Mighty buildings 3d printed homes

Mighty Buildings - Beautiful, Sustainable Homes for All

Welcome to

Stop choosing between speed, design, & protecting the planet.

Build with us

Faster construction time

Less waste generated by 3D printing

More tensile and flexural strength vs. concrete

Combining 3D printing, robotics, & material science

View technology

Mighty Kit System

Pre-built, factory-made 3D printed panels can be customized to any plan. They are assembled onsite, cutting construction times in half.

Learn more

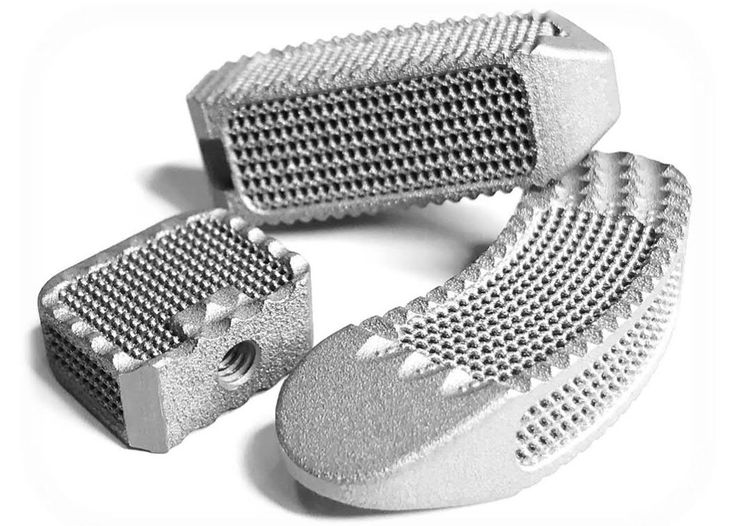

Material Science

Our patented Light Stone Material quickly cures into a stone-like composite and has 4x the tensile and flexural strength of concrete while weighing 30% less.

Learn more

Of production operations automated

Mighty Factory

We build panels in our factory and deliver them onsite ready to assemble, saving time and emissions.

Learn more

Recycled materials

Less waste produced per home

Homes built to reduce and withstand the effects of climate change

3D printing and our composite stone material, made from 60% recycled resins, allow us to build walls with less material and eliminate 99% of waste.

Sustainability

Developing for diverse communities and environments

We bring beautiful homes to market 2x faster. Customizable panels can be arranged in nearly any plan.

Mighty developments

Faster construction

Cut construction times in half

Beautiful homes, healthy planet

We are transforming residential construction through fast and versatile modern design that reduces time, labor, and waste.

About us

Design capabilities

Our kit system design quickly delivers almost any floor plan and our 3D printing capabilities offer unique exterior design possibilities.

Time and labor savings

Speed through design and assembly with less skilled labor and get faster returns on investment.

Environmental benefits

Our walls made from material composed of 60% recycled, sustainably sourced components, and produced with 99% less waste.

Why Mighty Buildings

"It is always challenging to introduce a new technology and a new product to the market. But with Mighty Buildings, it's a company filled with very smart people who are forward thinking and are working to solve problems everyday. And that's what I appreciate about working with Mighty Buildings… this is the Tesla of Housing!"

Basil Starr

CEO & Founder of Palari

"Out of all the modular, offsite fabrication solutions we are currently collaborating with, Mighty House is the most innovative. The Mighty House concept and product is incredibly exciting and is well placed to disrupt the construction industry across the residential sector."

David Herd

Managing Partner at BuroHappold

"UL has worked with Mighty Buildings since 2017 to develop a program for the evaluation of their 3D printed building unit and has successfully obtained the first UL certification for a 3D printed building unit and the first UL Evaluation Report of a 3D printed wall construction. "

"

Howard Hopper

FPE, Regulatory Services Manager at UL

Featured news

View all

November 4, 2022

Mighty Buildings completes 3D-printed net-zero home in southern California

Read more

June 22, 2022

3D printing can help the construction industry become carbon-neutral. Here's how

Read more

April 13, 2022

Airbnb Alums Join House 3D Printing Startup Mighty Buildings

Read more

Build a mighty career

Help us tackle housing and climate crises by building sustainable, beautiful, and mighty homes.

Join our team

Better for people and planet

You don't need to choose between speed, quality, design and protecting the planet, together we can build a better future for the construction industry and the environment.

Build with us

Mighty Buildings - Developments

Featured communities

Mighty House™ QuatroLocated in southern California within a hilltop gated community with inspiring mountain views.

This 2 bed, 2 bath 20-home (40 unit) development features modern zero net energy 1,171 sq. ft. homes built on one of the world’s finest hot spring aquifers. Homes will include an additional Mighty Duo™ ADU, swimming pool, pergola, hot tub, and fire pit.

Build with us

01 / 04

Exterior view of the Mighty House Quatro

02 / 04

Interior kitchen view featuring beautifully designed cabinetry

03 / 04

Interior living space

04 / 04

Close up of the 3D printed exterior texture

Mighty House™ Super Quatro

This southern California development has 30 beautifully designed zero net energy homes with inspiring views of mountainous desert landscapes (60 units total).

The 3 bed / 2.5 bath homes are 2,131 sq. ft. and include an additional 2 bed / 1 bath ADU with a 2 car garage on the property, and access to the community’s swimming pool, cabanas, hot tubs, fire pits, and outdoor showers.

Build with us

01 / 11

Mighty Super Quatro with optional parametric panels and optional Quatro ADU / Garage.

02 / 11

Mighty Super Quatro with optional parametric panels and optional Quatro ADU / Garage.

03 / 11

Mighty Super Quatro with optional parametric panels and optional Quatro ADU / Garage.

04 / 11

Mighty Super Quatro with optional parametric panels and optional Quatro ADU / Garage.

05 / 11

Mighty house interior living space featuring an open floor plan and modern lighting, and space efficient cabinetry.

06 / 11

Mighty house interior living space featuring an open floor plan and modern lighting, and space efficient cabinetry.

07 / 11

Mighty house interior walkway featuring modern LED lighting and space efficient cabinetry.

08 / 11

One of two Mighty house interior bedrooms featuring floor to ceiling windows.

09 / 11

The second of two Mighty house interior bedrooms featuring floor to ceiling windows.

10 / 11

One of two Mighty house bathrooms featuring modern hardware and space efficient design.

11 / 11

One of two Mighty house bathrooms featuring modern hardware and space efficient design.

Mighty House™

Two Story

Located on the Caribbean shores, this new 7-acre community features 3,000 sq. ft. 4 bed / 4.5 bath homes with access to world-famous beaches, with some homes enjoying ocean views.

The community has an advanced water-saving gray water system as well as a pool with pool house, clubhouse gym, BBQ area, and cabanas.

Build with us

01 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

02 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

03 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

04 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

05 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

06 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

07 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

08 / 08

Mighty Two Story shown with optional solar panels and other upgrades.

Reference designs

Floor Plan

Includes

This space and energy-efficient layout has artful kitchen cabinetry, modern appliances, HVAC, washer and dryer, and optional storage and solar panels. Designer: EYRC

1,176 sq ft

4 month assembly

Customizable Features

Floor plan design

Façade texture (exterior)

Paint color

Detail finishes

Floor Plan

Includes

Super Quatro offers the same conveniences, comforts, and space efficiency as Single Story but with an additional bedroom and larger living space.

2,131 sq ft

4 month assembly

Customizable features

Floor plan design

Façade texture (exterior)

Paint color

Detail finishes

First floor

Second floor

Includes

Our open, two-story layout takes elegant, ecological living to the next level with a deck, floor-to-ceiling windows, and modern design, along with all features of other floorplans.

3,000 sq ft

4-5 month assembly

Customizable Features

Floor plan design

Façade texture (exterior)

Finishes

Over 2x faster construction

Choose from a range of designs and order pre-manufactured walls, which arrive 100% complete.

Assemble onsite using standard machinery and labor.

Build with Us

Technology makes it possible

Made from our proprietary 60% recycled composite stone 3D printing material, our flat and parametric walls maximize flexibility. They have 4x more tensile and flexural strength and weigh 30% less than concrete.

Technology

Our expert services help realize your vision

We provide design and developer support services for each project, consisting of core (included) and additional services.

Core Design Services

- Design Review

- Sustainability

- Building Information Modeling (BIM)

Included in each project

Additional Design Services

- Conceptual Design

- Visualization

- Additional Services

Available upon request

Developer Support

- Assembly Training (Mighty University)

- Assembly Guidance for the first unit (Mighty Training)

- Supply chain management for Mighty Components

Included in each project

Additional Developer Support

- Project Management

- Supply chain management for non-Mighty components

- Customer Experience and Support

Available upon request

Better for people and planet

You don't need to choose between speed, quality, design and protecting the planet, together we can build a better future for the construction industry and the environment.

Build with us

17 real buildings printed on a 3D printer - The Future on vc.ru

3D printing technologies are developing extremely fast and are used in various areas of human life.

43664 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020. nine0003

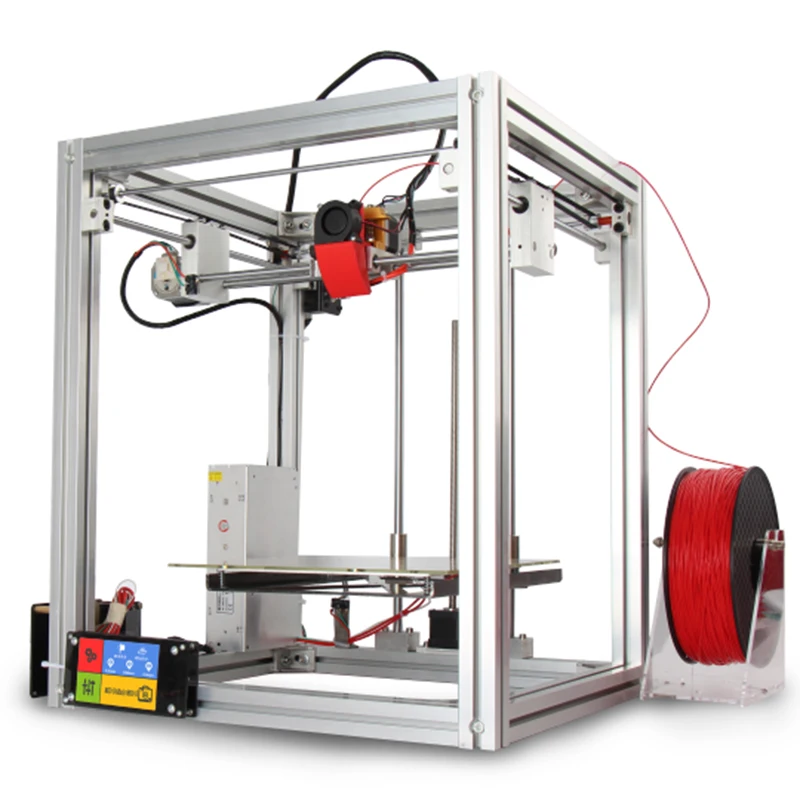

What is a 3D printer for construction.

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used. nine0003

The height and dimensions of the printed building depend on the specifications of the printer being used. nine0003

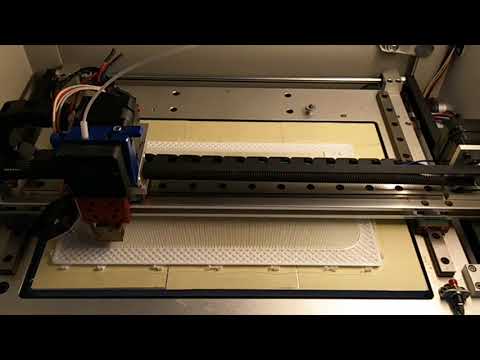

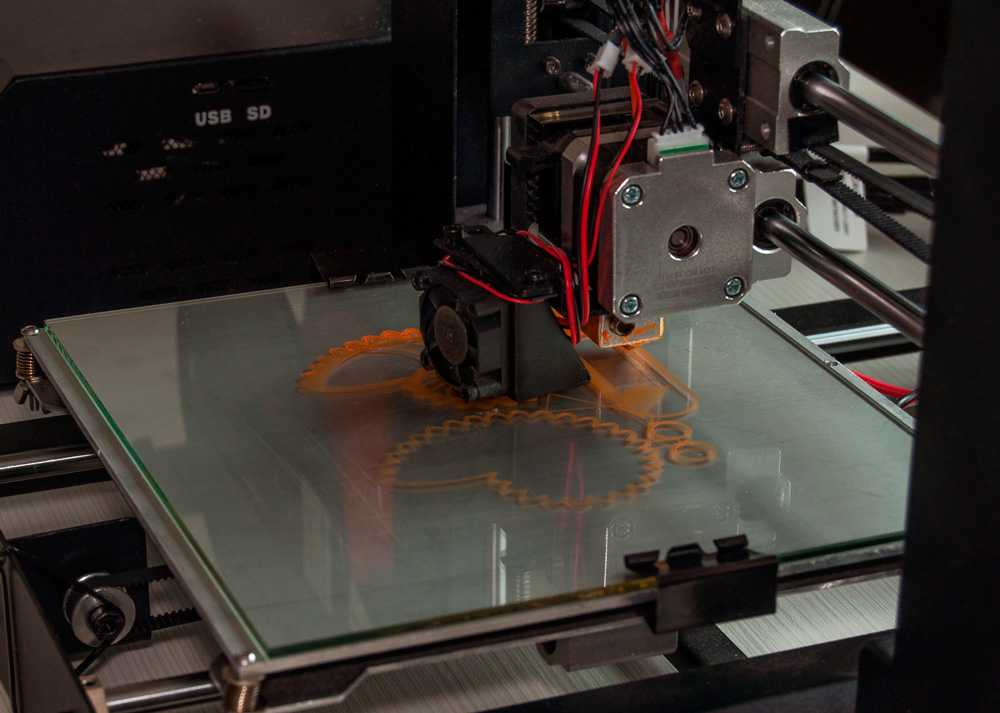

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete. nine0003

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

nine0027 High speed of construction of buildings and structures.

nine0027 High speed of construction of buildings and structures. - Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated. nine0028

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also eliminates the human factor in ordinary territories and reduces the likelihood of error.

1. June 2014. China. China's Shanghai WinSun Decoration Design Engineering Co has unveiled 3D printed houses at an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors. nine0003

Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors. nine0003

2. August 2014. USA. Andrey Rudenko's company Totalkustom printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Andrey Rudenko's Totalkustom company built apartments on the territory of a hotel in the Philippines, 10. 5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site. nine0003

7. October 2017. Russia. In Yaroslavl, the company Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. nine0010 Yhnova presented a five-room one-story house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype home in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. nine0010 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Company Crane Wasp using a three-bearing construction 3D printer erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime). nine0003

November 13, 2018. Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make. nine0003

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework. nine0003

nine0003

I am sure that in the future the entire construction process will be able to become fully automated, without human intervention, not only when printing foundations and walls, but also when printing ceilings and roofs, automatically install utilities, doors and windows. Also, perhaps in the future we will not be limited to printing houses of 2-3 floors, but will be able to move on to multi-storey construction. All this is no longer something impossible and has ceased to sound like fantastic dreams of a high-tech future. It is only necessary to give time for the natural evolution of 3D construction technology. nine0003

Print me a house - top 7 residential buildings printed on a 3D printer

Currently, there is a real technological breakthrough, thanks to which three-dimensional printers have appeared and the ability to print small architectural forms on them. Moreover, today in many countries of the world you can see printed houses and buildings in which you can really live, and 7 of them deserve special attention.

House of the future in the UAE

The name of this building, built in 2016, speaks for itself. And according to the words of the Government, the "House of the Future" became the first building, every detail of which was created using a printer in China.

The construction took a record 17 days and only 140 thousand dollars.

Like typical buildings, the "House of the Future" is equipped with running water, electricity and even the Internet. Now the office is actively used for various exhibitions and work events of the Future Foundation. nine0003

Chinese Villas by WinSun

In 2014, 10 houses built with modern technology appeared in the industrial park of Jiangsu Province in China. Different types of buildings were made for the exhibition by the popular company Shanghai WinSun Decoration Design Engineering Co. Houses have a different type of appearance, but at the same time they are distinguished by a relatively low cost.

So, the most expensive one cost the company 3 thousand pounds sterling.

A year later, WinSun presented two more printed buildings in Suzhou City. In terms of their external decoration, they differed little from the usual buildings, which cannot be said about the material that was used for their construction. The walls were made from building waste, which held its shape thanks to a special hardener.

Yaroslavl project

In 2017, the first residential building in Europe appeared in Yaroslav, which was recreated using 3D technologies. It took 2 years to build the house, but it took only a month to plant the main “box” on the foundation. Most of the work was carried out using a portal printer. nine0003

Today, the Yaroslavl House looks a little different from the usual living quarters.

It is also equipped with all necessary communications, being ready to move in. The AMT-SPECAVIA company was engaged in the construction of an atypical house, and its main task was to print a building suitable for life, and not at all another exhibition item.

The AMT-SPECAVIA company was engaged in the construction of an atypical house, and its main task was to print a building suitable for life, and not at all another exhibition item.

Fairy Castle in Minnesota

Andrey Rudenko from Minnesota has developed his own 3D printer and decided to try it out by printing a small structure in his backyard. This building was a miniature castle, symbolizing the active development of modern technologies in architecture and construction. nine0003

The building turned out to be truly fabulous.

The miniature castle, like its full-fledged relatives, received pointed towers and graceful arches. In the course of printing, Rudenko used the maximum tuning configurations, declaring that he was going to build a full-fledged living space with his help in the near future.

Italian house with a glass roof

In 2018, an atypical building with a glass roof with a total area of 100 sq m appeared in Italy, which was built in just a week. This speed was achieved through the use of a 3D printer to print individual elements. nine0003

This speed was achieved through the use of a 3D printer to print individual elements. nine0003

The house was reconstructed by two Italian companies: Arup and CLS Architetti.

Amsterdam Hut

Natural disasters often cause loss of housing. The Amsterdam architectural studio DUS decided to make the process of restoring the house as comfortable as possible.

In the end, using a 3D printer and durable bioplastic, they printed a "City Cabin", which turned out to be completely habitable. nine0003

The 25 cubic meter building contains a fold-out bed, a table and a window. As for the bathroom, it is located on a small lawn near the house.

Apartments in the Philippines

Businessman Lewis Yakic decided to expand his hotel in the Philippines, choosing for this not the most standard way. For this purpose, the man invited the already mentioned Rudenko, who printed the apartment on a printer.