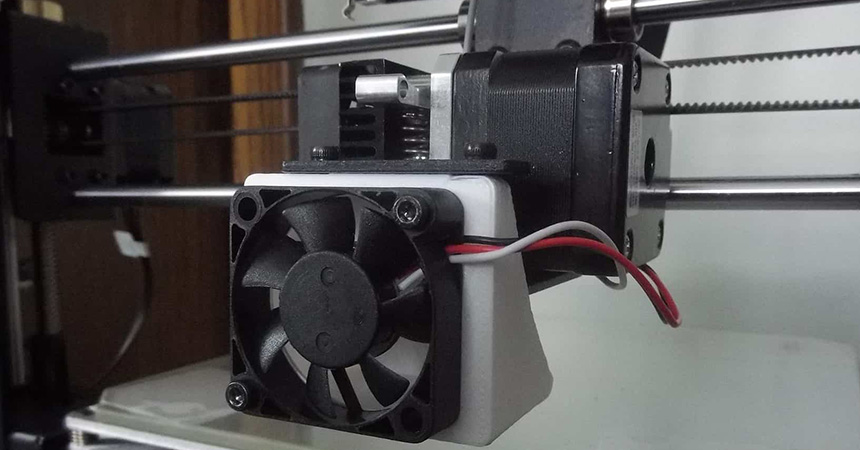

For example, the original design of this 3D printer does not include a duct fan to help direct air from the Anet A8 extruder fan to the nozzle. And air is needed to cool the extruded plastic and keep the 3D printer in proper working order. But there is also good news - Thingiverse already has a lot of mods for blowing. Here's a great one from a user named Arjjck.

One of the simplest mods is adding an extruder button to make it easier to use the 3D printer. This 3D printed button is definitely better than the standard extruder screw, which is almost impossible to press with your fingers. Such a simple 3D printed Anet A8 extruder button will save you the pain of changing 3D printing material.

Such a simple 3D printed Anet A8 extruder button will save you the pain of changing 3D printing material.

Extruder replacement is one of the Anet A8 upgrades that can greatly improve 3D print quality, so let's take a look at the interesting options.

E3D Titan extruder

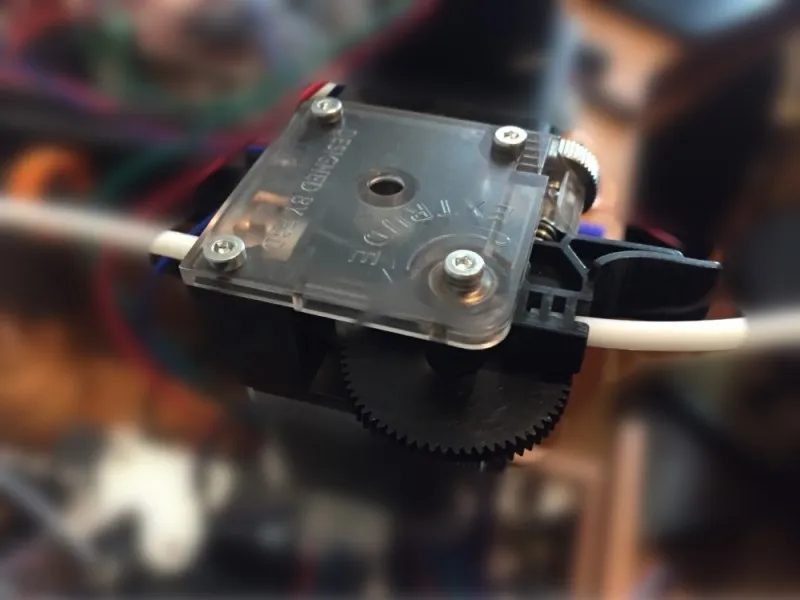

The E3D Titan extruder is ideal for those who want to print using different materials, not just PLA plastic. The lightweight E3D Titan reduces clogging and features specially machined teeth that are curved to grab fibers at right angles. The teeth improve the grip of the thread and increase the accuracy of its feeding.

This extruder has been manufactured to increase torque, reduce clogging and 3D print at higher resolutions. It is designed for use with the E3D v6 hotend, allowing you to print at higher temperatures, and the 3:1 gear ratio ensures more precise movement.

According to the manufacturer, this ratio gives the E3D Titan extruder the best performance in terms of accuracy and speed. Obviously lower gear ratios run too slow while higher gear ratios run too fast. Thus, the manufacturer concluded that a ratio of 3:1 is the best option, allowing the extruder to cope with the required degree of extrusion. The gear ratio increases resolution and promotes smooth 3D printing at low layer heights.

Obviously lower gear ratios run too slow while higher gear ratios run too fast. Thus, the manufacturer concluded that a ratio of 3:1 is the best option, allowing the extruder to cope with the required degree of extrusion. The gear ratio increases resolution and promotes smooth 3D printing at low layer heights.

The extruder supports 3D printing with 1.75 mm and 3 mm filaments and allows the use of materials such as abrasive carbon fiber, TPU, TPE and a number of other harder plastics. The E3D Titan has a solid construction thanks to injection molded parts. Unlike other more clumsy extruders, the design details eliminate the possibility of wiggle and improve accuracy. In addition to being lightweight for more torque, the E3D Titan has been built to be easy to assemble or disassemble.

LulzBot Taz Single Extruder Tool Head v2

LulzBot TAZ Single Extruder Tool Head v2 comes with a solid metal hex and can withstand temperatures up to 300°C (572°F). Thus, you will not have problems with materials such as ABS, PLA and HIPS. You can also use materials such as T-Glase, polycarbonate, nylon, as well as various types of threads filled with stone and wood.

You can also use materials such as T-Glase, polycarbonate, nylon, as well as various types of threads filled with stone and wood.

The extruder comes with two fans, one for the nozzle to help produce highly detailed prints, and one for the heatsink. The LulzBot Taz has gone through countless hours of testing and is a suitable replacement for the Anet A8 extruder.

Single Flexion Retrofit Kit Extruder

This extruder is much better than the standard Anet A8 extruder and guarantees high resolution and fewer failures. The Extruder Upgrade Kit includes precision machined components that give you the ability to print at full speed on flexible materials, using adjustable fine filament tension to maintain high 3D printing accuracy.

The Flexion extruder pushes the filament harder and the self-cleaning drive ensures no clogging during long 3D prints. This extruder uses a high rigidity lever to compress the filament, and an adjustable screw and cam is used to control the compression - for precise tension control. The Flexion extruder will work well with TPU, TPE, flexible PLA, Filaflex and Ninjaflex in addition to standard materials like PLA, PETG or ABS.

The Flexion extruder will work well with TPU, TPE, flexible PLA, Filaflex and Ninjaflex in addition to standard materials like PLA, PETG or ABS.

Flex3Drive Extruder

The Flex3Drive extruder is compatible with a wide range of hot ends and has a ratio of 40:1. With this ratio, it will print great first layers. It provides a direct feed to the hotend, but the motors are spaced apart to reduce moving mass and lighten the extruder. This results in smoother print head movement and reduces vibration.

This shaft-driven extruder is compact, small and fairly light. The extruder is equipped with cam-lock tensioners for constant material tension without the use of springs or screws. This is particularly suitable for tough materials, but there is an adjustable thread tension lever that does not require a firm grip.

Material loading is greatly simplified and the filament can be changed without stopping the 3D printing process.

Mounting the Flex3Drive hot end on the bottom of the extruder can be a pain, but worth it. This extruder is suitable for working with nozzles of the widest diameter. The drive gears are made on high-precision CNC machines, so there are no questions about the quality of the manufacture of these extruders.

This extruder is suitable for working with nozzles of the widest diameter. The drive gears are made on high-precision CNC machines, so there are no questions about the quality of the manufacture of these extruders.

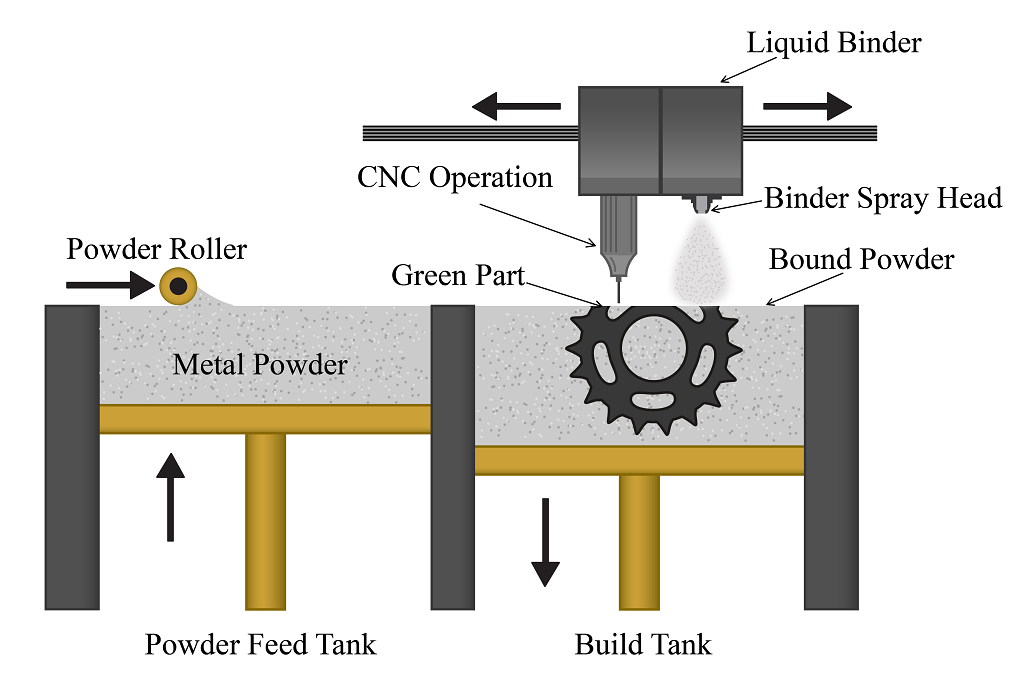

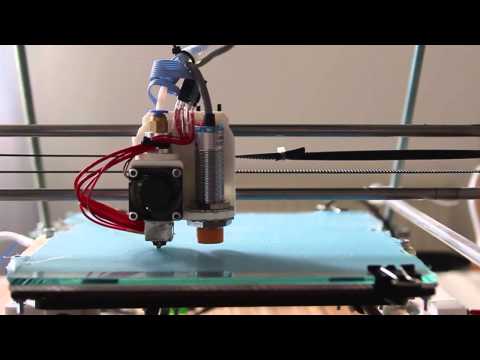

Bowden Type Extruders

Well, here's the holi comrade on our list of the best Anet A8 extruders. Bowden type extruder. An extruder in a Bowden layout means that the hot end is physically separate from the extruder. Typically the extruder is mounted on the inside or back of the Anet A8 3D printer and works like a "remote" extruder in the same way as a direct extruder: grabs the material and pushes it. However, the main difference is that the thread must pass through the tube before it reaches the hot end.

The Bowden Extruder significantly reduces the weight that the carriage needs to move during 3D printing and reduces carriage vibration, backlash and twitching. This is because when the extruder (with its mounts and motor) is out of the way, only the hot end can move. Therefore, less momentum needs to be overcome, and this makes Bowden designs the best choice for 3D printing complex parts.

Therefore, less momentum needs to be overcome, and this makes Bowden designs the best choice for 3D printing complex parts.

But this type of extruder has a downside. The separation of the hot end and extruder usually causes a delay or hysteresis. A longer material path means longer contact and more friction that the extruder must counteract. Therefore, the motors will need more torque to deliver the filament to the hot end. This makes it difficult to use Bowden extruders with flexible filaments. The longer path also means that the filament can warp, shrink, or stretch, resulting in inconsistent 3D printing.

While the Bowden extruder may work well on the Anet A8 3D printer, it may require some technical knowledge to install as the above issues may require certain settings in the 3D printer firmware. Hence, buying a Bowden type extruder can cause problems if you are not a true 3D printing enthusiast.

On the other hand, if you are confident in your skills and have no problem setting up your 3D printer, the Bowden Extruder may come in handy. With the right settings, you can get cleaner and smoother 3D models.

With the right settings, you can get cleaner and smoother 3D models.

Direct extruder for a 3d printer: an overview of the best types and types, which one is better to choose

The extruder is called the working head of a 3D printer. The plastic thread passes through it, melts and is squeezed out through the nozzle onto the work table. This is how objects are built layer by layer.

Types of extruders for 3D printer

There are two types of extruders: direct and bowden. They are slightly different in design and have their pros and cons.

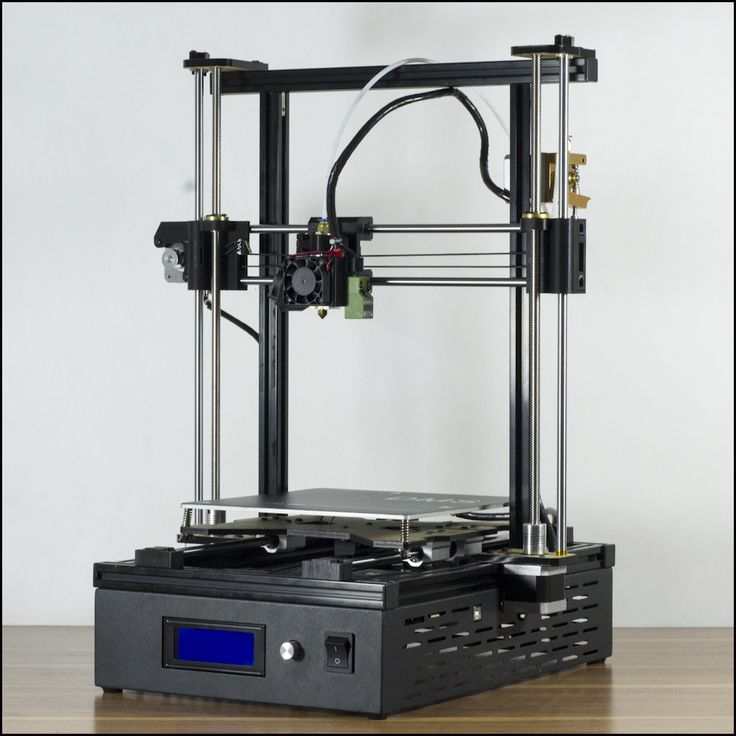

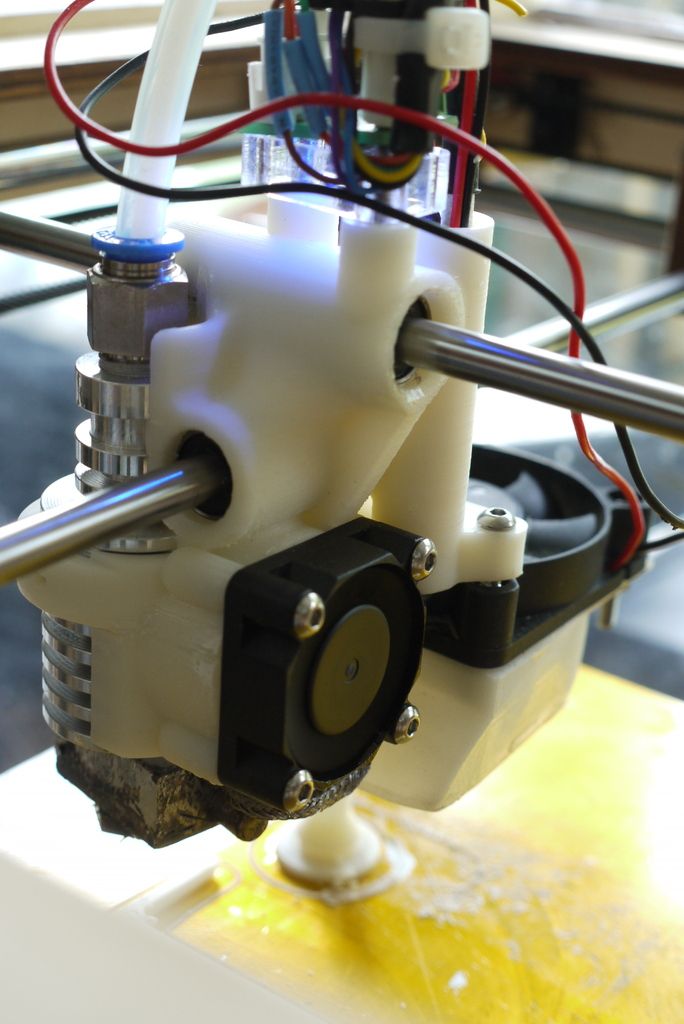

Direct extruder

Direct extruders are located directly above the hot end. Due to this, the distance from the gear train is minimal, which ensures more reliable work with flexible threads.

If a direct head is installed on the printer, this does not mean that it will print well with flexible filaments. In order for the print to be of high quality, it is necessary to monitor the position of the clamp, as well as pay attention to the gear device.

![]()

Direct extruders have more precise retraction control compared to Bowden. Positioning above the hot end significantly reduces the distance between the thread and the clamp. Therefore, the thread has less room for bending.

The direct printhead is bulkier. Because of this, inertia increases. Good print quality requires a solid rail design. Also, large head sizes affect print speed.

Main advantages of direct extruders:

- Media can be changed quickly and easily;

- minimum feed distance reduces error;

- can use flexible heads at relatively high speeds.

Disadvantages:

- increased weight compared to bowden;

- head design is more complex.

Bowden Extruder

When using the Bowden Extruder, the gear train and the motor are assembled on the machine frame. The weight of such a print head is less than with a direct extruder.

Bowden's main disadvantage is that as the thread travels through the Teflon tube that connects the hot end and the feed mechanism, it can deviate. The amount of deflection depends on the length of the tube. This disadvantage is especially pronounced during the use of flexible plastics. The print settings and the amount of retraction must be selected empirically.

The problem of friction must also be solved. The thread must be pushed through the tube. It is important that the torque is sufficient to carry out this process.

REFERENCE. Most home delta 3D printers come with bowden extruders.

Advantages:

- reduced weight of the carriage due to the fact that the engine is located on the frame;

- The print head is small.

Disadvantages:

- Printing with flexible plastic is difficult;

- needs a powerful motor to feed material;

- Printer error increases in proportion to tube length.

What is the best filament extruder to buy?

Now the cost of 1 kg of the cheapest thread is about $20. And the price of plastic from trusted manufacturers can reach up to 50% per 1 kg. Therefore, the issue of self-manufacturing of the filament is very relevant.

Filament extruders:

- Liman extruder. This device was invented by Hugh Liman. It can make filament with a diameter of 1.75 and 3 mm with an error of 0.01 mm and saves about 80% on the purchase of filament.

- Fischer extruder or STRUdittle. This is a compact device that allows you to make thread from ABS plastic. The speed of work is 30-60 cm per minute. The error does not exceed 0.05 mm if the filament is freely output. If you use a spool that automatically winds the thread, then the error is reduced to 0.03 mm.

- Filabot Original. The most famous development, which has good performance. Can work with ABS, HIPS and PLA.

The starting material can be granulated plastic or plastic waste. If waste is used, the particle size should not exceed 5 mm.

- FilaMaker. The device combines the functions of a crusher and an extruder. It has a neat design, high functionality and good performance. Can produce up to 1 m of filament per minute with an accuracy of 0.05 mm. The only drawback is the high price - $1200.

- Filastruder. Relatively cheap extruder, with which you can get 1 kg of thread in 12 hours. The speed of work is from 15 to 60 cm per minute. Speed depends on operating temperature, nozzle diameter and material used. The device is designed for ABS, but it can also be used for PLA, HIPS and nylon.

Overview of 3D printer extruders

Below are the most popular 3D printer extruders with detailed specifications.

MK8

This is the most popular direct extruder. It is easy to install and easy to use, suitable for most 3D printers. Costs approximately $15.

Device specifications:

- Thread diameter 1.75 mm;

- nozzle diameter can be from 0.2 to 0.5 mm;

- 12 V and 40 W heater;

- operating speed - 4 cm per second;

- device weight 450 g;

- operating temperature - from 190 to 250 degrees.

E3D TITAN AERO

Key features of the E3D TITAN AERO:

- direct drive;

- all-metal thermal barrier;

- maximum temperature - 285 degrees;

- gear ratio - 3 to 1;

- is suitable for flexible plastics.

The device is easy to install and easy to use. The original costs about $170, but you can buy a Chinese equivalent for about $40.

Includes:

- standard or mirror housing;

- heat sink;

- mounting connectors;

- fan;

- heating block;

- nozzle;

- Teflon tube;

- thermal paste;

- idle lever;

- thermistor cable and cartridge.

Learn more