Farsoon 3d printers

Farsoon 3D Printing in Medicine

In this article, we will look at how Farsoon equipment is used in medicine, what kind of parts are usually printed with it, and what advantages 3D printing provides for endoprosthetics and dentistry.

About Farsoon

Farsoon headquarters in Changsha National High-Tech Industrial Zone, Hunan, China

Farsoon Technologies is one of the world's largest suppliers of industrial additive manufacturing systems for polymer and metal laser sintering. The company's founder Xu Xiaoshu was formerly the CTO of DTM Corporation, now known as 3D Systems, the first company to use laser sintering in the early 1990s.

Farson HT1001P using Continuous Additive Manufacturing Solution technology

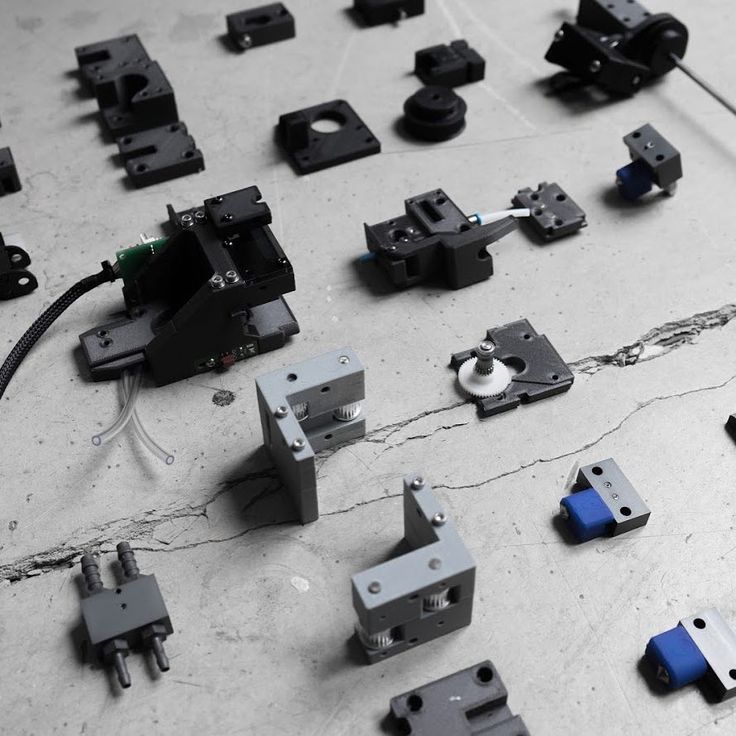

Farsoon has forged a world-class team of experts in all areas of knowledge required for producing industrial 3D printers: electrical and mechanical engineering, laser, scanning and optical equipment, thermal control systems, software development and materials for 3D printing.

Features and benefits of Farsoon Technologies

- Over 25 years of experience in additive manufacturing

- Over 100 patents

- 40% of the staff are involved in new equipment and technology development

- Over 40% of international sales

- More than 400 industrial equipment customers

The main advantages of additive technologies in medical use

- Shorter supply chains and reduced lead times

- No need for transportation and international shipping

- Reduced production costs of sophisticated 3D printed parts. Additive technologies (hereinafter — AT) allow you to design more complex geometry

- Creating complex structures that are impossible to manufacture with conventional production methods

- Manufacturing complex items is cheaper than creating it in parts with subsequent assembly

- Design optimization and replication

- ATs meet the growing demand for end product customization in the medical sector

- ATs have a wide range of medical applications

Farsoon medical fields of application

Farsoon equipment is used in medicine for 3D printing of biocompatible metal and plastic parts, mainly implantable endoprostheses, prototypes, surgical templates and guides.

Examples of Farson application in medicine

Porous tantalum knee implant

Farsoon system: FS271M

Material: Tantalum (Ta)

Partnership of Huaxiang Group and Challenge Hospital in China.

The patient is 84 years old. The biocompatibility of the 3D printed prosthesis, its strength, weight and load distribution within the entire bone is of key importance.

Tantalum is a biocompatible hard metal with a high melting point (3,020 °C), making it difficult to use in AT technologies.

An optimized porous 3D model was created using CT imaging data, to address the patient's knee injury. At 70–90% of pours in the implant, the porous structure is reminiscent of bone tissue, reducing weight and optimizing the implant’s structure. The manufacturing process parameters have been developed specifically for tantalum and integrated thanks to Farsoon's open parameter strategy.

According to the porosity structure study, when the porosity is 70%, the compressive strength and modulus of elasticity (100-200 MPa, 3-10 GPa correspondingly) are close to the parameters of human cortical bone. A set weight of the implant can be obtained by adjusting the structure and size of the pores.

A set weight of the implant can be obtained by adjusting the structure and size of the pores.

Farsoon partners in implantology

Prototyping in surgery

Pre-operation drill using PLS printed prototype.

A fixed guide plate was used to accurately select the insertion position prior to acetabular surgery.

Using the prototype of the acetabulum for preliminary analysis during the initial preparation, it was possible to accurately determine the angle of entry of the guides to fix the place of fasteners.

Farsoon system: SS403P

Material: FS3300PA

Result: more than 40 hip surgeries performed in 18 months with a 100% success rate.

Reduced overall operation time and sequelae rate compared to conventional surgery. Honored by the 2017 Bone Tech Innovation Award at the WOISE Conference.

Farsoon partners in surgery

Dentistry applications

Partnership with Pairui Dental (China)

Resolved issues:

- Increased labor costs while maintaining the same level of efficiency

- Parts’ defects in conventional processing.

Farsoon system: FS121M

Material: CoCrMoW

Printing time: 6 hours

Solution:

- A comprehensive industry solution including hardware, software, materials, applications for the dental industry.

- Proprietary software provides full access to over 70 3D printing settings, helping to achieve the correct balance between precision and efficiency.

- 150 crowns in 6 hours.

Farsoon partners in dentistry

Comparison of casting and 3D printing for dentistry

|

Test part |

Test result (traditional production) |

Test result (SLM print on Farsoon FS121M) |

|

Density |

8.5 g/cm3 |

8.65 g/cm3 |

The dental crown made by 3D printing on Farsoon MLS showed higher structure density and uniformity, compared to parts produced by the conventional casting method.

Farsoon integrated solutions for the medical industry

Dentistry

The FS121M model is an affordable and compact system for 3D printing with metal powders, with access to all the necessary settings’ changes, including the size of the laser spot. The dimensions of the printer are small, and in operation it does not require a large amount of additional equipment, so it will suit even a small dental clinic or lab.

Learn more about the Farsoon FS121M.

Implantology

The FS273M is a high-performance industrial production platform with advanced optical components, easy operation and access to print settings.

Learn more about the Farsoon FS273M.

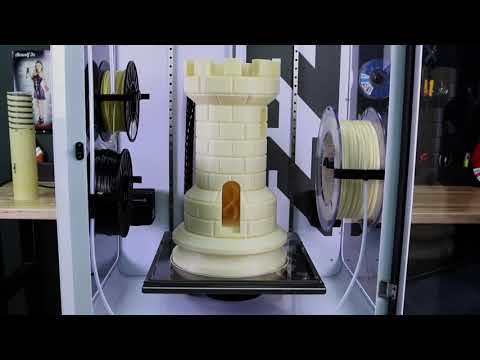

Prototyping

The Farsoon 403P and Flight 403P 3D printers series are high-performance industrial equipment for 3D printing with plastic materials. The flexibility of settings and advanced features of these series allow the user to print with a wide range of polymer materials, including high-temperature stress-resistant plastics and composites.

Learn more about the Farsoon 403P as well as its advanced series — Flight SS403P and Flight HT403P.

Bottom line

Additive manufacturing is reshaping the medical industry introducing faster production methods and making individually tailored guides, prostheses and implants more accessible at a larger scale.

Farsoon systems gained a lot of ground in the industry, offering advanced medical-focused solutions at the more affordable end of the price range. Although some technology-inherent issues such as high operating and material costs and certification requirements still remain, the vast array of machines in Farsoon’s lineup allow choosing the best fitting solution for your business.

Farsoon HT1001P - Product Specifications

Home / Products / Industrial 3D Printers / Farsoon HT1001P

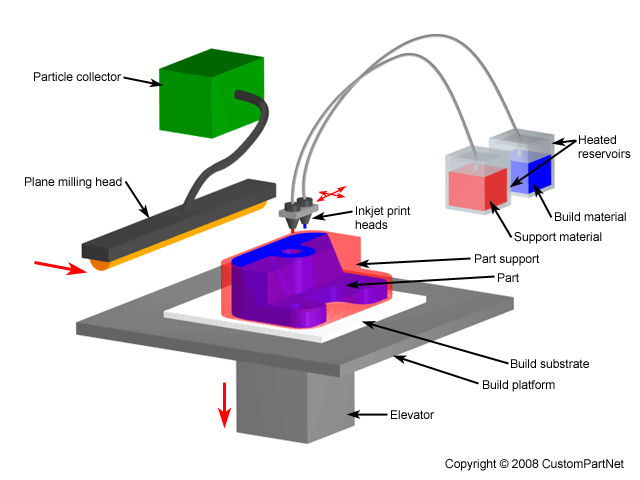

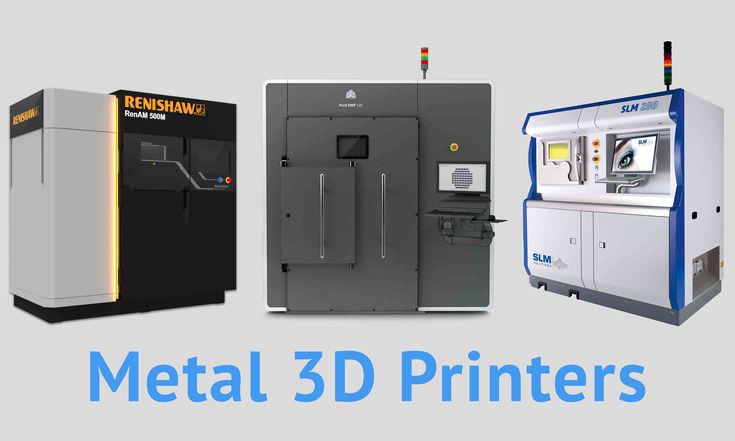

The Farsoon HT1001P is a Selective Laser Sintering 3D printer with continuous batch production capability. It features a closed loop powder system with increased automation and little need for operator interaction with the powder supply. The heated print chamber can reach up to 428°F / 220°C which enables you to print a wide range of […]

The heated print chamber can reach up to 428°F / 220°C which enables you to print a wide range of […]

The Farsoon HT1001P is a Selective Laser Sintering 3D printer with continuous batch production capability. It features a closed loop powder system with increased automation and little need for operator interaction with the powder supply. The heated print chamber can reach up to 428°F / 220°C which enables you to print a wide range of high performance materials. It has two high-precision three-axis galvo scanning systems.

Farsoon HT1001P specifications

- Company: Farsoon

- Application: Production

- Industry: Automotive, Aviation, Medical

- Technology: SLS

- Printer type: Large scale, SLS

- Year: 2019

Materials

- Materials: PA12, PA6, TPU, TPE

- Material system: Open material system

Build size (XYZ)

- Print size metric: 1000 x 500 x 450 mm

- Print size imperial: 39.37 × 19.68 × 17.

7 inches

7 inches

Properties

- Layer thickness: 60 - 300 Microns

- Laser: CO2, 2 x 100W

- Build rate: up to 15 kg per hour

Requirements

- Operating System: Windows 7

- Software: Farsoon MakeStar

- Power requirements: 380VAC, 50/60Hz, 25KVA, Three-phase Five-wire

Dimensions (XYZ) & weight

- Dimensions metric: 3750 x 2000 x 2170 mm

- Dimensions imperial: 147.6 x 78.7 x 85.4 inches

- Weight metric: 5000 kg

- Weight imperial: 11000 pounds

- Modix BIG Meter

1010 x 1010 x 1010 mm

Large scale, Filament deposition

from $13,500

Request a Quote - 3D Systems Figure 4 Standalone

124 x 70 x 196 mm

Resin

Price on request

Request a Quote - UnionTech π200

192 × 108 × 200 mm

Resin

Price on request

Request a Quote - UnionTech Lite 800

800 × 800 × 550 mm

Resin

Price on request

Request a Quote - Industry MAGNUM

1500 x 1200 x 1200 mm

Large scale, Pellet

€159.

Request a Quote 000

000 - 3D Systems ProX SLS 6100

381 x 330 x 460 mm

SLS

Price on request

Request a Quote

About Farsoon Technologies

Farsoon Technologies is a supplier of industrial systems (industrial 3D printers) for plastic laser sintering and metal powder laser fusion, founded in 2009 by Dr. Xu Xiaoshu. Dr. Xu served as the CTO of the industry's first laser sintering (SLS) company DTM Corporation (now 3D Systems) in the early 1990s. As one of the pioneers of additive manufacturing and laser sintering technology, Dr. Xu is a leading expert in laser sintering/melting technology with over 20 years of industry experience. Farsoon has built a world-class team of experts with competencies in all areas: electrical engineering, laser sintering, scanning and optical systems, thermal controls, materials development, and application development.

As an international diversified company, Farsoon is committed to providing world-class sales and support services for all of its products. This is realized thanks to numerous partners in various parts of the world. Farsoon Technologies also has offices in North America, Europe and, of course, China.

Farsoon was founded with a clear vision and philosophy of building open platform systems that allow users to freely innovate and expand the range of additive manufacturing technologies. Users of Farsoon systems have access to all key parameter sets in the system to customize solutions based on specialized applications and material requirements to meet their specific needs. We firmly believe that only by having an open system and finding new, better and more cost effective materials will the industry be able to continue its rapid growth.

Founder of Farsoon

“Additive manufacturing is playing an increasingly important role in many industries. As a player in the field of additive manufacturing, Farsoon Technologies is committed to driving innovation in mechanical engineering and materials development by unlocking real manufacturing applications. ”

”

Dr. Xu Xiaoshu

Founder and Chairman of Farsoon Technologies

Farsoon Americas

In pursuit of a global presence, Farsoon established the first branch company and direct distribution center in North America in 2017. Based in Austin, Texas, Farsoon Americas is a one-stop service distributor offering sales, service, and application development support for the North American market. Farsoon Americas is represented by industry veteran Philip Conner in charge of customer support and manufacturing as well as application development.

Farsoon Europe

Farsoon is committed to supporting its AM user base on a global scale. With this commitment, Farsoon is driving the growth of additive manufacturing in Europe with innovative and competitive products. In 2018, Dirk Simon (formerly BASF New Business GmbH) was appointed Managing Director of FARSOON Europe GmbH and became a member of Farsoon's global management team. Farsoon Europe works closely with European partners and customers to provide enhanced support and collaboration and is part of Farsoon's overall strategy for international growth.

3D Printer Farsoon ST252P at manufacturer's price with delivery - "TopStanok"

General characteristics

| Specification | FRS-ST252P | FRS-HT252P |

|---|---|---|

| General characteristics 3D printing | ||

| Print Technology | SLS | SLS |

| Media | Polyamide | Polyamide |

| Print area (WxDxH), mm | 250 x 250 x 320 | 250 x 250 x 320 |

| Minimum layer thickness, µm | 60 | 60 |

| Maximum build speed | 1. 2 l/h 2 l/h | 1.5 l/h |

| Weight kg | 2100 | 2100 |

| Equipment dimensions (WxDxH), mm | 1735 x 1225 x 1975 | 1753 x 1225 x 1975 |

| Media | Carbon fiber, PA, PPSU, TPU | Carbon fibre, PA, PPSU, TPU |

| Purpose | Aviation and space, Mechanical engineering, Medical, Education, Prototyping | Aviation and space, Mechanical engineering, Medical, Industrial, Prototyping |

| Chamber temperature, °C | 280 | 220 |

| Supported file format | . stl stl | .stl |

| Specifications | ||

| Thermal field monitoring | Eight-zone heater and intelligent temperature control systems | Eight-zone heater and intelligent temperature control systems |

| Operating system | Windows 10 64-bit | Windows 10 64-bit |

| Software | BuildStar®, MakeStar® | BuildStar®, MakeStar® |

| Operating ambient temperature, °С | 22-28 | 22-28 |

| Temperature control | Continuous real-time monitoring and optimization of surface temperature | Continuous real-time monitoring and optimization of surface temperature |

| Scanner | Galvo | high-precision three-axis digital systemGalvo | High Accuracy 3 Axis Digital System

| Scanning speed, m/s | 10 | 10 |

| Laser type | CO2 laser 100W | CO2 laser 60W |

| Layer thickness, mm | 0. |