Croc spurs 3d print

▷ croc spur 3d models 【 STLFinder 】

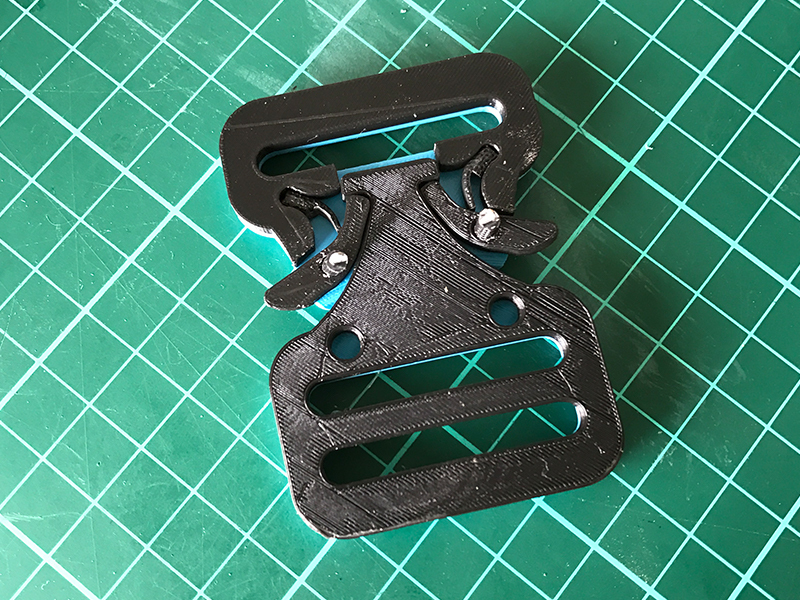

Croc Spur

thingiverse

a simple croc spur

Crocs Spur

thingiverse

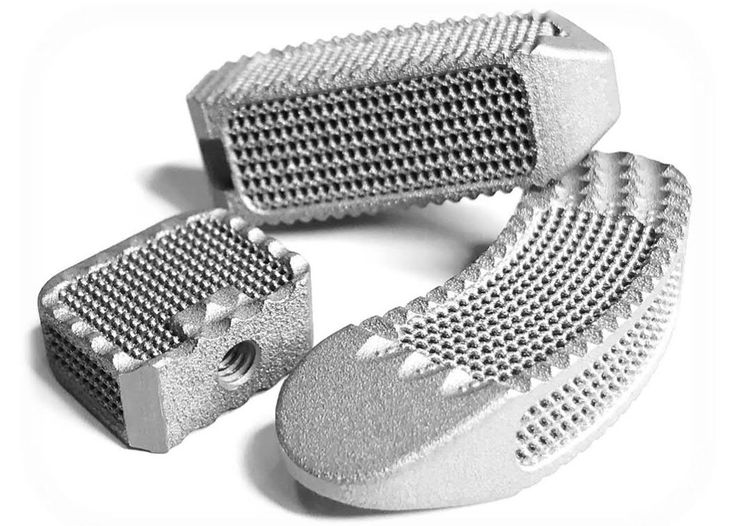

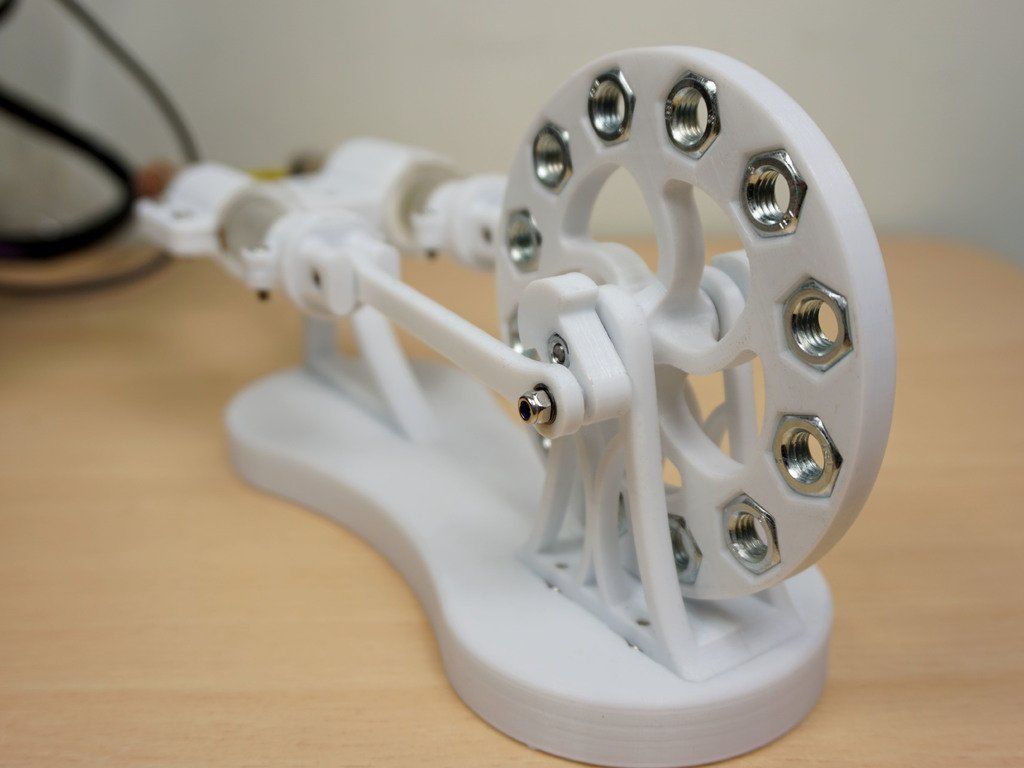

Croc Spurs. Not a new idea, but the ones out there were too long and didn't fit flush on the band. This one uses an 8mm m3 screw. Print 1 normal and 1 mirrored so that the screws face inward and are hidden. Options are print the full thing or the...

Croc Spur M3 Bolt Edit

thingiverse

I changed the spur rowel to use a M3 bolt and nut instead of the spike to reduce wasted plastic for supports and make the design more rigid. ...Still requires supports for the shank

Croc Spurs

thingiverse

... way through. ...I also made the holes just a little bigger so the spur spins easily when using an M3x16mm bolt and lock nut. I love the original design but this just makes the assembly a little quicker since I don't have to drill out the holes. ...

Croc

pinshape

Croc

Croc

sketchfab

Croc

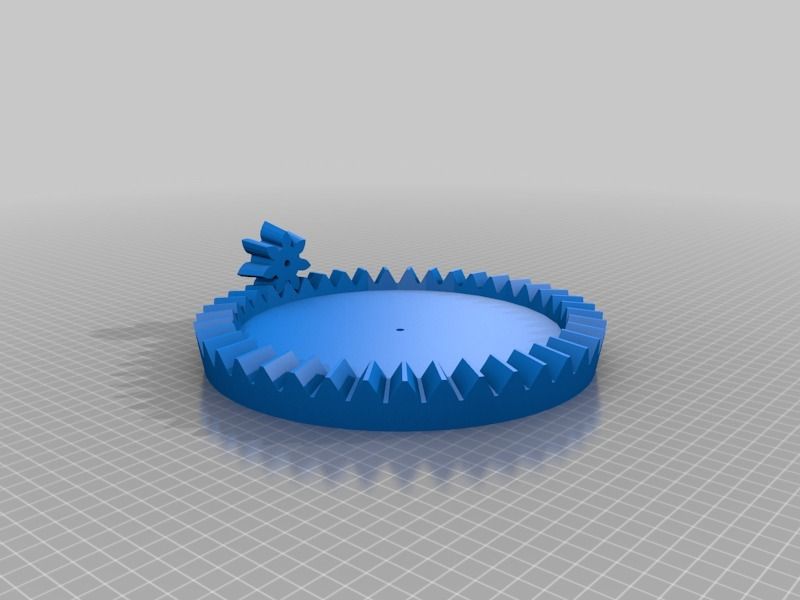

Spur

grabcad

Simple spur gear

Croc Croc Charm

thingiverse

. .. foot when you can load your crocs up with more crocs? ... You will need glue on hand, and you may need to widen the slot on the mini croc for the base to fit. ... also I cannot for the life of me remember where I got the croc model from, I apologise

.. foot when you can load your crocs up with more crocs? ... You will need glue on hand, and you may need to widen the slot on the mini croc for the base to fit. ... also I cannot for the life of me remember where I got the croc model from, I apologise

croc nut

cults3d

croc

Croc Axolotl

thingiverse

CROC AXOLOTL

croc nut

cults3d

croc nuts

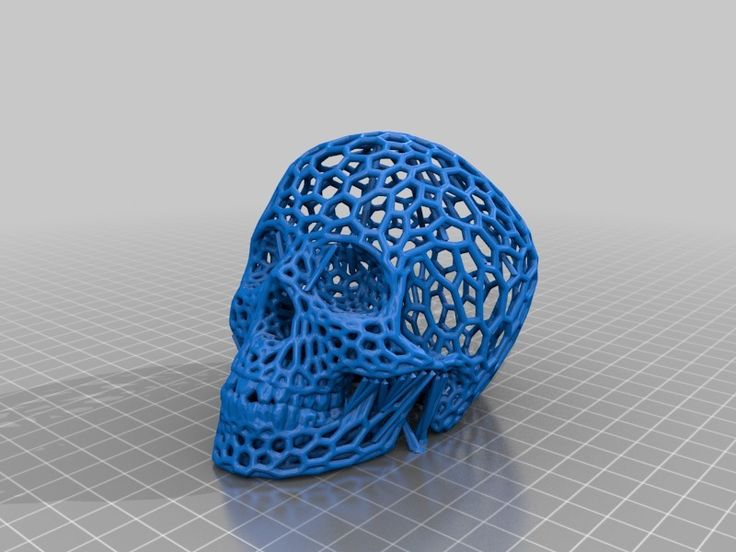

Killer Croc

sketchfab

Killer Croc, by DC Comics.

Croc Rings

thingiverse

A friend wanted a set of Croc Nuts (which I renamed Croc & Balls), and I wasn't interested in paying for an STL file that clearly just stole the nuts from "Balls for RC Cars" https://www.thingiverse.com/thing:1621102 Surprisingly, I couldn't quickly...

Croc

sketchfab

3D sculpt (using Blender 2.81) of a cartoon Crocodile in his natural environment.

Croc

thingiverse

Customized version of http://www.thingiverse.com/thing:140343 Created with Customizer! . ..http://www.thingiverse.com/apps/customizer/run?thing_id=140343 Instructions Using the following options:...

..http://www.thingiverse.com/apps/customizer/run?thing_id=140343 Instructions Using the following options:...

Croc

sketchfab

No description provided.

Croc

sketchfab

No description provided.

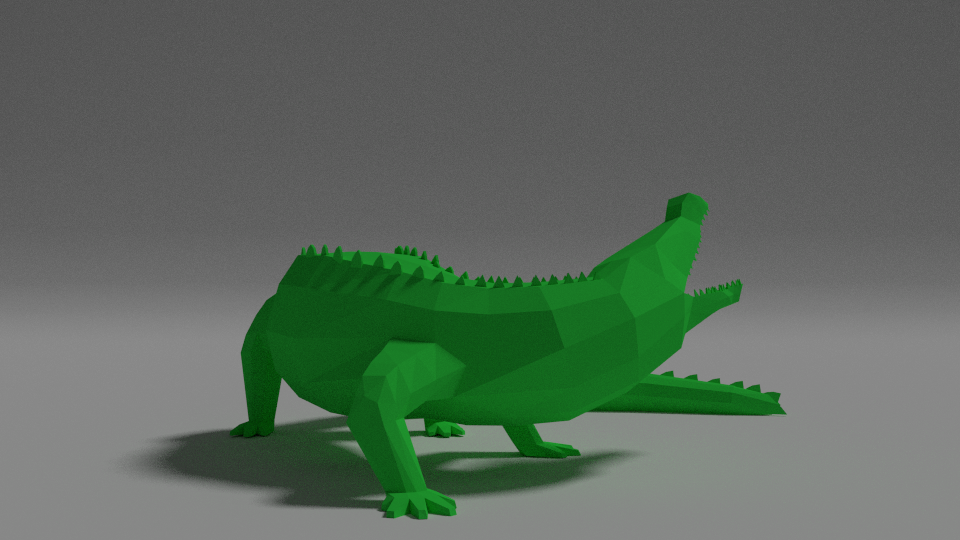

Croc

sketchfab

A low poly crocodile created for the online MMO Eldevin.

Croc

sketchfab

No description provided.

Croc

sketchfab

Photos Fabio E. ...Amador

Croc

thingiverse

This thing was made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/jaJxGoEIw7K

croc

sketchfab

No description provided.

croc tune

thingiverse

make your croc fast as a mf

T-Croc

grabcad

T-Croc Model in Zbrush , Final render in Keyshot.

Croc_remix

thingiverse

Remix of Croc to hopefully allow support free printing.

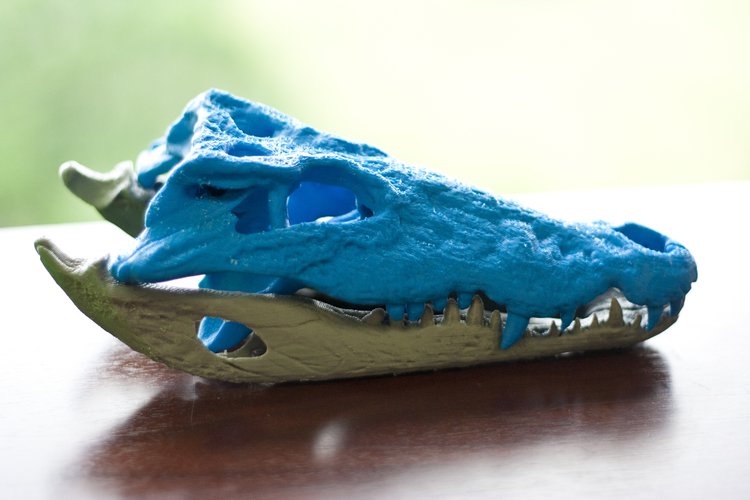

croc 3d

thingiverse

A 3D scan of a real Croc head

Croc Rivet

thingiverse

Broke my Crocs. Made this- fixed my Crocs. Instructions Print Glue Rivet together. ... Be patient with glue Enjoy

Croc Fangs

thingiverse

Croc fangs remixed it from https://www. thingiverse.com/thing:4730067 fill the whole croc for spike scale look

thingiverse.com/thing:4730067 fill the whole croc for spike scale look

Croc Rings

prusaprinters

A friend wanted a set of Croc Nuts (which I renamed Croc & Balls), and I wasn't interested in paying for an STL file that clearly just stole the nuts from "Balls for RC Cars" www.thingiverse.com/thing:1621102Surprisingly, I couldn't quickly find...

Mr Croc

thingiverse

Mr Croc can be printed in TPU or PLA. ... supports are recomended.

There Are Now 3D Printing Spurs That You Can Attach To The Back Of Your Crocs » Design You Trust

There Are Now 3D Printing Spurs That You Can Attach To The Back Of Your Crocs – Design You TrustDesign

Even outlaws need to sip their whiskey with a comfortable pair of Crocs on their feet, which is why today’s post is bringing out the inner-cowboy in all of us. Transport your heels to the Wild West with these Crocs spurs, which fit perfectly on the back strap of your favorite pair of Crocs!

Transport your heels to the Wild West with these Crocs spurs, which fit perfectly on the back strap of your favorite pair of Crocs!

More: Etsy h/t: sadanduseless

These spurs (or sprocs) currently fit the full size range of the regular Croc Clog. The All Terrain, Yukon Vista, and other wide strap Crocs models will not fit.

They’re made out of plastic and come in 5 different colors: black, white, silver, copper, and marble. The shop’s description also says to reach out to them if you’re looking for custom-colored Crocs spurs, as they can do additional colors, though they also include that these orders take a little longer to fulfill.

More Inspiring Stories

Glass Memorials That Contain The Ashes Of The Dead

We Knit The Unknittable: Meat, Champagne, Perfume And More

Artist Creates Edible Replica Of A House From Tim Burton’s Newest Movie

Artist Creates Exploding Trash Sculptures To Remind Us How Much Stuff We Own

The Craft Of Ladies' Hairdressing: Cool Pics That Show Unique Hairdos Of The '50s Ladies

Miyu Kojima Creates Miniature Replicas Of Lonely Deaths

Chocolate Fashion Show in Brussels

License Plates Of The USA By Jonathan Lawrence

Crack Yourself Up With Sean Charmatz’s Amazing Creations

Half Human Half Elf: The Superb Fantasy Post-Design 3D Art Works of Andrei Sigarev

Lovingly-Detailed Outlander Birthday Cake

Embarrassing Design Mistakes You Won’t Believe Actually Happened

This Napmobile Was Designed to Sell Mattresses

Beautifully Designed Fabric Fills Delhi’s Auto Rickshaw Interior With Vibrant Original Artwork

This Artist Has Created Some Awesomely Geeky Nesting Dolls

Twin Girls Have Awesome Twin Cosplays Featuring Creepy And Cool Anime, Movie, And TV Characters

Malaysian Artist 'Red' Hong Yi Creates Jackie Chan Portrait Using Thousands Chopsticks

Russian Artist Sculpts Clay Busts Of 4 Characters From Game Of Thrones

Boyfriend Lets His Quarantined Hairstylist GF Experiment With His Hair, Here’s The Result

This Awesome Suit Of Armor Made Entirely Out Of Magic The Gathering Cards

These 80-Year-Old Wooden Escalators Become A Beautiful Sculpture

Artist Imagines Famous Cartoon Characters With Human Bodies And The Result Is Bizarre

End Embarrassment: The Playful and Fun Toilet Paper Rolls from Japan

Add Some F-You Ambiance To Your Interiors

3d, crocs, fashion, spurs, wear

| Reliable Web Hosting You Can Trust |

|---|

The high-end, dedicated packages have everything you’d expect: Web Hosting - $6. 99/mo; Reseller Hosting - $13.49/mo; VPS Hosting - $14.95/mo; Dedicated Servers - $119.00/mo. 99/mo; Reseller Hosting - $13.49/mo; VPS Hosting - $14.95/mo; Dedicated Servers - $119.00/mo. |

bought a printer? Cheat sheet for beginners

No. At first I saw a printer from a friend, and ... caught fire.

Began to storm Youtube. During the month, in my free time.

The article is intended for beginners, contains links to the necessary sources and answers many questions. A more detailed guide can be found on the Internet, including here: https://3dtoday.ru/blogs/lemden/guide-beginners-what-to-do-with-the-printer-after-the-purchase-explana nine0009

Here I offer a short version with answers to those questions that are not on the surface. Such a cheat sheet.

What to see to dive into 3D printing?

Imbued with useful knowledge, I singled out for myself several authors, with whom I recommend starting your path too. I observed a lot of repetitive and similar questions that do not arise for those who watched the thematic videos of the channels listed below:

https://www. youtube.com/c/SorkinDmitry

youtube.com/c/SorkinDmitry

https://www.youtube.com/c/SIBMAKER

https://www.youtube.com/c/ChuchaTV3D

https://www.youtube.com/channel/UCxZiY2jvqSGqVJLJoNmSUcg

https:/ /www.youtube.com/c/Ugoloktechnary

https://www.youtube.com/channel/UCzAx6cyo5aQFQLm5L89gnlw

https://www.youtube.com/channel/UCAI40Wsj_DG2a-srtVqO-HQ

I realized that 3D A printer is a collection of knowledge that has been accumulating and collecting dust so far: electrical engineering, physics, mathematics, drawing, programming. What exactly you need to know - outlined in a separate article, so as not to stretch. nine0003

How to choose a printer?

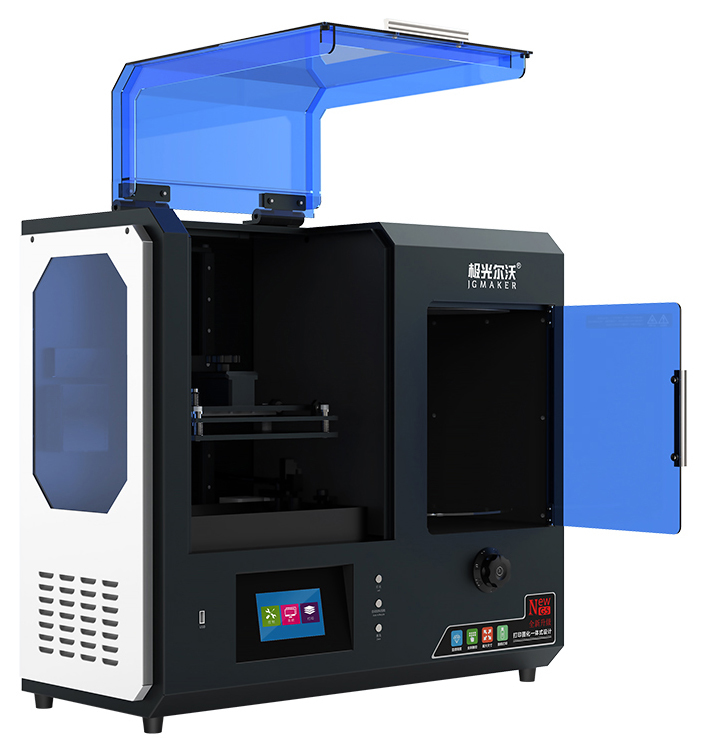

My choice, as a combination of information from viewed videos and recommendations from friends, fell on two models: Creality Ender 3 and Flying Bear Ghost 5 .

Based on my conditions, the semi-closed case Flying Bear Ghost 5 suited me more, so that the space occupied by it had a limit closed by walls - protection from children's hands and the ability to sew up the case with additional panels.

If you have purchased a different printer, then most likely some of the materials below may not be suitable for you.

How to buy a printer?

And now, for the new year, the stars converged, there was both a desire and an opportunity, and Aliexpress offered a good discount. Ordered for 18 thousand. Any other offers start from 25 thousand. This is my first expensive purchase on Ali, so there were concerns. I ordered it on January 4th, and on the 8th it already fell into my hands from a warehouse in Moscow. I did not have to pay customs duty, the goods had already been cleared through customs. nine0042 If the printer was traveling from abroad, you would have to pay an additional fee to the courier or directly at the post office upon receipt. Everything is not so scary, as I found out, and convenient.

What is important to do before buying a printer?

1. Find and coordinate with your cohabitants a place for the printer. It's not always easy, trust me. To avoid conflicts - do it in advance. The overall dimensions of the space occupied by the printer are indicated on the seller's website. For FBG5, the occupied space has the following dimensions: 39x44x58 cm (WxDxH), taking into account the protruding parts and the coil hanging on the back wall. Legs can confidently stand on a rectangle 380x335 mm. The length of the power cable (standard computer replaceable cord) is only 1 meter.

It's not always easy, trust me. To avoid conflicts - do it in advance. The overall dimensions of the space occupied by the printer are indicated on the seller's website. For FBG5, the occupied space has the following dimensions: 39x44x58 cm (WxDxH), taking into account the protruding parts and the coil hanging on the back wall. Legs can confidently stand on a rectangle 380x335 mm. The length of the power cable (standard computer replaceable cord) is only 1 meter.

2. Find a place to store small things from the printer: spare parts, tools, containers with alcohol and 3D glue (or whatever you are going to smear the table with, if you are going to). Of course, taking into account the inaccessibility for children, if any.

3. Buy an organizer for small things (better after buying a printer, when you understand the size that suits you). nine0003

How to assemble the printer?

Do you remember when you and someone binge together put together a new Lego set or something like that? Wow, it's the same thrill. I invited my brother over and we had a great time from the box to the first print. The printer was assembled according to the Russian video instruction https://www.youtube.com/watch?v=lXEG-zxVcXY in two parts. 20 minutes of video stretch to about 2 hours, if you do everything carefully and slowly. All the important points in the video are chewed, but in order not to disassemble the printer back later, I would add a few more tips from myself to them. nine0003

I invited my brother over and we had a great time from the box to the first print. The printer was assembled according to the Russian video instruction https://www.youtube.com/watch?v=lXEG-zxVcXY in two parts. 20 minutes of video stretch to about 2 hours, if you do everything carefully and slowly. All the important points in the video are chewed, but in order not to disassemble the printer back later, I would add a few more tips from myself to them. nine0003

By the way, the kit comes with a set of disposable tools necessary for assembly made of plasticine 3 steel, so it is worth purchasing spare hexagons for 1.5, 2 and 3mm , they will be needed where you need to tighten the complete screws tightly. I bought Dexter hexes from the green store and they passed all the necessary tests.

What else needs to be done during the first assembly of a 3D printer, so as not to disassemble it again later?

1. Buy lubricant in advance. nine0042 Litol-24 is suitable, but a more interesting one is also possible (lithium grease " Center Grease OIL EP 00 " or " Multifak EP2 ").

2. Look under the hood and take pictures of everything, and also stretch all the screw connections of the wires and check the adhesion of all the chips). First of all, you will find out if you have removable drivers.

3. Lubricate the guides and bearings (they come from the factory "dry"), as they say "tightly stuff with grease" (this and more, it is useful to preview https://www.youtube.com/watch?v=tMZQjHTBGfE and https://www.youtube.com/watch?v=-aV87Z2iBbc)

4. Align axles (more info https://flyingbear.info/en/solutions/build-problems) -tension-belts)

6. Pull all visible screws

7. Look under the hood and take pictures of everything (useful in the future)

and who to consult about 3D printing? nine0040

While watching the video from the beginning of the article, in the descriptions I came across links to thematic groups where professionals and beginners exchange experiences. Of course, it's better not to ask "stupid" questions and not ask for treatment from a photo, but who will stop you (although sometimes this is punishable by ignoring or even a ban). The answers to such questions have already been chewed many times by all the authors in their videos. Often, the answer to your question will only consist of a link to the desired video.

The answers to such questions have already been chewed many times by all the authors in their videos. Often, the answer to your question will only consist of a link to the desired video.

Vkontakte communities

https://vk.com/flyingbearghost5

Telegram chats

https://t.me/K_3_D

https://t.me/Ghostbustersss

Which sites should I bookmark?

While studying my questions, I have accumulated some reference mass of useful sites, which I share with you.

https://3deshnik.ru/wiki/index.php/Main_page

https://3dradar.ru/post/3dprint/

https://flyingbear.info/ru/mods

https:// amperka.ru/page/flying-bear-ghost-5-first-print

https://cvetmir3d.ru/blog/poleznoe/instruktsiya-po-sozdaniyu-makrosov-pri-workote-s-3d-printerami/

Stores

https://3diwell.com/catalog/Extruders/

https://trianglelab.net/products/

https://3dslon.ru/

https://www.rrf3dshop.ru/

https://amperka. ru

ru

https://creatorplanet. com/

https://letfix.ru/

https://spb.krep-shop.ru/katalog/bolty_i_vinty/din_912_2/

https://sunday-3d.store/

Sites with 3D models

https://3dtoday.ru/3d-models (since you are here)

https://www.thingiverse.com/ (the second name is "the well-known site", it is also "tinge")

https://www.prusaprinters.org/prints/83628-print-in-place-bag-clip/files

https://www.baizhongyun.cn/home/index

https: //the3d.ru/Catalog/Typ/1

https://www.yeggi.com/ (search engine for different sites with models)

Plastic shops

https://www.ozon.ru/category/plastik -dlya-3d-printer-15794/ (start here)

https://www.fdplast.ru/plastik-dlya-3d-printera/

https://www.sopytka.ru/products/prutki-dlya-3d-printera/

https://plastik-nit.ru/

https://bestfilament.ru/

Where and what kind of plastic to buy to start?

Do not believe it - Ozon will be enough for the first time. Here is a direct link to the category https://www.ozon.ru/category/plastik-dlya-3d-printera-15794/

Here is a direct link to the category https://www.ozon.ru/category/plastik-dlya-3d-printera-15794/

But take your time. A complete reel of plastic is enough for you to print a bunch of little things, practice and calibrate the printer. Personally, I was surprised that such a small coil was enough for so much. nine0003

In the meantime, while you are getting used to it, a new large coil will already arrive.

Of course, I advise you to start with PLA, as the easiest material for beginners. And if you need something stronger and more resistant to atmospheric phenomena, then purchase PETG. ABS - at the start, it definitely won’t suit you, besides, it gives out toxic fumes when printing and it’s highly not recommended to print it in the house without a special hood. He will also need warmth and dryness, which in the drain will be difficult to achieve. nine0003

In detail, almost all types of plastic that you can print can be found in video : https://www.youtube. com/watch?v=CzgOCkJbcxE

com/watch?v=CzgOCkJbcxE

And there is also a detailed article about most plastics: https:/ /top3dshop.ru/blog/podrobnyj-gid-po-vyboru-plastika-dlja-3d-pechati.html

Which company (filament manufacturer) do you prefer?

Know that one of the highest quality products, and the most expensive - "Bestfilament".

The pros also often print FDPlast and Filamentarno. nine0003

It is better to consult in chats.

It all depends on your needs. They praise the domestic manufacturer "NIT".

What is the first thing to do after assembly? Calibrations!

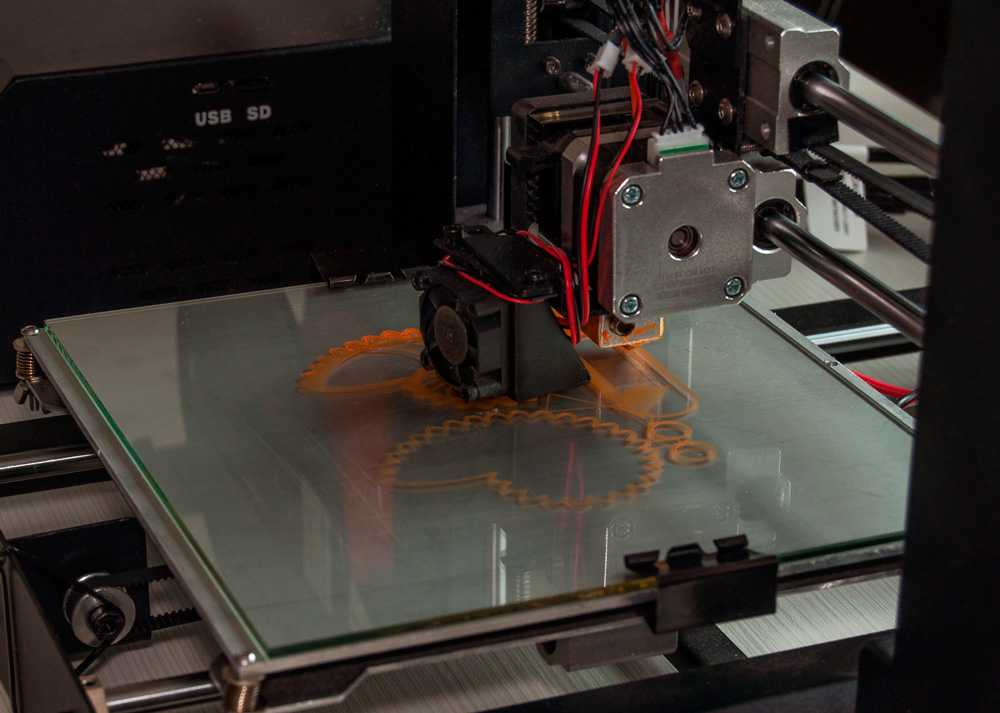

When the printer is assembled taking into account all of the above, well, or at least taking into account the minimum that was in the assembly video, then you can print the first model.

In order not to dive into the intricacies of preparing models for printing ("slicing" or cutting), there is already a file ready for printing on the memory card. And print it. For today, that's all you need. For about an hour you will enjoy watching the movements of the printer, find out what sounds and how loud it makes. nine0003

For about an hour you will enjoy watching the movements of the printer, find out what sounds and how loud it makes. nine0003

Tip: At first, plan any printing for the day. By no means in the evening or at night (if at home), because if the print takes longer than expected, then you and your bedmate will not enjoy being near the printer. Expect that small models will be printed in 1-2 hours, and large ones (or with complex patterns) up to 9 hours or more. For FDM printers, this is normal.

This is about the moment when you realize what "screaming" motors or "loud drivers" everyone was talking about and climb into the online store to order "silent" TMC2209 drivers.

In any case, after assembling the printer, there are calibrations.

I divided them into two types - basic and advanced.

Basic calibrations

- Table (or "bed" as you like) calibration IMPORTANT : calibration is done hot! i.e. the extruder and bed are heated to operating temperature before calibration - the one you will be printing on most of the time.

If the temperatures are higher, then the calibration will need to be repeated already for it. When calibrating, either a high-quality probe or a plain sheet of paper is used. During the calibration, they try not to touch the table. Very detailed about why and from what in this video: https://www.youtube.com/watch?v=uROS3xOac1o

If the temperatures are higher, then the calibration will need to be repeated already for it. When calibrating, either a high-quality probe or a plain sheet of paper is used. During the calibration, they try not to touch the table. Very detailed about why and from what in this video: https://www.youtube.com/watch?v=uROS3xOac1o - This is the minimum, without which it would not be worth starting printing, so as not to be disappointed in quality. PID calibration of the table and hot end It is done easily by sending a specially prepared file with a G-code for printing. Details are analyzed here: https://www .youtube.com/watch?v=aizbpcZ7LU0

- Calibration of extruder steps This is done in two steps. Well described in the video: https://www.youtube.com/watch?v=Mga_ezYDTNI

Next comes advanced calibrations that require accurate measuring tools (micrometer and caliper) and printing of calibration models. In addition, they will need to be selectively repeated for each new filament that you thread for the first time, because. these calibrations depend on the properties of the chosen plastic. nine0003

these calibrations depend on the properties of the chosen plastic. nine0003

Test models can be found both in the mentions in thematic videos and in articles, for example in this one: https://3d-diy.ru/wiki/3d-printery/luchshie-modeli-testovoj-pechati-3d-printerov/

Calibrations for a specific filament:

- Flow https://www.youtube.com/watch?v=Mga_ezYDTNI

- Accelerations and jerks https://www.youtube.com/watch?v=t5dJHWF -RGo

- Temperature and retracts https://www.youtube.com/watch?v=QNUZIsTMQb0

- Linear Advance Only available on custom firmware and Direct extruder. You have Bowden - put up with it, for now. /drive/folders/1ZUuk_V8Bdn0Vt0OC19J2wQ0Nd3v5MbL4

First, you will need to identify your motherboard.

Personally, after updating from 5.8.4 to 5.8.7, I lost the buzzer. He stopped emitting signals of different frequencies, and instead of them began to issue quiet clicks. nine0003

Read more about the boards in the article: https://sergey1560.

github.io/fb4s_howto/mks_board/

github.io/fb4s_howto/mks_board/ Do I need another (custom) firmware?

Only when you start to miss the power of your printer. Not earlier. Don't complicate. Enthusiasts have already done everything for you and there are options for advanced firmware. You can easily find them on the sites, links to which I left above.

I have already tested one of them and can recommend it as a working option: https://github.com/Sergey1560/Marlin_FB4S/releases

A little about WiFi on the printer

It will be useful to know that the module installed in the printer is only able to work with one connection (connection). It will not be possible to simultaneously connect to it from two programs (different or identical).

WiFi on the printer can be configured via the built-in web interface, but you need to know the IP to do this. There is nothing else to configure in this interface.

I strongly recommend that you bind the MAC address of the printer to the issued IP on the router in the LAN -> DHCP settings so that it becomes permanent for it (the same one was always issued).

It will be difficult to use the hostname of the printer. nine0003

It will be difficult to use the hostname of the printer. nine0003 What programs do I need to use the 3D printer?

Slicers

- Prusa Slicer https://www.prusa3d.com/page/prusaslicer_424/ Its interface is simpler than that of Cura, and in general, it is more convenient to manage settings with it. MKS WiFi plugin does not work (as of January 2022) with FBG5 5.8.7 firmware The plugin itself can be downloaded from the author: https://github.com/ArtificalSUN/MKS-WIFI_PS_uploader

- Cura https://ultimaker.com/software/ultimaker-cura the "Make beautiful" button, which will do everything for you. The MKS WiFi plugin installed from the marketplace (inside the program) works with any firmware version. True, it may not always connect to the printer from the first start, and the program just needs to be restarted, but if it is connected, it will not turn off, even if the printer is turned off and on before sending the job. nine0238

.

..and all the other slicers, there are many of them, but at first they will not help you. Some are paid, some praise waders from their swamp, but in fact, the above options will help you start to comprehend the art of slicing.

..and all the other slicers, there are many of them, but at first they will not help you. Some are paid, some praise waders from their swamp, but in fact, the above options will help you start to comprehend the art of slicing. In the review, you can find out which sites and programs can still be useful: https://www.youtube.com/watch?v=Q9PlMvpEnKs

How to better configure slicers, it is useful to watch in the video:

- Prusa Slicer https:/ /www.youtube.com/watch?v=BMbgFgzPcG8

- Cura https://www.youtube.com/watch?v=GInpsJu8bZE

- General stream about the nuances https://www.youtube.com/watch?v=Tu-ropzwhco&t=7872s

For setup and testing

- Repetier-Host https://www.repetier.com/download-now/ To send commands to the printer and monitor its status. To connect via LAN, specify the printer IP and port 8080

0043 for starters. They are built into Windows 10

- Fusion 360 To get the free version, just go to https://www.

autodesk.com/products/fusion-360/personal, click GET STARTED, fill in the details and get a free license! And here you can learn the basics from the video https://alexgyver.ru/how-to-get-fusion360/

autodesk.com/products/fusion-360/personal, click GET STARTED, fill in the details and get a free license! And here you can learn the basics from the video https://alexgyver.ru/how-to-get-fusion360/ - https://3dpt.ru/page/faq in Russian

- https://github.com/AndrewEllis93/Print-Tuning-Guide in English

- Address : st. Malovisherskaya, 1

- Phone : +7 (8162) 60-54-60

- Opening hours : Mon-Fri from 12:00 to 20:00, Sat-Sun from 10:00 to 18:00

- VKontakte : https://vk.com/kolokolschool_vn

- "Instagram" : https://www.instagram.com/kolokolschool_vn/

- Address : st. Velikaya, 14 (Novgorod Academic Drama Theater named after F. M. Dostoevsky, 7th floor)

- Phone : +7 (921) 194-22-62

- Opening hours : Mon-Fri from 9:00 to 18:00 (on request until 22:00), Sat-Sun on request

- e-mail : tboilvn@yandex.

ru

ru - VKontakte: https://vk.com/tboilvn

- "Facebook": https://www.facebook.com/tboilvn

- "Instagram": https://www.instagram.com/tboilvn/

Is slicing an art?

Yes, in my opinion, only having a certain experience and understanding the features of your printer can you successfully select print settings the first time. "Successfully" emphasize. Precisely fortunate, because it is almost impossible to pick them up "correctly". This is due to the individual characteristics of each instance of the printer, even within the same model. nine0003

It's like a professional photographer who has become close to his devices and, without looking at the switches, sets the desired modes so quickly that he manages to catch the "same shot" on the fly. This skill is gained only by experience. And for beginners it is very useful to peep how others do it.

Quality printing is the way of the samurai. You need to achieve harmony with your printer and plastic.Crab Lab Group

Common Printing Problems

The repeated printing problems that beginners have are also answered many times. You can search for your problem and its solution in the following articles:

and videos:

https://www.youtube .com/c/FLYINGBEAR3D Official Flyingbear channel (they don't have a website)

How to change the filament

It's not surprising to fill it, but it turned out to be not trivial to take it out, for example, for replacement. General recommendations are the same for all specialists.

Briefly : heat the extruder to the plastic printing temperature of -10%, turn off the heat, release the feeder clamp and push the plastic with your hand into the hotend, when it starts to flow with difficulty or stops completely, pull the rod back with a confident movement, then either turn the feeder into return line or pull out the entire filament with your hands. nine0003

nine0003

I would recommend this guide: https://flyingbear.info/solutions/printing-problems/how-to-replace-filament

Pay attention to the tip of the filament when replacing. By some forms of the tip, you can diagnose some hidden problems of the hot end. There is little information on the web on this topic.

P.S.

Enough for beginners. The cheat sheet turned out to be a bit long, but it seems to me that I have collected here all the most useful things to start with.

Three Novgorod sites where you can learn the new, places

places

2448

AUTION

Tatyana Alekseeva

Where to go in Veliky Novgorod to master virtual modeling, 3 D -scanning and laser cutting, do pottery, take part in master classes or listen to interesting lectures. In the review of the Lawn, we talk about three sites where you can acquire new knowledge and skills. nine0411

nine0411

Kolokol

The Kolokol pottery school, which opened in Veliky Novgorod, allows you to immerse yourself in ancient art and try your hand at creating ceramics. Master classes for Novgorodians began to be held in the spring on the street. Malovisherskaya, 1. A place has appeared in the city where, in a homely atmosphere, you can work at the potter's wheel, create beautiful dishes for yourself or your loved ones.

The Kolokol pottery school was founded in Voronezh, and then began to open in other regions. As reported by one of the founders of the school in Veliky Novgorod Svetlana Knyazeva , it happened by chance. There was an idea to find potter's wheels to conduct classes for children in the "House of the Sun" - a non-profit organization that helps people with Down syndrome. “We got to the site of the Kolokol pottery school, because the guys also produce pottery wheels, which we use. And they saw that you can talk with them about the franchise, ”Svetlana explained.

Opening up, we ourselves did not fully understand what we were doing. None of us have ever really sculpted. Now we have begun to understand that it is so cool, and everyone who comes is infected with it. I now have complete happiness and harmony. There is still fatigue, but this fatigue is pleasant - you can spend the whole day in the Bell, come home, and still there is no feeling of burden, as, for example, when you sat in the office. On the contrary, there are a lot of other ideas. nine0003

Yulia Nikolaeva One of the organizers of the Kolokol pottery school

Now there are nine people in the Kolokola team in Veliky Novgorod. Masters teach hand modeling, teach how to work on a potter's wheel. At master classes, they offer to make various products: plates, salad bowls, cups, or a set of ceramics at once. After class, the dishes dry for a week, then they are fired, glazed and fired again. After three weeks, you can pick up the finished product.

After three weeks, you can pick up the finished product.

- This is something akin to meditation. You penetrate into the creative process, this work on the circle is calm, appeasement. And when you have a product that you like, that you use in everyday life, that's great. I am overwhelmed with emotions when people like it, they leave here happy, satisfied.

Svetlana Knyazeva One of the founders of the Kolokol pottery school

You can sign up for a trial lesson at Kolokol free of charge.

Boiling Point

At the end of February, the Boiling Point opened in Veliky Novgorod, a space on the seventh floor of the Drama Theater where conferences, lectures, master classes, and educational courses are held. Since the launch, about 300 events have already been organized at this site, which were attended by more than 10 thousand people of various ages - from schoolchildren to pensioners. nine0003

Since the launch, about 300 events have already been organized at this site, which were attended by more than 10 thousand people of various ages - from schoolchildren to pensioners. nine0003

Novgorodians discussed the socio-economic development of the region, listened to lectures on improvement and urbanism, discussed the NTI 20.35 University initiatives, the Human Resources for the Regions project, and learned about the Teacher for Russia program. The events were organized by the regional Red Cross, the Novgorod Fund for the Development of a Creative Economy, the Kabeshka Children's Engineering School, the school of guides, psychologists and businessmen, students, and active citizens.

nine0003

We have three basic rules: non-commercial, non-religious and non-political. What is important: everyone can not only become a participant, but also organize something of their own. We want people not to be afraid to come. If a person wants to go out and tell something to the audience, share their experience, discuss some project, ideas, hold a volunteer meeting - our platform is absolutely free and open for free events.

But there is one condition: all events and their participants are registered on the Leader-ID portal, they need a phone number and email. nine0003

Program Director of the Collaborative Work Space "Boiling Point - Veliky Novgorod"3

As soon as the organizer fills out an application on the portal, it goes to the Boiling Point administrators. If the declared event meets all the conditions, the initiator is contacted and the details are clarified: how many people the event is designed for, whether equipment is needed, the entire venue or one of the five halls is booked. nine0003

You can follow the announcements and the program of events on the Leader-ID website or on the Boiling Points social networks.

Sintez

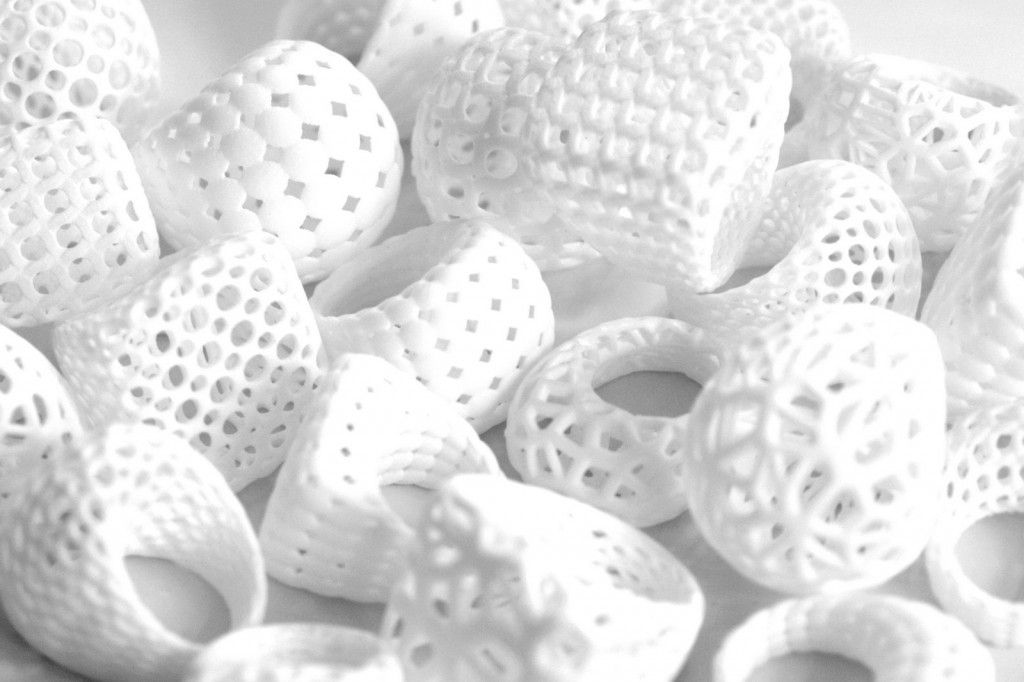

You can learn virtual modeling, the basics of programming, laser cutting and engraving, or master 3D scanning and printing at the Novgorod Center for Youth Innovative Creativity Sintez. It was opened in 2018 on the street. Cooperative, d. 8a. The site has modern equipment and specialized software; such areas as CNC milling, CNC turning, soldering, circuitry, and design are being developed here. nine0003

For example, you need to make some detail, a blank for painting, or something more complex - a laboratory bench, a model. Instead of drawing all this on paper, doing it with a file or a chisel, you can prepare a drawing in digital form and cut it out with a laser, or print it out on a printer, turn it on a milling machine. Not on the knee with a ruler, but in the program an exact drawing.

If earlier it could take months for the same laboratory stand, now they made a drawing in one day and cut it out with a laser in two hours. An architect needs a model: he does it not within two months, but within a week. The production process is accelerating, because the key competitive factor in the modern world is the production time. nine0003

Andrey Lebedev General Director of Sintez

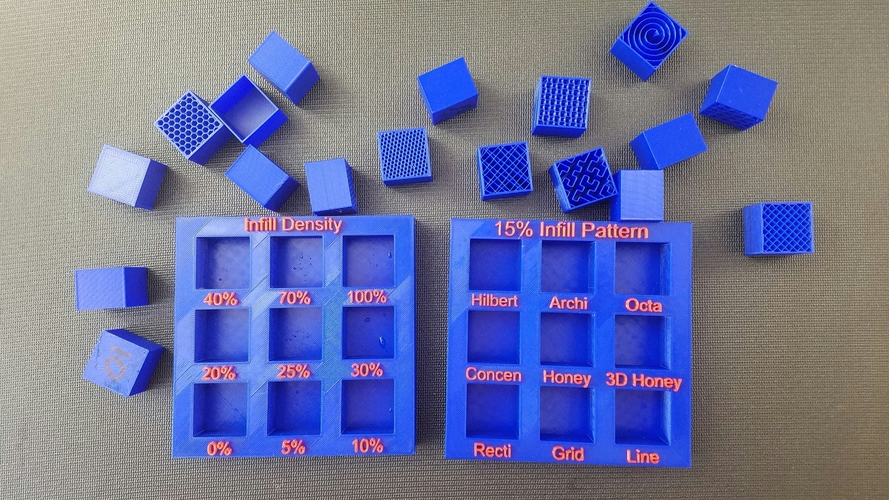

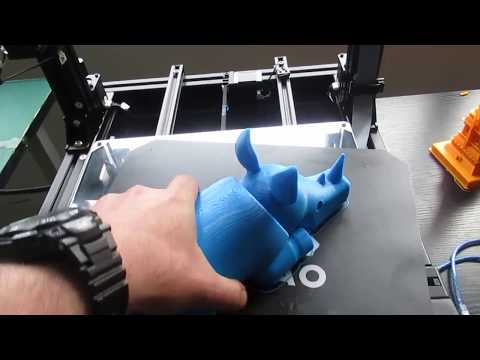

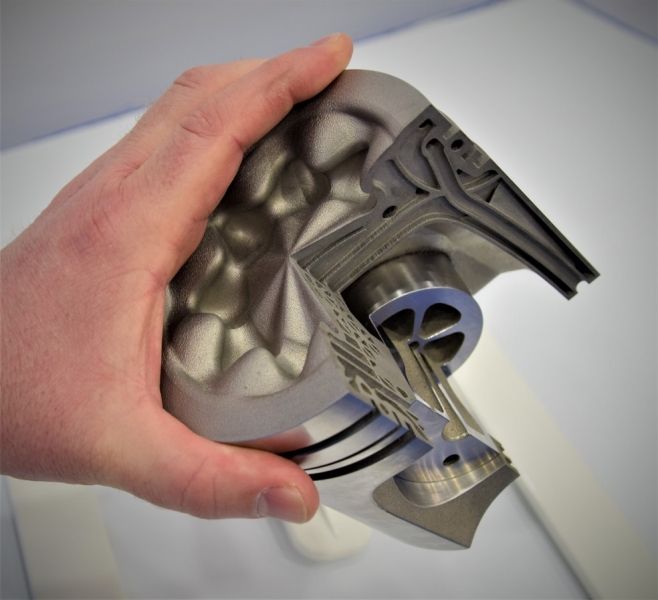

The 3D printing process can take two hours or several days. First, a sketch is prepared, then a 3D model, then a material is selected - different types of plastic. Then they proceed to the direct manufacture of the model, the duration of printing of which depends on how durable the product will be.

Nikita Matrosov Teacher of 3D printing and milling equipment

Souvenir products, small figurines are made in this way. Various mechanisms are also ordered, for example, for spraying water under high pressure.