3D printed missile

Missile best STL files for 3D printer・Cults

TU-143 Reys

Free

Stylized wheeled cannon figurine

€3.86

Ork Bomb

Free

AIM-9 air-to-air missile

€8

Rocket missile

€12

cruise missile AVMT300

€6

Javelin FGM-148 — Close Combat Missile System

€20

Extended Missile and Launcher for Nfeyma's Sphinx Missile Artillery

Free

grad missile box plus ammoa 1/35

€1

5 Feet 3D Printed Rocket Model

€2

FHW: Missile Bunker v1

Free

AIM-9L Sidewinder Missile 3D Printable

€73. 98

Boy Scout Go Kart

Free

Amusement Park Train

€3

throws a bomb / RPG

€3

TX4 Support Turret | Greater Good

€4

walker of war - light support artillery

€7.77

flying armor support - mobile flight vehicle

€7.77

S-300 -air missile system

€20

Angelic Support Squad

Free

Missile vehicle

€16

PANTSIR-S1

€6.30

Archer MLRS

€4.68

Gaslands Weird Weapon Number Two Set

€2. 34

34

Gaslands Weapon Set

€2.34

Gaslands Token Set

€2.34

Gaslands Spoiler Set

€2.34

LEGO Projectile/Missile/Bullet for Launcher Cannon 57029c01

Free

Missile Man (KJU)

Free

Ceti Support Drone Turret

€1.87

72 SCALE AGM-65 LOOK-A-LIKE

Free

Weapon FX

€1.62

Giant rocket missile giant rocket

€3.20

H-MLRS Heavy Mutiple Launch Rocket System

€4.68

SAM Carrier, SAM radar command, Missile Carrier, Rocket Carrier

Free

Multiple Launch Rocket System - MLRS

Free

Fieseler Fi 103 V1 "Free"

Free

missile truck

Free

Gaslands Conversion Kit

€2. 34

34

Troop transport for 6mm

Free

fusée falcon 9 SPACE X avec missile V1

€1

Gaslands Flamethrower Three Set

€2.34

Gaslands Clown Weapon Set

€2.34

MK3 SPACE KNIGHT EXPLOSIVE SODA CAN LAUNCHER

€2.82

AIM-9X Sidewinder Air To Air Missile -Fully 3D Printable

€73.98

American Mecha JES I Tactical Missile Carrier

€3

Missile Toe

€2.81

72 SCALE AGM-84A LOOK-A-LIKE

Free

Raytheon unveils the world's first 3D printed guided missile – By Futurist and Virtual Keynote Speaker Matthew Griffin

WHY THIS MATTERS IN BRIEF

3D printing can be used to make artificial human hearts, but on the other it can also be “weaponised” in increasingly sophisticated ways.

Interested in the Exponential Future? Join our XPotential Community, future proof yourself with courses from our XPotential Academy, connect, watch a keynote, or browse my blog.

3D printing is being used for all kinds of benign purposes today – from 3D printing clothes and sneakers, through to brain tumors, buildings, electric cars and electronics, and entire rockets. It’s also been used to 3D print guns and grenade launchers, explosives and munitions, and even nuclear reactors, on demand. And now, to up the ante, Raytheon, in a world first, have just announced that they’ve 3D printed their first guided missile.

Raytheon has been using and experimenting with the technology for years now, especially in the prototyping process. Now, however, the company says that they have 3D printed just about every component needed for a guided weapon. This includes the 3D printing of the rocket engines, the parts for the guidance and control systems, the fins on the missiles themselves, and more. Furthermore, Jeremy Danforth, an engineer at Raytheon, says that the potential is there for missiles to be 3D printed on demand in the field, as needed – and that is another game changer because it means that the world’s military will no longer necessarily have to stock pile tens of billions of dollars worth of expensive weapons.

Furthermore, Jeremy Danforth, an engineer at Raytheon, says that the potential is there for missiles to be 3D printed on demand in the field, as needed – and that is another game changer because it means that the world’s military will no longer necessarily have to stock pile tens of billions of dollars worth of expensive weapons.

Like many other high-tech firms, Raytheon has been looking more and more toward 3D printing as a means of fabricating products including the 3D printing of electronic circuits. They are currently in the process of developing a means to print out complex circuits as well as tiny microwave components which can be used in the production of the company’s Patriot air and missile defense system — a long-range, high-altitude, all-weather system that that can counter threats from tactical ballistic missiles, cruise missiles, and even aircraft/drones.

A cut away of the new 3D printed missile. Courtesy: Raytheon

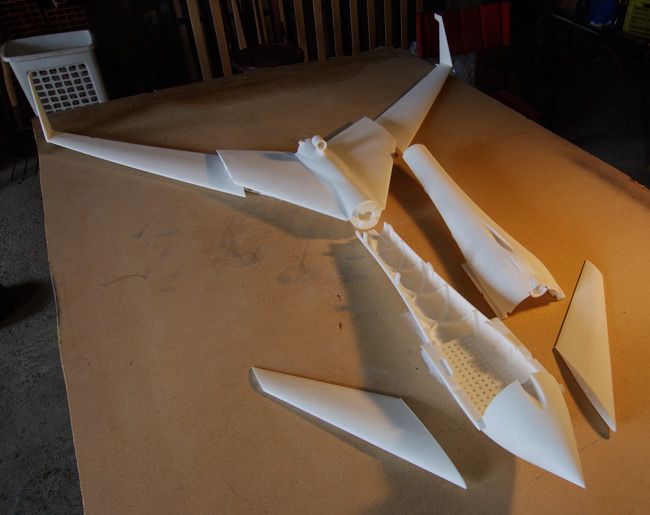

“When we print something, we have fewer piece parts, so your supply chain becomes simpler,” Leah Hull, additive manufacturing manager for Raytheon, said. “Your development cycles are shorter; you’re getting parts much faster. You can get a lot more complex with your design because [you can design] angles you can’t machine into metal.”

“Your development cycles are shorter; you’re getting parts much faster. You can get a lot more complex with your design because [you can design] angles you can’t machine into metal.”

Hull believes that someday the 3D printing of missiles will become a streamlined process that allows for soldiers to print and assemble missiles on the spot. While we are still a ways off from this becoming a reality, due to the fact that a more consistent production method will need to be developed in order to ensure safe, accurately performing weapons, Raytheon already has proven that it’s possible to 3D print these weapons.

“Before a warfighter can print a missile in the field,” Chris McCarroll, Raytheon director for the Raytheon University of Massachusetts Lowell Research Institute, explained, “you need [a] quality, controlled processes to fabricate all the component materials: the metallic strongbacks, and the plastic connectors, the semiconductors for processors, and the energetics and propulsion systems. The hard part is then making the connections between these components, as an example, the integrated control circuit that receives the command to light the fuse. At some relatively near-term point you may have to place chips down and interconnect them with printing. Or, in the future, maybe you’ll just print them.”

The hard part is then making the connections between these components, as an example, the integrated control circuit that receives the command to light the fuse. At some relatively near-term point you may have to place chips down and interconnect them with printing. Or, in the future, maybe you’ll just print them.”

Jeremy Danforth says that Raytheon is currently in the process of 3D printing “demos of many of the seeker components” for their missiles, and other companies have been 3D printing warheads. He says that, so far, his company has printed 80 percent of what would go into an entire working missile.

Of course this brings up the potential that this technology could get in the hands of the wrong people, but that would still require a lot of know-how, at this point in time, in order to develop a precise weapon of the caliber that Raytheon’s missile systems are capable of – however in time, as with happens with all technologies, they’ll eventually get into the wrong hands, probably after someone somewhere open sources the designs for such systems.

In the meantime Raytheon is focused on continuing to move toward 3D printing as a replacement for much of their other subtractive methods of manufacturing. It saves them time, money, and material, while also making what was previously impossible to manufacture, now very possible.

“You can design internal features that might be impossible to machine,” explained Raytheon engineer Travis Mayberry. “We’re trying new designs for thermal improvements and lightweight structures, things we couldn’t achieve with any other manufacturing method.”

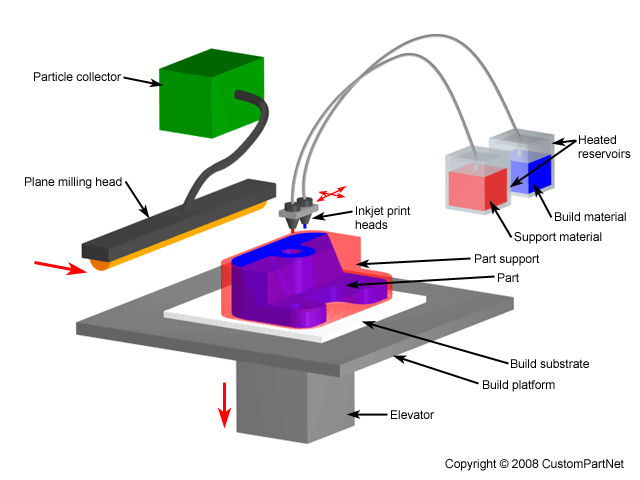

Raytheon is currently using both high-end 3D printers and their own custom modified lower-cost machines to print both functional and non-functional objects and components. Replacing older subtractive methods of manufacturing with these newer additive methods (3D printing) means that instead of using a large amount of material to create components which are almost microscopic, Raytheon is now turning to 3D printing as a means to lay down these tiny components one layer at a time, wasting literally nothing in the process.

“There’s currently a hierarchy in our manufacturing. We make the structures, the housings, the circuit cards, with the right materials, and then we integrate them into a system,” said McCarroll. “What we see in the near future is printing the electronics and printing the structures, but still integrating. Eventually, we want to print everything together. An integrated system,” he added.

Source: Raytheon

Relativity Space tests 3D printed launch vehicle

News

-printed components in the current iteration is already 85% and according to the developers' plans it will reach 95%.

During testing, nine first stage engines ran for twenty seconds ( see video ). The Aeon 1 power plants are 3D printed and run on methane and oxygen. The company uses various 3D printing technologies, including selective laser sintering of metal powders on 3D printers manufactured by the German company EOS and laser-plasma deposition of aluminum alloys in the form of welding wire on an additive system of its own design called Stargate.

Terran launchers will be able to launch up to 1250 kg of payload to low Earth or up to 900 kg into sun-synchronous orbit. The first flight will take place this year, although the exact date is still unknown: the company planned to launch in June, but the schedule has shifted to the right.

The first non-commercial launch will take place from Cape Canaveral, from Launch Complex 16, leased from the US Air Force and previously used to test Titan ICBMs and Pershing short-range ballistic missiles.

In the long term, Relativity Space expects to reduce production times to two months through automation and the widespread use of additive technologies. The cost of a single launch of Terran 1 is estimated at twelve million dollars. By 2024, it is planned to complete work on a heavier Terran R launch vehicle with a payload capacity of up to twenty tons. Read more about production at the facilities of Relativity Space in the material at this link.

Space Relativity Space Terran 1

Follow author

Follow

Don't want

4

Article comments

More interesting articles

22

Subscribe to the author

Subscribe to the author

Don't want to

The crew of the Russian segment of the International Space Station printed a bracket for mounting the camera...

Read more

7

Subscribe to the author

Subscribe

Don't want

In the future, such power plants will allow flying at hypersonic speeds with high fuel. ..

Read more

59

Subscribe to the author

Subscribe

Don't want

The 3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in...

Read more

Read blogs

-printer

Relativity Space co-founder, CEO Tim Ellis / Relativity Space / AFP

Relativity Space is printing a metal space rocket on a 3D printer that it invented specifically for this purpose. Almost all: printed 95%, and the remaining 5% are electronics, seals and some other items. 3D printing has many advantages. She's cheaper. She's faster. It is made on the spot, no need to wait until the parts are brought from another factory. It is stronger: fewer places for fastening parts. “The Shuttle had 2.5 million parts,” says Relativity Space co-founder Tim Ellis. “According to our estimates, SpaceX and Blue Origin have reduced this number to 100,000 per rocket. We have a thousand - less than in your car.

3D printing is used by many space companies, but only for individual components. Skeptics insist that no one knows how the printed rocket will behave during takeoff and in space. So far, the startup's first rocket, Terran 1, has successfully passed all ground tests. The first copy for a real flight is collected slowly and carefully checked. Now it is ready for 85%. A test flight is scheduled for the end of this year. But investors believe in the idea. Last November, Relativity Space completed a series funding round and raised $500 million. After that, according to research company Pitchbook, with a business valuation of $2.3 billion, Relativity Space became the second most valuable venture capital-funded space company in the world. In 1st place, of course, SpaceX (however, Pitchbook does not include Blue Origin in the rating, which is fully funded by Jeff Bezos).

Relativity Space has since raised another round, raising $650 million, based on a company-wide valuation of $4. 2 billion. reusable. After all, competitors do not sleep. Relativity Space is just one of more than a dozen rocket companies created in the last 10 years.

Launch from Mojave

Ellis was born in 1990 in Texas. He is the eldest of three children of an architect father and a dentist mother. As a child, Ellis was fond of Lego and persuaded his parents to buy about 200 sets. He immediately threw away the instructions from them and collected the spaceships he invented himself. Until now, the thumb of his right hand, when at rest, arched back more than his left - Ellis assured the Los Angeles Times that this was the result of long hours when he assembled and disassembled the parts of the designer.

As Ellis got older, he began making amateur films with his friends, mostly action movies, where the characters were often confronted by zombies. He entered the University of Southern California to become a screenwriter. But already in his first year, he became interested in the profession of an aerospace engineer and joined the Rocket Propulsion Lab at the university, which was engaged in the development of rockets.

The University of Southern California is known for its space program. Its alumni include Apollo 11 commander Neil Armstrong, astronaut and former head of NASA Charles Bolden, and Dana Rohrabaker, chairman of the House Space and Aeronautics Subcommittee. There are several laboratories where students create real rockets and satellites. “I was amazed,” Ellis recalled in an interview with the university website about the first time he went to test the rocket engine he designed and built with his comrades in the Mojave Desert. – I always advise students: take part in practical classes. So you will understand why you need to study this or that differential equation, scheme or line of code.

They wanted to be the first student group to launch a rocket into space. But, having carried out dozens of successful launches, they did not even achieve a suborbital flight - this was done by their successors in 2019, having developed more powerful engines.

Why leave Bezos and Musk

At Rocket Propulsion Lab, Ellis met and became friends with classmate Jordan Noon. Then their paths diverged for a while. Noon went to SpaceX, where he worked, among other things, on the Dragon 2 spacecraft. His emergency rescue system uses a 3D printed SuperDraco engine.

Ellis interned for three summers at Bezos' Blue Origin, and after graduation he was accepted full-time. He convinced Bezos to create a metal 3D printing division (by then many competitors, including Boeing, were doing it). He also created it from scratch. The traditional way of producing parts is turning on a lathe, stamping or casting with a mold. In 3D printing, robotic arms deposit layer upon layer of molten metal. A printed rocket has fewer parts, and therefore, places to connect them using welding, rivets, etc., and therefore fewer vulnerabilities. Skeptics object that if defects are found, the entire part has to be discarded and its manufacture must be started anew. But Ellis says that Relativity Space has developed a way to restart the printing process from the right place. “3D printed rockets are the future of rocketry and space exploration,” he told Inc. magazine.

Ellis and Noon often called each other and talked about rockets, although they worked for different space companies. They put together a rough cost structure to understand why rockets are so expensive. “80 to 90% goes to wages,” Noon told Bloomberg. 3D printing can dramatically reduce these costs.

Ellis once mentioned that he was going to start a startup to 3D print entire rockets. He later admitted to Inc. that he tried to get Bezos to print more parts for the rocket, but his suggestions were never fully implemented. Then he decided to take up rocket science himself. Noon liked the idea. Both left in December 2015 to create startup Relativity Space.

“I never saw him give up, give up, or fail to solve a problem, even a really difficult one,” Ellis told the Los Angeles Times of Noon. “I knew our startup was going to have a lot of problems, and he was the right person to make it all work.” And Noon noted: “I am strong in technical and practical aspects, and Ellis is strong in creative thinking and non-standard solutions. ”

For 1 kg of satellite

Relativity Space received its first money from venture investor Mark Cuban. Ellis and Noon made about 20 attempts to guess Cuban's email address, as Cuban preferred texting to other forms of communication. Some of the letters were returned with a note that such an address does not exist, some got to other people. But one of the addresses turned out to be correct, and Cuban read the letter with the headline "Space Is Sexy: 3D Printing of an Entire Rocket." Ellis and Noon asked for $100,000. Cuban, after five minutes of texting them, agreed to invest $500,000 (although they had to wait two months to check if they were fraudsters). “They are smart, resourceful, driven and always learning,” Cuban wrote in an email to The Times. “These are exactly the traits I look for in innovators.”

First, the startup needed to create a huge 3D printer - there were no models on the market suitable for their purposes. A lot of effort was put into this. But now the latest generation printer is able to print a part up to 32 feet (almost 10 m) high, while the height of the Terran 1 rocket is 115 feet (35 m). Ellis and Noon say that even if the rocket venture fails, they can always cash in on the sale of industrial 3D printers.

Terran 1 /Relativity Space

Created with Cuban's money, the first printer could print parts half the size of the last generation. But the working rocket engine printed on it made an impression on investors. First, they invested almost $10 million in the startup, then another $35 million, and in October 2019d. - another $ 140 million. Ellis and Noon planned to stop there. They did not want to dilute their share, and the funds raised should have been enough for the time before the first commercial launch, if they worked without haste. But in November 2020, another $500 million round of funding was raised. As Ellis explained to CNBC, “the development and scaling of the project needs to be accelerated. ” That summer, the startup moved to a new 11,000-square-meter headquarters in Long Beach, California. m, where there will be a site for the production of rockets (the most important thing is that their new printer climbed there in height). Over the past year and a half, the company has more than doubled the number of employees. She now has 400+ people and plans to hire 200 more this year.

Ellis told Inc. that they already have $1 billion in launch contracts from government and commercial entities. Terran 1 can carry up to 1250 kg of payload. This is smaller than SpaceX's Falcon 9, but larger than Rocket Lab's Electron. Relativity Space is targeting a mid-sized satellite niche, much like a car, Ellis said. Its competitors are the Russian Soyuz-2-1V and the European Vega. Or the same Electron, if Terran 1 displays several small satellites at once.

The launch cost of Terran 1 is $12 million, i.e. slightly less than $10,000 per 1 kg. Last year, Roscosmos CEO Dmitry Rogozin announced a more than 30% reduction in the price of launch services for a number of satellites to the level of SpaceX: to $15,000-17,000 per 1 kg instead of $20,000-30,000.

Target - Mars

The competitive advantage of Relativity Space is not only in cost, but also in the fact that it can print a rocket to customer requirements, changing both the diameter of the rocket and the shape of the fairing for the satellite - of course, within the limits allowed by aerodynamics, Forbes explained. And she can do it quickly. Once the technology has been proven in practice, Relativity Space is going to print the rocket in 30 days and take another 30 days for pre-launch tests, Ellis told Scientific American. According to him, even SpaceX takes 12 to 18 months to build a conventional rocket. But Musk claims that his reusable rocket is ready for a new flight 51 days after the previous launch.

So in June, Relativity Space raised another $650 million from investors to accelerate the development of its own reusable Terran R rocket (of course, also almost completely printed on a printer). Its first launch is scheduled for 2024. It will be larger than the first one - 216 feet (66 m) high and designed for 20 tons of payload.

For Ellis and Noon, the main thing is that this project is another step towards interplanetary flights. Musk is looking for a way to get colonists to Mars, and Ellis and Noon are hoping to help them settle on the Red Planet. "If you believe - and I believe - that Elon [Musk] and NASA will send people to Mars, then <...> they will need a whole bunch of things," Ellis told CNBC. “Our printers are reducing the amount of infrastructure that would need to be transported from Earth to Mars in order to establish a colony there,” explained Noon Inc. – Traditionally, you need to send tons of equipment for a factory that will be able to produce factories that, in turn, will produce cars, houses, warehouses ... In our vision of the future, you simply send a 3D printer to Mars that prints everything using Martian raw materials This". In a speech to the students of his alma mater, Ellis added: “We are going to 3D print the first rocket made in Mars <...> I don’t see a future in 50 years in which rockets will not be 3D printed.