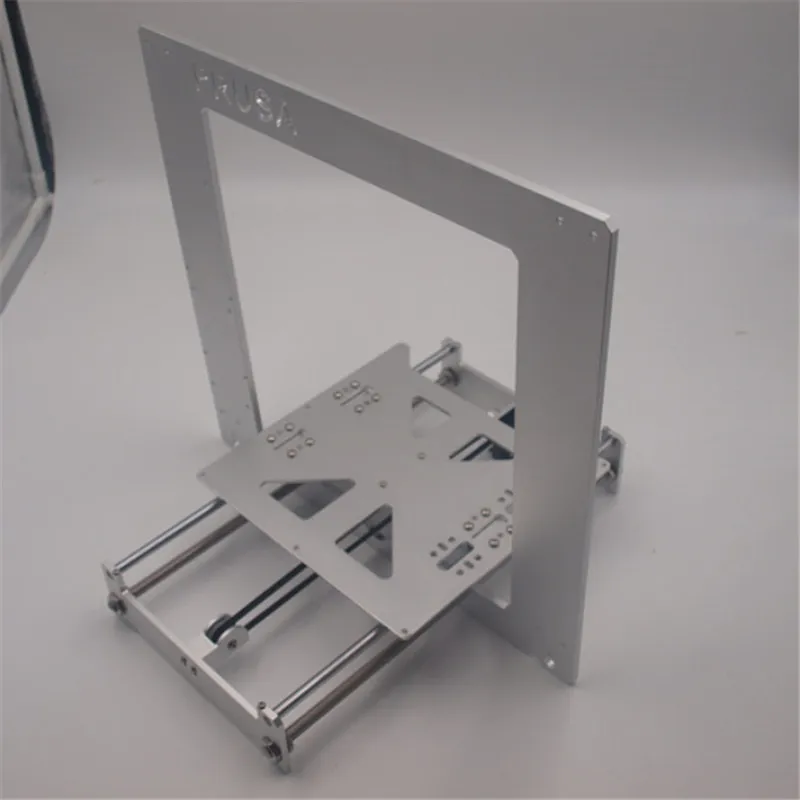

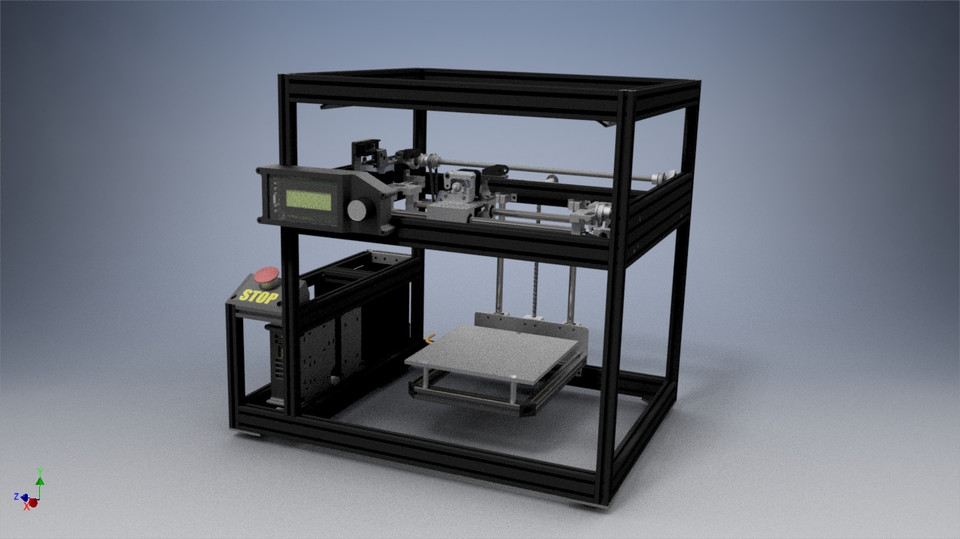

Minifab 3d printer

Minifab 3D: a new tooth within one hour, instead of days

By Milan Lenters

For many people it is a nightmare; a visit to the dentist. And all the more if you have to come back several times for a crown, for example. Minifab 3D wants to make sure that these “cowards” only have to make a single visit and are outside again within half an hour. Including a new crown in their mouths. This Mexican startup develops 3D printers specifically for dentistry to print crowns, new teeth and dental parts. “Dentists can spare a lot of time, instead of 15 actions they only have to perform three. As a result, patients are lying in the chair for a shorter time.”

Paola Dulanto is a dentist in Mexico and sees a lot of people who don’t like to come back for a second time (or third or fourth..) for a new tooth. That process could be done quicker, so she thought. Fabien Legay produces 3D printers for the consumer market in Mexico. Wouldn’t that be a good combination? Dulanto thought. Teeth and 3D printers. One and one is two.

Rooftop startup

About six years ago Minifab 3D started – “not in the garage like all Silicon Valley startups, but on the roof, because that’s where startups arise in Mexico.” – Legay wanted to start a business in drones. “But I couldn’t get parts anywhere. Where should I get them from?” Legay is shrugging his shoulders. He decides to build a 3D printer in order to make the parts for drones himself. “By the way, the first 3D printer I made was made out of wood.” Dulanto starts laughing: “but this drone never came, instead we are the market leader in Mexico in the field of 3D printers and everything that goes with it”.

Minifab 3D not only supplies printers to consumers but also delivers print materials and service to people who can’t manage to work it out for themselves. This goes so well that they were allowed to pitch for HighTechXL via a program of the Mexican government. That’s how they ended up in Eindhoven. “It took a lot of getting used to it at first”, says Legay, “nobody knows us here, so we have to show what we can do and that our product is good”, then laughing: “sometimes that’s frustrating. In Mexico, we are a successful company. We know we have something good, but not everyone here knows that yet.”

That’s how they ended up in Eindhoven. “It took a lot of getting used to it at first”, says Legay, “nobody knows us here, so we have to show what we can do and that our product is good”, then laughing: “sometimes that’s frustrating. In Mexico, we are a successful company. We know we have something good, but not everyone here knows that yet.”

Validating is key

At HighTechXL, they need to think about the market they’re tapping into right away. Can they serve the Netherlands with the same strategy as in Mexico? Dulanto’s experience as a dentist comes in handy here. “By developing a printer that makes it possible to print teeth with bio-resin, people don’t have to go back to the dentist four times. Instead of two weeks, it only takes a few hours,” tells Dulanto.

Unlike in Mexico, they do not focus on consumers in the Netherlands, but on dentistry. “We have had a great number of interviews in recent months to see what dentists are running into, what could be improved? Are they willing to buy a 3D printer? We had to validate everything from the very beginning. The fact that I am a dentist myself is an advantage. I know what’s going on.” she says. Legay complements it: “It’s incredibly hard work, you have to constantly prove yourself and show yourself everywhere. Showing how it works and explain the advantages over the traditional way. Sometimes it feels like we have to do everything all over again. But we learn a great deal out of it. We are pushed to make the most out of this programme.”

The fact that I am a dentist myself is an advantage. I know what’s going on.” she says. Legay complements it: “It’s incredibly hard work, you have to constantly prove yourself and show yourself everywhere. Showing how it works and explain the advantages over the traditional way. Sometimes it feels like we have to do everything all over again. But we learn a great deal out of it. We are pushed to make the most out of this programme.”

Every Sunday the best articles in your inbox!

Scaling up

Minifab 3D is currently negotiating for a partnership with DSM to provide the material for the teeth. “It is bio-material and has all kinds of safety labels including one from the FDA. Such a partner would give confidence, it is a signal to the outside world that we know what we are doing.” The company will soon start a trial with about 10 3D printers in the Netherlands. Dental practices in Mexico have also come forward willing to participate. “We’re going to analyse this trial and see what can be improved on the printer. The intention is to quickly scale up to 100 printers.” according to Legay, this is possible because they already have so much experience in Mexico, and their latest model is four times faster than the competitor’s, he says proudly.

The intention is to quickly scale up to 100 printers.” according to Legay, this is possible because they already have so much experience in Mexico, and their latest model is four times faster than the competitor’s, he says proudly.

When asked where they want to be in five years’ time, an ambitious answer follows: “five years? We are not looking ahead that far. We believe we can deliver results much earlier. Within 1 to 2 years we will be able to take significant steps in this market. Our aim is to grow rapidly in Europe. We already understand the mentality in the Netherlands better and better, sometimes the language is still a barrier. But we are open-minded and convinced that we are going to succeed.”

Support us!

Innovation Origins is an independent news platform that has an unconventional revenue model. We are sponsored by companies that support our mission: to spread the story of innovation. Read more.

At Innovation Origins, you can always read our articles for free. We want to keep it that way. Have you enjoyed our articles so much that you want support our mission? Then use the button below:

We want to keep it that way. Have you enjoyed our articles so much that you want support our mission? Then use the button below:

Donate

€

Personal InfoFirst Name *

Last Name

Email Address *

Fabrikator Mini 3D Printer - V1.5 - Transparent

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total Price

$0.00

Cart 0

want FREE shipping? Click here to find out more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshipppingEnabled}} Free Shipping on Eligible Orders {{/isFreeshipppingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9Enabled}} {{#list_image_url}}{{/list_image_url}} {{^list_image_url}}{{/list_image_url}}

{{#isFreeshipppingEnabled}}

Free Shipping on Eligible Orders

{{/isFreeshipppingEnabled}} {{#isAddToCartEnabled}} {{#isWarehouseAddToCartEnabled}} {{^is_combo_product}}

QTY: {{#isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}} {{^isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}}{{/is_combo_product}} {{/isWarehouseAddToCartEnabled}} {{/isAddToCartEnabled}} {{#availableInOtherWarehouses}} {{{availableInOtherWarehouses}}} {{/availableInOtherWarehouses}} {{#is_combo_product}} {{^isProhibited}} View Details {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Fabrikator Mini 3D Printer - V1.5 - Transparent

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00

Basket 0

{{/findAutocomplete}}

{{/isPromoted}} {{/isFlashDealEnabled}} {{#isPromoted}} {{/isPromoted}}SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#rating_summary}}

{{/rating_summary}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}} 9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Industrial Micro 3D Printing in Microelectronics

Contents

Introduction

The continuous development of the technical process results in electronics becoming smaller, more densely packed and subjected to more stringent conditions. Miniaturization, the growing number and density of electronic components, and higher data rates that generate more heat are just some of the challenges electronics designers face today.

Miniaturization, the growing number and density of electronic components, and higher data rates that generate more heat are just some of the challenges electronics designers face today.

Regardless of component size, engineers need electronic connectors that connect securely and retain their thermal and mechanical properties. If a smartphone or avionics connector does not meet the requirements for form, fit, and function, product launch may be delayed.

During the design process, engineers need prototypes that are as close to production quality as possible. During testing, it is very important to meet well-defined requirements. The electronics industry also needs a smooth market entry and support for faster production and efficient assembly.

Issue

Traditionally, manufacturers have used micro-injection molding to produce electronic components such as connector bases, chip sockets, and fiber array brackets.

Unfortunately, casting has two significant drawbacks, because this process requires a lot of time and financial costs. Making a tooling can take anywhere from 10 to 12 weeks. Moreover, if the final design changes, then all the created technological equipment for casting will simply not be needed, which will lead to additional costs.

Making a tooling can take anywhere from 10 to 12 weeks. Moreover, if the final design changes, then all the created technological equipment for casting will simply not be needed, which will lead to additional costs.

Solution

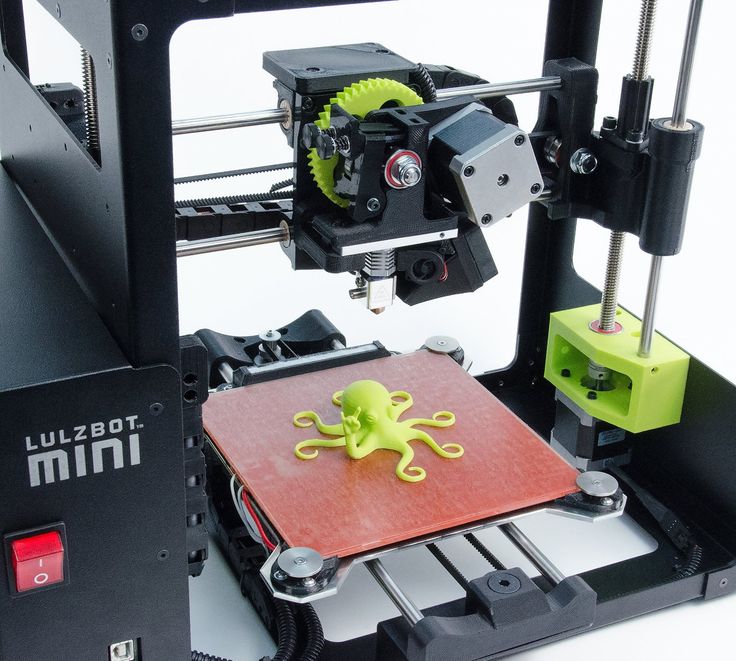

3D printing eliminates the need for injection molding tooling and can reduce time to market across multiple design iterations and test cycles. However, most 3D printers for creating small parts force engineers to compromise between production speed, part accuracy and surface quality.

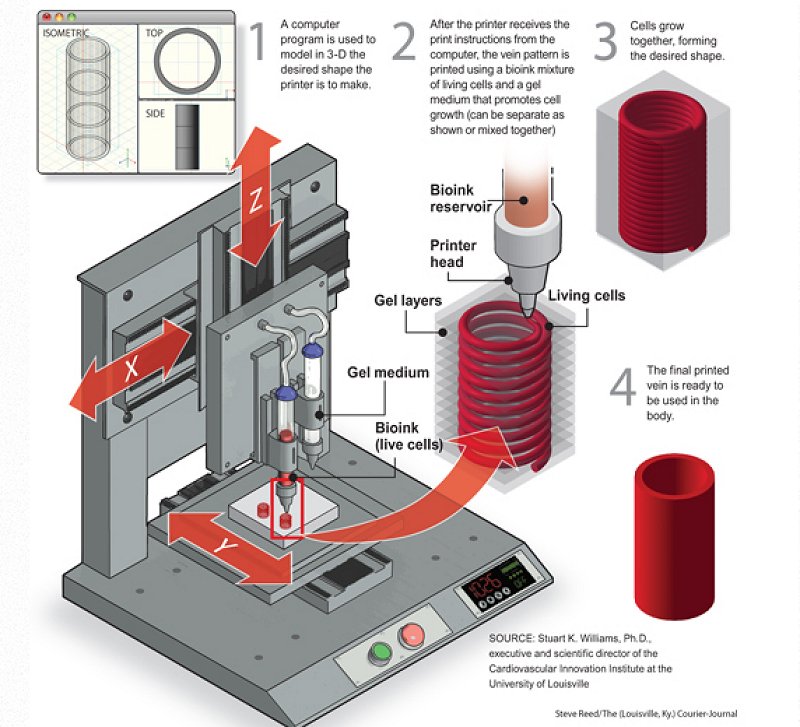

Boston Micro Fabrication offers a one-stop solution for all the industry's challenges and challenges. BMF's Projection Micro-Stereolithography (PµSL) technology allows you to quickly print small electronic components with the exact specifications required for parts such as electronic connectors. Today BMF offers a unique micro 3D printing solution that matches precision injection molding in terms of resolution, size and tolerances. PμSL supports electronics manufacturing in other ways as well.

Result

Electronic components printed using PµSL technology use photopolymer resins with reliable thermal and mechanical properties. This is important in applications where 5G products are exposed to high temperatures, need to be securely connected, and ensure efficient assembly. During PCB assembly, for example, reflow soldering exposes surface mount components to high temperatures. In IC sockets, integrated circuit (IC) pins must provide reliable but solderless connections. Both methods require reliable components that withstand the test and achieve the required volumes.

LGA chip package

Approximately 2500 trapezoidal holes. Each hole has a raised structure

Length 75 mm ± 25 µm / Print time: 3 hours / 1 piece ( S 140)

Microxyma panel

(376 holes / distance 0.2mm ± 0.025mm)

9000 9000 9000 The foundation of the connecting0092

(Minimum hole diameter 0.

Learn more