3D printed bullet

Bullet best 3D printing models・Cults

Bill Bala

€1

9mm round

Free

6.35mm (.25 cal) heavy2x airgun pellet

€3.50

Perfect Fit Ammo Reloading Tray : All Calibers

€1.86

Militech Rifle Crusher

€40

S&W .44 SPL Hollow Point Bullet Prop for Blade Runner PKD Blaster

€6.50

ROUNDY bullet holder

€1.30

MTS 225

€28.72

No Pew Chamber Flag

Free

Bullet Turn Signal

Free

Lady Bug-Brad Pitt

€3. 25

AMMO BOX - .357 Mag - 50 ROUNDS

€1.25

AMMO BOX - .357 Mag - 50 ROUNDS

€1.25

Glock 43/43X training barrel kit (read description)

€2.67

Glock rmr cover plate with optic sight (READ DESCRIPTION)

€1.52

GrimGuard Miscellaneous

€2.79

Piggy bank "9mm bullet

€2

Blue Magazine - 5.56mm X 45mm - hollow

Free

9mm bullet valve cap tire

€0.60

BULLETS SET, DUMMY BULLETS

€2.38

9x19 brass bullet, dummy bullet

Free

12.

7mm X 99mm (.50 BMG) NATO Bullet

7mm X 99mm (.50 BMG) NATO BulletFree

12.7mm X 108mm Bullet

Free

9mm X 19mm Bullet

Free

FOREGRIP

€1.67 -30% €1.17

HICAPA AND BLACK DRAGON LİPS SPARE PART

€1.60 -30% €1.12

7.5" ammunition

€1.70

7.62mm X 67mm (.300 Winchester Magnum) Bullet

Free

7.62mm X 54mm R Bullet

Free

7.62mm X 51mm NATO Bullet

Free

bullet, pellet for air rifle 4.

5 mm

5 mm€0.75

Key ring Bil Bala Mario Kart / Key ring Bullet Bil

Free

9mm parabellum

Free

Bullet Train White Death Goon Oni Mask

€6.52

7.62mm X 39mm Bullet

Free

5.56mm X 45mm NATO Bullet

Free

Bad Bunny, wolf, bullet train

€6.45

Sig Sauer SIG 516 (Prop gun)

€5.81

Corner cutter tool set

€5

3 in 1 Remington Revolver Set Cap Gun BB 6mm Fully Functional Scale 1:1

€11.99

Remington Revolver 1858 Cap Gun BB 6mm Fully Functional Scale 1:1

€9. 99

99

The Ace Revolver 1858 Cap Gun BB 6mm Fully Functional Scale 1:1

€8.99

LEGO Projectile/Missile/Bullet for Launcher Cannon 57029c01

Free

H. R. Giger

€12.99

Royal Enfield Motorcycles Workshop Garage Biker Parking Warning Sign

€1.58

Ammo Box Key Hanger (Print-in-place)

€1.50

Bullet Keychain .308 Winchester

Free

9x19mm Bullet Keychain

Free

3d Print Bullets - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 844 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Scientists 3D printed bulletproof material

In the scientific world, there are so-called "theoretically possible materials". These are substances that in theory can be created and they do not contradict any laws. At the same time, for one reason or another, it is impossible to create them at this stage. However, exploring the potential of such materials, you can create something new. This is what happened to scientists at Rice University, who 3D printed a very strong structure with a very large braking force.

These are substances that in theory can be created and they do not contradict any laws. At the same time, for one reason or another, it is impossible to create them at this stage. However, exploring the potential of such materials, you can create something new. This is what happened to scientists at Rice University, who 3D printed a very strong structure with a very large braking force.

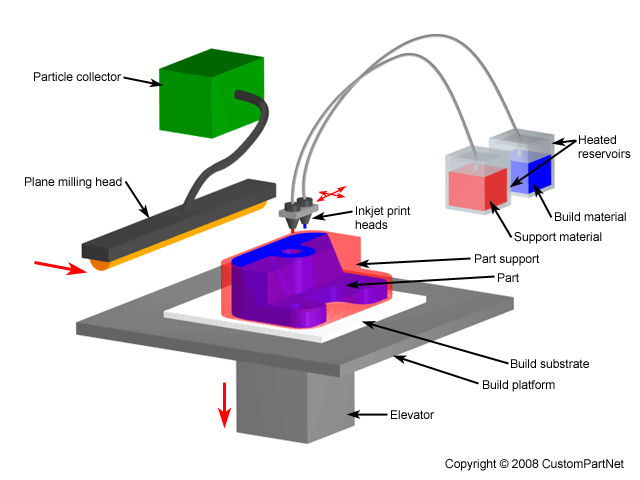

3D printers make it possible to create unique materials

During their tests, the researchers printed a cube of lattice polymers that is littered with holes. It has been tested to be almost as hard as diamond and is capable of stopping bullets with impressive efficiency. We regularly write about the creation of new unique materials on our website. So subscribe to stay up to date.

The starting point for this experimental material is a substance known as tubulane. First invented at 1993, tubulans are complex structures of cross-linked carbon nanotubes that can be calculated to be incredibly strong, but an efficient way to produce them has so far eluded scientists. However, the advent of 3D printing opens up some interesting possibilities.

However, the advent of 3D printing opens up some interesting possibilities.

There are many theoretically possible systems that people cannot recreate, says lead author Seyyed Mohammad Sajjadi. But with the development of 3D printing, we are getting closer to taking advantage of previously predicted mechanical properties and bringing unknown materials to life.

Rice University engineers used tubulane theory to create different types of microscopic blocks using computer simulations, and later to create 3D printed polymer versions to see how they work. The capabilities of the newly created lattice structures were tested in a series of tests.

See also: How big data is helping to discover new properties of common materials . The results of the tests were impressive: the cube with a lattice structure stopped a bullet flying at a speed of 5.8 km per second ten times more effectively than a conventional cube of the same size.

The bullet is stuck in the second layer of this design.

Seyyed Mohammed Sajjadi explained. - And the whole block was covered with cracks.

Comparison of two cubes made from the same material but with different structures

The team also pressed the material under pressure in the lab, and once again it showed impressive strength. The study was published in the journal Small, and a number of experiments on new material were posted online to demonstrate the technology. You can see the results in the video below.

Instead of cracking under load, the tubular blocks tended to collapse on their own and absorb the pressure. The size of the structures is only limited by the capabilities of a 3D printer, and different versions of the material, made from metal, ceramics and polymers, can have different properties, the scientists say. The team is working on further optimization of the project, including for application in the field of construction of facilities, the creation of durable objects and for the aerospace industry.

3D printingScientific materials

To submit a comment, you must or

Can airguns and firearms be printed

Is it possible to make a gun on a 3D printer and is it legal?

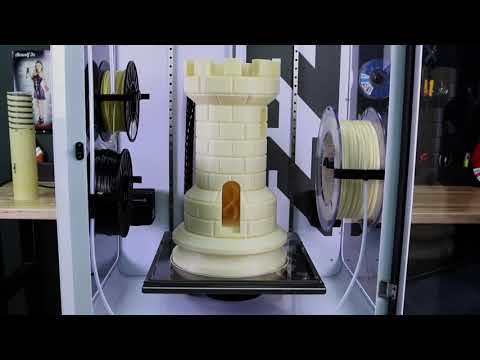

Today's 3D printers offer enormous possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

Can firearms be 3D printed?

As far back as 2013, a young American activist for the free sale and distribution of weapons proved that plastic weapons can be printed on a 3D printer. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Today's 3D printers are capable of printing any CAD model, and these models of firearms have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

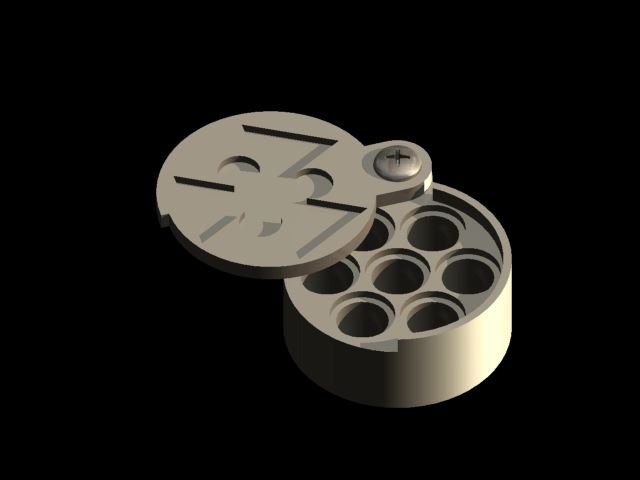

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapon printing technology was made by Defense Distributed, which brought together a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much more difficult to access blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- operating time before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a "serious" criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource. At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always keep in mind that there are significant disadvantages:

- illegal production;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The development potential of 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics. In the future - a significant increase in the resource and the provision of automatic firing.

Significantly increases the reliability of printed pistols and carbines SLS technology using metal powder. Such weapons already differ little from the factory metal models. While it is very expensive, which significantly limits the application.