Metal 3d printing san francisco

3D Printing Service for San Francisco, California

CapabilitiesCustom Online 3D Printing ServiceCaliforniaSan Francisco

High Quality San Francisco, California 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your San Francisco, California 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

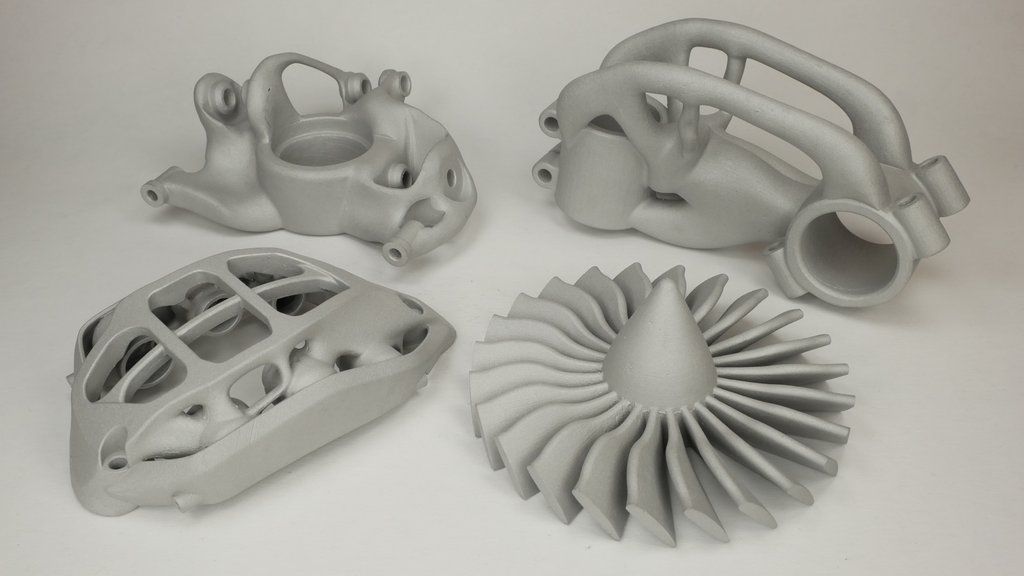

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

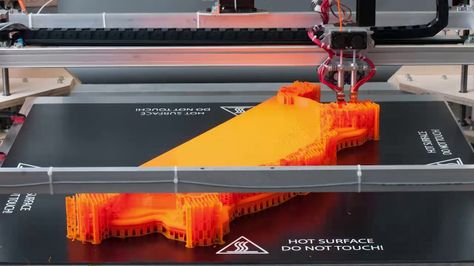

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

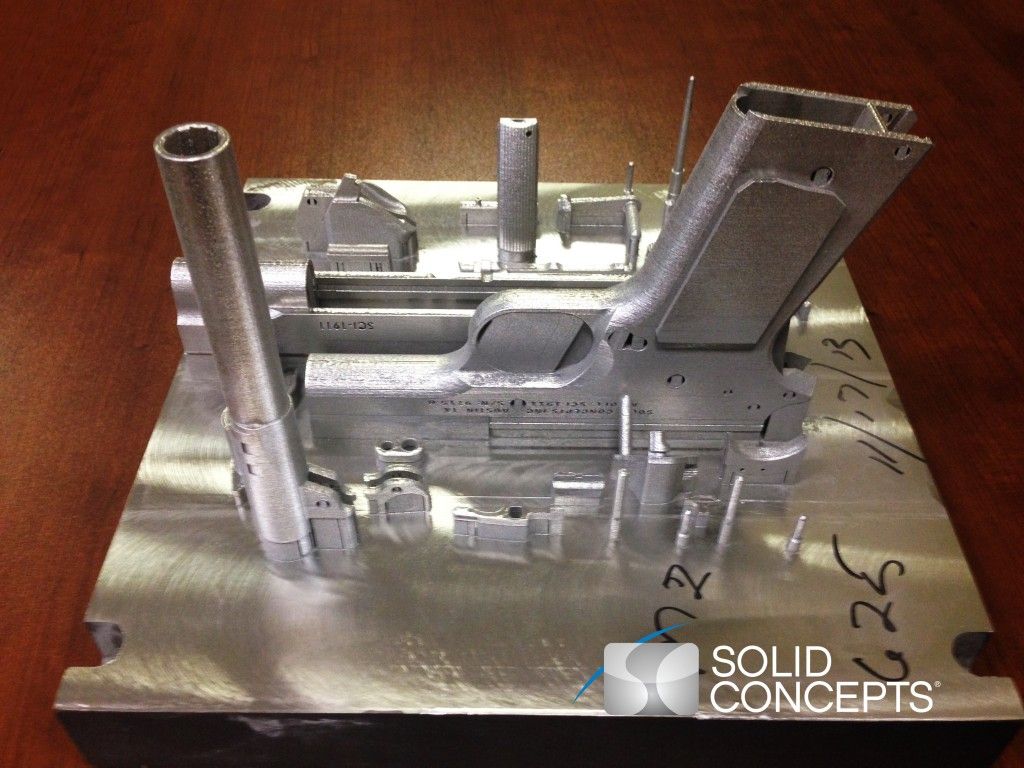

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near San Francisco, California

Oakland

CaliforniaBerkeley

CaliforniaBurlingame

CaliforniaPalo Alto

CaliforniaFremont

CaliforniaMountain View

CaliforniaSunnyvale

CaliforniaSanta Clara

CaliforniaSan Jose

CaliforniaStockton

CaliforniaElk Grove

CaliforniaSacramento

CaliforniaModesto

CaliforniaFresno

CaliforniaCarson City

NevadaReno

NevadaSparks

NevadaBakersfield

CaliforniaOxnard

CaliforniaSanta Clarita

California

Ready to start making custom 3D printed parts?

Protocafe - Home Page

Protocafe - Home PageWelcome to ProtoCafe!

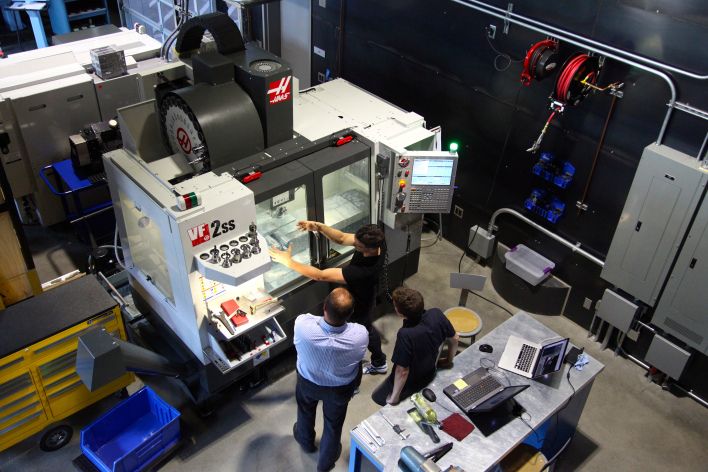

ProtoCafe is the industry leader in the Bay Area for design, rapid prototyping, and manufacturing services. Having developed the 3d printing market in the San Francisco Bay Area, for the past 10 years ProtoCafe has continually pushed the boundaries of design and fabrication along with our clients. We provide our customers with end-to-end solutions from concept to prototype, through design iterations, to low and mid-volume production.

Having developed the 3d printing market in the San Francisco Bay Area, for the past 10 years ProtoCafe has continually pushed the boundaries of design and fabrication along with our clients. We provide our customers with end-to-end solutions from concept to prototype, through design iterations, to low and mid-volume production.

Our Value Proposition

Zero Loss. Zero Disclosure.

Our new state of the art facility offers an extraordinary level of security and effective physical security controls throughout our premises. We provide secure, restricted, access controlled work environment for all development, production, & storage areas.

FAST

Our speed is unparalleled, we’ve been known to turn 3D printed parts in less than a day. We work with our customers and provide them

with a variety of options to meet their quality and aesthetics all while staying within their required time frame.

HIGHEST QUALITY

We start by investing in only the highest accuracy technology to deliver superior results to our customers. Our quality procedures follow strict ISO compliance to ensure the best quality products. Every order must meet our quality standards.

EXPERT ADVICE

People come to us because we can fabricate what no one else will even attempt. We have never no-bid a customer but are always up front regarding the complexity of a project. Our manufacturing experts will try to build the impossible!

Client Testimonials

“ProtoCafe has been knowledgeable, kind and professional, and most importantly in the prototyping world, high quality and ON TIME! I'd recommend working with them on your next project!”

“I have used ProtoCafe on multiple occasions to come through on prototypes needed for quick design iterations and casting models for functional testing.ProtoCafe is creative in the solution options and likes to solve our hard problems.”

“I worked with ProtoCafe to develop large quantity castings for functional testing [that] needed to meet some production requirements (strength, clear/transparent, flammability). ProtoCafe put together the best effort to support the project to meet our technical requirements and aggressive schedule. The castings were delivered on time and functional as designed.”

Services

Rapid Prototyping

HIGH RESOLUTION

FULL COLOR

METAL- DMLS/DMP

SLS- Selective Laser Sintering

SLA- Stereolithography Large Platform

ELASTOMERS

LASER CUTTING

MODEL FINISHING

QUICK FINISH

TRADESHOW QUALITY

RAPID CASTING

LOW VOLUME PRODUCTION

Overmolding

Design

3D Scanning & CAD

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D)A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture.

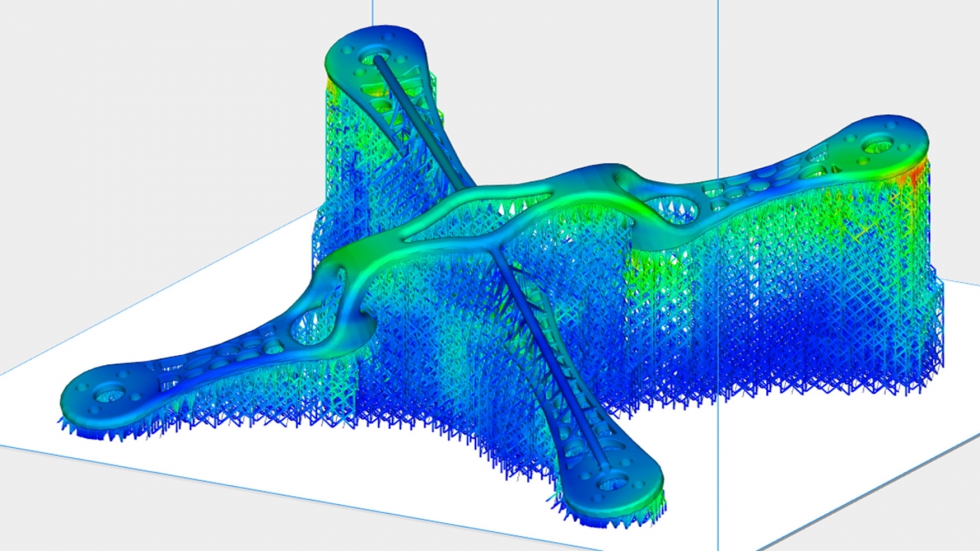

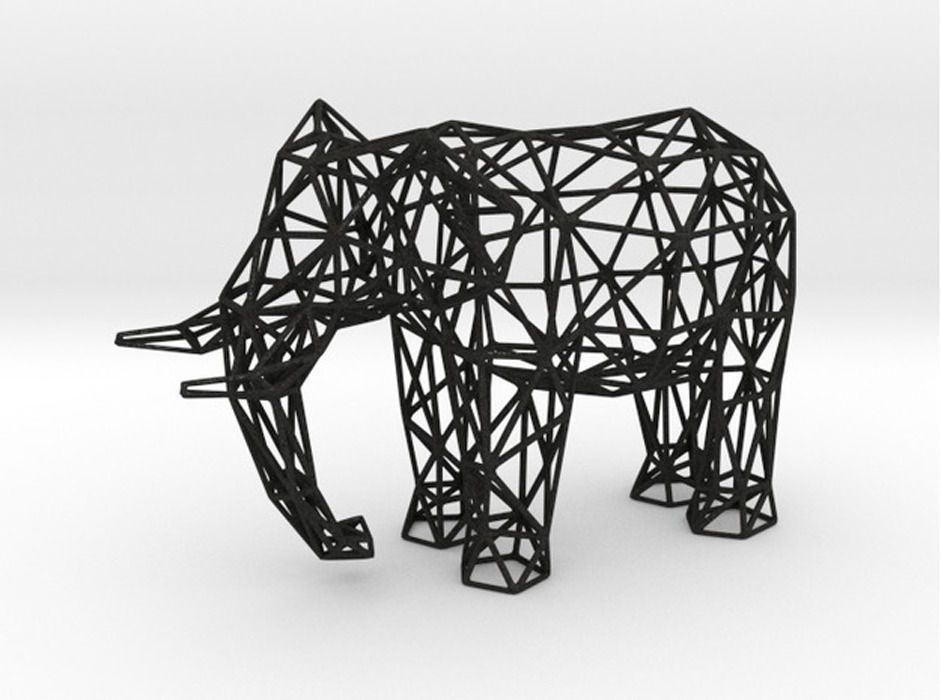

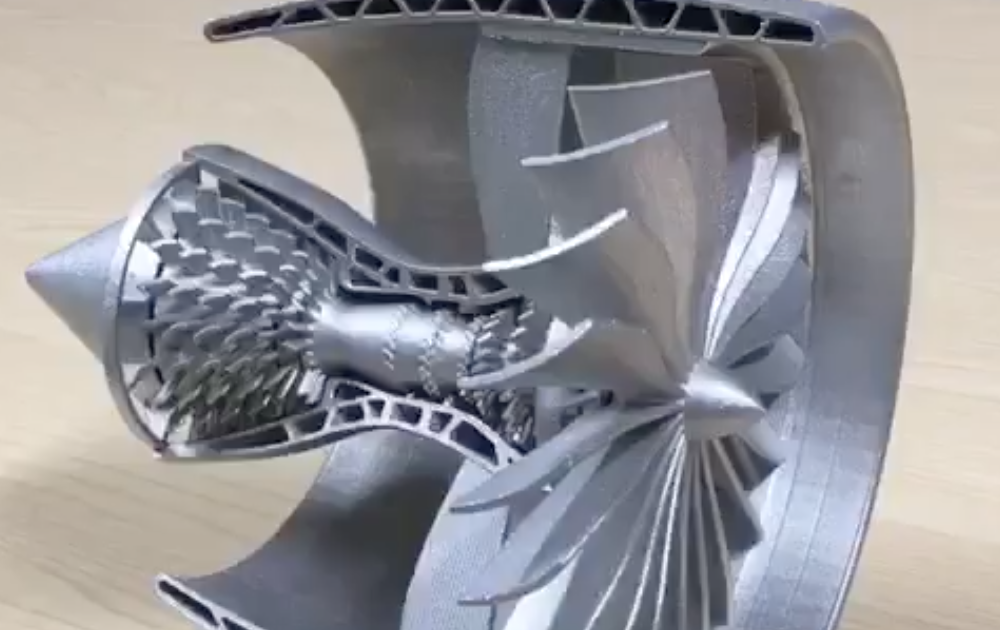

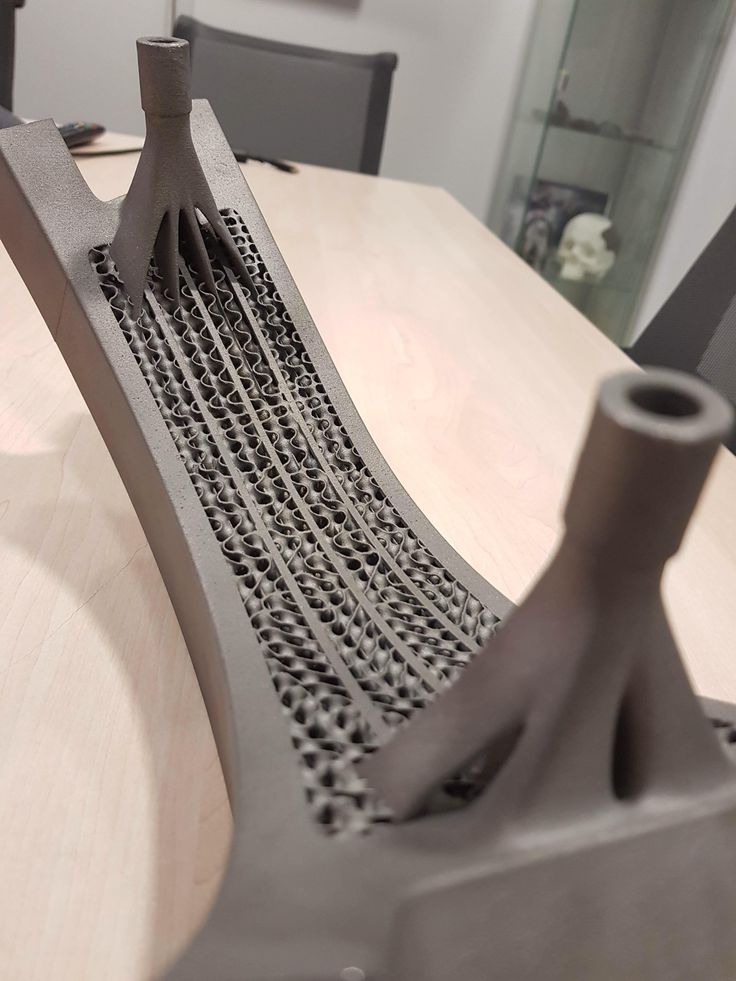

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D) Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc. ), then all these parameters can be incorporated into the product at the production stage.

), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods.

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish.

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast.

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts.

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts.

(Source: BCN3D)While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology.

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal) Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel.

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal tools.

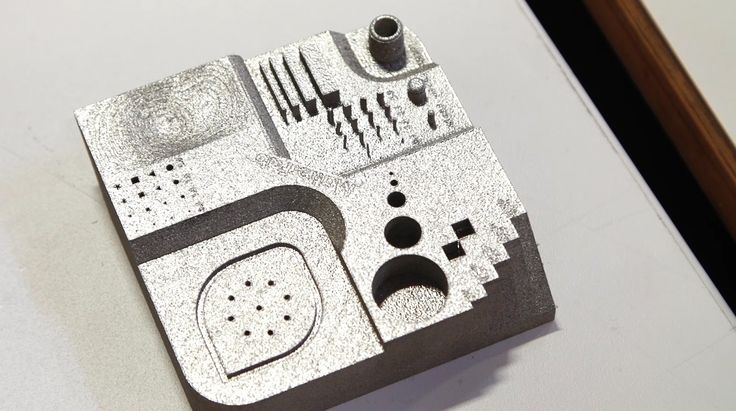

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

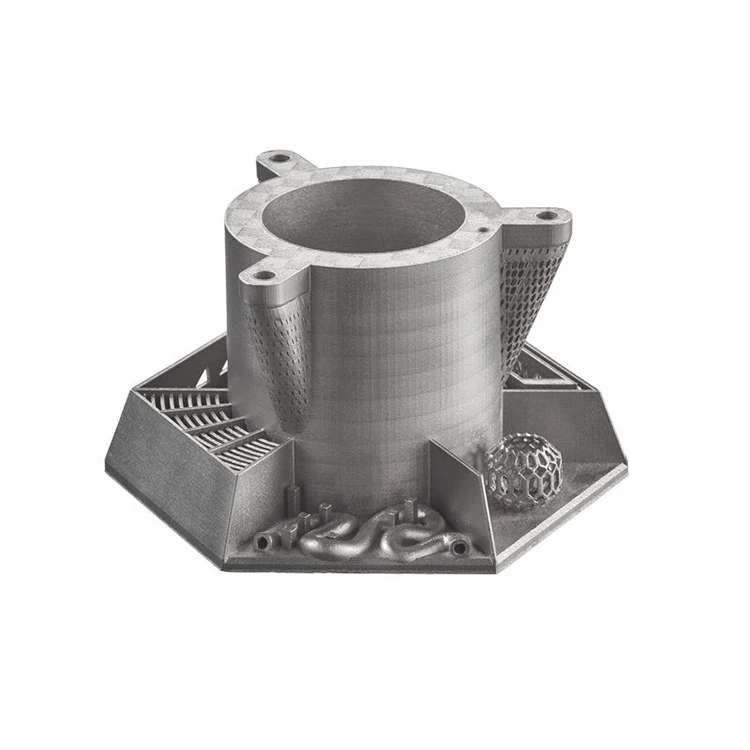

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

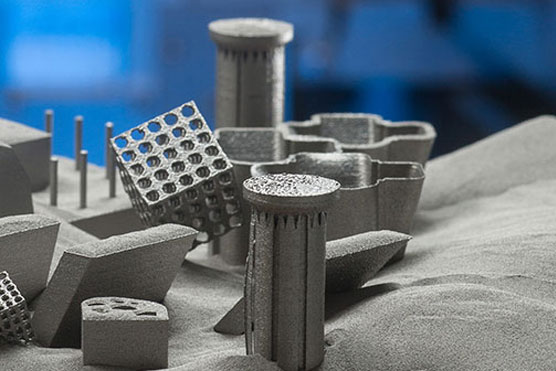

Binder Jetting

Binder 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding.

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer.

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation.

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding.

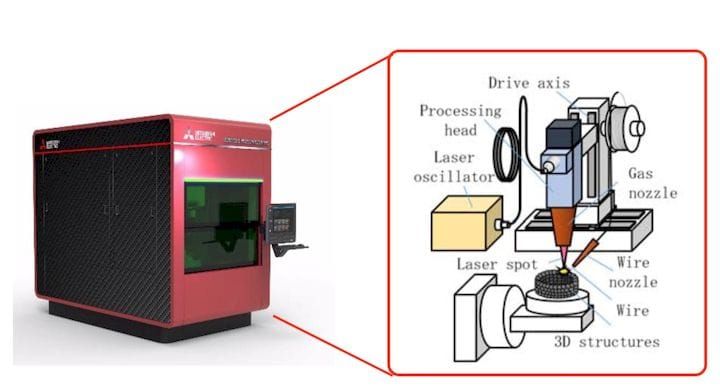

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D)Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining.

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

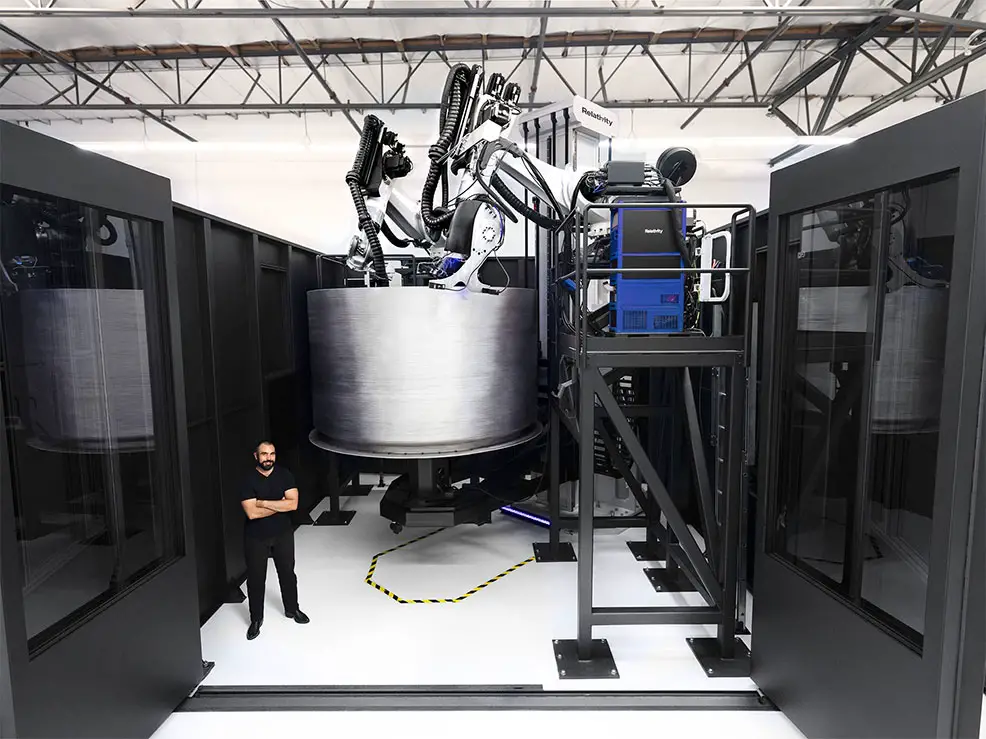

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field.

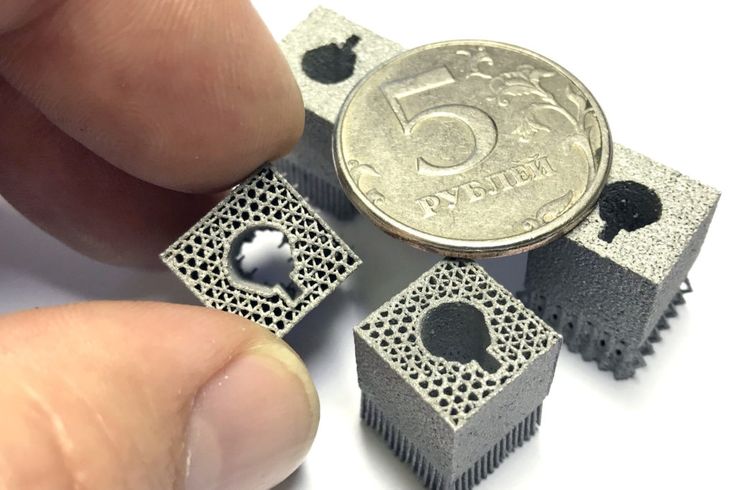

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint)Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts.

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel.

Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise.3D metal printing - technologies and printers / Habr

3D metal printing is becoming more and more popular. And this is not surprising: each metal print material offers a unique combination of practical and aesthetic properties in order to meet the requirements of various products, whether they are prototypes, miniatures, decorations, functional parts or even kitchen utensils.

The reasons for printing with metals are so strong that 3D printing with metals is already being introduced into mass production. In fact, some 3D printed parts have already caught up, and some have even surpassed those produced by traditional methods.

Traditional production from metals and plastics is very wasteful - in the aircraft industry, for example, up to 90% of materials go to waste. The output of products, in some industries, is no more than 30% of the material used.

Metal 3D printing uses less energy and reduces waste to a minimum. In addition, the finished 3D printed part can be up to 60% lighter than a milled or cast part. The aviation industry alone will save billions of dollars in fuel costs by reducing the weight of structures. But strength and lightness are needed in other industries. Yes, and economy too.

Metal 3D printing at home

What can you do if you want to try 3D metal printing at home? Metal printing requires extremely high temperatures, it is unlikely that you can use a regular FDM 3D printer for this, at least not yet. The situation may change in a few years, but now this is not available to home 3D equipment.

The situation may change in a few years, but now this is not available to home 3D equipment.

If you want to make metallic-looking printouts at home, the best option is to use plastic containing metal particles.

Such as Colorfabb Bronzefill or Bestfilament Bronze.

These filaments contain a significant percentage of metal powders, but also enough plastic to print at low temperatures with any 3D printer. At the same time, they contain enough metal to look, feel and have a weight close to that of a metal object.

Items made of iron-containing filament even rust under certain conditions, which adds credibility, but they cannot rust through and deteriorate from this - and this is their advantage over real metal objects.

Benefits of these materials:

- Unique print look

- Ideal for jewelry, figurines, homewares and decor

- High strength

- Very little shrinkage during cooling

- Heated table optional

Cons:

- Low product flexibility, depends on print design

- Not considered safe in contact with food

- Requires fine tuning of nozzle temperature and filament feed rate

- Product post-processing required - grinding, polishing

- Fast extruder nozzle wear - filament with metal is very abrasive compared to conventional materials

The general printing temperature range is typically 195°C - 220°C.

Metal 3D printing for industry

If you are looking to purchase a real metal 3D printer for enterprise use, then there are two pieces of news for you - good and bad.

The good news is that their range is quite wide and continues to expand - it will be possible to choose a device that meets any technical requirement. Further in the article you can see this.

The only bad news is prices. The cost of professional metal printing printers starts anywhere from $200,000 and goes up indefinitely. In addition, even if you choose and purchase the most inexpensive of them, the purchase of consumables, scheduled maintenance with the replacement of components, and repairs will be a separate blow. We do not forget about the staff and the costs of post-processing products. And at the stage of preparation for printing, you will need special software and people who can handle it.

If you are ready for all these expenses and difficulties - read on, we will present some very interesting samples.

https://youtu.be/20R9nItDmPY

Metal 3D printing application

Some industrial sectors already use metal 3D printers, they have become an integral part of the production process, which the average consumer may not be aware of:

The most common example is medical implants and dental crowns, bridges, prostheses, which are already considered the most patients. Reason: They can be 3D printed faster and cheaper and tailored to the individual needs of each patient.

The second, equally common example: jewelry. Most major manufacturers are gradually moving away from 3D printed molds and stencils to direct metal 3D printing, and titanium printing allows jewelers to create designs that were previously impossible.

In addition, the aerospace industry is becoming more and more dependent on 3D printed metal products. Ge-AvioAero in Italy is the world's first fully 3D printed factory that produces components for LEAP jet engines.

The next industry using metal 3D printers is the automotive industry. BMW, Audi, FCA are already seriously considering applying the technology to series production, not just prototyping, where they have been using 3D printing for years.

It would seem - why reinvent the wheel? But here, too, 3D metal printing has found application. For several years now, manufacturers of bicycle components and frames have been using 3D printing. Not only in the world, but also in Russia, this has become widespread. Exclusive bike manufacturer Triton is finishing up a project with a 3D printed titanium frame element that reduces weight without compromising strength.

But before metal 3D printing really takes over the world, there are a few major challenges that need to be overcome. First of all, it is the high cost and low speed of production of large series by this method.

Metal 3D Printing Technology

Much can be said about the use of metal-printing 3D printers. There are specifics, but the main issues are the same as with any other 3D printers: software and hardware limitations, material optimization and multi-material printing. We won't talk much about software, except to mention that major publishers such as Autodesk, SolidWorks, and SolidThinking all develop software products for use in metal 3D printing so that users can bring any shape imaginable to life.

There are specifics, but the main issues are the same as with any other 3D printers: software and hardware limitations, material optimization and multi-material printing. We won't talk much about software, except to mention that major publishers such as Autodesk, SolidWorks, and SolidThinking all develop software products for use in metal 3D printing so that users can bring any shape imaginable to life.

Recently, there have been examples that 3D printed metal parts can be as strong as traditionally produced metal components, and in some cases even surpass them. Created using DMLS, the products have the same mechanical properties as those of solid cast counterparts.

Let's take a look at the available metal 3D printing technologies:

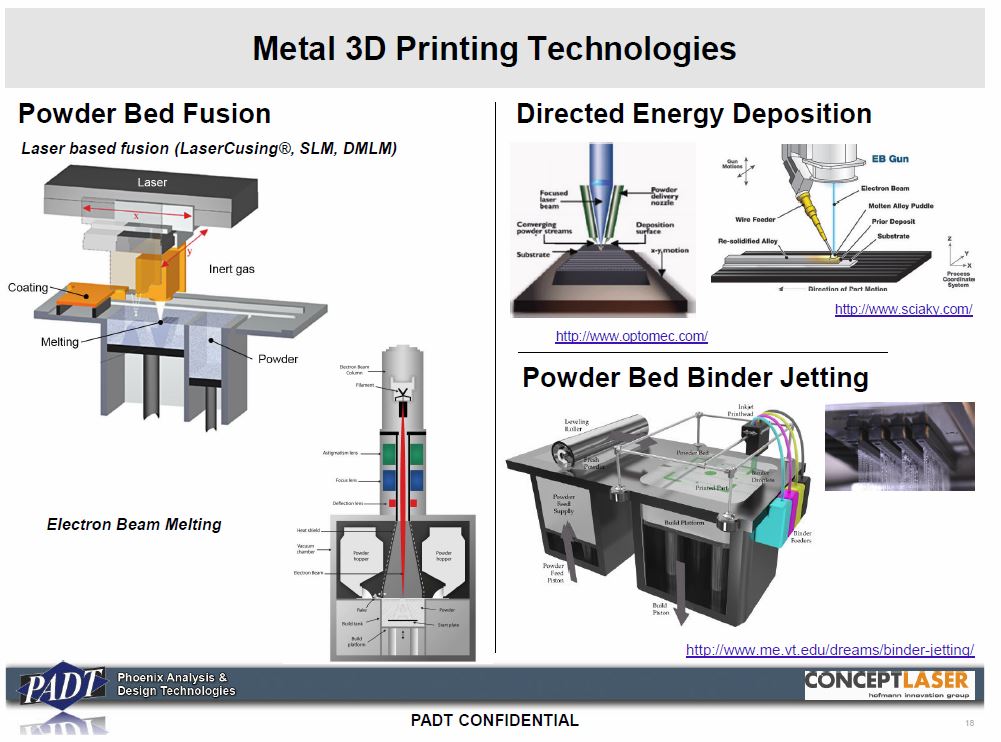

Process #1: Layer by layer powder fusion

The process of 3D printing metals that most major companies use these days is known as powder bed fusion or sintering. This means that a laser or other high-energy beam fuses particles of evenly distributed metal powder into a single whole, creating layers of the product, one after another.

There are eight major metal 3D printer manufacturers in the world, most of them located in Germany. Their technologies go under the acronym SLM (Selective Laser Melting) or DMLS (Direct Laser Metal Sintering).

Process #2: Binder Jetting

Another professional method with layer-by-layer bonding is gluing metal particles for subsequent firing in a high-temperature furnace, where the particles are fused under pressure, making up a single metal whole. The printhead applies the coupling solution to the powder substrate in layers, like a conventional printer on sheets of paper, after which the product is sent to firing.

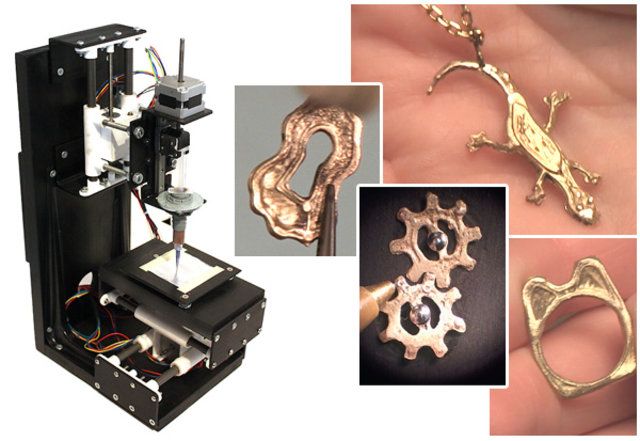

Another similar but different technology based on FDM printing is mixing metal powder into metal paste. Using pneumatic extrusion, the 3D printer extrudes it, much like a 3D construction printer does with cement, to form 3D objects. After the desired shape is printed, the objects are also sintered in an oven. This technology is used by the Mini Metal Maker, perhaps the only more or less affordable metal 3D printer ($1600). Add the cost of a small kiln.

This technology is used by the Mini Metal Maker, perhaps the only more or less affordable metal 3D printer ($1600). Add the cost of a small kiln.

Process #3: Welding

You might think that among the metal printing technologies there is no similar to the usual FDM, however, this is not entirely true. You can't melt metal filament in the hot end of your 3D printer, but the big manufacturers have the technology and use it. There are two main ways to print with solid metal material.

One of them is called DED (Directed Energy Deposition), or laser cladding. It uses a laser beam to fuse metal powder that is slowly released and deposited from an extruder, forming layers of an object with an industrial arm.

This is usually done inside a closed chamber, however, with MX3D, we see the possibility of implementing a similar technology in the construction of a real full-size bridge, which is due to be printed in 2017 in Amsterdam.

The other is called EBM (Electron Beam Manufacturing), a technology for forming layers of metal raw materials under the influence of a powerful electron beam, with its help create large and very large structures. If you do not work in the defense complex of the Russian Federation or the United States, then you are unlikely to see this technology alive.

A couple of new, barely emerging technologies, used so far only by their creators, are presented below - in the section on printers.

Metals used

Ti - Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing, and certainly one of the most versatile as it is both strong and lightweight. It is used both in the medical industry (in personalized prosthetics) and in the aerospace and automotive industries (for the manufacture of parts and prototypes), and in other areas. The only catch is that it is highly reactive, which means it can explode easily when in powder form, and should definitely only be used for printing in an inert Argon gas environment.

SS - Stainless steel

Stainless steel is one of the most affordable metals for 3D printing. At the same time, it is very durable and can be used in a wide range of industrial and artistic applications. This type of steel alloy containing cobalt and nickel has high elasticity and tensile strength. 3D printing of stainless steel is used mainly only in heavy industry.

Inconel

Inconel is a modern superalloy. It is manufactured by Special Metals Corporation and is a patented trademark. Consists, for the most part, of nickel and chromium, has high heat resistance. It is used in the oil, chemical and aerospace industries (for example: to create distribution nozzles, on-board "black boxes").

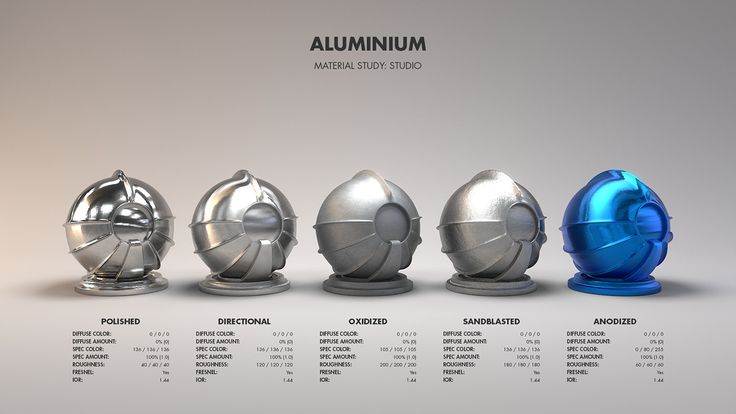

Al

Due to its inherent lightness and versatility, aluminum is a very popular metal for 3D printing applications. It is usually used in the form of various alloys, forming their basis. Aluminum powder is explosive and is used in printing in an inert Argon gas environment.

Aluminum powder is explosive and is used in printing in an inert Argon gas environment.

CoCr - Cobalt Chrome

This metal alloy has a very high specific strength. It is used both in dentistry - for 3D printing of dental crowns, bridges and clasp prostheses, and in other areas.

Cu

With rare exceptions, copper and its alloys - bronze, brass - are used for casting using burnt patterns, and not for direct metal printing. This is because their properties are far from ideal for industrial 3D printing applications, they are more commonly used in arts and crafts. With great success, they are added to plastic filament - for 3D printing on conventional 3D printers.

Fe - Iron

Iron and magnetic iron ore are also mainly used as an additive to PLA filament. In large-scale industry, pure iron is rarely used, and we wrote about steel above.

Au, Ag — Gold, silver and other precious metals

Most powder fusing 3D printers can work with precious metals such as gold, silver and platinum. The main task when working with them is to ensure the optimal consumption of expensive material. Precious metals are used in 3D printing of jewelry and medical products, as well as in the production of electronics.

Metal 3D Printer

# 1: Sciaky EBAM 300 - titanium rod

For printing really large metal structures, Sciaky's EBAM is the best choice. This device can be any size, to order. It is used primarily in the US aerospace and defense industries.

As a production model, Sciaky sells the EBAM 300. It has a working area with sides of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is one of the fastest commercially available industrial 3D printers. Structural elements of aircraft, the production of which, according to traditional technologies, could take up to six months, are now printed within 48 hours.

Sciaky's unique technology uses a high power electron beam gun to melt 3mm thick titanium filament, with a standard deposition rate of about 3-9 kg/h.

#2: Fabrisonic UAM - ultrasonic

Another way to 3D print large metal parts is Ultrasound Additive Manufacturing Technology (UAM) from Fabrisonic. The brainchild of Fabrisonic is a three-axis CNC machine with an additional welding head. The metal layers are first cut and then welded together using ultrasound. Fabrisonic's largest 3D printer, "7200", has a build volume of 2 x 2 x 1.5 m.

# 3: Laser XLine 1000 - metal powder

One of the largest metal powder 3D printers on the market has long been the Concept Laser XLine 1000. It has a build area of 630 x 400 x 500mm and takes up space like a small house.

The German company that made it, which is one of the suppliers of 3D printers for aerospace giants such as Airbus, recently introduced a new printer, the XLine 2000.

2000 has two lasers and an even larger build volume of 800 x 400 x 500 mm. This machine, which uses patented LaserCUSING technology (a type of selective laser melting), can create objects from alloys of steel, aluminum, nickel, titanium, precious metals, and some pure materials (titanium and bar steels.)

All major players in the metal 3D printing market: EOS, SLM, Renishaw, Realizer and 3D Systems, as well as Shining 3D, a rapidly growing company from China.

# 4: M Line Factory - Modular 3D Factory

Displacement: 398.78 x 398.78 x 424.18 mm

1 to 4 lasers, 400 - 1000 watts each.

The M Line Factory concept is based on the principles of automation and interaction.

M Line Factory, from the same Concept Laser and operating on the same technology, does not focus on the size of the workspace, but on the convenience of production - it is a modular architecture apparatus that divides production into separate processes in such a way that these processes can occur simultaneously, not sequentially.

This new architecture consists of 2 independent machine nodes:

M Line Factory PRD (Production Unit)

Production Unit consists of 3 types of modules: dosing module, printing module and overflow module (tray for finished products). All of them can be individually activated and do not form one continuous piece of equipment. These modules are transported through a system of tunnels inside the machine. For example, when new powder is supplied, the empty powder storage module can be automatically replaced with a new one without interrupting the printing process. Finished parts can be moved outside the machine and immediately automatically replaced by the next jobs.

M Line Factory PCG (Processing Unit)

This is an independent data processing unit that has an integrated sieving and powder preparation station. Unpacking, preparation for the next print job and sieving take place in a closed system, without the participation of the operator.

# 5: ORLAS CREATOR - 3D printer ready to go

The creators of ORLAS CREATOR position this 3D printer as the most affordable, easy-to-use and ready-to-use, does not require the installation of any additional components and third-party programs, capable of printing directly from a complete CAD / CAM file of their own design.

All the necessary components are installed in a relatively compact case, which needs a space of 90x90x200 cm. It does not take up much space, although it looks impressive, and it weighs 350 kg.

As can be understood from the table given by the manufacturer, the metal powder is sintered by a rotating laser system, in layers 20-100 µm thick and with a “pixel” size of only 40 µm, in a nitrogen or argon atmosphere. You can connect it to a regular household power supply if your wiring can withstand a load of 10 amperes. Which, however, does not exceed the requirements of an average washing machine.

Laser power - 250 watts. The working area is a cylinder 100 mm in diameter and 110 mm in height.

#6: FormUp 350 - Powder Machine Part Method (PMPM)

The FormUp 350, powered by Powder Machine Part Method (PMPM), was created by AddUp, a joint venture between Fives and Michelin. This is the latest metal 3D printing machine, first introduced in November at Formnext2016.

The principle of operation of this 3D printer is the same as that of the above colleagues, but its main feature is different - it lies in its inclusion in PMPM.

The printer is designed specifically for industrial use, in 24/7 mode, and is designed for exactly this pace of work. The PMPM system includes quality control of all components and materials, at all stages of their production and distribution, which should guarantee consistently high performance, in which Michelin has a huge long-term experience.

# 7: XJET - NanoParticle Jetting - Metal Inkjet

The nanoparticle injection technology involves the use of special sealed cartridges with a solution containing a suspension of metal nanoparticles.

Nanoparticles are deposited and form the material of the printed product.

Considering the claimed features of the technology (the use of nano-sized metal particles), it is easy to believe the creators of the device when they claim its unprecedented accuracy and print resolution.

# 8: VADER Mk1 - MagnetoJet - Metal Inkjet

Zack Vader's MagnetoJet technology is based on the study of magnetohydrodynamics, and more specifically, the ability to control molten metal using magnetic fields. The essence of the development is that a drop of a strictly controlled size is formed from molten aluminum, and these drops are used for printing.

The size of such a droplet is from 200 to 500 microns, printing occurs at a speed of 1000 drops per second. Printer working area: 300 mm x 300 mm x 300 mm

Media: Aluminum and its alloys (4043, 6061, 7075). And, even though it is only aluminum for now, the printer is 2 times faster than powder ones and up to 10 times cheaper.

The Mk2 is scheduled for release in 2018 and will be equipped with 10 printheads, which should increase print speed by 30 times.

# 9: METAL X - ADAM - atomic diffusion

Markforged introduced a new metal 3D printing technology - ADAM, and a 3D printer working on this technology - Metal X.

ADAM (Atomic Diffusion Additive Manufacturing) - atomic diffusion technology. Printing is done with metal powder, where the metal particles are coated with a synthetic binder, which is removed after printing, allowing the metal to fuse together.

The main advantage of the technology is the absence of the need to use ultra-high temperatures directly in the printing process, which means that there are no restrictions on the refractoriness of the materials used for printing. Theoretically, the printer can create 3D models from heavy-duty tool steels - now it is already printing with stainless steel, and titanium, Inconel and D2 and A2 steels are in development.