Smithsonian 3d printing files

Ten Smithsonian Artifacts You Can 3-D Print | At the Smithsonian

Meilan Solly

Associate Editor, History

The Smithsonian Institution’s 3-D digitization portal currently features 124 interactive artifact models. Of these offerings—among others, the list includes Amelia Earhart’s flight suit, a Tyrannosaurus rex skeleton and the remnants of a supernova—just under 100 are available for download as 3-D print-ready files, making it easy for art, history and science lovers alike to obtain their very own copies of objects from the Smithsonian’s extensive collections.

Printing a miniature model of Neil Armstrong’s Apollo 11 spacesuit or a T. rex cranium is as simple as uploading a file to one of the many on-demand printing services found across the web. Shapeways, for example, charges $20.53 for a one-twentieth versatile plastic scale model of the famed dino predator’s skull and $129. 51 for a 9-inch-tall rendering of Armstrong’s lunar gear. Makexyz, meanwhile, charges $48.90 for an FDM-printed plastic version of the spacesuit and $12.90 for a model of the famed dino predator’s head. Other online printing services include 3D Hubs, Sculpteo and i.materialise.

Compare price points for specific projects at Craftcloud, then have the models conveniently shipped to your front door. To lower costs, try resizing renderings or experimenting with printing materials from resin to copper, nylon plastic and polylactic acid.

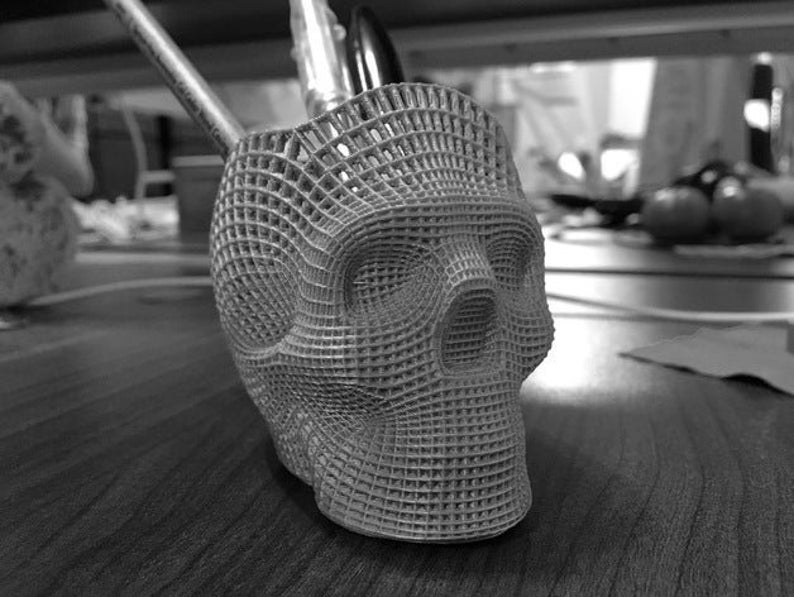

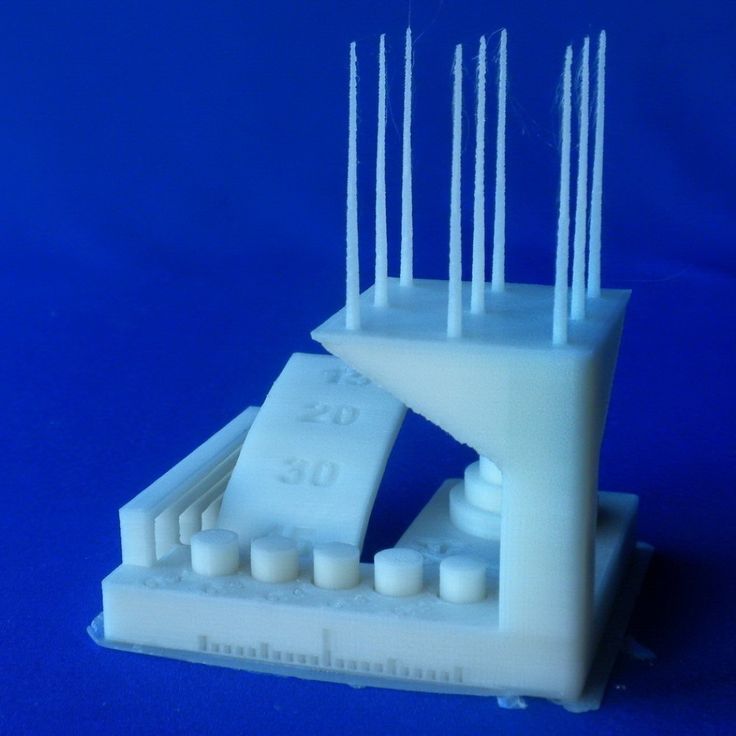

3-D printed model of a coral skeleton Courtesy of the Smithsonian Digitization Program Office A 3-D printed model of platform boots worn by actor Carl Hall Courtesy of the Smithsonian Digitization Program OfficeNovice printing enthusiasts seeking a more hands-on experience may want to check their local library. This Google Maps view spotlights around 900 public, academic, school and government libraries with 3-D printers available to patrons; most libraries charge for materials but offer use of the actual printer at low or no cost. Alternative options include commissioning a local printing service, finding a nearby makerspace, visiting a 3-D printer-equipped UPS Store or purchasing a printer oneself.

Alternative options include commissioning a local printing service, finding a nearby makerspace, visiting a 3-D printer-equipped UPS Store or purchasing a printer oneself.

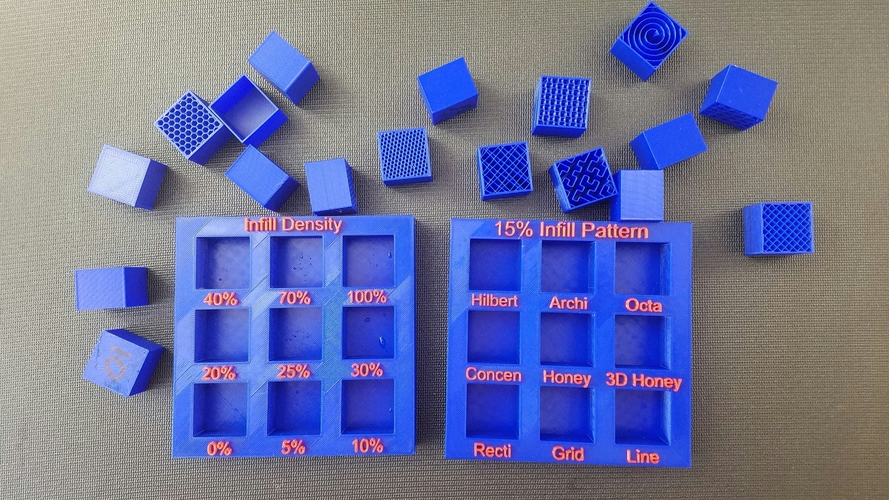

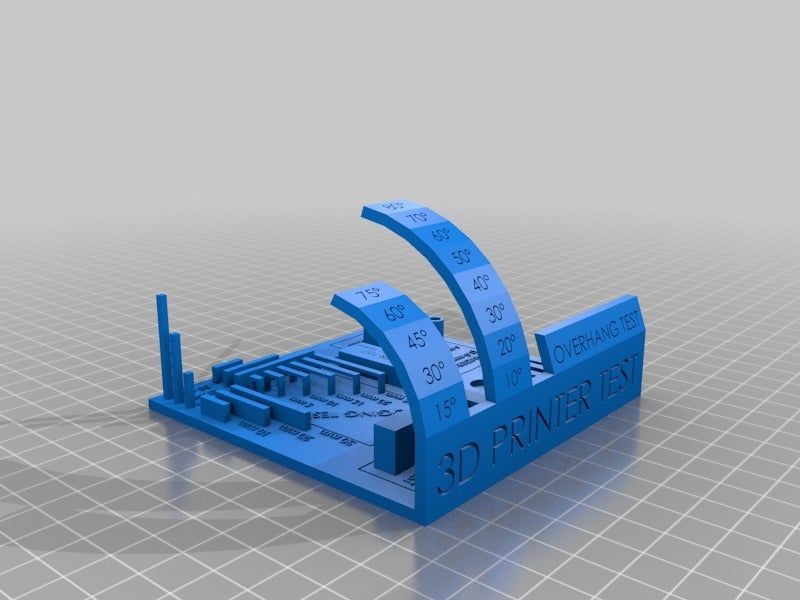

A few tips from Vince Rossi, head of the Smithsonian’s 3-D program: Artifacts must be “watertight solids” lacking “really small little delicate parts” in order to print successfully. A decidedly leak-prone 3-D model of a Revolutionary War gunboat, as well as the multi-component Wright Flyer, are therefore available as interactive models but poorly suited for 3-D printing. Some files may need to be resized in order to use printing services: Download a free 3-D modeling program like Meshmixer to scale models down. A professional printing service is probably the best option for those hoping to add a splash of color to their models.

“By 3-D scanning [artifacts] and making them downloadable to build online, we're able to increase access,” says Rossi. “That's kind of our general mission, … to increase access to content outside of our physical walls. ”

”

Regardless of which method you choose and whether you’re printing an object as a gift, coffee table decoration or personal memento, here are ten Smithsonian artifacts for your consideration.

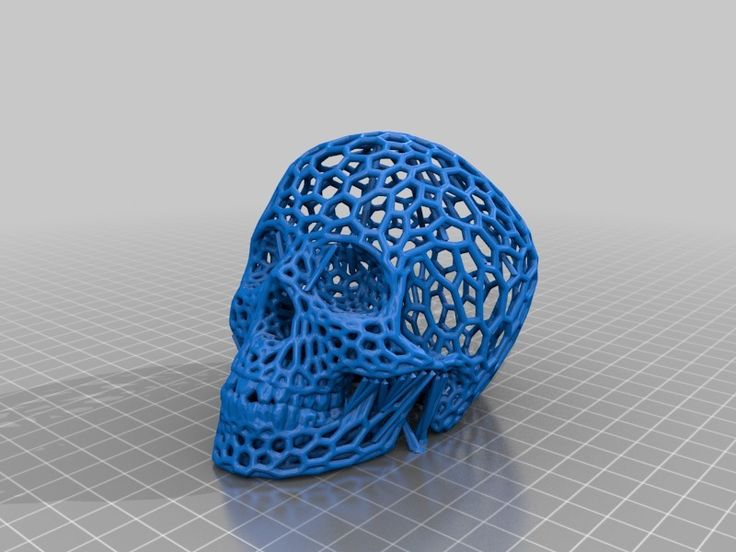

Tyrannosaurus rex and Triceratops skullsThe artifact: Nicknamed the “Nation’s T. rex,” this specimen—unearthed by a rancher hiking in Montana in 1988—measures an imposing 15 feet tall and 40 feet long. Now on view in the National Museum of Natural History’s “Deep Time” fossil hall, the dinosaur’s skeletal specter grips a hapless Triceratops (actually a composite specimen assembled from the remains of multiple dinosaurs) in its jaws.

“The T. rex is decapitating the Triceratops,” Matthew Carrano, the museum’s dinosaur curator, explained in 2018. “You can see the head is being levered off the neck. There are lots of small details there for visitors who take the time to find them.”

A 3-D printed rendering of the T. rex skull Courtesy of the Smithsonian Digitization Program Office

rex skull Courtesy of the Smithsonian Digitization Program Office The 3-D model: In April 2014, the Smithsonian’s 3-D digitization team used hand-held 3-D scanners to capture high-resolution surface and color information for each of the T. rex’s more than 200 bones, which arrived at the museum in a series of 16 wooden crates. Two years later, the researchers visited the Ontario facility where the T. rex and Triceratops were being assembled to record additional data with Lidar scanning technology. Print-ready files of both dinosaurs’ skulls (scaled down to one-twentieth of their original size) are available for download via the Smithsonian’s 3-D portal. The page also offers a one-twentieth scale model of the two dueling dinosaurs, but Rossi says the complexity of this file makes it difficult to print.

Alternative options: Make a woolly mammoth skeleton strike a jaunty pose with this movable model created by toy designer Teraoka Gensyou—or stick with the original non-articulated version. The download browser also features the fossilized jaw and skull of an unnamed dolphin species, the skull of a shrub ox unearthed in New Mexico’s Carlsbad Caverns, and a Jurassic Period ammonite.

The download browser also features the fossilized jaw and skull of an unnamed dolphin species, the skull of a shrub ox unearthed in New Mexico’s Carlsbad Caverns, and a Jurassic Period ammonite.

The artifact: Two life masks made just five years apart reveal the toll of a presidency marked by civil war. Abraham Lincoln’s secretary, John Hays, described one, cast by Chicago sculptor Leonard W. Volk in April 1860, as “full of life, of energy, of vivid aspiration.” He dubbed the second, cast by sculptor Clark Mills in February 1865—just two months before the president’s assassination—“so sad and peaceful in its infinite repose.” Hays added, “A look as of one on whom sorrow and care had done their worst without victory is on all the features. ”

”

According to the 3-D portal, Volk created his life mask by covering the then-51-year-old presidential hopeful’s face in wet plaster. After the plaster hardened, Volk said, Lincoln “bent his head low and took hold of the mold, and gradually worked it off without breaking or injury.” Over the next 32 years, the sculpter used this original plaster cast to create additional busts and statues of the president.

Mills’ life mask, meanwhile, was made by applying wet plaster to the president’s oiled-down face and beard. The plaster hardened in 15 minutes, at which point the sculptor had Lincoln “twitch his facial muscles until the mask broke into pieces.” Mills then reassembled these pieces to form the likeness; his son, Theodore H. Mills, gifted a plaster impression crafted from the original mask to the Smithsonian Institution in 1889.

Sculptor Clark Mills cast this life mask in February 1865—just two months before the president’s assassination. Courtesy of the Smithsonian Digitization Program OfficeThe 3-D model: In 1888, 33 Lincoln admirers donated Volk’s personal copies of the life mask, as well as bronze replicas cast by sculptor Augustus Saint-Gaudens, to the U. S. government with the caveat that “the original plaster casts should never be tampered with.” To comply with this requirement, the digitization team scanned a 1917 cast made from a bronze mask rather than the original plaster version. The digitized Mills mask was scanned from a 1917 cast of the 1889 one gifted by the sculptor’s son. Both the Mills and Volk life masks are available for download.

S. government with the caveat that “the original plaster casts should never be tampered with.” To comply with this requirement, the digitization team scanned a 1917 cast made from a bronze mask rather than the original plaster version. The digitized Mills mask was scanned from a 1917 cast of the 1889 one gifted by the sculptor’s son. Both the Mills and Volk life masks are available for download.

Alternative options: The download browser boasts a plethora of presidential material. Among others, the list includes a pair of Lincoln’s plaster hands cast by Volk in May 1860, a bronze relief of Theodore Roosevelt, an Andrew Jackson silver medal, a marble bust of George Washington, a bronze sculpture of James Garfield, a bronze bust of Franklin D. Roosevelt and a mixed media shadow box featuring a bust of Jimmy Carter.

Whale fossil Whale MPC 677 was the most complete specimen found at the site. Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Paleontologists unearthed the skeletons of more than 40 marine animals—the majority of which were baleen whales—while conducting excavations at Cerro Ballena, a fossil site in Caldera, Chile, between 2010 and 2011. This specimen, dubbed whale MPC 677, dates to the late Miocene Epoch and is between 7 to 9 million years old. Per a study published in Proceedings of the Royal Society B in 2014, MPC 677 was the “most complete fossil rorqual [whale] specimen” found at the site. Based on analysis of the so-called “whale graveyard,” scientists identified toxic algal blooms as the animals’ most likely cause of death.

This specimen, dubbed whale MPC 677, dates to the late Miocene Epoch and is between 7 to 9 million years old. Per a study published in Proceedings of the Royal Society B in 2014, MPC 677 was the “most complete fossil rorqual [whale] specimen” found at the site. Based on analysis of the so-called “whale graveyard,” scientists identified toxic algal blooms as the animals’ most likely cause of death.

The 3-D model: Because the Cerro Ballena site was situated in the middle of a major construction project, paleontologists only had a short window of time to excavate the skeletons. Rossi and colleague Adam Metallo traveled to Caldera shortly after the discovery. As Rossi told Smithsonian magazine's Abigail Tucker in 2012, “Day and night, we passed the scanner back and forth.” Despite the time crunch, the duo managed to scan the entire site, including a 26-foot-long whale skeleton digitized at a “level of detail normally reserved for baseball-size objects. ” Using this digitization data, the team also printed a 30-foot-long replica of MPC 677 that is now on view at the National Museum of Natural History. Both full-scale and scaled down versions of the fossil are available for download.

” Using this digitization data, the team also printed a 30-foot-long replica of MPC 677 that is now on view at the National Museum of Natural History. Both full-scale and scaled down versions of the fossil are available for download.

Alternative options: Other fossils primed for printing include a Priscacara serrata fish, a Stephanoceras juhlei ammonite and a shasta ground sloth’s coprolite (essentially fossilized feces). These selections are among the nearly 146 million scientific specimens held by the Natural History Museum.

Neil Armstrong's spacesuit

Neil Armstrong's Apollo 11 spacesuit Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Neil Armstrong wore this spacesuit during his history-making trip to the moon on July 20, 1969. As Ellen Stofan, director of the National Air and Space Museum, said earlier this year, “The complexity of the suit ensured it could support human life in the harshest of environments: extreme heat and cold, radiation, micrometeorites and the threat of cuts from sharp rocks all had to be taken into consideration. ” Still, Stofan added, the garment wasn’t “designed to last half a century on display,” and in 2006, curators removed it from public view for extensive conservation.

” Still, Stofan added, the garment wasn’t “designed to last half a century on display,” and in 2006, curators removed it from public view for extensive conservation.

In July 2019—just in time for the 50th anniversary of the Apollo 11 launch—Armstrong’s suit went back on view following 13 years of restoration work. A Kickstarter fundraising campaign raised more than $700,000 for conservation efforts, enabling the team to stabilize and safeguard the artifact, as well as conduct high-tech scans needed to create an accurate 3-D model of the historic attire.

The 3-D model: The Smithsonian’s team of “laser cowboys” drew on four different scanning techniques to build a model of the suit. Per the 3-D portal, digitization experts used laser arm scanning to capture surface detail, photogrammetry to ensure accurate color, structured light scanning to document color and geometry, and CT scanning to record the garment’s interior. The resulting interactive model boasts an eerie, X-ray-like “interior” view of the suit and annotations detailing the suit’s various features: among others, an American flag shoulder patch, an oxygen supply connector and a urine transfer tube.

“The 3-D model really offers you a deeper experience so that you're not just kind of frozen in one single view that a photographer has chosen for you, but you have the complete freedom to explore any view,” says Rossi. “You're able to look at all these new areas that you can't as a human being in the museum.”

Print-ready models available for download include the full-size suit, a 9-inch-tall version of the suit and a rendering of Armstrong’s left glove.

Alternative options: The digitization portal also offers a model of the flight suit worn by aviation pioneer Amelia Earhart when she crossed the Atlantic Ocean solo in 1932 and 3-D print-ready files of various sections of the Apollo 11 Command Module, including its hatch door, exterior and pilot seat.

Seriatopora hystrix skeleton A geologist found the coral skeleton specimen while conducting a research survey in Fiji. Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Scientist James Dana collected this and other coral specimens while participating in the government-funded U. S. Exploring Expedition between 1838 and 1842. By the end of his trip, Dana had gathered 300 geological fossils, as well as specimens representing 400 coral species and 1,000 crustacean species. (The scientist found this specific Seriatopora hystrix skeleton in Fiji.) Charles Darwin later told Dana that if he had “done nothing else whatever, [this expedition] would have been a magnum opus for life.” The On the Origin of Species author added, “I am really lost in astonishment at what you have done in mental labor. And then, beside the labor, so much originality in all your works.”

S. Exploring Expedition between 1838 and 1842. By the end of his trip, Dana had gathered 300 geological fossils, as well as specimens representing 400 coral species and 1,000 crustacean species. (The scientist found this specific Seriatopora hystrix skeleton in Fiji.) Charles Darwin later told Dana that if he had “done nothing else whatever, [this expedition] would have been a magnum opus for life.” The On the Origin of Species author added, “I am really lost in astonishment at what you have done in mental labor. And then, beside the labor, so much originality in all your works.”

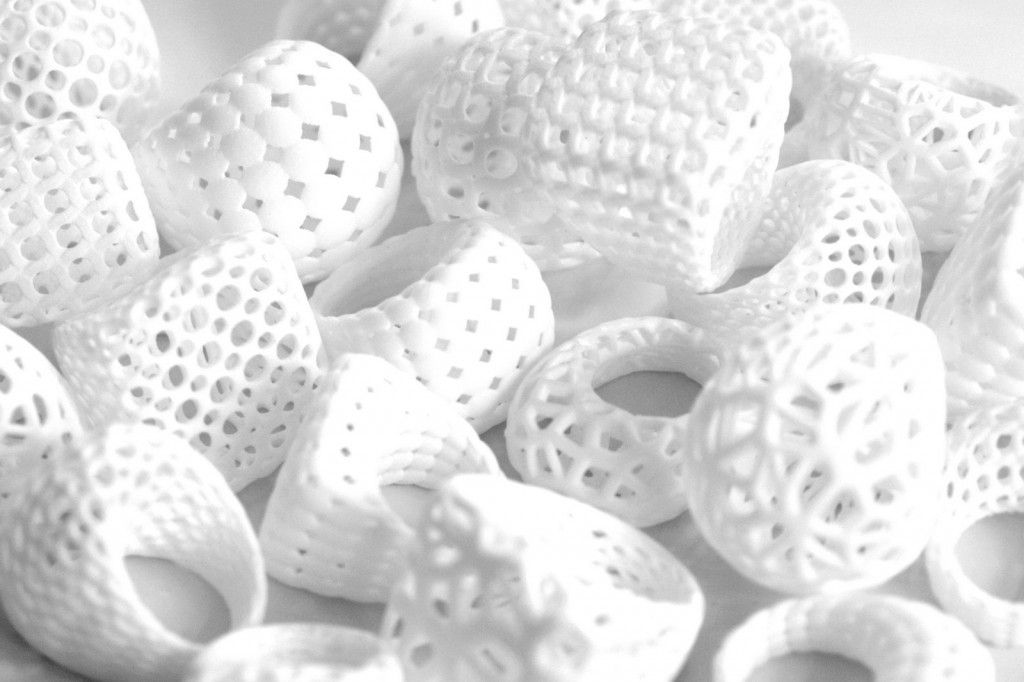

The 3-D model: Digitization officers used cameras to photograph and scan this S. hystrix skeleton. Per the 3-D portal, the skeleton actually represents a large colony of individual coral animals, or polyps. These anemone-like creatures secrete a type of calcium carbonate known as argonite, enabling them to convert seawater into stone and provide both food and habitat for other marine animals.

Alternative options: Flora and fauna featured on the download page include a Chesapeake Bay blue crab, the Eulaema bee and an Embreea herrenhusana orchid.

Key Marco Cat The 500- to 1,500-year-old Key Marco Cat statue Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Archaeologist Frank Hamilton Cushing discovered the Key Marco Cat while conducting excavations on Florida’s Marco Island in 1896. The 6-inch-tall wooden figurine was remarkably well-preserved by an oxygen-free layer of mud; although many of the wooden artifacts unearthed during the same dig have since disintegrated, the Key Marco Cat remains in fairly good shape. According to the 3-D portal, the region’s early Calusa inhabitants likely carved the statue—half-feline and half-human, it appears caught in the midst of a transformation—between 300 and 1500 A.D. To create the kneeling figure’s “sweeping lines, smoothness, and fine, clean edges,” its makers may have used shell scrapers, a shark’s tooth and sandpaper-like shark skin. Animal fat probably provided the carving’s finish and polish.

Animal fat probably provided the carving’s finish and polish.

The 3-D model: In 2018, the Smithsonian Institution partnered with the University of South Florida Library’s Digital Heritage and Humanities Collections to carry out structured light scanning and high definition imaging of the Key Marco Cat. The 3-D model produced by this partnership captures details such as cracks in the figure’s tail region, a nicked area on the ear, and cracking and loss on the feet.

Alternative options: Centuries-old archaeological and artistic artifacts available for download include a Shang dynasty lidded ritual ewer in the form of an elephant with masks and dragons; an ancient Chinese ewer depicting birds, snakes and humans; a bronze fangyi, or lidded ritual wine container, dating to China’s early Zhou dynasty; and a limestone winged monster statue made during the Qi dynasty’s reign.

CasA supernova remnant

The remnants of an exploded star Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Approximately 330 years ago, light from a stellar explosion 11,000 light-years away in the Cassiopeia constellation reached earth. The supernova released shock waves and extremely hot radioactive matter into the surrounding space, leaving behind a field of debris called a supernova remnant. The energetic outburst fused heavy chemical elements that are only created when large stars go supernova. These heavy elements within supernova remnants —including Cassiopeia A (Cas A)—are then “swept up by the next generation of stars and planets,” writes Kimberly Arcand, visualization lead for NASA’s Chandra X-Ray Observatory. Such cosmic explosions are “the way that Earth got the elements that are in our bodies, throughout our atmosphere, and across the planet.”

The 3-D model: Researchers from the Smithsonian’s Astrophysical Observatory collaborated with Harvard University’s Astronomical Medicine Project to transform X-ray, infrared and optical data into the multi-wavelength 3-D reconstruction seen online. The model features multiple layers, including an outer shock wave, high-velocity plumes (or jets) shooting out beyond the shock wave, and a small, ultra-dense neutron star left at the center of Cas A. Different colors represent various types of debris produced by the star’s explosion.

The model features multiple layers, including an outer shock wave, high-velocity plumes (or jets) shooting out beyond the shock wave, and a small, ultra-dense neutron star left at the center of Cas A. Different colors represent various types of debris produced by the star’s explosion.

Alternative option: At first glance, a headless Buddha sculpture housed at the Freer Gallery of Art appears to have little in common with the remnants of an exploded star. But both boast connections with the cosmos: The life-size figurine is actually called the “Cosmic Buddha.” Carved in northern China during the late sixth century, the limestone statue’s surface is covered in narrative scenes that catalog both the life of the historical Buddha, Siddhārtha Gautama, and a symbolic “Realms of Existence” map. The Cosmic Buddha 3-D model, made using scans taken in fall 2011, enables researchers (and history aficionados) to study the sculpture’s intricate carvings in more detail than ever before.

Panel for a cabinet door

This panel dates to the late 16th or early 17th century. Courtesy of the Smithsonian Digitization Program OfficeThe artifact: This elaborate French or Flemish panel dates to the late 16th or early 17th century. As Cooper Hewitt curator Susan Brown explains, the silk, metal and beaded piece was likely created by a team of professional male embroiderers: One would have hand-painted the panel’s silk background, while another would have sewn its raised metallic features or needle-laced the leaves. According to the 3-D portal, the scene depicted in the work alludes to the biblical fall of man and Adam and Eve’s expulsion from the Garden of Eden. Snakes seen circling a tree at the center of the image symbolize not only temptation and evil, but the burgeoning field of medicine; a salamander, meanwhile, represents regeneration and healing.

“Whether the designer intended to captivate the eye with extravagant materials and workmanship or to invite moral and spiritual contemplation,” the Cooper Hewitt notes, “an abundance of detail supports either pursuit. ”

”

The 3-D model: Rossi suggests printing the panel in color to best accentuate its intricate details. Users may need to scale down the model in order to use Shapeways, Makexyz and other online printing services. To resize a rendering, try editing the file with a free 3-D modeling program like Meshmixer. Find step-by-step instructions here.

Alternative options: Interior decorating buffs can download a variety of furnishings and household items, including vases, a Qing dynasty porcelain bowl and a mahogany armchair made in New York around 1810.

Bell X-1 The Bell X-1 plane piloted by Chuck Yeager Courtesy of the Smithsonian Digitization Program OfficeThe artifact: This Bell X-1 plane—named “Glamorous Glennis” in honor of pilot Chuck Yeager’s wife—was the first to fly faster than the speed of sound. During an October 14, 1947, flight, Yeager reached a speed of 1,127 kilometers, Mach 1. 06, at an altitude of 13,000 meters; less than a year later, on March 26, 1948, he topped his previous record by attaining a speed of 1,540 kilometers, Mach 1.45, at an altitude of 21,900 meters. According to the National Air & Space Museum, the United States government continued using the bright orange plane until mid-1950. At the time of its “retirement,” the X-1 had completed 19 contractor demonstration flights and 59 Air Force test flights.

06, at an altitude of 13,000 meters; less than a year later, on March 26, 1948, he topped his previous record by attaining a speed of 1,540 kilometers, Mach 1.45, at an altitude of 21,900 meters. According to the National Air & Space Museum, the United States government continued using the bright orange plane until mid-1950. At the time of its “retirement,” the X-1 had completed 19 contractor demonstration flights and 59 Air Force test flights.

The 3-D model: Digitization staff used laser scanners to capture the plane’s geometric data and photogrammetry to capture color information. As Rossi explained in 2015, the team had trouble scanning the X-1’s glass windshield and dark blue circles painted near the plane’s wings. The glass proved difficult to scan because the team’s lasers simply passed through it, while the paint patches failed to absorb the pulses of light emitted by the laser. To work around these issues, the digitization officers relied on CAD software and careful manual editing. A scale model of the plane created from laser scan data is available for download.

To work around these issues, the digitization officers relied on CAD software and careful manual editing. A scale model of the plane created from laser scan data is available for download.

Alternative options: The gunboat Philadelphia and the Wright Flyer aren’t viable candidates for 3-D printing, but the digitization portal does include several other flight- and transportation-related artifacts: Try downloading Earhart’s flight suit or various components of the Apollo 11 Command Module.

Costume boots for The Wiz Actor Carl Hall wore the platform boots while portraying the title character in a musical called The Wiz. Courtesy of the Smithsonian Digitization Program OfficeThe artifact: Actor Carl Hall wore these platform boots while playing the title role in The Wiz, a 1975 Broadway musical that reimagined L. Frank Baum’s The Wonderful Wizard of Oz through the lens of modern African-American culture. The production—lauded for showcasing an “unapologetically American way of life”—won seven of the eight Tony Awards for which it was nominated, including the coveted Best Musical prize.

The production—lauded for showcasing an “unapologetically American way of life”—won seven of the eight Tony Awards for which it was nominated, including the coveted Best Musical prize.

The 3-D model: According to the National Museum of African American History & Culture, which houses an array of costumes designer and director Geoffrey Holder crafted for the show, the leather boots are affixed atop wooden platforms (the soles measure 1.5 inches tall, while the heels stand 3 inches tall). A tour of the 3-D costume model reveals otherwise overlooked details, like the word “Wiz” scribbled onto the shoes’ soles in black ink. These soles are covered in non-skid black rubber to keep Hall from slipping on stage.

Alternative option: In 1988, 14-year-old Seba Johnson became the youngest alpine skier in the Olympic Games’ history. She was also the first African-American woman to compete in the sport at the Olympics. Her vegan-friendly synthetic ski boots are available for download via the 3-D portal.

Rossi and the rest of the digitization team plan on adding more models to the 3-D portal (which is set to be revamped early next year) in the near future.

“I as a Smithsonian employee am incredibly fortunate because I’ll see some of this amazing stuff behind the scenes,” says Rossi. “But my goal is how do we unlock more of this collection. What you see on the website is really just a tiny, tiny, tiny, small fraction of ... potential [artifacts]. The thing that excites me is how do we scale up the technology so that we can unlock more of these collection objects for research [and] education around the country and the world.”

The Smithsonian's 3D Printable Library « Fabbaloo

By Kerry Stevenson on February 17th, 2020 in Service

Tags: @smithsonian, models, museum, repository, scanning

Partially 3D printing Mammoth skeleton from the Smithsonian [Source: Fabbaloo]The Smithsonian is clearly one of the world’s leading museum institutions, and as such it holds literally millions of priceless artifacts.

Over the past years the organization has been quietly — or sometimes not so quietly — 3D scanning some of its more prominent pieces.

3D scanning is a practice that should be undertaken by all museums, as they do risk the loss of works should disaster occur. And it does, with the most obvious example being the terrible fire in Brazil that destroyed that country’s central museum and virtually all of its artifacts.

If only they had 3D scanned the objects there would at least be a digital representation of the object, even if it was physically lost. We wrote a piece on this concept after the Brazil museum disaster.

That advice has been taken up by several leading museums, apparently including the Smithsonian. However, in almost all cases the detailed 3D scans are kept privately and not exposed to the public, who, might, for example, 3D print them.

It seems many museum officials are under the mistaken impression that someone would 3D print all of their pieces and set up a competing museum elsewhere to draw off their business. For some museums, this is the reason they don’t allow use of digital copies.

For some museums, this is the reason they don’t allow use of digital copies.

That’s unfortunate because these digital representations can be used in a variety of ways to leverage the knowledge, sometimes worldwide. Multiple researchers could investigate the structure of a bone from distant locations, for example. Or students in an elementary school could be thrilled by the design elements in a medieval sculpture that’s been 3D printed for them to handle.

The Smithsonian is doing some things right, however. They have created a digital portal through which anyone can access for viewing and even download a number of notable 3D models. Currently they offer access to 124 3D models, far, far lower than the size of their collection, reputed to number over 150M items.

But despite the low number of accessible models, there are some great items there that can be used in the ways described above. There are classic sculptures, noted artifacts, such as the Apollo 11 capsule door, ancient coins, skeletons, fossils and fashions. There’s something for everyone.

There’s something for everyone.

I encourage you to explore this repository, as it contains 3D scans of extremely high resolution. These are terrific 3D models.

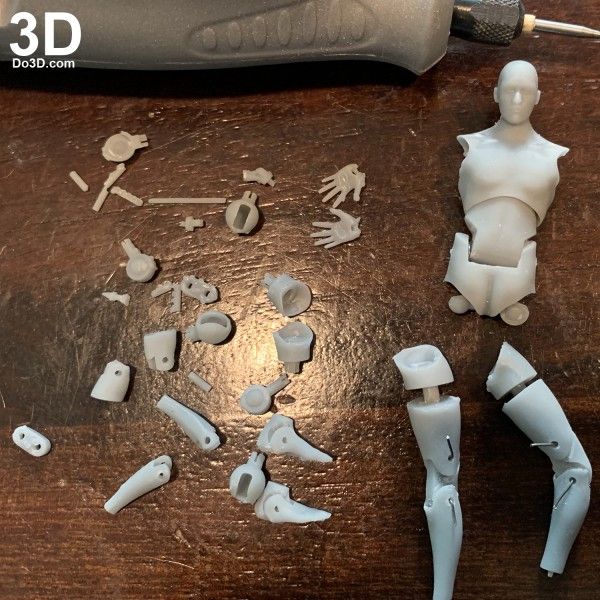

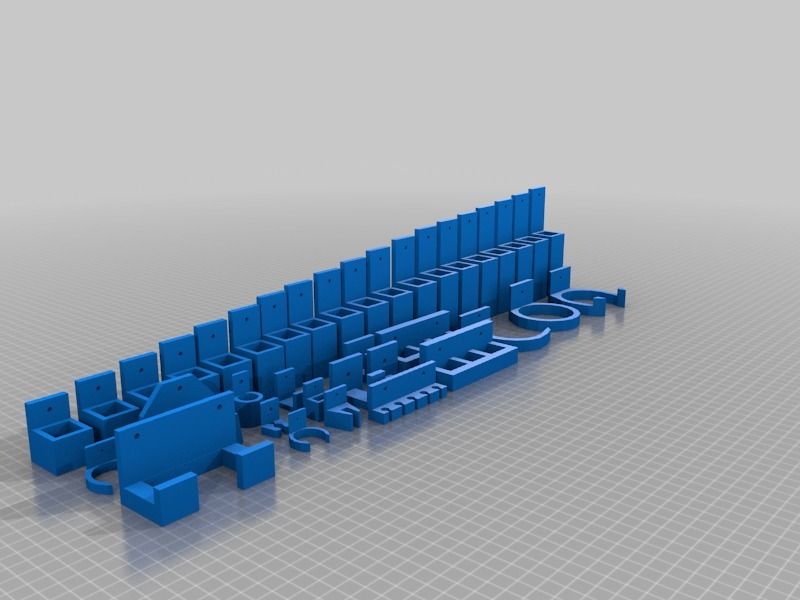

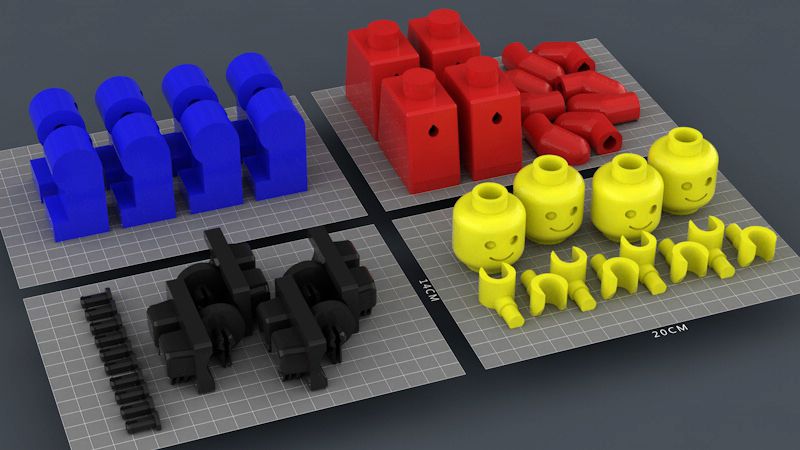

Personally, I’m now working on 3D printing a skeleton of a Mammoth, and you can see my progress at top. It comprises 16 parts and probably 80 hours or so of 3D print jobs. That, plus painting and assembly.

Which 3D model will you work on?

Via Smithsonian

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Giant 3D printed skeleton of a prehistoric whale appears at the Smithsonian Institution

Archive

3D Systems, in collaboration with the Smithsonian Institution, wanted to give 21st-century people the chance to see ancient fossils for themselves and printed more than 20 exhibits as they were discovered by archaeologists.

nine0003

nine0003 Archaeologists discover whale fossils

The collection is crowned by prehistoric whale fossils found in the Chilean desert. The length of a copy of a minke whale printed on a 3D printer is as much as 6 meters.

This whale was found in one of the largest fossil sites discovered in recent years. Its real remains are kept in the museums of Caldera and Santiago. Thanks to the joint efforts of 3D Systems and the Smithsonian Institution, visitors to the National Museum have the opportunity to see a 3D printed copy of his skeleton. nine0003

“We are delighted to be part of this fantastic project,” said Avi Reichenthal, President and CEO of 3DS. “It certainly contributes to the universal accessibility of national treasures.”

Screenshot of Smithsonian X 3D

However, 3D Systems and the Smithsonian have set themselves the goal of not only 3D printing physical replicas of fossils for all museum visitors to see, but also creating an interesting Smithsonian 3D website. Video, animated gif-files and images posted on it will allow visitors to see in detail the process of 3D printing of these masterpiece exhibits. nine0003

Video, animated gif-files and images posted on it will allow visitors to see in detail the process of 3D printing of these masterpiece exhibits. nine0003

The site documents literally every step of creating these 3D models, from blueprints and scanning to printing. What's more, thanks to the Smithsonian X 3D Explorer, visitors will have virtual control over all the 3D objects featured in the collection.

One of the many features available on the site

Nine videos detail the work done and the tools used by the 3D Systems and Smithsonian team. All of them are posted on the website. These videos give a general idea of what is going on in the museum and may well be of help to the educational program. nine0003

Reichenthal says, “The Smithsonian has shown its foresight and great knowledge of modern technology by using 3D printing to preserve today's and tomorrow's exhibits and show them to a global audience. His actions are a convincing proof of the enormous potential inherent in 3D printing. ”

”

The collection, which includes fossils ranging in length from 30 cm to 6 meters, can be viewed on display at the National Museum of Natural History at the Smithsonian Institution. The entrance is free. The museum is open from 10:00 to 17:30. nine0003

Article prepared for 3DToday.ru

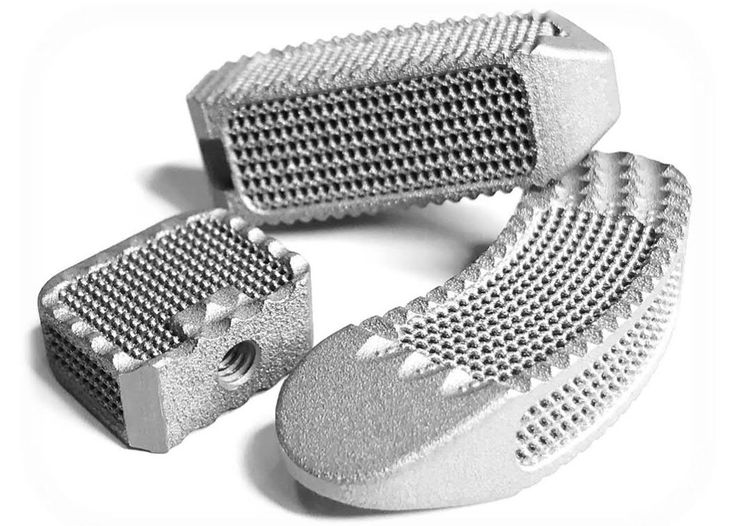

in prototyping, dentistry, small batch production, customized products, miniatures, sculptures, mock-ups and more.

Who invented the 3D printer? What was the first 3D printing technology? And what was the first thing they printed on a 3D printer? Let's open the veil of secrecy over a huge number of interesting facts and stories about the emergence of technology. nine. , which layer-by-layer formed a rigid object from a photopolymer resin with the help of UV illumination.

In fact, he described a modern photopolymer printer, but failed to provide the necessary data for patent registration within a year, as required by patent law, and abandoned the idea. However, in many sources it is he who is called the inventor of 3D printing technology. nine0003

However, in many sources it is he who is called the inventor of 3D printing technology. nine0003

In 1983, three engineers - Alain Le Meho, Olivier de Witt and Jean-Claude André from the French National Center for Scientific Research, in an attempt to create what they called a "fractal object", came up with the idea of using a laser and a monomer, which, under the influence of a laser, turned into a polymer. They applied for a patent 3 weeks before the American Chuck Hal. The first object created on the apparatus was a spiral staircase. Engineers called the technology stereolithography, and the patent was approved only in 1986 year. Thanks to them, the most famous file format for 3D printing is called STL (from the English stereolithography). Unfortunately, the institute did not see any prospects in the invention and its commercialization, and the patent was not used to create the final product.

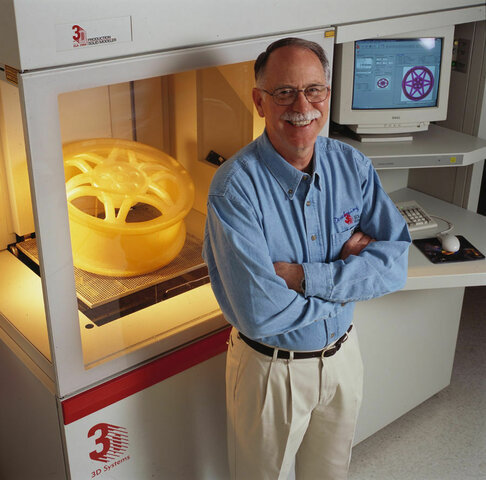

Chuck Hull, Inventor of SLA Laser Stereolithography At the same time, Chuck Hull was working for a company that made countertop and furniture coatings using UV lamps. The production of small plastic parts for prototyping new product designs took up to two months. Chuck came up with the idea to speed up this process by combining UV technology and layering thin plastic. The company gave him a small laboratory for experiments, where he worked in the evenings and weekends. As a material, Chuck used acrylic-based photopolymers that harden under the influence of ultraviolet radiation. One night, after months of experimentation, he was finally able to print a sample and was so elated by luck that he walked home. Chuck showed his invention to his wife. It was an eyewash cup, more like a communion cup, according to the wife. It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington. nine0003 Hull's Cup

The production of small plastic parts for prototyping new product designs took up to two months. Chuck came up with the idea to speed up this process by combining UV technology and layering thin plastic. The company gave him a small laboratory for experiments, where he worked in the evenings and weekends. As a material, Chuck used acrylic-based photopolymers that harden under the influence of ultraviolet radiation. One night, after months of experimentation, he was finally able to print a sample and was so elated by luck that he walked home. Chuck showed his invention to his wife. It was an eyewash cup, more like a communion cup, according to the wife. It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington. nine0003 Hull's Cup

Chuck Hull filed a patent on August 8, 1984 and was approved on March 11, 1986. The invention was called "Apparatus for creating three-dimensional objects using stereolithography. " Chuck founded his own company - 3D Systems, and in 1988 launched the first commercial 3D printer - the SL1 model.

" Chuck founded his own company - 3D Systems, and in 1988 launched the first commercial 3D printer - the SL1 model.

Another new 3D printing method appeared around the same time as SLA printing. This is selective laser sintering SLS , which uses a laser to turn loose powder (instead of resin) into a solid material. was developed by Carl Deckard , a young undergraduate student at the University of Texas at Austin, and his lecturer Prof. Dr. Joe Beeman . And the idea belonged to Karl. In 1987, they co-founded Desk Top Manufacturing (DTM) Corp. However, it will take at least another 20 years for SLS 3D printing to become commercially available to the consumer. In 2001, the company was bought out by Chaka Hull, 3D Systems. nine0003 Scott Crump, developer of FDM 3D printing (1988)

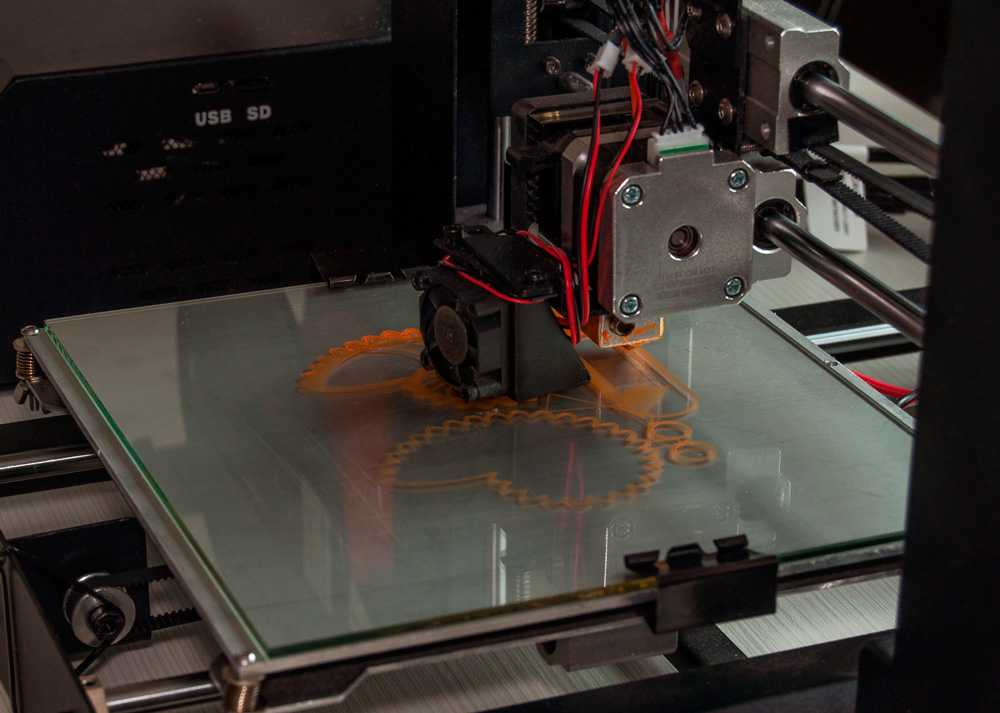

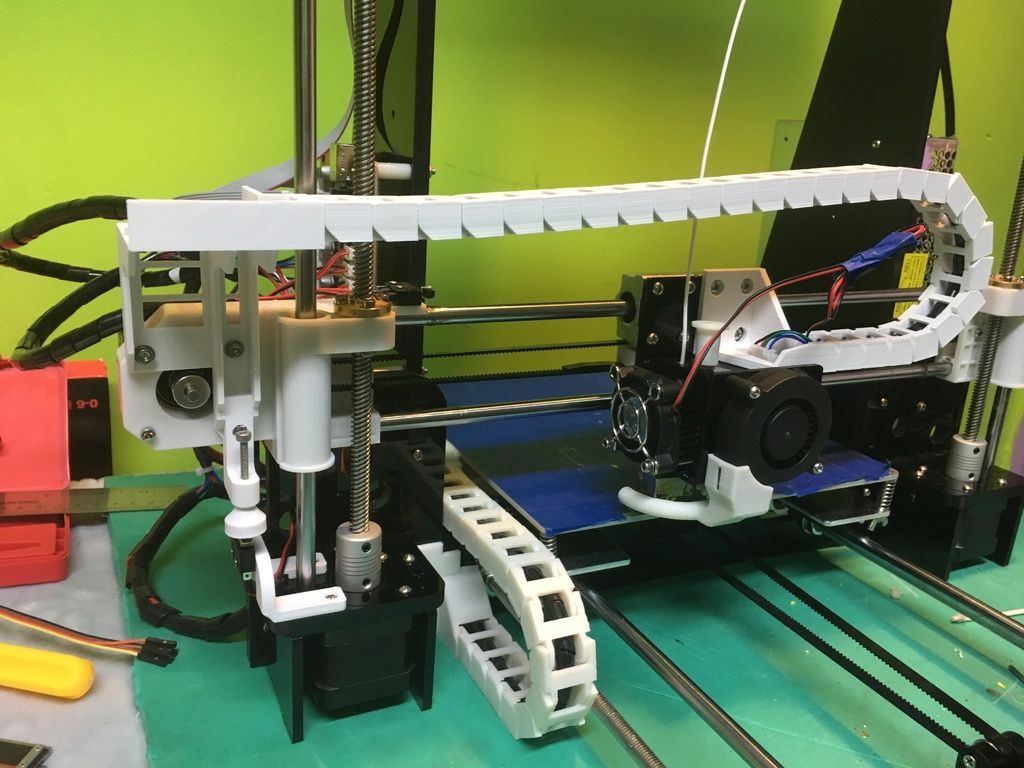

Surprisingly simpler and cheaper 3D printing is FDM (Fused Deposition Modeling) was created after SLA and SLS, in 1988. Its author was aeronautical engineer Scott Crump . Crump was looking for an easy way to make a toy frog for his daughter and used a hot glue gun to melt the plastic and pour it into layers. Thus, the idea of FDM 3D printing was born, a technology for layer-by-layer deposition of a plastic thread. Crump patented a new idea and co-founded Stratasys with his wife Lisa Crump at 1989 year. In 1992, they launched their first production product, the Stratasys 3D Modeler, on the market.

Its author was aeronautical engineer Scott Crump . Crump was looking for an easy way to make a toy frog for his daughter and used a hot glue gun to melt the plastic and pour it into layers. Thus, the idea of FDM 3D printing was born, a technology for layer-by-layer deposition of a plastic thread. Crump patented a new idea and co-founded Stratasys with his wife Lisa Crump at 1989 year. In 1992, they launched their first production product, the Stratasys 3D Modeler, on the market.

Milestone 2: 3D printing becomes available

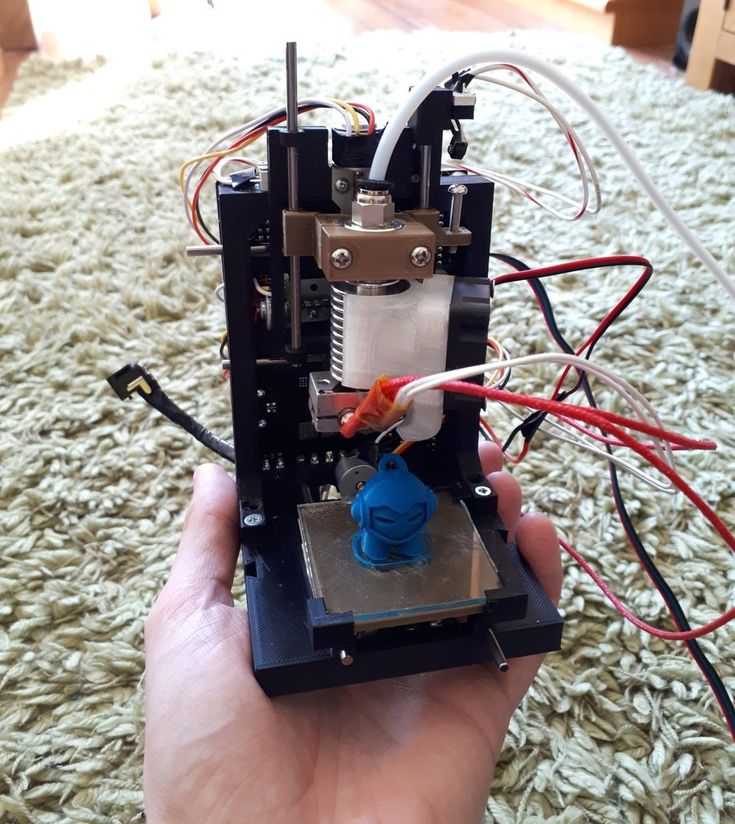

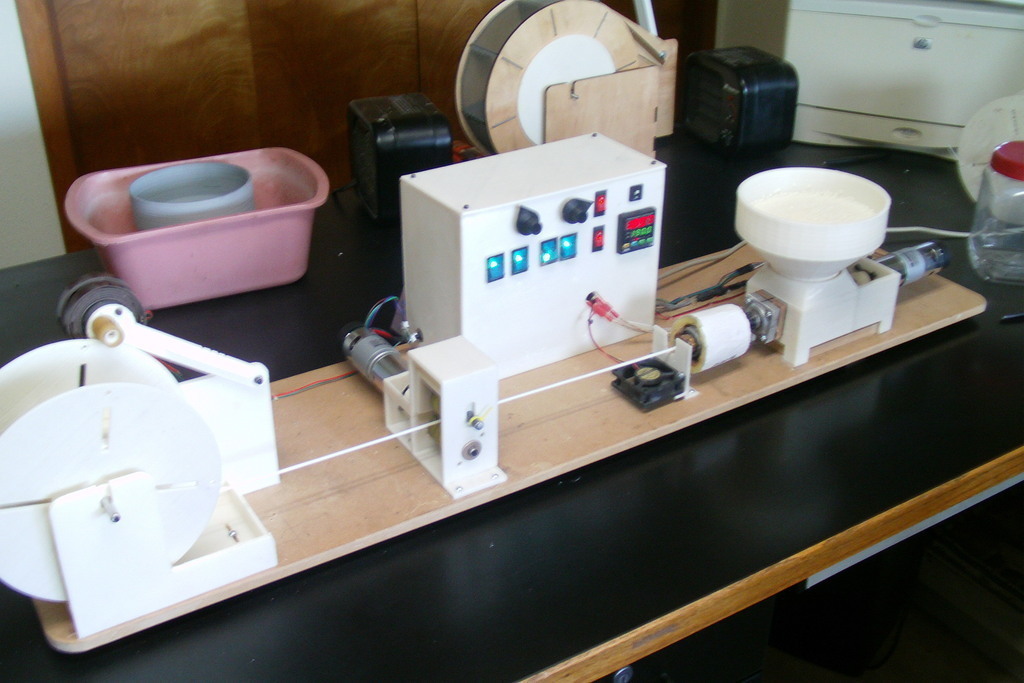

The first machines built by 3D Systems and Stratasys were bulky and expensive. The cost of one was hundreds of thousands of dollars, and only the largest companies in the automotive and aerospace industries could use them. Printers had a lot of limitations and could not be widely used. The development of technology has been very slow. 20 years later, in 2005, the RepRap (Replicating Rapid Prototyper) project appeared - a self-replicating mechanism for rapid prototyping. nine0003

nine0003

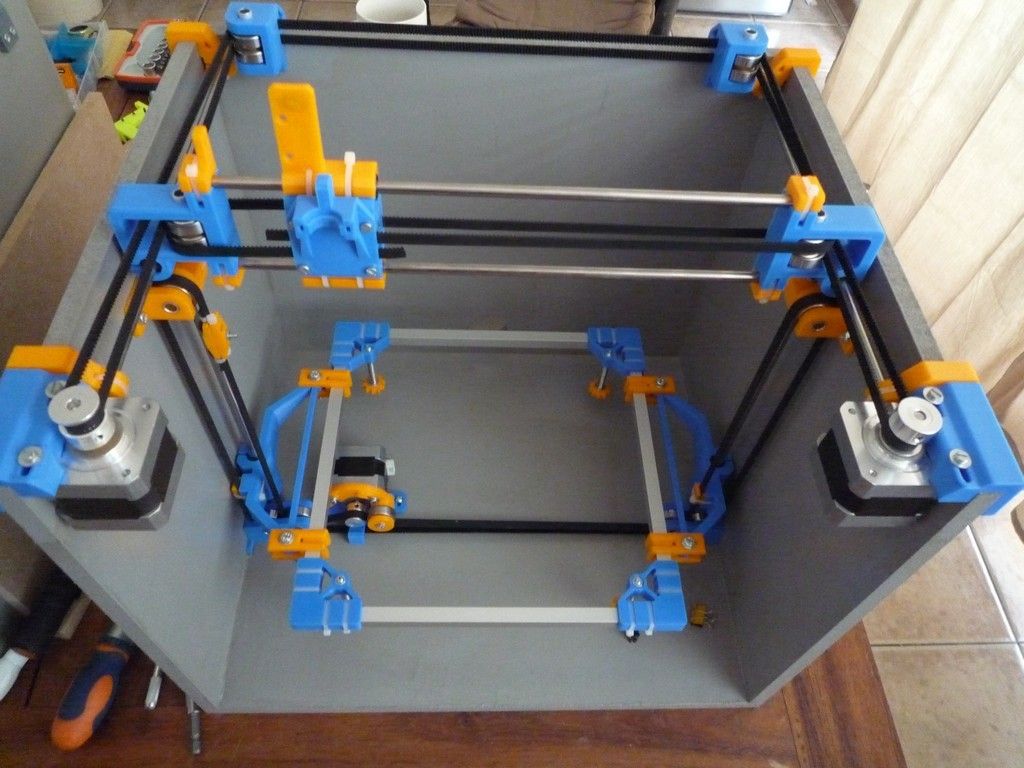

It was inspired by Dr. Adrian Bauer from the University of Bath in the UK. The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. In the photo, all the plastic parts of the "child" are printed on the "parent". But in fact, a group of enthusiasts led by Adrian were finally able to create budget 3D printer for home or office use .

The idea was quickly taken up by three New York technologists and started a desktop FDM printer company, MakerBot. This was the second turning point in the modern history of 3D printing. nine0003

Other technologies were being developed in parallel. One of them is bioprinting. Thomas Boland of Clemson University has patented the use of inkjet printing to 3D print living cells, making it possible to print human organs in the future. Dozens of companies around the world conduct research in this area.

Another important use of the new technology was the creation of prostheses, first conventional, and then bionic.