3D printing dentistry

5 Ways 3D Printing has Redefined the Dental Industry

Additive manufacturing has affected many industries, but few stand to benefit as much as the medical fields, including dentistry.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

Read on to discover five ways in which the digital workflows are revolutionizing the dental industry.

While dentistry has always required high levels of customization, the industry has traditionally relied mostly on manual methods to create custom appliances. Today, digital workflows enable mass customization in a consistent, automated way, requiring less labor and incurring lower costs.

Everyone has a dentition—the pattern of development and arrangement of teeth—unique to them. Dental indications must, therefore, be made to match each individual patient’s anatomy. With traditional manual workflows, the quality of the finished products is highly dependent on the skills of a given technician. Achieving consistent and high-quality dental products with so many potential sources of error is incredibly difficult and expensive.

Intraoral scanners can capture scans directly from the patient, replacing manual impressions with fast and accurate digital impressions. Alternatively, desktop scanners in dental labs can be used to scan traditional alginate and PVS impressions.

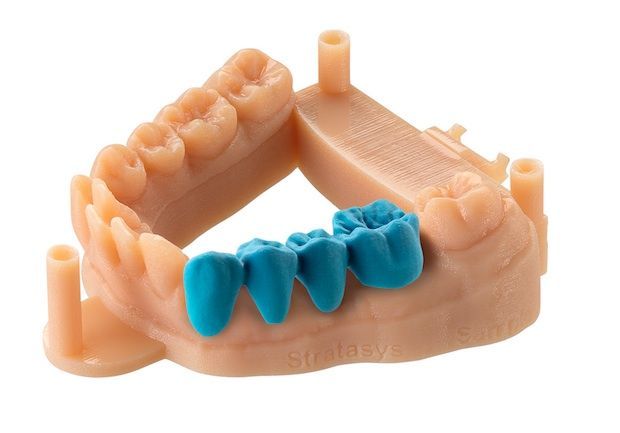

With digital workflows, each dental product is precisely detailed to the specifications dictated by the patient's anatomy. 3D printers are like Swiss-army knives—no other tool can produce such a wide variety of dental products with consistently high quality. Using dedicated materials, labs and practices can use 3D printers to produce orthodontic models, highly accurate crown and bridge models, surgical guides, castable or pressable restorations, aligners, retainers, long-term biocompatible dental products like splints or dentures and more.

Digital technologies simplify workflows, reduce the room for error and the amount of labor required, resulting in time and cost savings on both the lab's and practice's side.

Orthodontics as a dental specialty has come a long way since traditional metal wired braces. While still necessary in some complex cases, removable clear aligners provide an appealing alternative today and have been used to treat millions of patients.

Clear aligners, one of the most popular orthodontic treatments today, couldn't exist without digital technologies such as 3D printing.

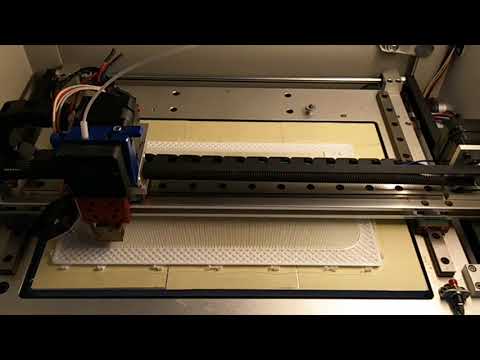

Clear aligners couldn't exist without digital technologies; their manufacturing process is a brilliant combination of multiple digital workflows. An orthodontist or dentist first captures an impression of a patient's dentition with a 3D intraoral scanner or takes a traditional impression for the lab to scan. The digital model provides a basis to plan the progressive stages between the current and desired teeth positions. Each stage is then 3D printed and the aligners are thermoformed over these 3D printed molds.

Each stage is then 3D printed and the aligners are thermoformed over these 3D printed molds.

Traditionally, the 3D printers used in this process were large and complex to use and prohibitively expensive. Now, smaller format desktop 3D printers can create molds for thermoformed appliances, opening up the possibility for any lab or practice to produce aligners and retainers in-house and expand production without adding substantial overhead.

Ashford Orthodontics, the largest orthodontics laboratory in the UK produces thousands of clear retainers using 3D printed models.

Digital technologies can augment complex surgical procedures. CBCT, virtual placement planning, and surgical guides are becoming the new standards of care in implantology. With them, the accuracy of implant placement during surgery is all but guaranteed, the risk of surgical complications fall, and clinical results are improved overall. Let's look at the workflow-enhanced production of a surgical guide as an example.

To create a guide, implantologists combine intraoral scan data of a patient's dentition and anatomy of the patient osteotomy from a CBCT or cone beam scanner. Based on the anatomical data, practitioners use CAD software to plan treatment with high accuracy and then use a 3D printer to produce a guide that is ready to be used in surgery.

A 3D printed surgical guide used in surgery.

Formerly, the only ways of producing surgical guides was through milling or 3D printing on industrial 3D printers. But due to the complex and expensive machinery involved, these guides could easily cost hundreds of dollars, which made them cost-prohibitive in most cases. Now with desktop 3D printing, the costs are down by a factor of 10-100X, paving the way for guided surgeries to become the standard.

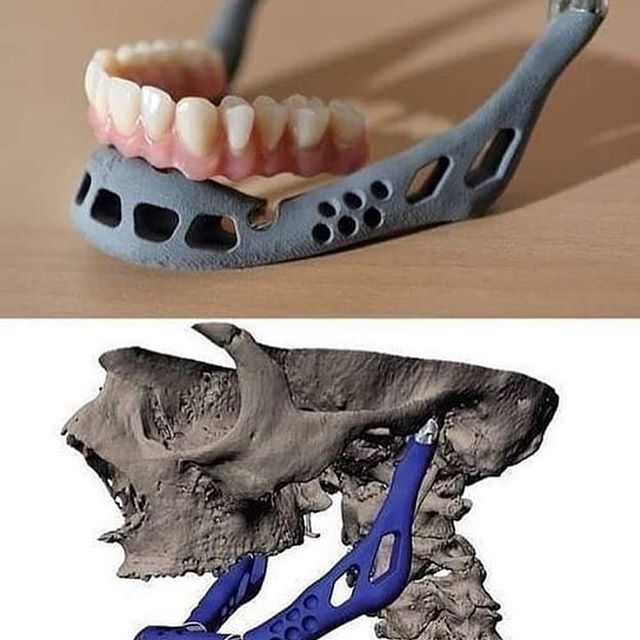

Traditional denture manufacturing is a time-consuming and labor-intensive analog workflow that involves multiple patient visits and production steps. It is a complex craft with a steep learning curve and dental labs increasingly struggle to find technicians with the advanced skills and expertise required to produce them.

Dentures are one of the latest innovations in digital dentistry. They offer an efficient and cost-effective manufacturing solution and a major step toward the overall simplification of the dental laboratory manufacturing process.

Digital dentures are cost-effective and offer a consistent workflow for a high-quality end product.

Denture production with the digital workflow includes fewer steps and less variability, resulting in a more consistent workflow for a high-quality end product every time. Digital denture designs are also reusable, shareable, modifiable, and easy to reproduce with 3D printing. The affordable hardware, lower material costs, and time savings (less labor) all contribute to a substantial cost advantage over their handcrafted counterparts.

Scanning solutions, software tools, and materials are developing rapidly to take digital dentures to their full potential. As they do, digital dentures are bound to replace or supplement the traditional workflow for an increasing share of the 50 million dentures produced a year globally and pave the way for more inclusive denture solutions for everyone who needs treatment.

At the end of the day, it's the patients who stand to gain the most from the advances in digital dentistry.

Starting with the visit to the dentist or orthodontist, being able to visualize a dental procedure can be as reassuring for the patient as it is helpful for the practitioner. Virtual treatment planning, diagnostic wax-ups, and highly detailed replicas can help patients envision and understand the treatment they will be receiving in great detail, reducing anxiety and increasing patient acceptance.

Highly detailed replicas can help patients envision and understand their treatment.

Considering workflow and treatment improvements, taking an impression of a patient's dentition with intraoral scanning is quicker and more comfortable than traditional alginate and PVS impressions. The products themselves can be more aesthetically pleasing (clear aligners) and treatments more accurate and less invasive (digital implantology and surgical guides). Processes are generally faster as digital elements remove superfluous steps, making the patient's visit quicker and easier.

Precise and consistent treatments mean that patients are vastly less likely to need to return for repeat work on the same problem, saving their time and money. But a satisfied patient is more likely to become a return customer and refer others, contributing to the long-term success of all dental businesses.

These are just some examples of the wider scope of changes that digital dentistry and 3D printing processes are bringing to the dental industry.

Despite the narrative of “traditional vs. digital workflows” used frequently to promote the latter, contemporary dental workflows can combine the best of both. The support of digital workflows translates to a plethora of new possibilities for the industry and a raft of improvements for the customer.

Find out more about how Formlabs is driving this change, learn about the range of dental indications, and request a free sample part for yourself to see the quality firsthand.

Request a Sample 3D Printed Part

Dental 3D Printers - SprintRay Inc.

Let's get one thing straight:

3D printing solutions must know exactly which problems they're trying to solve.

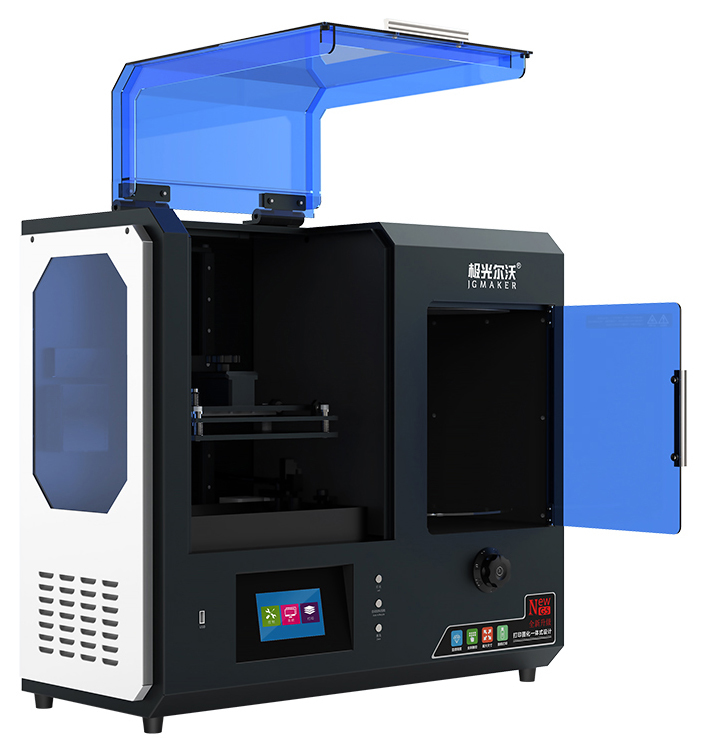

Thanks to recent advances in technology, design, and materials, the role of dental 3D printers is rapidly expanding from dental labs into individual practices. So how does this hyped-up technology actually work, and what about 3D printing makes it such a great fit for dentistry? And why are SprintRay 3D printing products are the forefront of the market?

RayWareDental Print Software

The adoption of dental 3D printers is driven by continuous innovation in three major categories:Biocompatible Materials

Materials innovation is at the heart of dental 3D printer adoption. While the production of models is crucial for many practices, the creation of dental appliances that can be placed intraorally, such as night guards, surgical guides, and digital dentures, are a critical to the advancement of this technology's role in dentistry.

Accuracy and Repeatability

Accuracy and repeatability are essential for dental 3D printers. In order to provide the highest standard of care and final fit and finish, extremely high accuracy is a non-negotiable. Recent advancements in materials and printing technology have supercharged the accuracy of 3D printers such as SprintRay Pro.

Production Speed and Scalability

In order to keep pace with a busy office, a good dental 3D printer should offer rapid print speeds and high overall production throughput. These are a factor of build plate size and light delivery technology and should not be overlooked.

Biocompatible Materials

View All Materials

Dental 3D printers reached an inflection point when biocompatible materials became widely available for desktop machines. These FDA-compliant materials made 3D printed parts safe for intraoral use and offered great mechanical properties, propelling desktop 3D printers into dental practices all over the world.

Since the introduction of biocompatible materials for 3D printing in dentistry, the emphasis has been on improving mechanical properties to provide intraoral parts that have great strength and a high resistance to wear. Because materials innovations can come from anywhere, it’s important to choose a 3D printer that offers support for third-party materials.

Accuracy and Repeatability

Accuracy Study

One of the central requirements of dental manufacturing is very high accuracy and repeatable results. Bringing manufacturing of models and other appliances in-office only pays off if the technology can provide the tight tolerances required for fitted parts. But it isn’t enough for a single print to provide accuracy; the results need to be easily replicated over time. Though printers can be easily bucketed into categories based on the details of their underpinning technologies, these categories rarely tell the full story.

While many 3D printers on the market provide high theoretical accuracy, not all offer results that are repeatable over time. The hallmark of a true dental 3D printer is to have both high accuracy and repeatability. As 3D printing technology continues to mature, there is an emphasis on the way light is delivered to the build area to ensure accurate, repeatable results.

Production Speed and Scalability

Speed Comparison

Same- and next-day production of dental appliances is a longtime dream of digital dentistry, and dental 3D printers have the capacity to make this dream a reality. But while certain aspects of 3D printing technology have begun to converge, there is still a massive difference in production speed and scalability. A large portion of these discrepancies are motivated by the technology that underpins each printer type, but many are not.

While dental 3D printers are sometimes used to printing only one or two parts at a time, many cases require the rapid fabrication of a large number of parts. Clear aligner cases are the obvious standout, but batched nightguards, surgical guides, and denture bases all require large print volume as well. Emphasis of development in this region of the technology is focused on reducing both single-part as well as full-batch print speeds.

Clear aligner cases are the obvious standout, but batched nightguards, surgical guides, and denture bases all require large print volume as well. Emphasis of development in this region of the technology is focused on reducing both single-part as well as full-batch print speeds.

Reading Between the Voxel Lines

Parsing the jargon from the technology can be difficult. Here's where to start.

Digital dentistry is largely served by a type of 3D printers that fall under the umbrella term stereolithography. These printers use light to cure photosensitive, liquid resin. Broadly speaking, there are three ways to deliver that light, each with its own advantages and drawbacks.

DLP Projector

Projector-based Stereolithography- Long operating life

- Highly accurate

- Fast print speeds

The technology used in DLP 3D printers is the descendant of what you might find projecting your home theater system. Projecting in a wide arc that reaches the entire resin vat at once, DLP printers are low maintenance, accurate, and very fast, making them perfect for digital dentistry.

Projecting in a wide arc that reaches the entire resin vat at once, DLP printers are low maintenance, accurate, and very fast, making them perfect for digital dentistry.

Laser-SLA

Laser-based Stereolithography- Smooth surface finish

- Slow print speeds

- Complicated system

Like a consumer laser pointer, the light source in laser-SLA printers is a tiny pin dot of light. This pin dot reflects off of a rotating mirror and into the resin vat, drawing each layer as it goes. Because it must trace each part, laser printers are much slower for large jobs.

LCD Panel

Masking-based Stereolithography- Smooth surface finish

- Fast print speeds

- Costly, frequent repairs

Just like your smartphone, LCD printers use a small LCD screen to deliver light to the resin vat. These printers are very similar in principle to DLP, but can be very cheap to produce. However, the LCD screens in these printers are often consumable, requiring frequent replacement.

These printers are very similar in principle to DLP, but can be very cheap to produce. However, the LCD screens in these printers are often consumable, requiring frequent replacement.

The 30-Minute Dental 3D Printer

Here’s why DLP is right for digital dentistry.

While the ability to produce dental appliances in-office is revolutionary to digital dentistry, the speed of an individual 3D printer can make a substantial difference. A practical way to measure the outcome of this speed is to measure its output via the 30-minute test, which shows both the on-demand printing speed as well as the overall throughput of the printer. Because of its bespoke DLP projector, SprintRay Pro can produce a full platform of dental arches in around 25 minutes.

SprintRay Pro

Thanks to its simple touchscreen interface, swivel hood, and magnetized build plate, 5 minutes is all that it takes to turn the printer around for another job.

For a more rigorous test of overall speed and throughput of SprintRay Pro and its competitors, read our in-depth blog post on the subject.

Laser-SLA competitor

Laser-SLA printers use a pin-dot of light to cure photopolymer resin. While this results in clean surface finish, laser printers experience extremely slow print speeds, making it unacceptable for the needs of digitial dentistry.

LCD competitor

LCD printers often utilize a smaller build plate due to the size constraints of LCD panels. While they have high printing speed, they require frequent, costly light source replacement.

Cutting-edge Digital Dentistry Powered by SprintRay

The SprintRay 3D printing ecosystem is designed for the unique needs of dental professionals. With SprintRay as your partner, pushing the boundaries of what’s possible in dentistry has never been easier.

Schedule Consultation

Desktop 3D Printer

Automated Wash/Dry

Automated Post-processing

3D Printing Materials

3D Printing Software

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar. nine0003

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary. nine0003

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

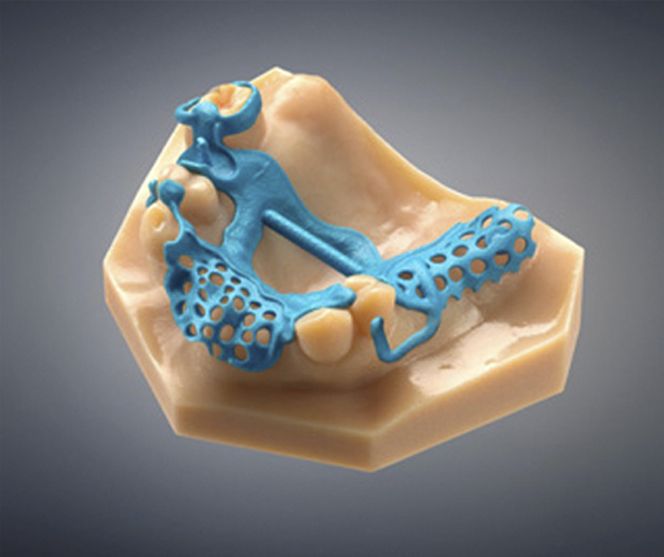

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery. nine0034

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks. nine0003

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

Digital LED projection (DLP). nine0014 Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

nine0014 Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay. nine0003

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality. nine0003

Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality. nine0003

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

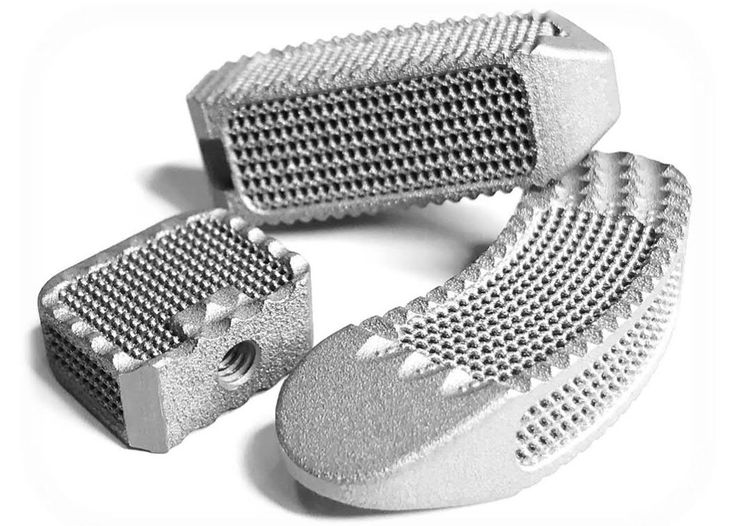

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D. nine0003

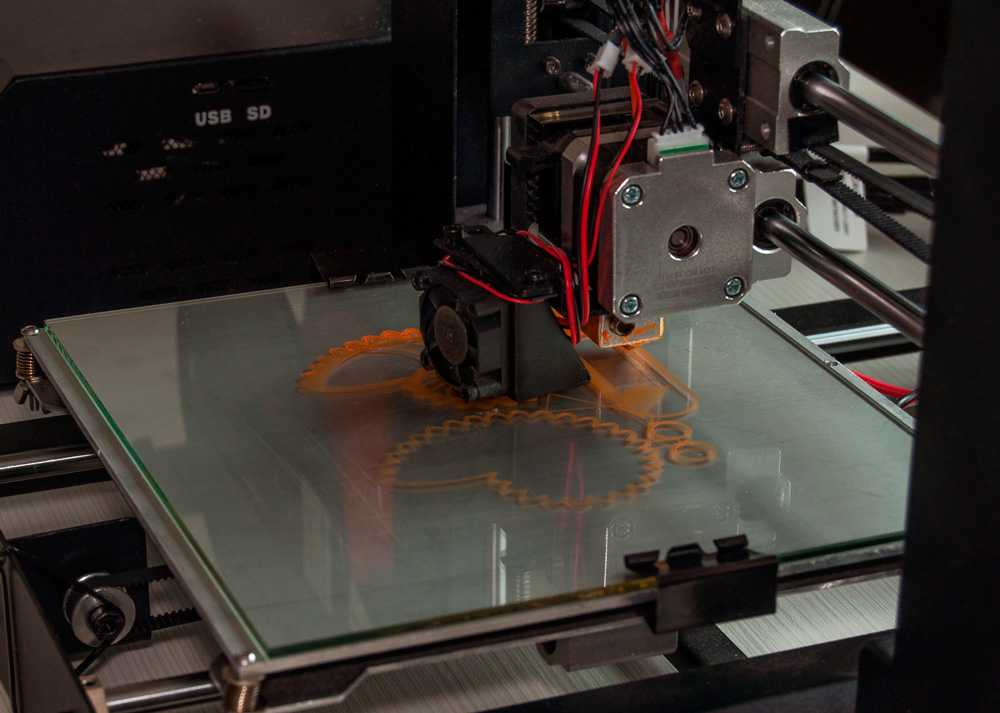

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic. nine0003

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

nine0003

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here. nine0003

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here. nine0003

← General requirements for the placement of portable X-ray machines | TOP-5 Backlit Physiodispensers →

3D printing in dentistry, which photopolymer printer to choose?

Application

Follow author

Subscribe

Don't want

3

Article applies to printers:

Elegoo Saturn ANYCUBIC Photon Mono X Anycubic Photon S 3D printing is used in almost all fields of activity, one of which is medicine. With the help of this technology, it became possible to manufacture high-quality prostheses, because the printed elements are much cheaper, often stronger, and the process of their production is simpler. 3D printers are most actively used in dentistry. nine0003

3D printers are most actively used in dentistry. nine0003

To apply this technique in dentistry, it is necessary to understand how models are created on a 3D printer, what characteristics the equipment should have, and what materials may be required for this. It should be remembered that the process is quite complex and requires a clear sequence:

First you need to get a model of the future workpiece. To do this, using a specialized device, the oral cavity is scanned. After that, all the proportions and nuances of the original sample are fixed so that the printer can accurately recreate the product. nine0003

The software then makes the necessary adjustments. Often, the intelligent system in the software does this by itself, without third-party intervention, however, checks and improvements improve the quality of the product. In addition, they help eliminate existing defects, so less post-processing is required.

Print. 3D printer for dentistry allows you to produce prostheses and other blanks necessary for treatment. Below we will analyze each of these points in more detail.

Below we will analyze each of these points in more detail.

For the manufacture of dental implants, it is necessary to use a 3D printer capable of high-quality printing. It guarantees time and cost savings as well as ease of use. It should be remembered that the blank for 3D printing can be made in different ways:

The first way is to scan the finished plaster cast. In this case, electronic models can be obtained with small deviations and need to be improved, so the impression takes more time to make.

The second way is to use a professional intraoral (intraoral) scanner. This equipment allows you to get fairly accurate parameters from the jaw, but the price of a device that performs intraoral scanning will be much higher than a 3D printer. nine0003

Today, even small clinics can purchase a 3D printer, but each device has its own characteristics. The final result is made up not only of the accuracy of converting the received information into the finished product, but also of the quality of the read file, so it is necessary to refine, eliminate defects through special software. In some cases, software alone is not enough. If these factors are taken into account and efforts are made to improve the quality of prostheses, their service life will increase and post-processing will decrease. nine0003

In some cases, software alone is not enough. If these factors are taken into account and efforts are made to improve the quality of prostheses, their service life will increase and post-processing will decrease. nine0003

The choice of material for 3D printing is important in solving dental problems. Good results can be achieved with BlueCast , FunToDo and Anycubic Dental Resins. The listed dental photopolymers are compatible with almost all LCD printers. The advantages of using them are high detail and perfectly smooth surfaces of printed objects, the ability to produce small and complex products with good physical and mechanical properties, as well as ease of post-processing and inexpensive price. nine0003

Due to the wide variety of products and performance, it is not easy for novice users to choose the right 3D printer for dentistry. Many 3D printer sellers recommend starting from factors such as "speed and quality", but we cannot fully agree with this, if only because the quality of 3D printing is a combination of factors: printer technical capabilities, photopolymer properties, software and operator experience that controls the printer. And the print speed sometimes even goes against the “quality”, judge for yourself: a novice driver who has just graduated from a driving school should not immediately buy a sports car and practice high-speed races. nine0003

And the print speed sometimes even goes against the “quality”, judge for yourself: a novice driver who has just graduated from a driving school should not immediately buy a sports car and practice high-speed races. nine0003

That's why the first printer we recommend to dental technicians who decide to optimize their work is the Anycubic Photon S or Elegoo Mars Pro 3D printers. Moreover, the price of these models has now been reduced due to the introduction of monochrome lines of 3D printers to the market. These are two very popular models, which not only have a huge user experience of the 3D printing community, but also always have consumables and spare parts at affordable prices. nine0003

For users who are already familiar with the 3D printing process, for those who need fast printing as well as a large printable area, we recommend the line of monochrome printers.

- Elegoo Mars 2 Pro (Mono LCD) is a printer with a small printable area, but due to the monochrome display, it is characterized by increased productivity and ease of use.

The Anycubic Photon Mono is on par with it.

The Anycubic Photon Mono is on par with it. - Elegoo Saturn Mono 4K is a 3D printer in the Elegoo range, which is suitable for creating complex prototypes in the medical industries. The device is included in the middle price range and features increased productivity, as well as 4K resolution and high detail up to 50 microns, which allows you to accurately print fine details.

- Anycubic Photon Mono X is a 3D printer that works with almost any photopolymer resin. It has the same large desktop 192×120×245mm, monochrome LCD 4K screen, high speed as Elegoo Saturn. nine0034

In addition to photopolymer 3D printers for dentists, in our store you can always buy the most popular printer models at affordable prices.

- Flying Bear Ghost 5 - popular 3D printer with BMG Dual Drive extruder

- Anycubic i3 Mega S 3D printer

- Anycubic Mono SE - high-speed photopolymer 3D printer with monochrome LCD and WiFi function

- 3D printer Anycubic 9033 9034 9034 Pro 030 Pro 2.

Learn more