Hobbyking 3d printer review

Turnigy Fabrikator Mini 3D Printer review! (TinyBoy) – Tom's 3D printing guides and reviews

It’s cheap. But is it good? The Fabrikator Mini tries to be the most affordable 3D printer out there, but i think it leaves out a few too many core features.

Last one that’s listed on Hobbyking

TinyBoy 2 campaign

TinyBoy 1 source files

How low can you go? Or actually, how low do you have to go to make a $175 3D printer? Well, stick around to find out as we take a deeper look at the Turnigy Fabrikator Mini from Hobbyking, which is exactly that.

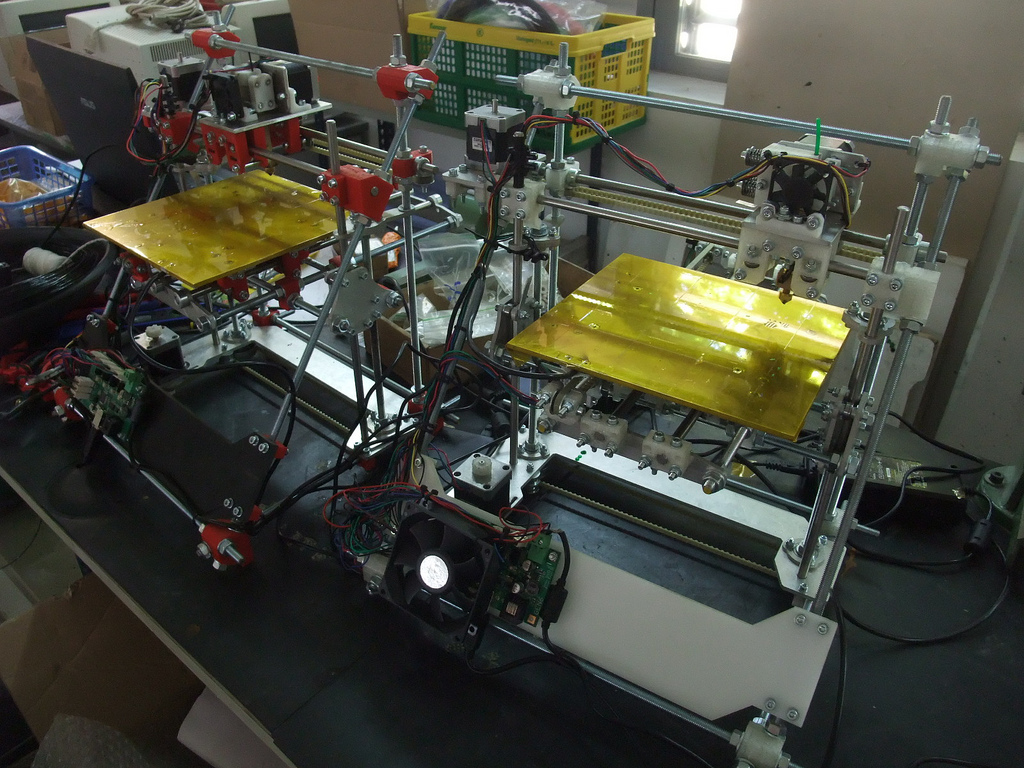

Now, surprisingly, this isn’t the only complete 3D printer you can buy for less than $200. In fact, for probably the same price once you factor in shipping, you can get a Prusa i3-esque machine with an LCD, a heated bed, and around 16 times the build volume of the Fabrikator Mini. But if you watch my review of the Malyan M150, a printer that is actually a good bit more expensive than that, you’ll get to see some of the flaws these rock-bottom 3D printers can come with. With something like the Fabrikator Mini, you will get the same experience anybody else is getting with it because you will receive the same hardware every single time – as opposed to simply buying the cheapest i3 from a random seller and getting a surprise package every single time. So what is the Mini Fabrikator all about? Well, let me show you its features! Actually, there’s not a lot to talk about since there are not noteworthy features per se. I guess the biggest “feature” would be its size, as it only takes up a 150mm square footprint on a desk. This is small enough to fit in the actual build area of most of my other 3D printers! Of course, you do sacrifice build area on the Fabrikator Mini that way, which leaves it with an 80mm cube build volume. Sure, that’s tiny, but i still think it’s a very usable size for its intended purpose, in fact, probably 95% of the things i print fit into this volume. The Fabrikator Mini is also surprisingly silent once you add the included feet, which come with a foam pad on their underside.

These also lift up the bottom of the printer to allow for additional airflow, since some users complained about overheating of the motor drivers, which, in my case, didn’t seem to be a problem. But only after i retuned the driver’s current setting, which, out of the box, is set so high that not only the motor driver will shut down eventually, but it will actually heat up the smaller-than-usual NEMA14 motors so much that they will warp the thin acrylic frame. On the other hand, if you tune down the stepper drivers too much, there are reports of these brass bushings starting to bind and causing the motors to skip steps, thus ruining your print. In my case, it printed perfectly fine after setting the driver’s reference voltage to about 0.7V. This is a bit higher than most viewers recommended in the live unboxing stream, but i had to add an external fan anyways, which in this case also cools the motors, but mostly serves as a part cooling fan. You see, this printer is made to work with PLA – it doesn’t have a heated bed, after all – and PLA needs a part cooling fan to print well, which the Fabrikator Mini does not have out of the box.

These also lift up the bottom of the printer to allow for additional airflow, since some users complained about overheating of the motor drivers, which, in my case, didn’t seem to be a problem. But only after i retuned the driver’s current setting, which, out of the box, is set so high that not only the motor driver will shut down eventually, but it will actually heat up the smaller-than-usual NEMA14 motors so much that they will warp the thin acrylic frame. On the other hand, if you tune down the stepper drivers too much, there are reports of these brass bushings starting to bind and causing the motors to skip steps, thus ruining your print. In my case, it printed perfectly fine after setting the driver’s reference voltage to about 0.7V. This is a bit higher than most viewers recommended in the live unboxing stream, but i had to add an external fan anyways, which in this case also cools the motors, but mostly serves as a part cooling fan. You see, this printer is made to work with PLA – it doesn’t have a heated bed, after all – and PLA needs a part cooling fan to print well, which the Fabrikator Mini does not have out of the box. These two prints were done from the exact same gcode, the left one without the fan, the right one with. Quite a big difference! Now, if you don’t want to just have a fan sitting on the table next to the printer, you can download and print one of the fan shrouds you can find online – again, an advantage of having a somewhat stable platform from a single vendor.

These two prints were done from the exact same gcode, the left one without the fan, the right one with. Quite a big difference! Now, if you don’t want to just have a fan sitting on the table next to the printer, you can download and print one of the fan shrouds you can find online – again, an advantage of having a somewhat stable platform from a single vendor.

Other than the printer itself, a power supply, a few extra sheets of blue painter’s tape for the bed and the feet, you don’t get a whole lot in the package. I guess the PLA sample isn’t really worth mentioning since it’s literally just enough for, like half a test print. The initial unboxing experience is really simple – you load the print profile into Repetier host – if you want to use Cura or any other slicer, you will need to type them in manually – adjust the bed height with this little screw on the back, plug in the bowden tube and you’re ready to print.

Now, the print quality in general is pretty ok – especially for the money. Of course, grey PLA does amplify any quality issues on camera, but except for some slight layer inconsistencies, it’s really ok. Which was expected, given that the default print speed is a whopping 15mm/s – for comparison, i run most of my other printers at 60mm/s, which is, i guess, a normal speed. But on the Fabrikator Mini, anything faster will start showing some artifacts from the extremely weak linear guide system. The first print i started actually used the wrong slicing profile and had it printing at 40mm/s, which worked, but it also only had smooth surfaces, so there wasn’t any risk of ending up with ringing artifacts. It’s also set up for quite low accelerations and uses a bowden system, so the forces on this motion system are fairly low. Still, XXmm unsupported linear rails and this tiny M4 Z-axis spindle, which has a ton of backlash, all in combination with the 4mm thin acrylic frame are anything but trust-inspiring. But in the end, it works! So i had the Fabrikator Mini set up for a full day of printing, and printed off 8 of these clamps that i’ll be using in an upcoming project.

Of course, grey PLA does amplify any quality issues on camera, but except for some slight layer inconsistencies, it’s really ok. Which was expected, given that the default print speed is a whopping 15mm/s – for comparison, i run most of my other printers at 60mm/s, which is, i guess, a normal speed. But on the Fabrikator Mini, anything faster will start showing some artifacts from the extremely weak linear guide system. The first print i started actually used the wrong slicing profile and had it printing at 40mm/s, which worked, but it also only had smooth surfaces, so there wasn’t any risk of ending up with ringing artifacts. It’s also set up for quite low accelerations and uses a bowden system, so the forces on this motion system are fairly low. Still, XXmm unsupported linear rails and this tiny M4 Z-axis spindle, which has a ton of backlash, all in combination with the 4mm thin acrylic frame are anything but trust-inspiring. But in the end, it works! So i had the Fabrikator Mini set up for a full day of printing, and printed off 8 of these clamps that i’ll be using in an upcoming project. Except for some slight variations of the first layer bed height, these all came out very consistently and reliably. Pop one off, start the next one, rinse and repeat, all day long.

Except for some slight variations of the first layer bed height, these all came out very consistently and reliably. Pop one off, start the next one, rinse and repeat, all day long.

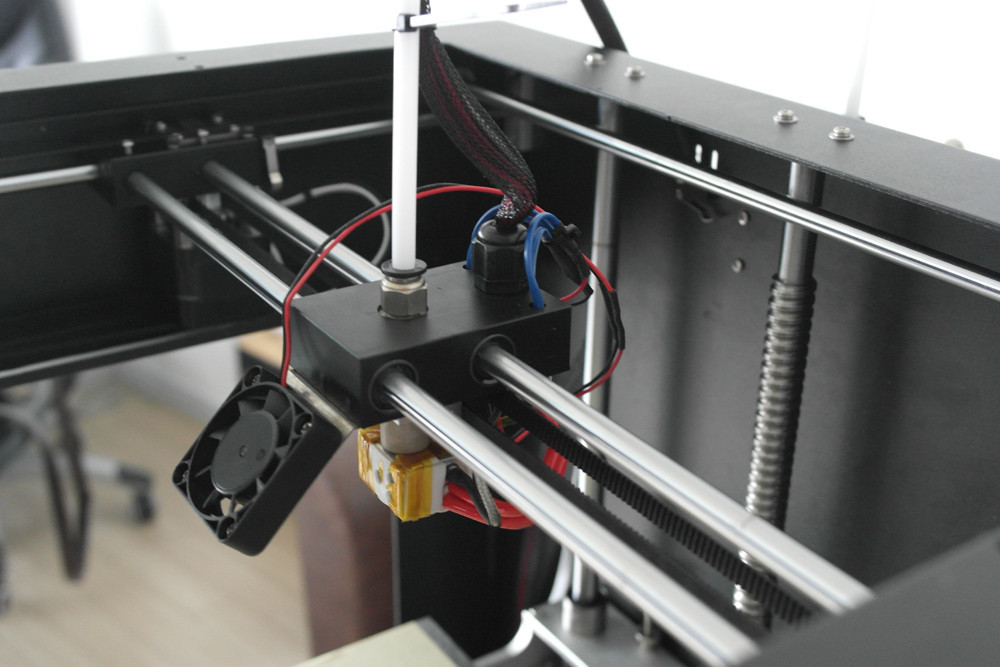

So there are actually a few nice features in here that you wouldn’t expect in an “as cheap as possible” 3D printer. On is the E3D v6 imitation, which, i mean, doesn’t add a whole lot of value as-is, as, as usual it’s not particularly well-made and uses a heatbreak that is much too thick, wastes a bunch of power, but also heats up the heatsink so much that it’s incredibly easily to jam the hotend if you pull out the filament too slowly when swapping filament. What will happen is that the filament will stick to the warm, but not hot metal sides and form a pretty solid plug, something the genuine one avoids by not heating up the heatsink so far and by putting a bit extra effort into making the heatbreak smooth inside.

Also surprising to see here is the fully featured MKS base mainboard. Five stepper drivers, three power outputs, a heated bed output, and as expected for a cheap-ish board, standard Allegro stepper motor drivers and zero consideration for component current limits or any sort of failsafes. Ironically, though, now my smallest and my largest cartesian 3D printers use the exact same boards.

Ironically, though, now my smallest and my largest cartesian 3D printers use the exact same boards.

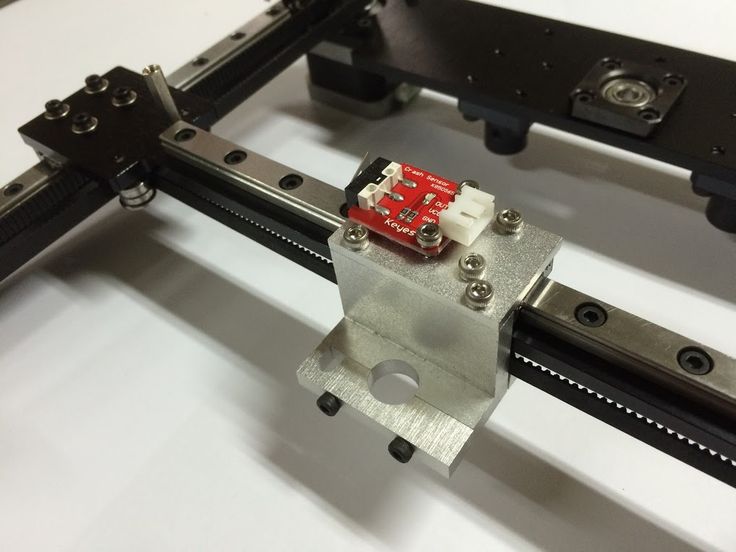

And the way the belts are set up here is pretty ingenious. Instead of just using a single loop, it uses this hoist-like system, which reduces the torque needed from the motor and also increases positioning accuracy.

And that’s why i kinda like the Turnigy Mini Fabrikator – yeah, sure, it’s super cheap and barely any features to write home about, but it’s got that vibe to it where it tries to do more with less and is mostly successful with it.

Now, this machine is not designed by Turnigy aka Hobbyking, it’s a project from TinyBoy aiming to provide affordable 3D printer for education – for that job, i think the way the Turnigy version is put together with the lack of a part cooling fan and the overheating issues, it’s just barely not enough to fit that bill. Educators are notoriously short on time and typically don’t want to spend it on getting a machine like this to work well. But – and here’s the kicker – there is a new version coming up, the TinyBoy 2, which was launched on Indiegogo a good year ago and should have been shipping by now, but TinyBoy’s CEO dropped out for a while due to medical issue and it looks like, they now are actually producing the new machines. I fully expect the new version to become available at Hobbyking again, seeing that the original one has been quite popular. As of right now, this exact machine here is on backorder and it looks like none have been shipped out for a while, so i can’t really recommend ordering it it right now. But it is a promising base for that next model.

But – and here’s the kicker – there is a new version coming up, the TinyBoy 2, which was launched on Indiegogo a good year ago and should have been shipping by now, but TinyBoy’s CEO dropped out for a while due to medical issue and it looks like, they now are actually producing the new machines. I fully expect the new version to become available at Hobbyking again, seeing that the original one has been quite popular. As of right now, this exact machine here is on backorder and it looks like none have been shipped out for a while, so i can’t really recommend ordering it it right now. But it is a promising base for that next model.

With this exact setup, you could make it work really well if you can and want to do a bit of tinkering, and with things like the fake v6, the big bowden extruder and the MKS board in there, you do even have the option of taking this entire thing apart and using those components to build something bigger if you feel like you need the extra space.

So those were my impressions on the Hobbyking Turnigy Fabrikator Mini aka TinyBoy v1. 5 – if you’re looking for a similar machine, but, like, want it right now, check out my review of the Printrbot Play right up here. Now, for this video, if you enjoyed it, leave it a thumbs up, if not, a thumbs down, if you want to stay up to date as new videos come out, get subscribed, and if you’re really into what i’m doing here, drop me a dollar or two on Patreon. And that’s about it, see you in the next one or in this weekend’s livestream right here on Youtube.

5 – if you’re looking for a similar machine, but, like, want it right now, check out my review of the Printrbot Play right up here. Now, for this video, if you enjoyed it, leave it a thumbs up, if not, a thumbs down, if you want to stay up to date as new videos come out, get subscribed, and if you’re really into what i’m doing here, drop me a dollar or two on Patreon. And that’s about it, see you in the next one or in this weekend’s livestream right here on Youtube.

This video is licensed as Creative Commons Attribution Share-alike thanks to my supporters on Patreon!

Music is Jahzzar – Halley, licensed CC-BY-SA

Turnigy X5S 3D Printer (US Plug)

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total Price

$0. 00

00

Cart 0

want FREE shipping? Click here to find out more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshipppingEnabled}} Free Shipping on Eligible Orders {{/isFreeshipppingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9Enabled}} {{#list_image_url}}{{/list_image_url}} {{^list_image_url}}{{/list_image_url}}

{{#isFreeshipppingEnabled}}

Free Shipping on Eligible Orders

{{/isFreeshipppingEnabled}} {{#isAddToCartEnabled}} {{#isWarehouseAddToCartEnabled}} {{^is_combo_product}}

QTY: {{#isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}} {{^isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}}{{/is_combo_product}} {{/isWarehouseAddToCartEnabled}} {{/isAddToCartEnabled}} {{#availableInOtherWarehouses}} {{{availableInOtherWarehouses}}} {{/availableInOtherWarehouses}} {{#is_combo_product}} {{^isProhibited}} View Details {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Choosing the best 3D printer for home and hobby (FDM) / Aliexpress product selections and more / iXBT Live

iXBT. com projects require cookies and analytics services. By continuing to visit project sites, you agree to our Cookie Policy

com projects require cookies and analytics services. By continuing to visit project sites, you agree to our Cookie Policy

How do I decide which 3D printer is right for home and hobby/modeling? The article will provide basic tips for choosing a model, as well as a list of the most popular printers with good reviews.

Buying a 3D printer from Aliexpress is a dream of many. The printer will help in hobbies and creativity, in work and study. 3D printers were developed as a means of rapid prototyping, but now they are available to everyone, and today's prices are very encouraging. But the problem of choice is more acute than ever: what to take?

First you need to answer the most important question: what do you need a 3D printer for? What will you print on it? So:

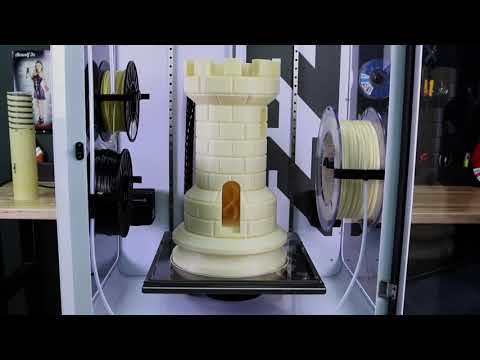

1) Decide on the size of the working area. Usually it is a square 200 x 200 mm (or 200 mm diameter for delta printers), print height up to 250 mm. This option is the most versatile and most common. Printers with a larger Z-axis (vertical) size, such as delta printers, are suitable for printing tall models. For printing large-sized products, you need to choose printers with dimensions of 300 x 300 x 300 mm or 400 x 400 x 400 mm. I draw your attention to the fact that with an increase in the size of the model, the printing time increases many times over.

Printers with a larger Z-axis (vertical) size, such as delta printers, are suitable for printing tall models. For printing large-sized products, you need to choose printers with dimensions of 300 x 300 x 300 mm or 400 x 400 x 400 mm. I draw your attention to the fact that with an increase in the size of the model, the printing time increases many times over.

2) Decide on the basic functionality of the printer, namely: how much you need a touch screen (and what size), printing with Wi-Fi, a color extruder, the presence of auto-calibration or filament sensors. One of the most useful features is the ability to continue printing after a crash, where the printer remembers where it stopped. The rest is for an amateur.

3) Try to choose 3D printers from local stock. For example, when applying, select "From the Russian Federation". Thus, you avoid overpayment due to the duty on parcels, and receive the ordered in a short time.

The best choice of 3D printer for home and hobby

3D printer CREALITY 3D Ender 3 V2 3D printer CREALITY 3D Ender 3 PRO 3D printer LONGER LK4 PRO

Probably the most popular in the Russian-speaking community are 3D printers from Сreality-3D, specifically: Ender-3 and Ender-3 Pro. The ratio of price and quality can be considered ideal, with promotions and coupons, printers can be purchased for a symbolic cost. I will highlight the main differences: Creality-3D Ender-3 comes as a pre-assembled kit, that is, it takes about 15 minutes to prepare for printing. Everything is already set up, you just twist the frame to the base and level the table. As for the improved Ender-3 PRO version from Crealuty, this is an updated Ender-3 model with cured sores and improved accuracy, new motor drivers, a more powerful power supply, with the ability to save print progress when the power is turned off. The Ender-3 PRO is shipped disassembled, so you'll have a couple of hours of fun assembling with instructions. Another good option is the Longer LK4 Pro printer. This is an inexpensive and easy-to-learn printer, reliable as a Kalashnikov assault rifle. There are also no particular problems with consumables: plastics such as ABS / PLA / PETG are suitable.

The ratio of price and quality can be considered ideal, with promotions and coupons, printers can be purchased for a symbolic cost. I will highlight the main differences: Creality-3D Ender-3 comes as a pre-assembled kit, that is, it takes about 15 minutes to prepare for printing. Everything is already set up, you just twist the frame to the base and level the table. As for the improved Ender-3 PRO version from Crealuty, this is an updated Ender-3 model with cured sores and improved accuracy, new motor drivers, a more powerful power supply, with the ability to save print progress when the power is turned off. The Ender-3 PRO is shipped disassembled, so you'll have a couple of hours of fun assembling with instructions. Another good option is the Longer LK4 Pro printer. This is an inexpensive and easy-to-learn printer, reliable as a Kalashnikov assault rifle. There are also no particular problems with consumables: plastics such as ABS / PLA / PETG are suitable.

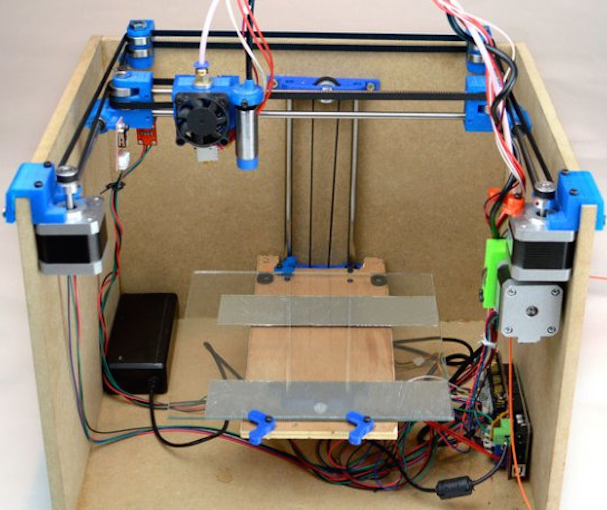

Cubes: CoreXY and H-Bot

CREALITY 3D Ender 5 3D printer Flyingbear Ghost 5 3D printer ANYCUBIC 4Max Pro 3D printer

Advanced models of 3D printers with a rigid cube frame and kinematics hidden inside the case. There are CoreXY and H-Bot options to choose from. Unlike Prusa i3 clones ("dry-tables"), "cubes" are preferable for responsible printing and for printing tall models. The table moves in height (along the Z axis), and the head moves only in XY, which allows you to print an order of magnitude better. The printers have a fully metal, rigid frame, an inductive self-leveling sensor, a huge (3.5") touch control display, a filament sensor. printers, the article on which is available at the link.0003

There are CoreXY and H-Bot options to choose from. Unlike Prusa i3 clones ("dry-tables"), "cubes" are preferable for responsible printing and for printing tall models. The table moves in height (along the Z axis), and the head moves only in XY, which allows you to print an order of magnitude better. The printers have a fully metal, rigid frame, an inductive self-leveling sensor, a huge (3.5") touch control display, a filament sensor. printers, the article on which is available at the link.0003

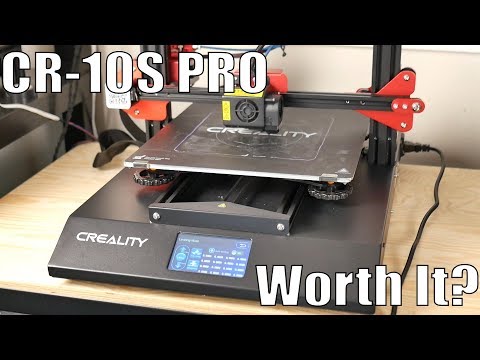

3D printers with large print area

3D printer Creality CR-10 S5 3D printer Artillery Sidewinder X1

I often get questions about which 3D printers to choose for printing large-sized models, for example, printing REA cases, flower pots and vases, etc. Suitable models such as Artillery Sidewinder, Creality CR-10, Tevo Tornado and others. By choosing such a printer, you get a huge tool with a working field of 300 x 300 x 400 mm. You can even print a tall hookah flask. For example, the CR-10 printer is a great, proven model from Creality3D. The link is already the third generation, corrected and supplemented. Another representative of printers with a huge field is the advanced 3D printer Artillery Sidewinder-X1. For relatively little money, you get a large printer with a printable area of as much as 300 x 300 x 400 mm. The printer has an exceptionally well-thought-out design - protective covers are provided, flexible cables are laid in cable channels, electronics are hidden in a special box in the basement.

The link is already the third generation, corrected and supplemented. Another representative of printers with a huge field is the advanced 3D printer Artillery Sidewinder-X1. For relatively little money, you get a large printer with a printable area of as much as 300 x 300 x 400 mm. The printer has an exceptionally well-thought-out design - protective covers are provided, flexible cables are laid in cable channels, electronics are hidden in a special box in the basement.

Dual Extruder & Color Printers

Geeetech A20M Mix-color 3D Printer JGMaker Artist-D Dual 3D Printer

Printer. This is an excellent model, which features two independent extruders (directs) and a large print area: 31 x 310 x 350 mm. And the interesting Geeetech A20M Mix-color model can mix the colors of the filament right during printing, allowing you to get different shades in the finished model. What is a 3D printer and how to work with it, you can see in the review of a 3D printer from Tronxy.

As for the choice of consumables, modern models of 3D printers print well with common plastics such as ABS / PLA / PETG, which are available from local manufacturers. To print with soft polymers (TPU/Flex), you need to choose a printer with a direct extruder designed for such a filament. Add the selected models to the cart, so you can track the price changes (discounts are expected until the end of December).

News

Publications

The nature of the Earth presents a huge number of interesting phenomena and miracles to man. Some of them we see often, but many are extremely rare and are a unique combination of different...

After the widespread use of neural networks, the human community began to worry about the fact that AI will soon replace people in many professions. If this happens, many...

Lately from Russia left the majority of pet food manufacturers, which affected both the owners of dogs and cats, and breeders. Fortunately holy the place is not empty for a long time. ..

..

How many times he burned himself, stepped on a rake, but still continued to eat the cactus. This is how I wanted to start my story. For the past few years, I have been buying from a well-known Chinese store, but the conditions are...

For everyday use, considered in review new from Haylou good enough. Earbuds X1 Neo in principle they cannot boast of powerful bass, but good ergonomics,...

Most Egyptian apartments use prepaid electricity meters that cut off the electricity supply when they are in arrears. For payment, special cards are used, ...

Which 3D printer to choose for home and hobby use

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get.

This is not at all the result that a beginner who first got acquainted with 3D printing will get.

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”).

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

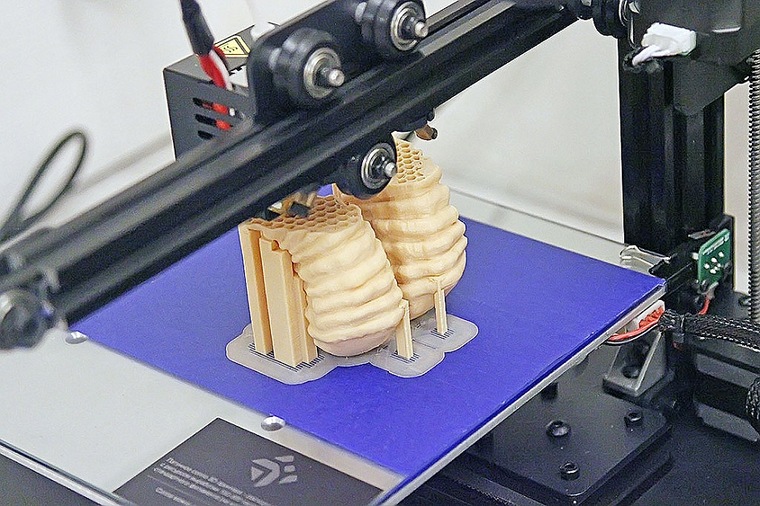

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon.

If it is necessary to produce large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

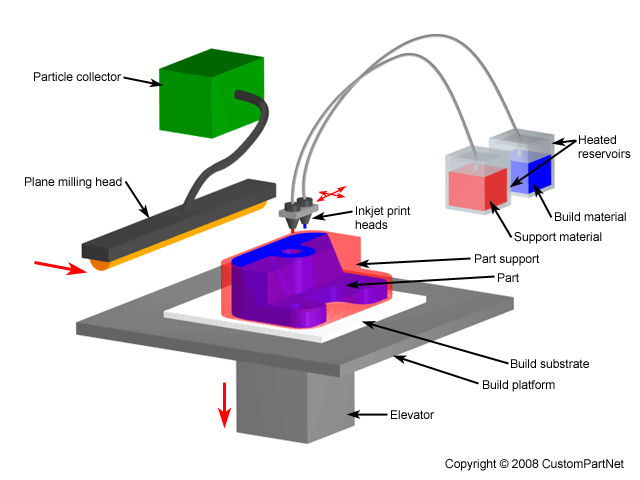

FDM technology builds a model using molten plastic filament, which is fed from the print head. The print head (extruder) “grows” the model layer by layer on the printing table.

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA.

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0072

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

How DLP works

Pros:

-

Faster production of models due to the illumination of the entire layer

-

Consumables are slightly cheaper than SLA

-

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

-

small cost

-

Cheap parts

Cons:

-

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology)

-

Possible stray light

-

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation. Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers.

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area. The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choose FDM printer

If you plan to produce large and diverse functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work.

Some printer models can be “upgraded” in the future. For example, if necessary, purchase spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons.

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

Pros:

Cons:

-

Slow print speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds. -

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you have to be a little inventor. Or find a ready-made solution on the Internet.

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of the moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y. But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

-

High print quality

-

High print speeds without loss of quality.

-

Can be easily closed completely

Cons:

MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

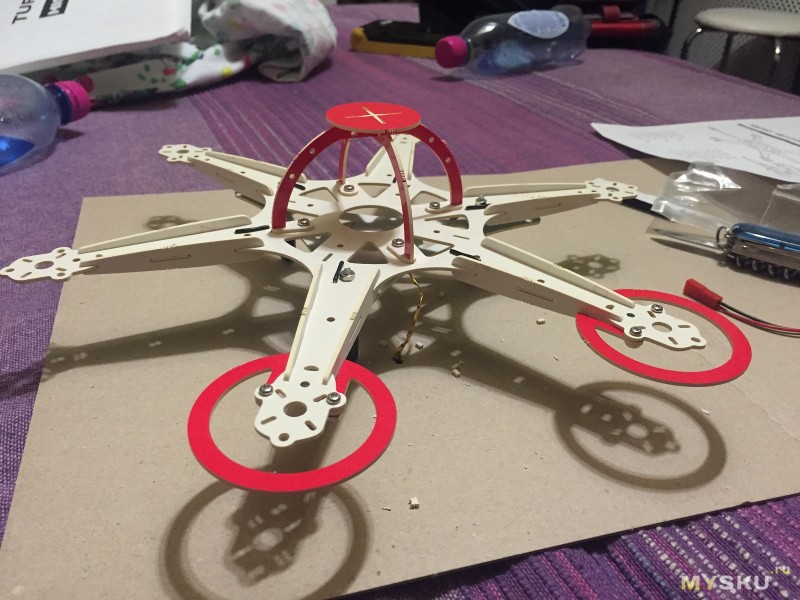

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body.

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to take into account some design features.

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer.

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct.

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feeding diagram

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics.

This increases the weight of the print head, but allows you to print with any kind of plastics.

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage.

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a resume function after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other extras that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

Flying Bear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer.

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice. A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited.