Industrial resin 3d printer

For Dental Lab,High Efficiency,LCD 3D Printing

For Dental Lab,High Efficiency,LCD 3D Printing-

Technical Theory

We use Fresnel lens integrated light source to make sure the light vertical to the screen, image accurately and luminous power well-distributed, which can reduce the data distortion compared to the matrix source LCD.

-

High Precision, Continuous Printing Capabilities

Mercury D6K, with 6K high resolution, can print the standard dental mold within the range of ± 50 μ m, which leads to the quality of smooth and delicacy. FEP film enhance continuous printing capabilities up to 100,000 layers.

-

Large Printing Area

288mm×162mm(W×L) 13.3inches.High Efficiency,up to 7.5 pairs of complete dental models or 12 pairs of 1/4 dental models can be print at the same time by Mercury D6K. High Speed, dendal models of 17.5mm hight can be printed with 68mins by Mercury D6K. (thickness of layer is 0.05mm)

-

Easy to Operate

We use large IPS touch screen (7 inches ) ,which is convenient for pressing /touching. It provides users a full perspective to check the printing status.

For More Applications

Restoration Model Removable Partial Model Implant Model

Technical Specification

-

Mercury-D6K

Maximum Part Volume:288*162*160mmPrinting Speed:15cm/h(50μm layer thickness)Technology:LCD,6KPixel Size(XY Resolution):50μmPrinting Accuracy:±0.

05mmLayer Thickness:0.05mm,0.1mmPrinter Size:W568*D490*H646mmPackage Size:W700*D645*H780mmNet Weight of Printer:50kgResolution:5760*3240

05mmLayer Thickness:0.05mm,0.1mmPrinter Size:W568*D490*H646mmPackage Size:W700*D645*H780mmNet Weight of Printer:50kgResolution:5760*3240

SoonSer 3D Printing Material Catalog

SoonSer 3D Printing Material CatalogFilter by

SLA Resin DLP Resin

- SLA Resin (S-ST-9001)

- Standard-Grey

- Resin (S-ST-9008)

- Standard-Clear

- SLA Resin(S-CL-7001)

- Standard-Colorful

- SLA Resin (S-ST-5001)

- Tough-Clear

- SLA Resin (S-CA-6002)

- Tough-Black

- SLA Resin (S-ST-9012D)

- Tough-Resin Plus

Industrial 3D printers for printing resin-coated sand for injection molds and polystyrene

SLS technology (Selective Laser Sintering - Selective Laser Sintering)

SLS 3D Printer Scheme for Polymer Coated Sand and Polystyrene

Technical parameters of industrial 3D printers SLS-PS

| Model nine0019 | SLS-500PS | SLS-1000PS | SLS-1200PS | SLS-1400PS |

| CO2 laser, Power W | 55 | 100 | 100 | 100*2 100*4 |

| Scanning system Dynamic focus nine0019 | 8 m/s | 8 m/s | 8 m/s | 8 m/s*2 8 m/s*4 |

| Print Layer Thickness | 0. 08-0.3mm 08-0.3mm | |||

| Print Accuracy | ±0.2mm (L≤200mm), ±0.1% (L>200mm) | |||

| Print chamber size mm nine0019 | X500 Y500 Z400 | X1000 Y1000 X600 | X1200 Y1200 Z600 | X1400 Y1400 Z500 |

| Powder supply | Two pistons on both sides | |||

| Print material | Color coated sand, polystyrene | |||

| Operating system | Windows XP | |||

| Software | HUST 3DP (independent research and development) | |||

| File Format | stl, online cuts in the process of formation, changing the layer thickness, scanning. 3D visualization | |||

| 3D printer dimensions mm nine0019 | X2070 Y1280 Z2080 | X2150 Y2170 Z3100 | X2350 Y2390 Z3400 | X2520 Y1790 Z2780 |

| Power supply | 3 phases, 4 lines with earth, 380V±10%, 50Hz | |||

| Working temperature | 18-25°С | |||

| Operating Humidity | Not more than 60% | |||

| Power input kW | 3 | 4 | five | 9/16 |

Catalog

Download >>> View >>>

Video

Related products

3D printer SLA-600

Industrial stereolithographic 3D printer SLA on photopolymer resin

Industrial 3D printers for metal printing using EBM technology

Equipment for the production of metal powders for 3D printers using induction vacuum melting and gas atomization

Industrial 3D printers for metal printing SLM nine0003

Industrial 3D Metal Printers LMD

Industrial 3D printers for printing with nylon (polyamide) and polypropylene powder

Industrial 3D printers for printing ceramics

Auxiliary equipment for additive 3D manufacturing and prototyping

How to choose an industrial 3D printer

Your city: Moscow

Right?

× Choose the city closest to you:

Moscow Saint Petersburg Vladivostok Novosibirsk Ekaterinburg Kazan Nizhny Novgorod Chelyabinsk Omsk Rostov-on-Don Samara Krasnoyarsk Voronezh Perm

Volgograd Krasnodar Saratov Tyumen Tolyatti Izhevsk Barnaul Ulyanovsk Irkutsk Khabarovsk Makhachkala Yaroslavl

▼ Show more

Deselect

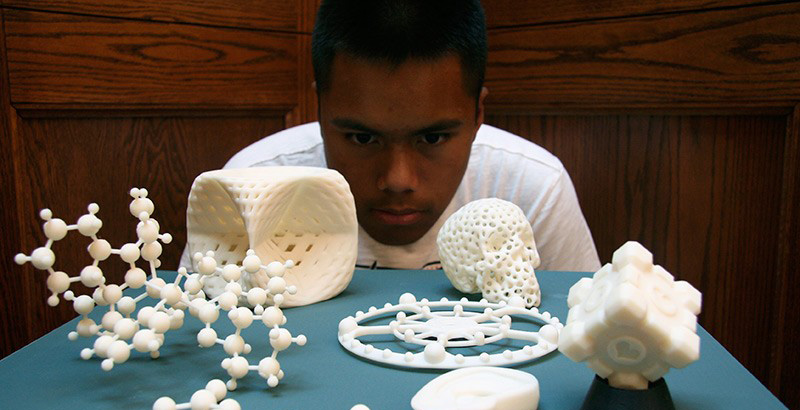

Industrial 3D printing technologies are rapidly advancing in many ways, passing critical thresholds of print quality, reliability and cost structure. Recent advances in hardware, materials, and software have made 3D printing accessible to a wider range of businesses, allowing more companies to use tools previously limited to a few high-tech industries. nine0003

Recent advances in hardware, materials, and software have made 3D printing accessible to a wider range of businesses, allowing more companies to use tools previously limited to a few high-tech industries. nine0003

Today, industrial 3D printers are accelerating innovation and supporting businesses across industries including engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

An industrial 3D printer can revolutionize business and reduce production costs and lead times.

Industrial 3D printing processes

The most commonly used 3D printing technologies are Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), PolyJet and Direct Metal Laser Sintering (DMLS). nine0003

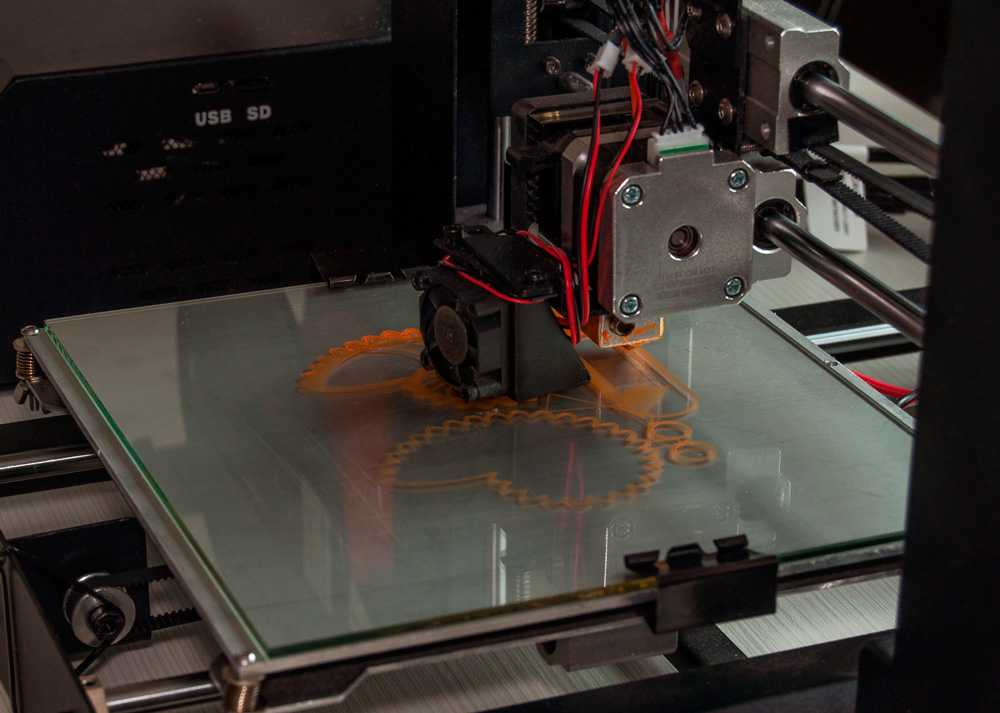

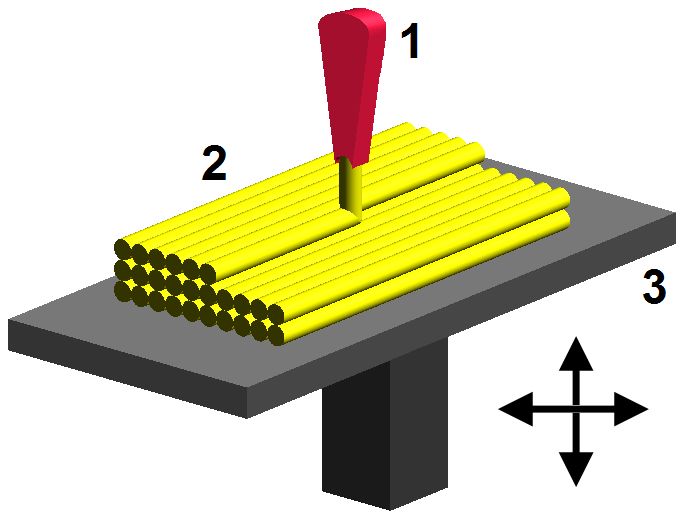

FDM (Fused Depsition Modeling)

FDM 3D printing is one of the oldest and most widely used additive manufacturing techniques in the world. It consists of applying subsequent layers of molten material and allowing adjacent layers to cool and merge with each other before applying the next layer.

FDM technology can be described as the reverse process of CNC numerical cutting. 3D models are converted into g-codes, which are sets of instructions. They serve to position the drivers and thus to precisely extrude in order to create another layer. The technology basically uses the exact amount of material needed for a particular part, as opposed to CNC methods that result in a lot of wastage of the material we use. nine0003

The resolution of a high prototype is affected by many factors such as driver positioning accuracy, user calibration, or the quality of the material used in FDM 3D printing. Typically, the FDM print tolerance is 0.15mm to 0.25mm.

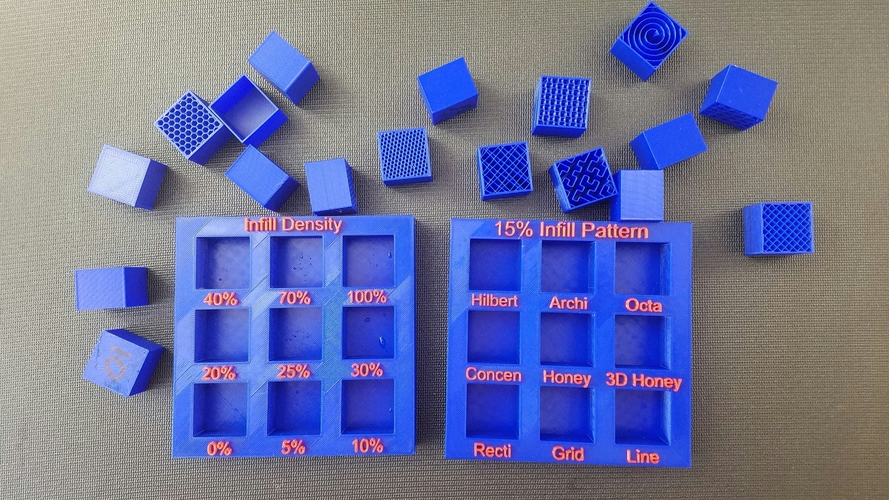

The biggest benefit of FDM is the quick adjustment of the infill of 3D printed models. This means it's very easy to print a prototype just to check setup and finish. With little internal filling or even a hollow core, we save on material costs. Upon completion of the design phase, we can carry out a final inspection or start a small or medium production series with the final filling of the appropriate 3D printing. nine0003

nine0003

SLS (Selective Laser Sintering)

SLS technology - selective laser sintering - consists in fusing polyamide particles using a high-energy laser beam. The process begins by filling the chamber with powdered material. As the print progresses, the build surface lowers and another layer of powder is added. Polyamide powder is sintered carefully, layer by layer. The solution allows the production of geometrically complex elements with high dimensional accuracy compared to other 3D printing methods. nine0003

SLS is particularly interesting in terms of the use of materials that are widely used in the plastics industry, including polyamides.

SLS printers use a powerful laser to melt fine polymer powder particles. The unmelted powder supports the part during printing and eliminates the need for special support structures, making SLS a particularly effective choice for complex mechanical parts.

The ability to produce parts with superior mechanical properties makes SLS the most common polymer additive manufacturing technology for industrial applications. nine0003

nine0003

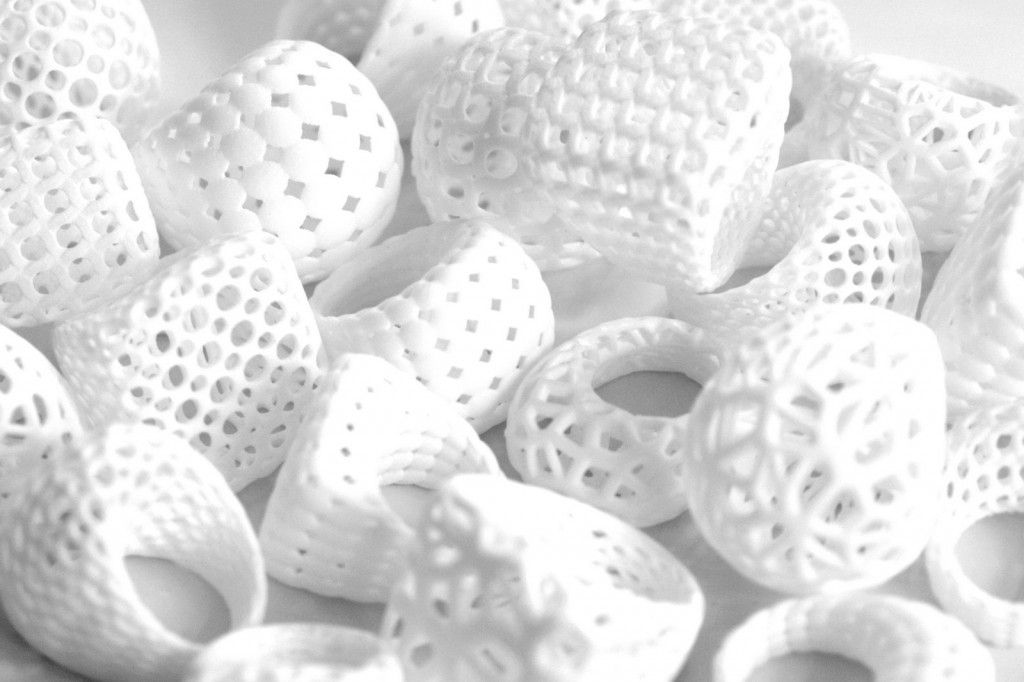

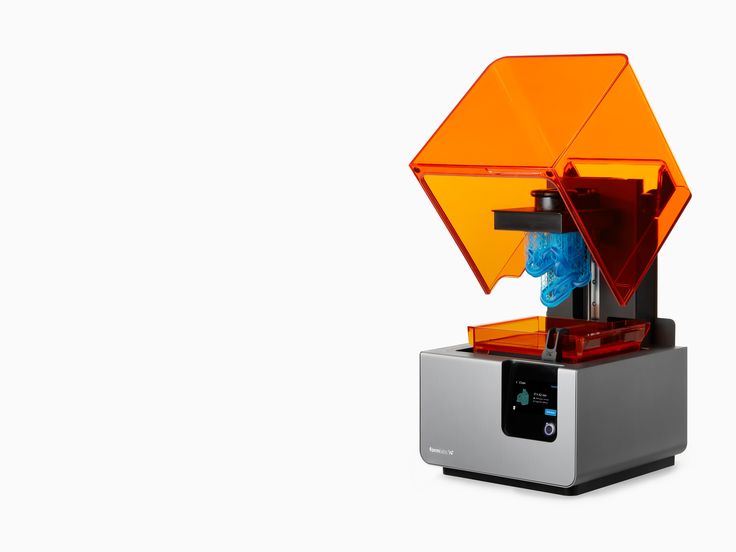

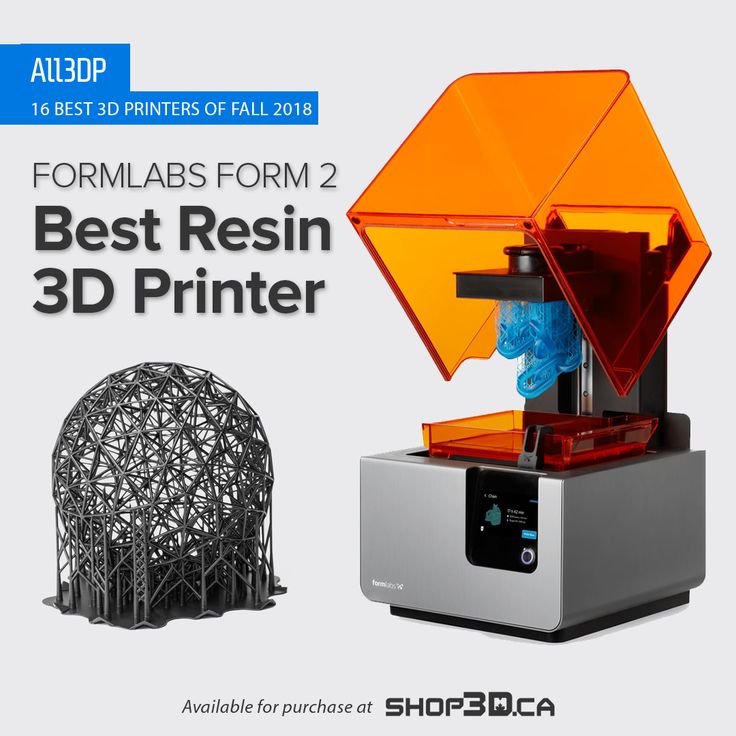

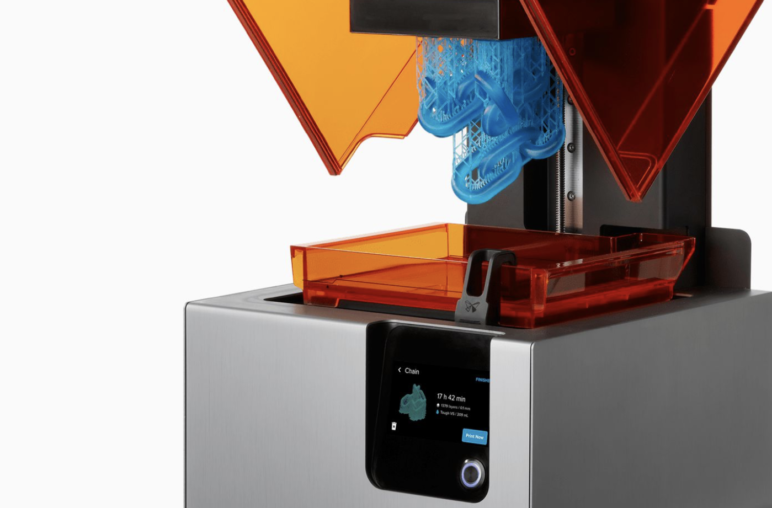

SLA (Stereolithography)

SLA (Stereolithography) is a 3D printing technology using liquid photopolymer resin. In this technology, the model material is cured with a UV laser beam to achieve the final geometry. The material required for SLA printing - liquid resin - is stored in a tank, into which the working platform is gradually immersed, and then locally illuminated (at the places where the corresponding model is created) with a UV laser. The resin curing by illumination is repeated until the part is ready and the latter is rinsed with isopropyl alcohol to remove any polymer that has not cured. After cleaning, the printout is placed in a special lighting fixture, where the resin models acquire their final properties. nine0003

Stereolithography is one of the most precise 3D printing technologies in the world. This allows you to recreate even the smallest details on printed models. SLA printout accuracy is 0.1mm to 0.2mm.

SLA parts have the highest resolution and precision, the sharpest detail and the smoothest surface of any plastic 3D printing technology. The main advantage of SLA is its versatility. SLA resin formulations offer a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

The main advantage of SLA is its versatility. SLA resin formulations offer a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

SLA is an excellent choice for highly detailed prototypes requiring tight tolerances and smooth surfaces, as well as shapes, tools, templates, medical models and functional parts. It also offers the highest heat rejection temperature of 238 degrees Celsius, making it an ideal choice for certain engineering and manufacturing applications, as well as the widest selection of biocompatible dental and medical materials.

DMLS (Direct metal laser sintering)

DMLS is one of the most advanced technologies. 3D printing uses a powerful laser to fuse metals and alloys at the microscale. The main application of DMLS is the creation of metal parts of complex geometry. Immediately after the 3D printing process, the parts are fully functional (heat resistant, strong and durable). In fact, parts are even better than cast parts in terms of density, which is reflected in their mechanical properties.

In fact, parts are even better than cast parts in terms of density, which is reflected in their mechanical properties.

Direct metal laser sintering is very advantageous compared to traditional production methods, as even the most complex elements can be produced in a single production run, which means lower production costs. DMLS technology, combined with topological analysis, makes it possible to produce parts that are lighter than those obtained by traditional manufacturing methods. nine0003

DMLS metal parts are exceptionally strong and have a very high weight-to-strength ratio. High resistance materials such as 316 L tool steel, aluminum alloy, titanium, or inconel (an alloy of nickel and chromium) are commonly used.

PolyJet

PolyJet 3D technology is one of the most precise 3D printing technologies in the world. The principle of operation is close to SLA technology, as it is based on the curing of liquid resin. However, in this case, photopolymer resins are cured with UV lamps. The thickness of a single layer printed using this technology is only 0.016mm (smaller than the thickness of a human hair). Technology accuracy less than 0.099 mm cannot be achieved by other additive technologies.

The thickness of a single layer printed using this technology is only 0.016mm (smaller than the thickness of a human hair). Technology accuracy less than 0.099 mm cannot be achieved by other additive technologies.

PolyJet technology will prove to be suitable for the manufacture of precision elements where high precision is required, thanks to the use of resins with different properties, especially mechanical ones, and a soluble base material. It is designed for rapid prototyping and high quality final prototypes with a smooth surface.

The use of industrial 3D printers

The number of industries using 3D printing to improve the efficiency of production and workflow is steadily growing. This technology is widely used in the jewelry industry, in dental laboratories for the manufacture of crowns, bridges and implants, as well as in the production of hearing aids and prostheses that are ideal for patients. nine0003

The first commercial 3D printing technology was invented in 1984 by Charles Hull. Nearly 30 years have passed and the 3D printing industry has rapidly evolved from stereolithography to bioprinting.

Nearly 30 years have passed and the 3D printing industry has rapidly evolved from stereolithography to bioprinting.

Medicine is perhaps the most interesting area of application. 3D printing in this industry is used in a wide range of applications - from the production of prostheses and hearing aids to the bioprinting of body parts. Breakthroughs in this area are happening quickly and spectacularly.

In architecture and construction, 3D printing is used to create detailed models of buildings. In the past, architects only relied on CAD software to design structures. With 3D printing, you can now convert CAD files to 3D printable files. Thus, architects and engineers can easily modify 3D structures and test different market opportunities with a faster, more affordable prototype. Some of the benefits of 3D printing in architecture and construction include the reduction of material waste and the invention of innovative shapes and structures. nine0003

3D printing is used to produce complex parts for the electronics, automotive and aerospace industries. Automotive giants such as GM, Jaguar Land Rover, and Audi have been using this technology for quite a while now to make auto parts. Leading aircraft manufacturers such as Airbus and Boeing are using this technology to improve performance, reduce maintenance and fuel costs. Boeing used this technology to create environmental control ducting (ECD) for the 787 aircraft. The production and assembly of the ECD is quite complex, as it consists of about 20 different parts, which can now be 3D printed as a single unit. 3D printing aircraft components that are 65% lighter but just as strong as traditional parts saves a lot of money and also reduces carbon emissions. The sums that aircraft manufacturers save are huge. The aviation industry is poised to 3D print an entire aircraft by 2050. nine0003

Automotive giants such as GM, Jaguar Land Rover, and Audi have been using this technology for quite a while now to make auto parts. Leading aircraft manufacturers such as Airbus and Boeing are using this technology to improve performance, reduce maintenance and fuel costs. Boeing used this technology to create environmental control ducting (ECD) for the 787 aircraft. The production and assembly of the ECD is quite complex, as it consists of about 20 different parts, which can now be 3D printed as a single unit. 3D printing aircraft components that are 65% lighter but just as strong as traditional parts saves a lot of money and also reduces carbon emissions. The sums that aircraft manufacturers save are huge. The aviation industry is poised to 3D print an entire aircraft by 2050. nine0003

Even NASA is more than willing to use this technology in their space missions. NASA engineers 3D print parts for a space launch system. NASA recently sent a robot to Mars that has almost 70 custom 3D printed parts. Scientists are also exploring the possibility of using this technology on the International Space Station to manufacture spare parts on site.

Scientists are also exploring the possibility of using this technology on the International Space Station to manufacture spare parts on site.

The possibilities of 3D printing are endless. Because the target market is very huge and competition is minimal, these applications will inevitably grow rapidly and displace traditional 3D printing engineering applications. nine0003

The latest generation of industrial 3D printers has made prototyping and final parts faster and more affordable, opening the door for virtually every company to use 3D printing to improve product development and manufacturing.

See also: What to consider when choosing a 3D scanner

Application for 3D scanning

I have read the Privacy Policy and agree to the processing of my personal data. nine0003

Service request

I have read the Privacy Policy and agree to the processing of my personal data.

I have read the Privacy Policy and agree to the processing of my personal data.