How to prime 3d prints

How to Prime and Paint 3D Printed Parts (With Video)

Primer

Primer is a special type of paint that adheres strongly to the part and provides a uniform surface for paint to bond with. Different primers have different uses. A spray-on primer is the best way to paint your printed parts because it quickly covers a surface with an even coating. Brush-on primers are available, but they are tricky to work with and better for fine touch ups. For best results, choose a primer and paint that are plastic compatible and from the same brand. We like Krylon and Montana (though both are thick formulas), but nothing really compares to Tamiya brand model paint - it goes on extremely thinly and evenly, preserving delicate surface details.

Rotary Tool

Because sometimes you want to sand fast. With interchangeable bits, rotary tools offer a variety of options for sanding and polishing parts. Drum sanding bits quickly sand down supports, while steel wire brushes smooth surface marks. Rotary tools are rough, so you will still need sandpaper for a smooth finish. There are plenty of great brands: Dremel and Craftsman are popular in the states, Proxxon in Europe. To avoid scorching your part, turn down the RPMs to the minimum (usually 500-1000) and use a light touch.

Hand Files

Not as clumsy or as random as a palm sander. A more elegant tool…for a more civilized age.

One of the most simple yet effective tools, a hand file removes supports and sands down surfaces. Using a firm grip, you can remove marks with more control than with a rotary tool. Keep a wire brush on hand and clean the file’s teeth often (otherwise plastic and resin will gum up teeth). Like a rotary tool, a hand file will leave a rough surface, so it’s best for removing the larger support marks.

Sand Paper

The most unglamourous tool in the shop, sandpaper has come light years in the last decade with the release of flexible sanding sheets. Available at home improvement stores, flexible sanding sheets last 15 times longer than paper ones. They don’t curl, puncture or crease.., and they hey can be used wet, which reduces dust and prevents buildup in the sanding tooth. Because they flex, they can easily reach small interior spaces and rounded surfaces.

They don’t curl, puncture or crease.., and they hey can be used wet, which reduces dust and prevents buildup in the sanding tooth. Because they flex, they can easily reach small interior spaces and rounded surfaces.

Dust Removal

Even after wet sanding, some dust will remain. Remove buildup with water and a soft scrub brush (an old toothbrush works). For serious cleanup, an inexpensive sonicator can quickly remove fine particles caught in corners and cracks of a surface. If you work in an area with hard water, using deionized or distilled water will prevent spotting between painting.

Tack Cloth

Tack cloth is a soft, slightly sticky cotton cloth designed to remove remaining dust and leave a clean surface for painting. Let your model dry before using the tack cloth — the waxy surface does not work well with water.

Painting Block, Dowels & Drill

This simple trick will save you grief in the spray booth (we were excited when we saw this technique in a modelmaking how-to video by Adam Savage). By mounting your 3D print on a dowel (often you can use a preexisting hole in the part), you can quickly maneuver while spraying, allowing you to get to all sides and into the nooks and crannies of the part without creating any fingerprints. When you want to add an even coat to all sides of your model, this is pretty essential. We recommend ordering a variety of size of dowels. To minimize the hole size on a part, start with a small size and work your way up until the model feels firmly seated. Drill a corresponding hole in a block of wood or MDF and insert the part with the dowel - now you can keep the model hands free while spraying.

By mounting your 3D print on a dowel (often you can use a preexisting hole in the part), you can quickly maneuver while spraying, allowing you to get to all sides and into the nooks and crannies of the part without creating any fingerprints. When you want to add an even coat to all sides of your model, this is pretty essential. We recommend ordering a variety of size of dowels. To minimize the hole size on a part, start with a small size and work your way up until the model feels firmly seated. Drill a corresponding hole in a block of wood or MDF and insert the part with the dowel - now you can keep the model hands free while spraying.

Safety Equipment

Spraypainting means working with airborne particulates and solvents, both of which pose health hazards. Remember to use a NIOSH approved respirator and work in a well ventilated workspace. While painting, wear nitrile gloves to avoid spraying paint on your hands and and also protect your model from fingerprints.

Ultimate Guide to Painting 3D Prints

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

If you’re an engineer or product designer creating concept models, a prop or set designer, artist, or an educator looking to add incorporate a bit more creativity into your classroom 3D printing activities, painting your models can be a great solution.

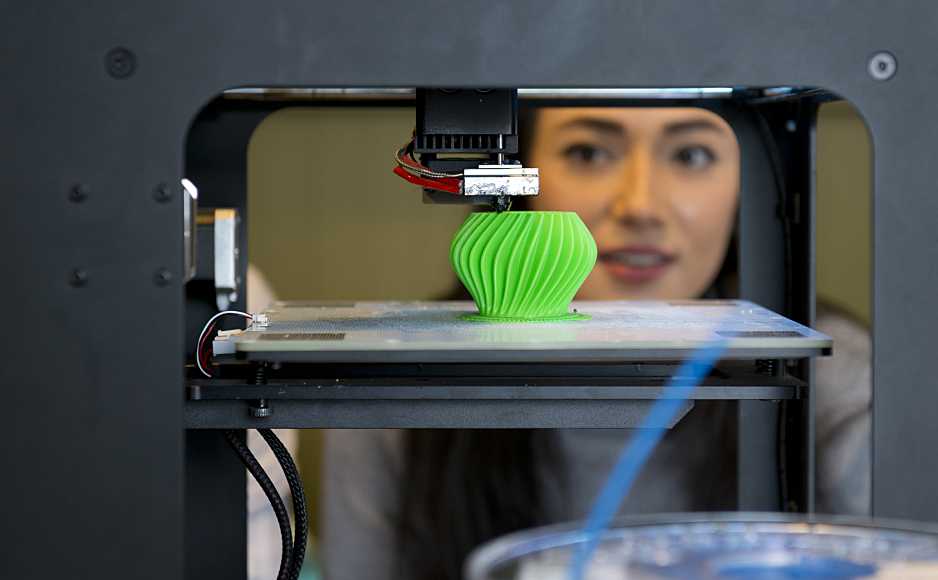

In this tutorial, we’ll show you how to create a nearly automotive quality paint job on any of your 3D printed objects.

Working time will vary depending on your model. Including drying time, the process shown took us about 6 hours from start to finish.

SUPPLIES

3D Print

Rubbing alcohol

Paper towels

Spray primer/filler

Spray paint

Hanging cord

80, 120, 240, 220, 1000 grit sandpaper

Needlenose pliers

Bondo

Sanding block & sandpaper

Gloves

Eye protection

Respiratory Mask

Need some of these products? We've curated an Amazon wish list for you.

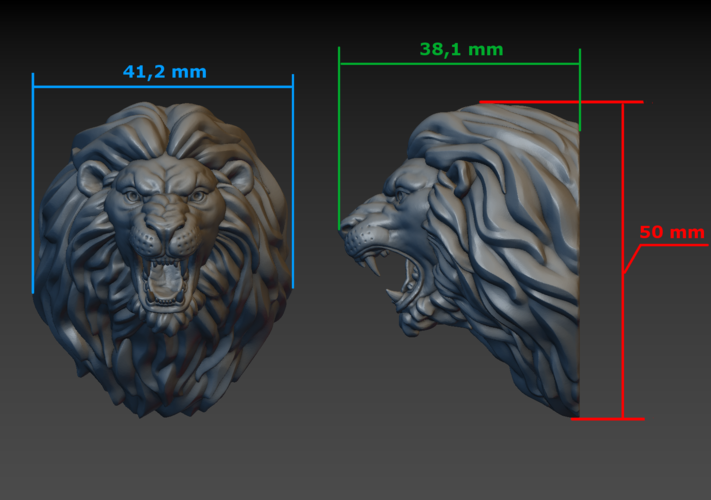

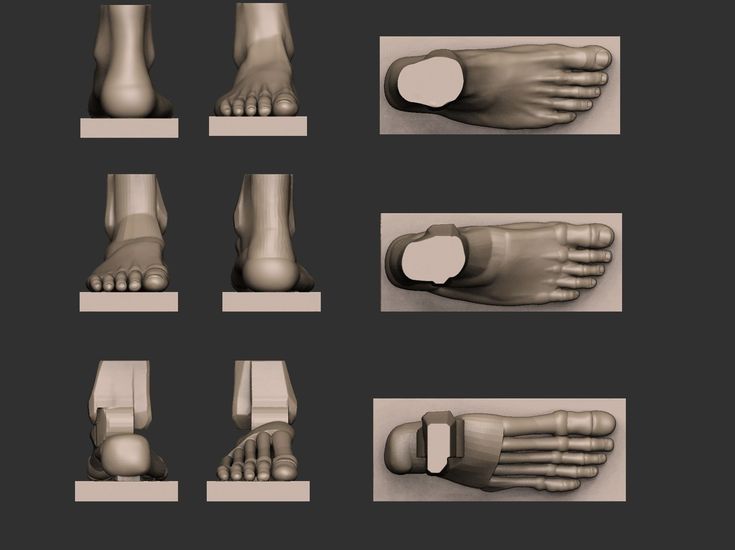

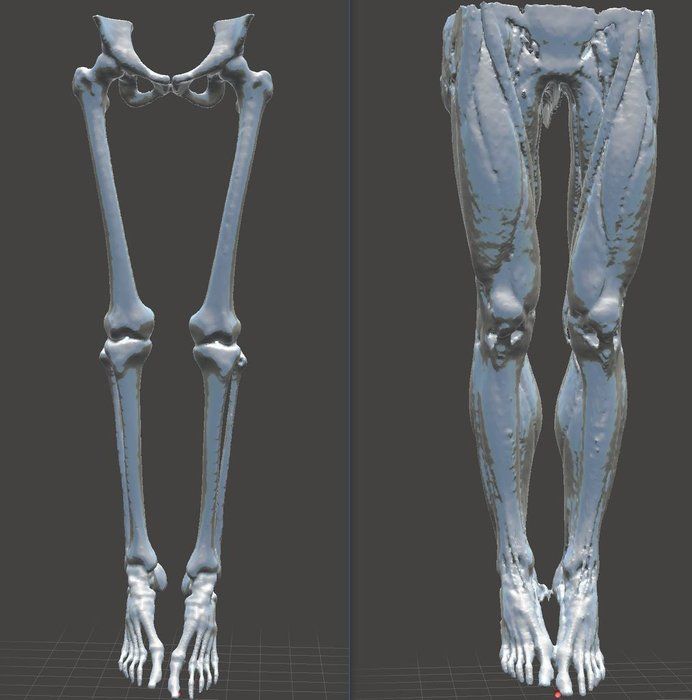

STEP 1: PREPARE & PRINT MODEL

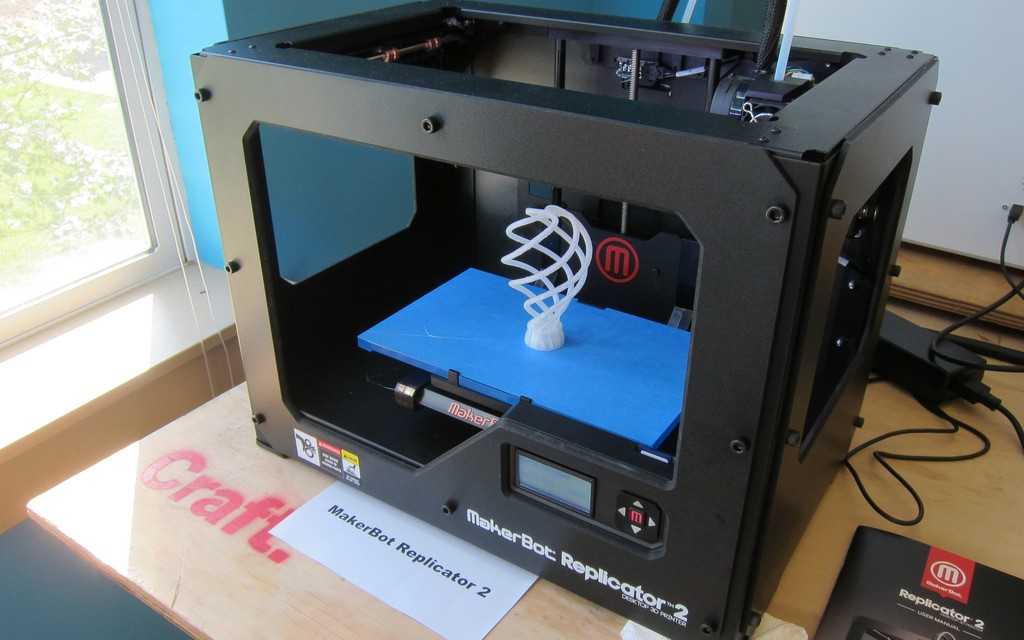

When preparing models for painting in MakerBot Print, keep in mind how your print settings will affect the quality of your paint job.

Consider: Print settings, print orientation, number of build plates

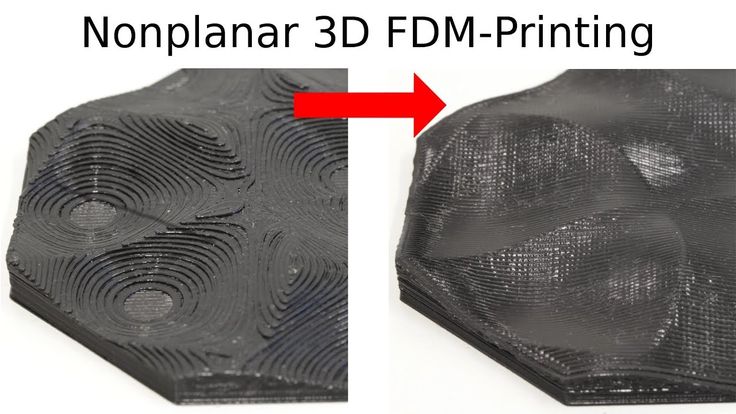

Surfaces printed in the Z axis will have the smoothest surface finish.

Printing models in 100 micron layer resolution will result in a slightly smoother surface finish, but will take significantly longer.

If possible, avoid placing support material in places you intend to paint as they will require more post processing to remove completely.

Supplies used: Needle-nose pliers or flush cutters

After you remove your print from the build plate of your printer, you will need to remove any raft or support material.

A. Remove prints from the build plate

B. Remove rafts

C. Remove large pieces of support

D. Approach smaller pieces and fine details

Supplies used: Sanding block, electric sander, 80,120, 240, 400, & 1000 grit sandpaper, Cyanoacrylate glue (super glue), Bondo

For the highest quality paint surface, an optional next step is to sand your model.

Make sure to wear eye protection, gloves, and a respiratory mask.

A. Dry sand the model using 80-240 grit sandpaper

B. Wet sand the model using 400 & 1000 grit sandpaper

C. Glue the parts of your model together

D. Apply filler to any gaps or blemish in your model and sand once dry

Find more detailed information here on gluing and sanding.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

Supplies used: Hanging cord

Once your model is ready for painting - hang it in an open, dust free space with plenty of ventilation. This will allow you to paint all surfaces evenly without having to handle the model while paint is drying.

A. Tie hanging cord around the model

B. Hang the model in an open room with a tarp

STEP 5: PRIMER/FILLER

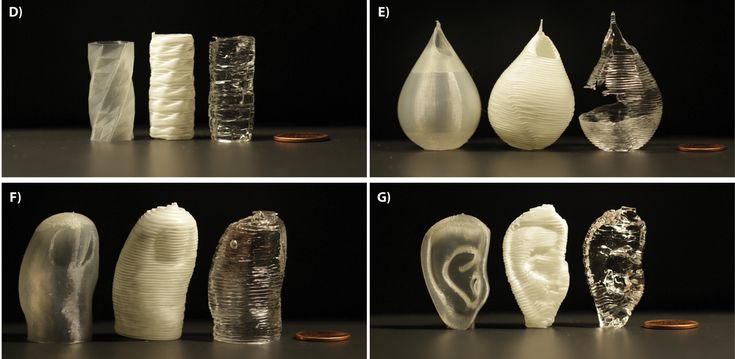

Whether you have chosen to sand your model and apply filler or you are simply painting a rough PLA model printed at high resolution, a few layers of primer/filler will fill any small surface imperfections before painting.

Primer filler is a high build spray filler that comes in aerosol form and can be purchased at most local hardware stores.

Before spraying remember to wear gloves, eye protection, and a respiratory mask.

BE SURE TO:

Shake well before use

Use wide strokes beginning and ending in space outside of the model

Hold the can 10-12 inches from the model

Paint in thin layers using a misting technique

AVOID:

Painting in thick layers

Holding the can in any spot for a long time

Holding the can too close to the model

Once you’ve sprayed 2-3 layers of primer/filler, allow your model to dry for 30-40 minutes.

STEP 7: SAND

A. Lightly sand your model with 1000 grit sandpaper (dry). This will smooth the surface of the model as the primer filler tends to create a rough surface texture similar to sandpaper.

B. Evaluate for quality.

C. If there are still surface imperfections you would like to smooth, continue to apply consecutive layers of primer/filler, and sand.

Once you are happy with the model surface, move on to painting.

STEP 8: PAINT

When choosing paint, you typically have a large degree of freedom as to which color and type of paint you use. Make sure to pick something that adheres well to plastic.

A. Choose a paint

B. Test for color in an inconspicuous location before painting the entire model

C. Let the paint sit overnight to cure

TIP:

Typically the paint will be dry to touch within an hour or so, and ready to polish within 24-48 hours.

If you’d like to protect the surface of your painted model, you can also apply a thin clear coat at this point.

In the end, you’re left with a beautiful painted model ready for approval presentation, enhanced for sets or galleries, optimized for better classroom learning, or simply improved for better innovation.

Here you can see just how far we have come.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Gluing

Sanding

Inserts

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Hair Dryer Shell

Ferro

10/2/2015

https://grabcad.com/library/hair-dryer-shell-1

Powered by MakerBot Learning.

How to prime and paint 3D printed models (with video)

Primer

Primer is a special paint that adheres strongly to the part and ensures that the paint adheres to the surface evenly. There are different primers designed for different purposes. Spray primer is the best way to paint 3D printed parts as it quickly covers the surface in an even coat. There are primers available for brush application, but they are difficult to work with and are better suited for fine finishes. For best results, choose a plastic-compatible primer and paint from the same manufacturer. We love the Krylon and Montana brands (although they are thick), but Tamiya's paint is unparalleled - it forms a very thin and even coat, retaining all minor surface features.

Rotary tool

Sometimes you need to finish sanding quickly. The use of interchangeable nozzles for rotating tools allows you to grind and polish models in various ways. The drum allows you to quickly grind marks from supporting structures, and steel wire cleans marks well on flat surfaces. Rotary tools are designed for rough cleaning, so you will need sandpaper to make the surface smooth. There are many great brands: Dremel and Craftsman are popular in the US, and Proxxon is popular in Europe. In order not to burn your model, reduce the speed to a minimum (usually 500-1000) and do not apply pressure to the tool.

Flat files

These tools are not as clumsy or inaccurate as a hand sander. An elegant instrument...for a more civilized age.

The flat file is one of the simplest yet most effective tools for effectively removing support structures and sanding surfaces. By holding it firmly in your hand, you can remove marks with greater precision than with a rotary tool. Keep a wire brush handy and clean the file blade regularly (otherwise plastic and resin can get stuck in it). Like a rotary tool, a flat file leaves a rough surface, so it is best used for removing large imperfections.

Keep a wire brush handy and clean the file blade regularly (otherwise plastic and resin can get stuck in it). Like a rotary tool, a flat file leaves a rough surface, so it is best used for removing large imperfections.

Sandpaper

Sandpaper is the ugliest tool in the workshop. Over the past decade, it has made a real breakthrough with the release of flexible sanding sheets. Flexible sanding sheets can be purchased at hardware stores. They last 15 times longer than paper ones. They won't curl, puncture or bend, and can be used wet to reduce dust and prevent build-up. Thanks to their flexibility, they easily reach small interior spaces and rounded surfaces.

Dust removal

Even after sanding with a damp tool, a small amount of dust remains. Remove plaque with water and a soft brush (an old toothbrush is fine for this purpose). For serious cleaning, you can take an inexpensive ultrasonic device that will quickly remove small particles trapped in corners and surface cracks. If you are working in a hard water area, using deionized or distilled water will help prevent blemishes between coats.

If you are working in a hard water area, using deionized or distilled water will help prevent blemishes between coats.

Dust Pad

The Dust Pad is a piece of soft and slightly tacky cotton cloth designed to remove remaining dust and provide a clean surface for painting. Let your model dry before using the dust cloth: the waxed surface reduces its effectiveness on wet surfaces.

Block, pins and drill

This little trick will keep you out of trouble in the paint booth (we were ecstatic when we saw this technique in Adam Savage's how-to video). By mounting the model on a pin (you can often use a pre-drilled hole in the part), you can quickly maneuver while spraying and paint the model from all sides, penetrating hard-to-reach places and leaving no fingerprints. If you want to apply an even layer on all sides of the model, this is very important. We recommend ordering pins in different sizes. To make the hole in the part as small as possible, start small and increase until the model is firmly seated. Drill an appropriate hole in the block of wood or chipboard and mount the model to it with a dowel - now you do not have to hold the model with your hands while spraying.

Drill an appropriate hole in the block of wood or chipboard and mount the model to it with a dowel - now you do not have to hold the model with your hands while spraying.

Protective equipment

Spray paint involves working with aerosols and solvents that are hazardous to health. Be sure to use a National Institute for Occupational Safety and Health (NIOSH) approved respirator and work in a well-ventilated area. When painting, use nitrile gloves to keep the paint off your hands and to avoid leaving fingerprints on the model.

Processing priming and painting

In this article we will tell you how to properly process and paint 3D printed models made of REC PLA, REC RELAX, REC ABS, REC FLEX, REC ETERNAL plastic.

PLA does not react to most solvents and has a very smooth and hard surface so it does not adhere well to most paints and is difficult to surface.

RELAX is also resistant to most solvents but can be easily machined. Due to the smooth surface, a primer is required to hold the paint on the surface.

Due to the smooth surface, a primer is required to hold the paint on the surface.

ABS has excellent sandability and dissolves in many solvents, including acetone. Painting is very simple, most paints adhere well to the surface.

FLEX is very difficult to any mechanical or physical processing, however, elastic paints fit perfectly on it without additional manipulations, especially in a thin layer.

ETERNAL has almost the same painting properties as ABS, but for best results it is best to use adhesive primers.

Preparation

RELAX, ABS and ETERNAL are easy to machine. Also, the materials are perfectly primed with all types of primers for plastic and leveled with all types of polymer putty.

FLEX, it makes sense to cover with silicone for leveling the surface, kwik seal silicone sealant will do. Before curing, it can be applied with a spatula or finger and smoothed with water. (more on that in a second article)

PLA is hard to sand and has good adhesion to acrylic and epoxy. So it's best to use an acrylic leveling primer or acrylic putty to sand them rather than the PLA itself.

So it's best to use an acrylic leveling primer or acrylic putty to sand them rather than the PLA itself.

Painting

There are many painting methods, but there are several types that are most suitable for 3D printing.

Variety of inks is wide, the most suitable inks for printing products are usually acrylic or epoxy based.

When spray painting, position the object comfortably and preferably horizontally.

The paint, depending on its type, needs to be sprayed at a certain distance from the object, usually between 10 and 30 cm.

It is best to paint in several layers, methodically and slowly.

Remember that by varying the distance, you can change the density of the paint application, as well as create shades on objects. And using masking tape, you can create patterns or shield some parts from others when painting in different colors.