3D print kayak

Kayak best 3D printing files・Cults

Big Fish 103 Kayak Slim Pocket

€0.99

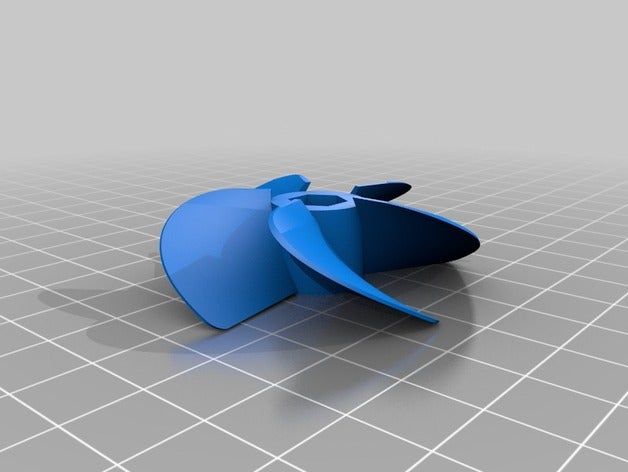

Optimized, power saving, toroidal propeller for 56lbs Electric trolling motors - Small Size

€5

Toroidal propeller for 56lbs electric trolling motor for small boats - Large SIZE

Free

Old Town PDL 106/120 rear seat risers

€9.99 -30% €6.99

Kayak Cable Hatch Native Water Craft Slayer Max 12.5

€3

Mercury / Mariner Inflatable Pump Nozzle

Free

kayak lovers in water

€2.50

Packraft / Kayak Anchor line winder / holder

€4. 61

OLD TOWN SPORTSMAN 106 MK SEAT RISERS

Free

Jonny Bass 100 Motor stand

Free

Surfski rudder plug for moulding/casting from.

Free

Handle. Created for a surfski Paddle shaft grip.

Free

Cargo Canoe

€1.87

Canoeing Medal List

€2.50

Kayak (Canoe) Medal List

€2.50

kayak

€4.92

Shearwater Helix Transducer Adapter

Free

Helix 5 Head Unit Bracket

Free

Kayak Claw Anchor Storage

Free

Fishing bobber/floater

Free

Turbine Water Jer

€0. 59

59

Stake-Out-Stick Mount

Free

Kayak scupper plug

Free

Air pump adapter - Double lock valve

Free

Line/rope float for Kayak/Boating

Free

Minimalist sloop

€5

Flag mounts for thing 1993269 Kayak flag and light

Free

Scotty Flush mount bottom plug

Free

Old Town Sportsman 106 MK Seat Risers

Free

Fishing Rod Holder

€1.50

kayak J bar mounting bracket

Free

Canoe or Kayak Grab Handle

Free

Canoe Polo Model Boat

Free

Paddle Clip

€1. 25

25

Camera Mount Cup holder v2

€0.61

Cup Holder for GoPro mount

€0.61

Roof rack for kayak

Free

26mm Kayak Oar T-Handles

€9.37

Sword Grips with Knuckle Straps for Oculus Quest 2 controllers

€3.51

Sword Grips with Knuckle Straps for Oculus Rift S controllers

€3.51

ITIWIT Decathlon Pump Adapters

€2.50

kayak fin

€2

Zelda's Sheikah eye wall decal

€0.50

Mechanical Beaver Canoe

€2.50

Filler washer for Hobie Lynx H-Rail

Free

0 degree mounting bracket for LiveScope

€5

Lifetime Kayak - Back Strap Clip

€0. 61

61

Propeller for Haswing W20 electric outboard motor

Free

What to 3D Print? How About A Full Size Kayak

0Shares

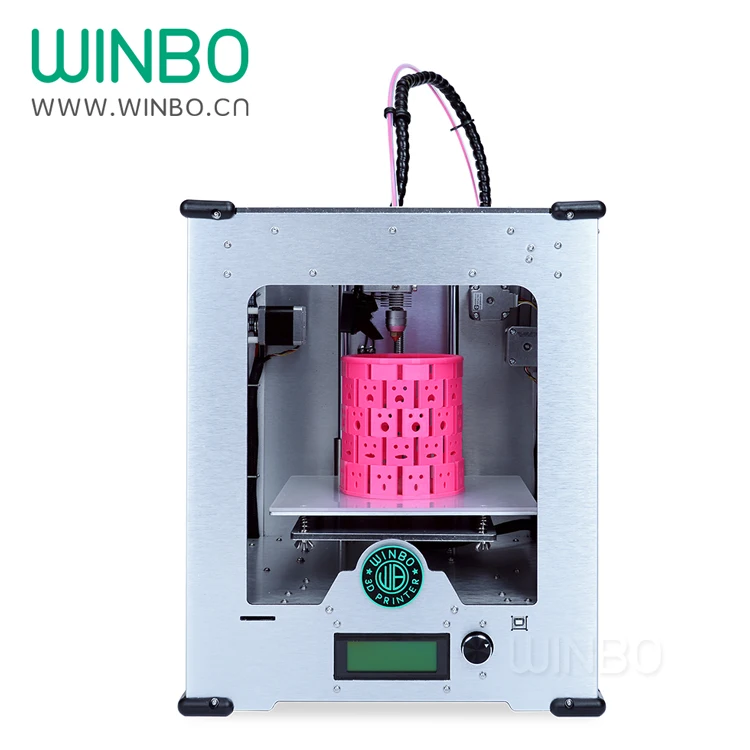

In the ever changing world of 3D printing one concept is constantly heard: the only limit to what you can create is your imagination. That implies that all other limitations, such as size, shape, practical use and materials, are just imaginary limits that we create ourselves. Jim Smith, a 3D Systems engineer, maker and founder of the Grass Roots Engineering blog took this concept quite literally and simply pushed the limits a little farther away. About 5.08 meters (5 ft 8in) farther away as that is the size of the first fully 3D printed kayak he created with about $500 worth of material.

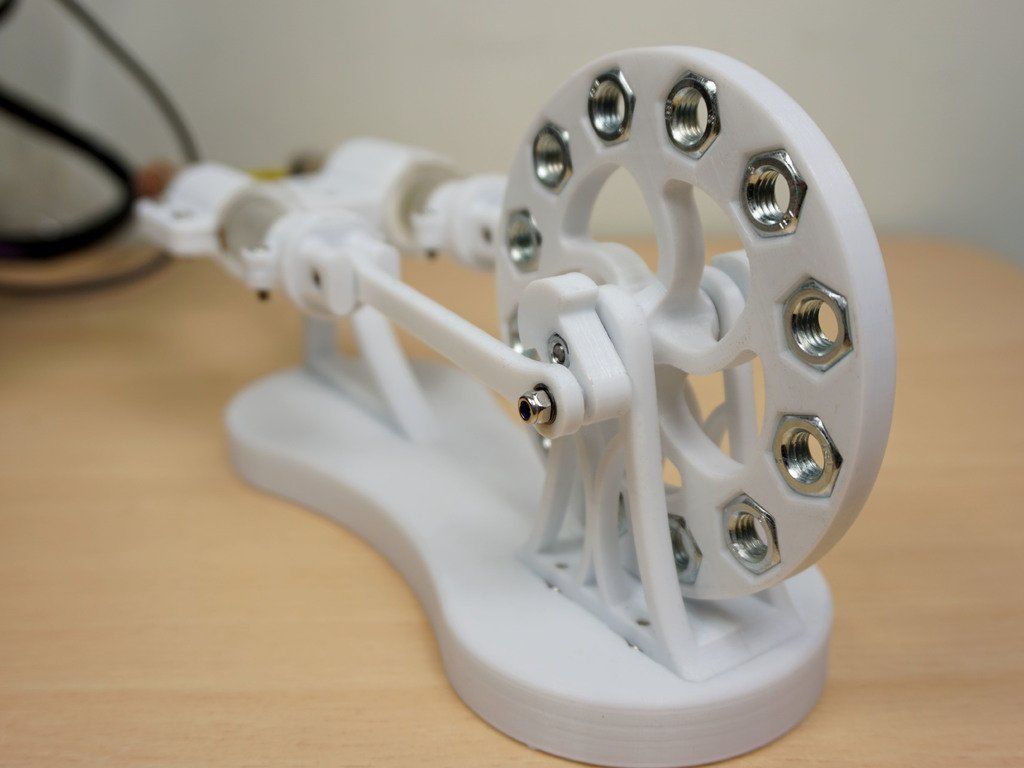

The 3D printed kayak is made of ABS plastic, machine screws, brass threaded inserts and a little silicone caulk in between parts for water tightness. As Jim says: “That’s it. And it Floats” And he can kayak around in it. Of course that is not entirely “it”. 3D printing something that large is not something anyone can do and no one said that pushing the limits of imagination does not take a lot of work.

Of course that is not entirely “it”. 3D printing something that large is not something anyone can do and no one said that pushing the limits of imagination does not take a lot of work.

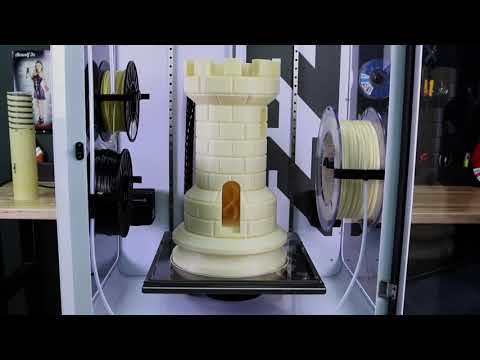

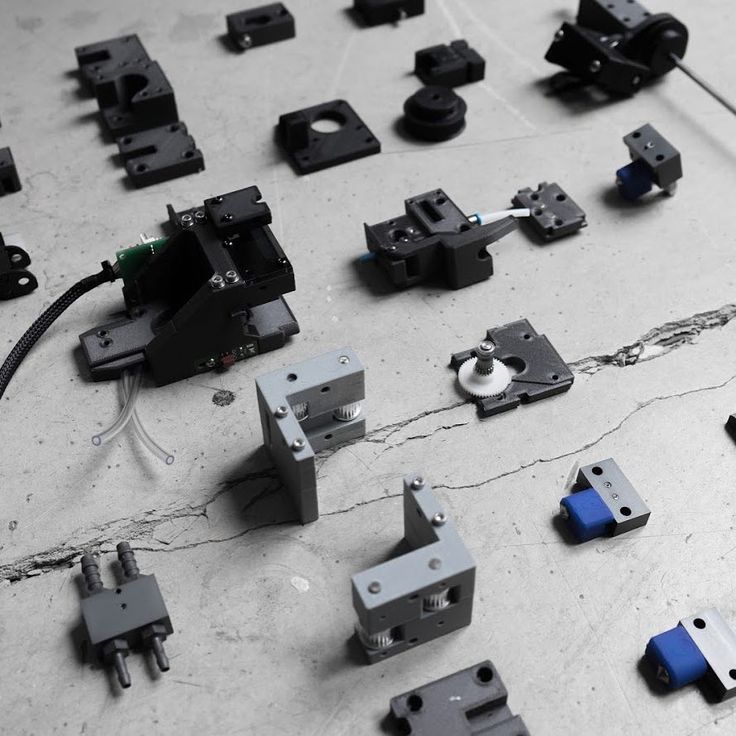

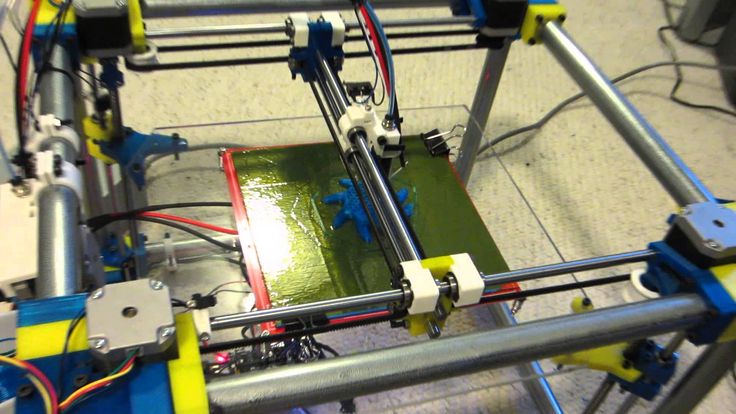

To make the kayak, Jim built his own large volume FFF 3D printer and printed the parts inside a heated chamber so that the ABS would not warp, crack or deform. In total there are 28 3D printed (very colourful) parts for a design inspired by the Siskiwit Bay kayak by Bryan Hansel but heavily modified for 3D printability. For macroscopic practical objects, resolution is not a big issue so the parts were printed with a layer resolution of .65 mm, which allowed him to save on time and materials. The design also made room for cameras at the bow and stern, as well as handles and space for future add ons.

As mentioned previously, the kayak measures 5.08 meters in length — it’s worth repeating. Its width is 0.52 meters and its total weight is 29.29 Kg (of which 26.48 Kg is the weight of the 3D printed ABS plastic parts. Total print time: 1012.65 hours. That is 42.19 days, so basically a month and a half. It sure took a lot longer than ordering it from eBay, but try to make your very first kayak at home using traditional tools. My guess is that it would take you quite a bit more. If you are a maker (and probably even if you are not) you will likely find the video below rather inspiring.

Total print time: 1012.65 hours. That is 42.19 days, so basically a month and a half. It sure took a lot longer than ordering it from eBay, but try to make your very first kayak at home using traditional tools. My guess is that it would take you quite a bit more. If you are a maker (and probably even if you are not) you will likely find the video below rather inspiring.

Davide Sher

Davide was born in Milan, Italy and moved to New York at age 14, which is where he received his education, all the way to a BA. He moved back to Italy at 26 and began working as an editor for a trade magazine in the videogame industry. As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

DIY kayak in 3D. Charlotte's print

26-year-old American Jim Smith printed a real kayak by spring. Of course, to do this, he first had to upgrade his home 3D printer...

But is that a problem for an engineer who has 500 bucks, 1000 free hours and one fix idea?

March 18 on the website of the inventor Jim Smith there was news about the newly printed kayak "Charlotte":

“I have completed a fully 3D printed kayak upgrade. The boat is 5.08 meters long and cost me $500 to build. Made of ABS plastic, brass screws and silicone seals. Like this. And she swims . And I can ride it. In order to print some of the large parts of the kayak, I had to redesign my home 3D printer. The part must fit completely in the working chamber so that deformations or cracks do not appear on it.

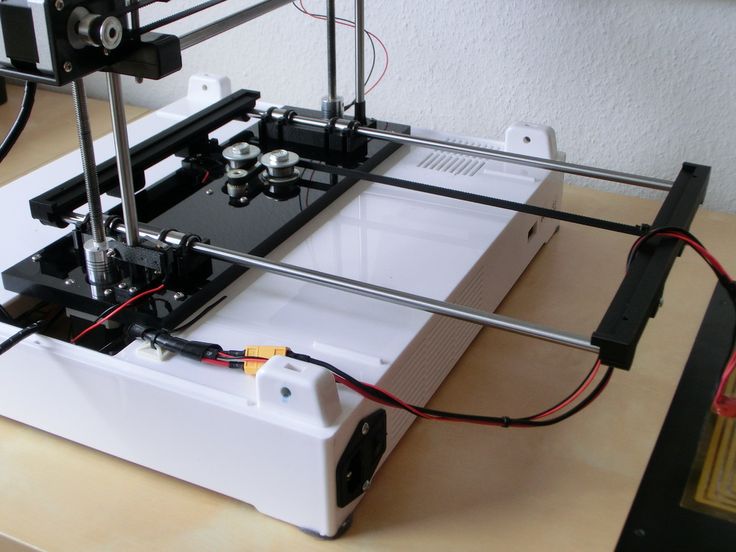

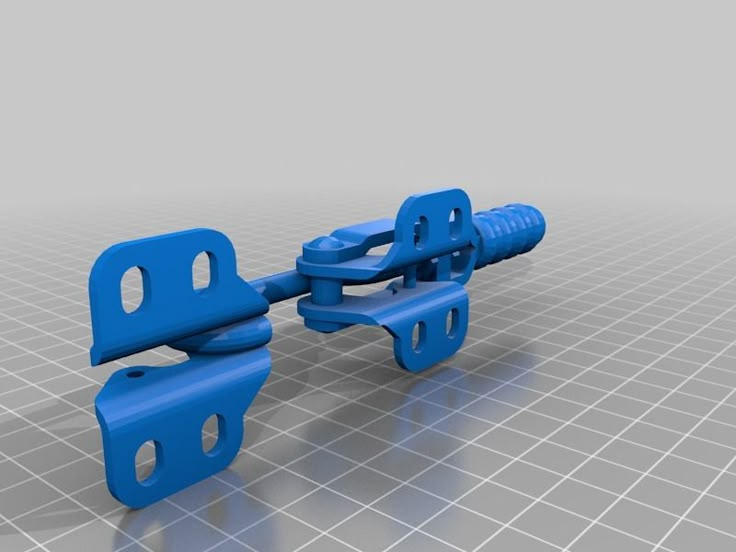

Pictured: the printer that Jim built and the kayak that the printer that Jim built printed.

How did he do it?

In 2008, Jim designed and built a large 3D printer at his home based on the RepRap printer. Two years later, he completed his thesis on this topic and became an engineer at 3D Systems, the world's leading printer manufacturer. In 2010, Jim created a site that quickly gained popularity and became a platform for Jim to talk about his experiments and the possibilities of the latest technology.

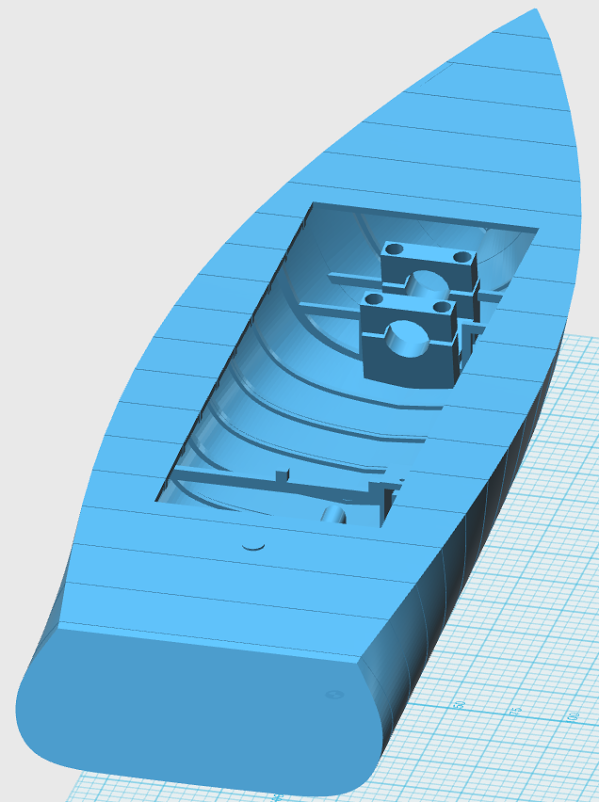

“The design of the boat was originally based on the Siskiwit Bay, which was created in 2008 by Brian Hansel. It's a proven design, and the widest part of the boat was made from just two pieces. However, I had to significantly change the design to make it possible to print the boat on the printer. Moreover, I changed its shape, focusing on my weight and height. I created the 3D design from 2D drawings, so I just shortened the width of the hull a bit.”

Pictured: Brian Hansel's Siskiwit Bay prototype kayak and blueprint kit, which he sells for $30.

The kayak is made up of 28 plastic parts that are individually printed and then screwed together. Silicone seals prevent water from entering the boat.

“I divided the housing into parts so that printing each part required my printer to run at maximum power. To reduce print time and material consumption, I made a layer of 0.65 mm. The case has a thickness of 6 mm, it has internal stiffening ribs. Thanks to these features, the boat is stronger and lighter, and less plastic is required. On the bow and stern of the kayak, I added camera mounts, handles and some other things that will come in handy in the future,” Jim explains.

Specification:

length - 5.08 m

Width - 0.52 m

Weight - 29.29 kg, of which 26.48 kg are printed plastic parts, the rest - fasteners

Seal time 1012.65 hours (42.19 days)

Plastic ABS is a durable, impact resistant, non-toxic, moisture resistant material. Due to these and other properties, it is excellent for the manufacture of large car parts, housings for household and office equipment, all kinds of appliances, apparatus, furniture and sports equipment.

Due to these and other properties, it is excellent for the manufacture of large car parts, housings for household and office equipment, all kinds of appliances, apparatus, furniture and sports equipment.

Technology and DIY

“I designed and built my own printer and wanted to print something to demonstrate the potential of this technology for personal use. I've always loved rowing, I live on a lake, I have a 3m Necky kayak that I'm used to. But rowing in a printed boat is something! And she has more speed,” says Jim.

The world's first 3D part appeared 9March 1983. Today, printers create weapons, airplanes, ears, stem cells, and whipped cream tarts. One can only guess what the inventors will come up with in the next 30 years! Layered deposition technology is becoming more and more accessible. You won’t have time to look back, as everyone who wishes will start printing kayaks for themselves. Of course, except for those who print the canoe first.

Of course, except for those who print the canoe first.

Charlotte Seal

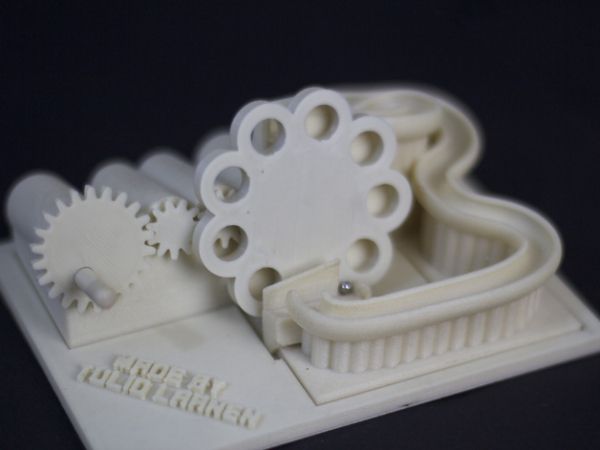

Photo: The largest part of the boat (1.505 kg, dimensions 381x229x275 mm)

Photo : Printing Parts in the Printer Workshop

9000 9000 9000 9000 9000 BEDAROAREN

Photo of : silicone finish

Oksana Lans for CanoeSport - CanoeSport.ru

9 amazing examples that can be 3D printed.

How does 3D printing work? How is 4D printing different? Amazing examples of 3D and 4D printing in action.

1. Bones and muscles. 2. Ovaries. 3. Baking. 4. Food. 5. Buildings. 6. Kayak. 7. Art for the blind. 8. Materials with shape memory. 9. Anything your mind can imagine.

When a person first learns about the existence of a 3D printer and 3D printing, most often he asks why I should buy a 3D printer and what I can do with it.

We answered the first question in our article 10 reasons to buy a 3D printer for home use, and we will try to answer the second in this post.

We are faced with a rather difficult task, because the possibilities of printers and 3D printing are so limitless that it is basically impossible to fit all the answers in one post.

We won't bore you with listing the endless options for models that can be printed on a home 3D printer, but we will try to show several areas where the potential of 3D printing has manifested itself to the maximum.

Given the rise of 3D printing over the last 10 years, it seems that 3D printing will have a very wide range of applications for the foreseeable future, and could become especially powerful when combined with trends such as mass personalization.

This article can be read by both beginners in this field and experts in this innovative technology. So before we get to the amazing uses of 3D printers around the world, it's worth saying a few words about 3D printing technology itself.

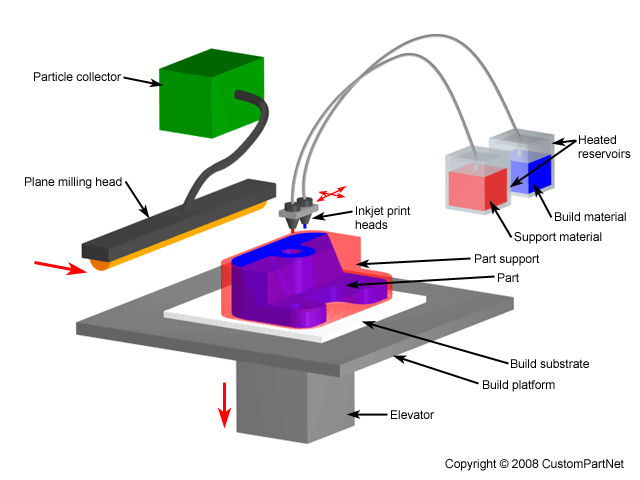

How does 3D printing work?

3D printing (also known as "additive manufacturing") involves creating a 3D object from a digital file. After the file is transferred, the 3D printer applies successive layers of material until the object is ready.

Each layer is a thin (typically 0.1-0.2 mm) cross section of the actual object.

Most materials used in 3D printing are thermoplastics, a type of plastic that becomes liquid when heated, but solidifies when cooled and does not lose strength.

However, as technology advances, researchers are finding more and more new materials that can be used in 3D printing.

In addition to plastic, metal, concrete, biomaterials, foodstuffs and even moon dust can be used.

The main advantage of the additive approach is that even the most complex shapes can be created in a simpler way and with fewer materials than traditional production methods (which is good for the environment and profit).

In addition, the need for transportation is reduced, since you can buy a 3D model (digital file) on the other side of the world and print it in your hometown.

3D printing is also a game-changer for rapid prototyping, custom manufacturing, and the creation of personalized products.

This is the most adaptable and economical technology for designing and creating one-off, unique, new or exclusive products.

How is 4D printing different?

4D printing is like 3D printing, but with a twist. Thanks to this new dimension, 3D printed objects have the ability to change their shape on their own under the influence of external factors such as light, heat, electricity, magnetic field, etc.

transform over time in response to certain stimuli and does not require human intervention to facilitate the process.

In simple terms, the created object can be programmed to change its shape when certain triggers appear, such as water or heat.

For example, a storage box may collapse, or a structure may recover from weather damage.

But fundamentally, 4D printing is a pioneer in additive manufacturing, which means it's still in its experimental stages.

Amazing examples of 3D and 4D printing in action.

As you can probably imagine, 3D and 4D printing technologies have the potential to revolutionize the industrial world and change the trivial production process. But these technologies have a much wider application than conventional industrial processes, and many of the applications of 3D printing can really surprise you.

Here are 9 amazing and unexpected uses for additive manufacturing.

1. Bones and muscles.

At the Wake Forest Institute for Regenerative Medicine, researchers have been able to print bones, muscles, and ears—a process known as bioprinting—and successfully implant them in animals. What is really interesting is that the printed tissue survived after being implanted and became a functional tissue.

Wake Forest's research was funded in large part by the Armed Forces Institute for Regenerative Medicine, a military organization working to develop regenerative treatments for critically injured soldiers.

The development of 3D-printed graft tissues can certainly benefit both military personnel and civilians.

Hundreds of thousands of people are currently on the waiting list for organ transplants.

Bio 3D printing could do away with waiting lists entirely with custom-made organs specifically designed for individual patients based on MRI and CT scans.

One of the most basic challenges in bioprinting is to make printed tissue survive long enough to form blood vessels and nerves and fully integrate with the body it is implanted in, so this research and experiment is incredibly promising.

2. Ovaries.

Overcoming infertility is often a long, painful and costly process. But one groundbreaking experiment offers hope that we may see a new, innovative treatment approach in the future. At Northwestern University's Feinberg School of Medicine in Chicago, mice have been implanted with synthetic printed ovaries.

The ovary was created using a porous gelatin scaffold. Gelatin is a form of collagen, the most abundant protein in mammals. Compared to natural collagen, gelatin is more broken down, so it can be turned into ink that can be used in a 3D printer.

Gelatin is a form of collagen, the most abundant protein in mammals. Compared to natural collagen, gelatin is more broken down, so it can be turned into ink that can be used in a 3D printer.

A female mouse with 3D printed synthetic ovaries conceives and gives birth to healthy offspring. The researchers said the study could lead to fertility treatments for women with cancer.

3. Baking.

Ukrainian architect turned pastry chef Dinara Kasko made a name for herself on Instagram by posting photos of her striking geometric pastry. Dinara uses a 3D printer to create incredible molds that she then casts and sells around the world.

Drawing inspiration from mathematical models, as well as from the objects around her, Dinara Kasko creates unsurpassed masterpieces of confectionery art. They are so good that sometimes they are even a little sorry to eat.

In our blog, we wrote about Dinara and her cakes back in 2017, when she was just starting to experiment with shapes and enter the global market.

For her startup, she used a regular home 3D printer and PLA plastic for 3D printing.

Her success story is definitely noteworthy and a great example of turning a hobby into a start-up.

4. Food.

Natural Machines Foodini 3D printer is designed to create personalized printed meals. It can print pizza, bean burgers, and a range of healthier dishes from edible ingredients.

If in the previous paragraph we described the indirect use of a 3D printer to create baking dishes, now we go directly to printing food on a 3D printer.

The 3D food printer not only allows you to create the most unpredictable shapes on your plate or on your toast, but also transforms the culture of food consumption.

The picture below shows the same breakfast. This is traditional oatmeal. But you must admit that 3D printed oatmeal looks much more appetizing.

Foodini is part of a consortium called #EITOncofood, which focuses on new, innovative food solutions for cancer patients. The project takes into account nutritional needs and sensory changes, promoting the enjoyment of food and preventing malnutrition.

The project takes into account nutritional needs and sensory changes, promoting the enjoyment of food and preventing malnutrition.

As a result of their research, they found that printing products in abstract, unusual forms is highly desirable. When receiving such an unusual presentation, patients get the feeling that someone is preparing a meal especially for them.

5. Buildings.

Talking about the possibilities of 3D printing, one cannot fail to mention the architectural sphere. 3D printers and 3D printing have made life much easier for architects and engineers. It's not a secret for anyone that before bringing an architectural structure to life, architects create its scale model.

An architectural model is a physical representation of a structure created to explore aspects of an architectural design or to communicate design ideas.

Sketch models are created to explore the interaction of volumes, different points of view or concepts in the design process.

They can also be useful when explaining a complex or unusual project to builders or as a discussion point between designers and consultants such as architects, engineers and urban planners.

Presentation models can be used to demonstrate, visualize or sell the final project. The model is also used as display pieces, such as as part of a building, or as part of a museum exhibition, such as scale replicas of historic buildings.

World renowned company Killa Design used 3D printing technology to design and develop the Museum of the Future, Office of the Future and SRG Tower, a 111-story residential skyscraper in Dubai.

Quoting Sean Killa, partner at Killa Design, one sentence explains the importance of 3D printing in construction.

Killa said, “3D printing helps us present and explain ideas during creative brainstorming sessions and greatly speeds up the design process.”

In addition to models that can be printed on simple, low-cost 3D printers, printing of full-fledged residential buildings, bridges and other structures is already being introduced around the world.

In addition to the buildings of the future, we also mentioned in our blog about the "world's first 3D printed settlement" for Latin America, as well as a 3D printed footbridge in Shanghai.

6. Kayak.

Jim Smith of Grass Roots Engineering, who proved that an industrial kit is not needed to create impressive 3D printed objects, created a full-size kayak on a home printer in 42 days. It took about $500 to make a colorful kayak that is fully waterproof and works.

John Smith first took to the water on his printed kayak back in 2014, when most in Ukraine viewed a 3D printer as an expensive toy capable of reproducing only useless souvenirs for the New Year or Easter.

7. Art for the blind.

The Unseen Art project, run by Helsinki-based designer Mark Dillon, uses 3D printing to give blind people the chance to experience classic art that many sighted people take for granted.

“Imagine not knowing what Mona Lisa's smile looks like or Van Gogh's sunflowers.Imagine that you heard people talk about them and knew they existed, but could never imagine them. For millions of blind people, this is a reality,” explains Mark Dillon.

Unseen Art uses 3D imaging and sand-based 3D printing to recreate these works of art at a scale and quality that can be displayed in museums.

Although their approach is unique, the Unseen Art project is not the first to come up with this concept. 3D printing has been used to turn photographs into "tangible memories" and even to help a blind mother "see" her unborn baby's ultrasound.

8. Shape memory materials.

4D printing is certainly less common than 3D printing, but one example shows how it could be used in the future. Researchers at the Livermore National Laboratory Lawrence printed a silicone material that is flexible and can change when exposed to heat.

This effect can be used, for example, to create a truly individual, form-fitting shoe that adapts to the wearer's foot.