Metal 3d printing quote

Metal 3D Printing Service for Custom Parts

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars & Trade Shows

Blog Videos FAQs Educators & Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability & Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Get quality metal 3D-printed prototypes and production parts. Request an online quote today.

GET METAL PARTS

Certifications

ISO 9001:2015 | AS9100D | ITAR Registered

Jump to Section→ Capabilities

→ Available Alloys

→ Compare Material Properties

→ Surface Finishes

→ Post-Processing

→ Why Metal 3D Printing?

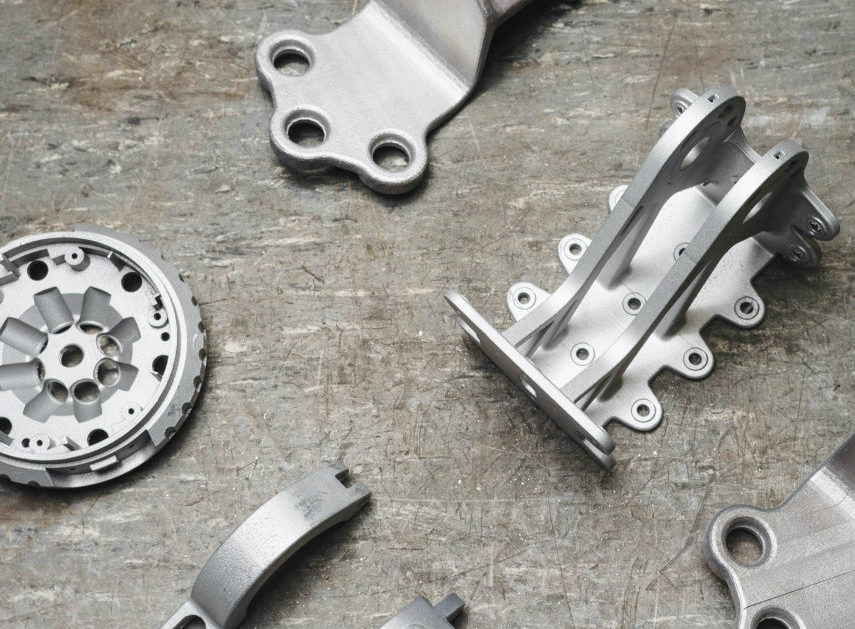

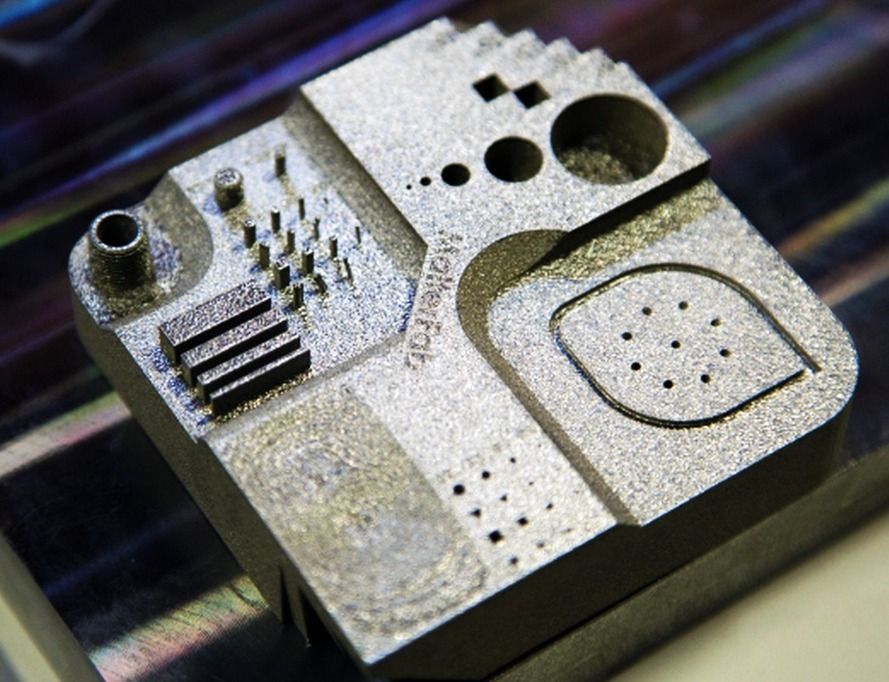

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.

A range of metals produce final parts that can be used for end-use applications.

Metal 3D printing technology is commonly used for:

- Prototyping in production-grade materials

- Complex geometries

- Functional, end-use parts

- Reducing metal components in an assembly

We hope you find this guide helpful. If the file did not download, you can find it here.

Jump start your metal 3D printing with this guide that covers material selection, design, post-processing, and quality inspections.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

Metal 3D Printing Capabilities

Our basic guidelines for metal 3D printing include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Metal 3D Printing Tolerances

For well-designed parts, tolerances of +0.003 in. (0.076mm) plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

Max Dimensions

Layer Thickness

Minimum Feature Size

Tolerances

*At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine

Metal 3D Printing Material Options

Below is our available metal alloys for 3D printing. Various heat treatments are available depending on material.

Various heat treatments are available depending on material.

Stainless Steel (17-4 PH)

Stainless Steel 17-4 PH is a precipitation hardened stainless steel that is known for its hardness and corrosion resistance. If needing a stainless steel option, select 17-4 PH for its significantly higher tensile strength and yield strength, but recognize that it has far less elongation at break than 316L. Final parts built 17-4 PH receive vacuum solution heat treatment as well as H900 aging.

Primary Benefits

- Heat treated for full hardness and strength

- Corrosion resistance

LEARN MORE>

Stainless Steel (316L)

Stainless steel 316L is a workhorse material used for manufacturing acid and corrosion resistant parts. Select 316L when stainless steel flexibility is needed; 316L is a more malleable material compared to 17-4 PH. Final parts built in 316L receive stress relief application.

Primary Benefits

- Acid and corrosion resistance

- High ductility

LEARN MORE>

Aluminum (AlSi10Mg)

Aluminum (AlSi10Mg) is comparable to a 3000 series alloy that is used in casting and die casting processes. It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- Thermal and electrical conductivity

LEARN MORE>

Inconel 718

Inconel is a high strength, corrosion resistant nickel chromium superalloy ideal for parts that will experience extreme temperatures and mechanical loading. Final parts built in Inconel 718 receive stress relief application. Solution and aging per AMS 5663 is also available to increase tensile strength and hardness.

Primary Benefits

- Oxidation and corrosion resistance

- High performance tensile, fatigue, creep, and rupture strength

LEARN MORE>

Cobalt Chrome (Co28Cr6Mo)

Cobalt Chrome (Co28Cr6Mo) is a superalloy is known for its high strength-to-weight ratio.

Primary Benefits

- High performance tensile and creep

- Corrosion resistance

LEARN MORE>

Titanium (Ti6Al4V)

Titanium (Ti6Al4V) is a workhorse alloy. Versus Ti grade 23 annealed, the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength, elongation, and hardness. Final parts built in Ti6Al4V receive vacuum stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- High temperature and corrosion resistance

LEARN MORE>

Compare Material Properties

20 μm = high resolution (HR)

30, 40, and 60 μm = normal resolution (NR)

- US

- Metric

| Materials | Resolution | Condition | Ultimate Tensile Strength (ksi) | Yield Stress (ksi) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 199 | 178 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 198 | 179 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 82 | 56 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 85 | 55 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 39 | 26 | 15 | 42 HRB |

| 30 μm | Stress Relieved | 50 | 33 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 43 | 27 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 182 | 112 | 17 | 39 HRC |

| 30 μm | As Built | 176 | 119 | 14 | 38 HRC | |

| Inconel 718 | 20 μm | Stress Relieved | 143 | 98 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 144 | 91 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 208 | 175 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 139 | 83 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 201 | 174 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 153 | 138 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 144 | 124 | 18 | 33 HRC |

| Materials | Resolution | Condition | Ultimate Tensile Strength (MPa) | Yield Stress (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 1,372 | 1,227 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 1,365 | 1,234 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 565 | 386 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 586 | 379 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 268 | 180 | 15 | 46 HRB |

| 30 μm | Stress Relieved | 345 | 228 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 296 | 186 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 1255 | 772 | 17 | 39 HRC |

| 30 μm | As Built | 1213 | 820 | 14 | 38 HRC | |

| Copper (CuNi2SiCr) | 20 μm | Precipitation Hardened | 496 | 434 | 23 | 87 HRB |

| Inconel 718 | 20 μm | Stress Relieved | 986 | 676 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 993 | 627 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 1434 | 1207 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 958 | 572 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 1386 | 1200 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 1055 | 951 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 993 | 855 | 18 | 33 HRC |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Surface Finish Options

Standard Finish

Expect roughness values of 200 to 400 µin Ra (0.005 to 0.010mm Ra), depending on material and resolution. Support structures are removed and layer lines are visible.

Custom Finish

We offer brushed surfaces in a range of grits and polished mirror finishes. Be sure to indicate if the custom surface finish is for functional or aesthetic purposes so we can best consult you on our custom options.

Post-Processing Capabilities for Metal 3D-Printed Parts

Improve strength, dimensional accuracy, and cosmetic appearance of final metal components with DMLS for production.

Surface Finishing

- 3- and 5-axis milling

- Turning

- Polish (Mirror or Brushed)

- Passivation

- Wire EDM

- Tapping and reaming

Heat Treatments

- Stress relief

- NADCAP heat treatment

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Mechanical Testing

- Tensile

- Rockwell Hardness

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

Why Use Metal 3D Printing?

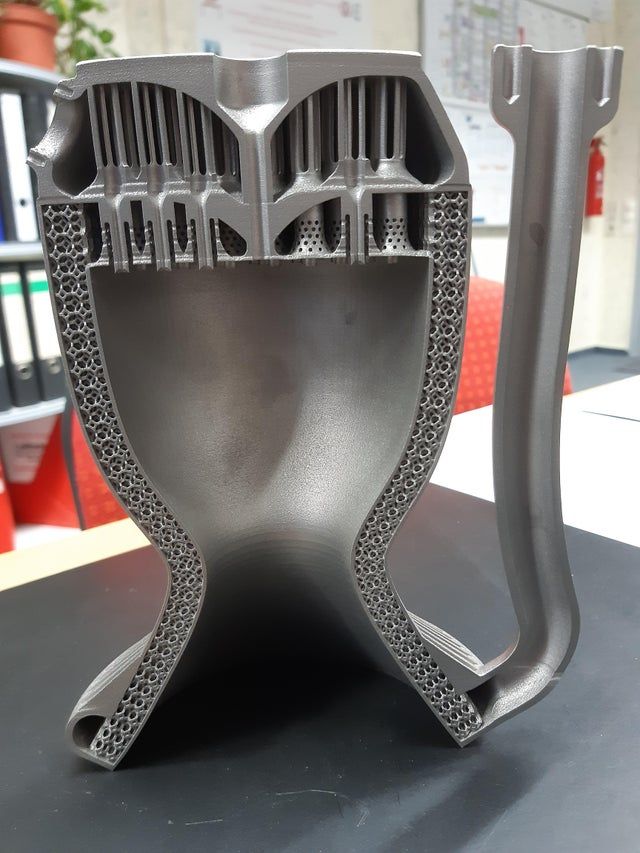

See how metal additive manufacturing technology can be used to reduce components within an assembly, fabricate complex geometries, and ultimately save you time and costs.

Click to enlarge

How Does Metal 3D Printing Work?

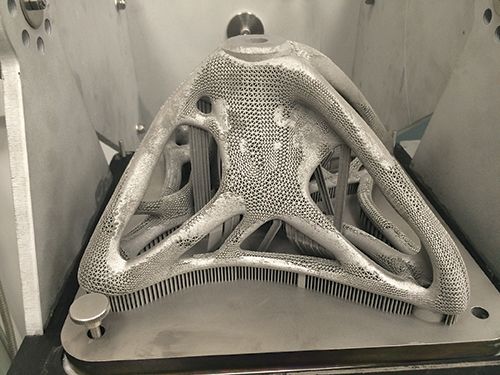

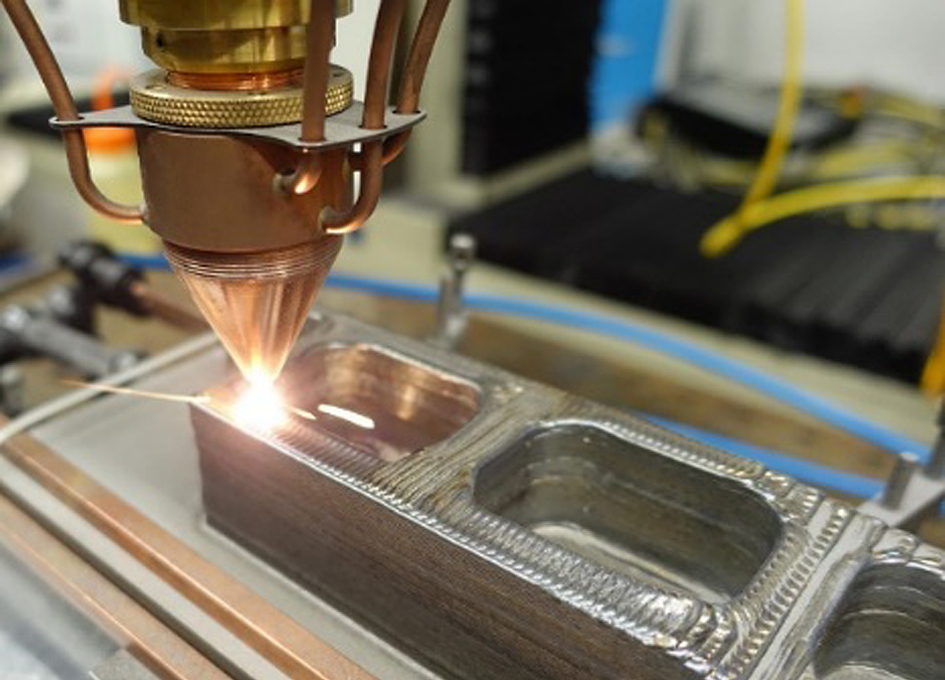

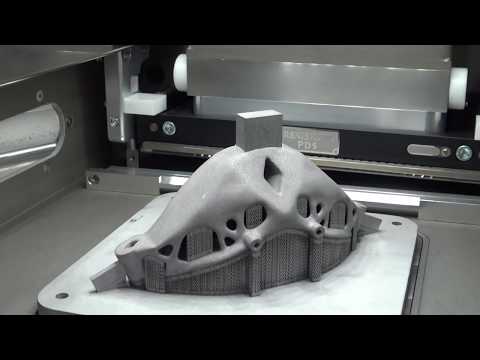

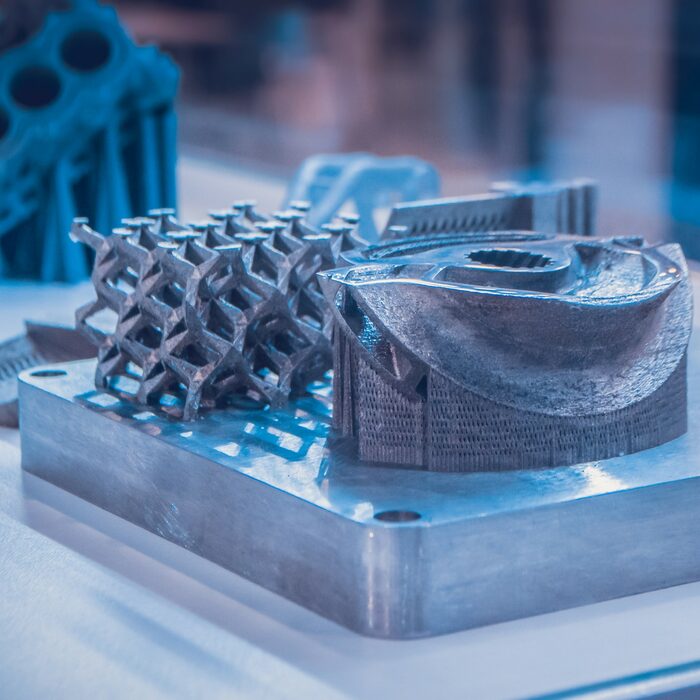

The DMLS machine begins sintering each layer—first the support structures to the base plate, then the part itself—with a laser aimed onto a bed of metallic powder. After a cross-section layer of powder is micro-welded, the build platform shifts down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build finishes, an initial brushing is manually administered to parts to remove a majority of loose powder, followed by the appropriate heat-treat cycle while still fixtured in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any needed bead blasting and deburring. Final DMLS parts are near 100 percent dense.

Large Format Metal 3D Printing

We recently added the GE Additive X Line to our fleet of metal 3D printers to build large Inconel 718 and Aluminum (AlSi10Mg) parts. Have a project that might be a good fit? Contact us and we can discuss your requirements.

Have a project that might be a good fit? Contact us and we can discuss your requirements.

Learn More >

Metal 3D Printing for Production

Improve strength, dimensional accuracy, and cosmetic appearance for end-use metal components with post-processing options like CNC machining and heat treatments.

Learn More >

Resources

Design Tip

Post-Processing for Metal 3D Printing

Learn how to improve dimensional accuracy, surface roughness, and mechanical properties on metal parts with high-requirement applications.

Read Design Tip

White Paper

Combining Part Assemblies with Additive Manufacturing to Reduce Cost and Increase Performance

How to find the right opportunities to consolidate multi-part assemblies into single components with industrial 3D printing

Read White Paper

Blog

Inconel 718: A Workhorse Material for Additive Manufacturing

Inconel 718 is a go-to material for additive manufacturing of metal parts.

Read Blog

Blog

Large Format 3D Printing for Aluminum and Inconel Parts

When you’re printing really large parts in metal, it’s great to have a choice of materials. Aluminum and Inconel 718 both make a lot of sense, but which one is the best for your application?

Read Blog

Instant quotes on 3D-printed parts

Get A QuoteCustom Metal 3D Printing Service

CapabilitiesCustom Online 3D Printing ServiceCustom Metal 3D Printing Service

High-quality Industrial Metal 3D Printing: DMLS and Binder Jetting Service |

Free Shipping on All US Orders - No Minimums

What is Metal 3D Printing?

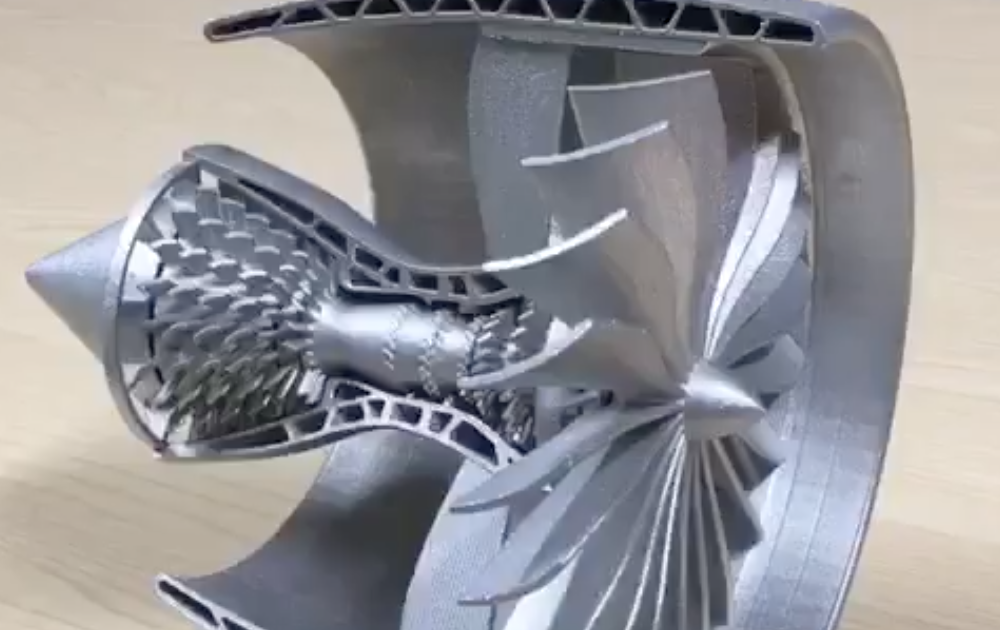

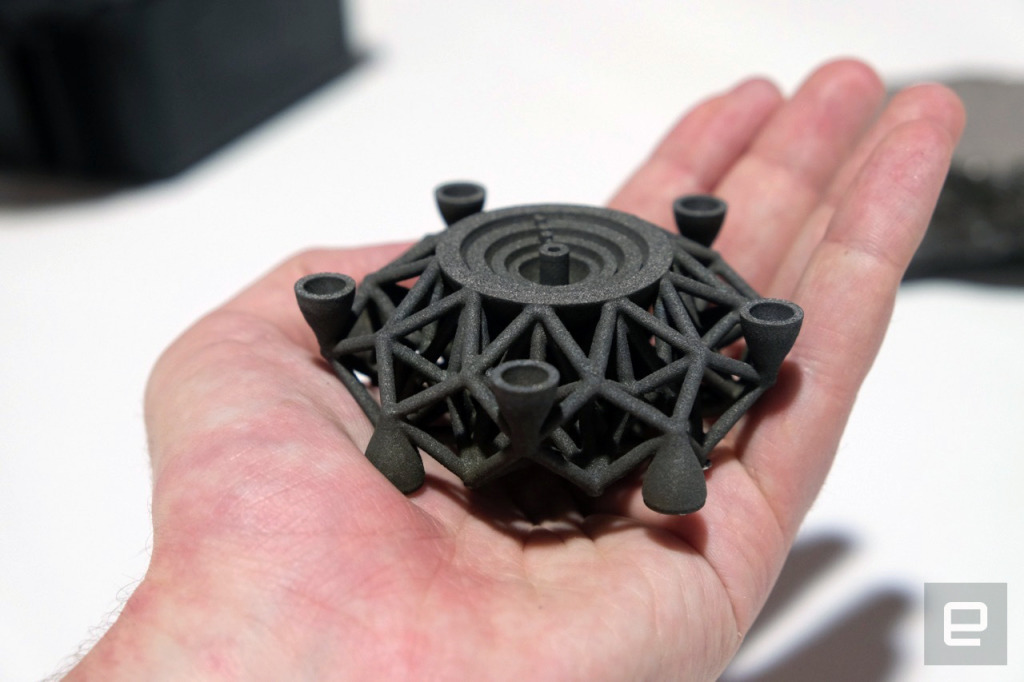

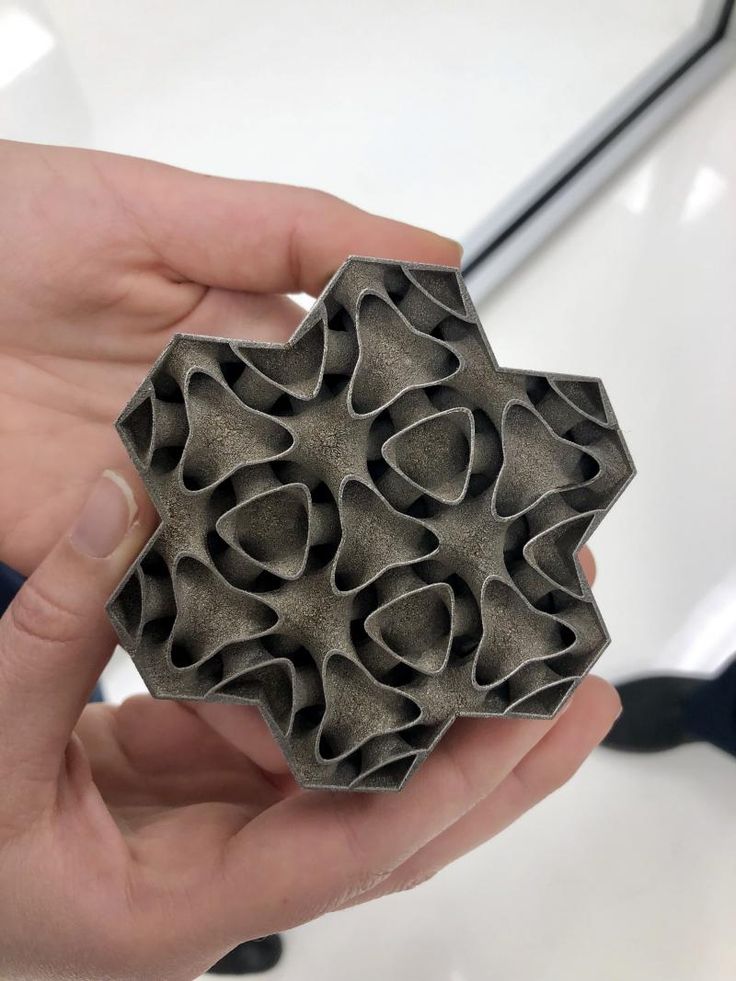

Metal 3D printing, an additive manufacturing process, produces parts by fusing together metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

It can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

Advantages of Metal 3D Printing

Metal 3D printing is advantageous because it can produce high-performance, complex metal parts that are suited for a range of end environments. Metal 3D printed parts are isotropic, meaning they have even, multi-directional strength, and have the superior mechanical properties of metals like aluminum, stainless steel, titanium, Inconel, tool steel, and stainless steel-bronze composites.

3D metal printing can also be used to combine multiple assembly components into one part. This typically results in a stronger structure by reducing the points of failure introduced by threads and inserts.

With metal 3D printing, CAD file information is sent directly to a printer meaning parts are typically cheaper and faster than producing machined metal parts. Machined metal parts have overhead costs like tooling set-up and longer machining time. Most 3D print metal parts can be turned around in less than a week.

Most 3D print metal parts can be turned around in less than a week.

Metal 3D Printing

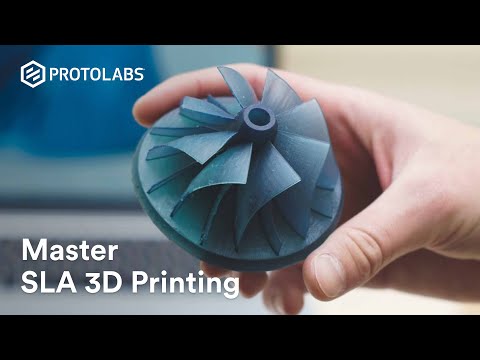

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Upload your CAD files to get an instant quote on parts. Free shipping on all US orders.

Metal Binder Jetting 3D Printing Service

Choosing Between DMLS or Binder Jet Metal

Xometry's 3D metal printing services include direct metal laser sintering (DMLS) and metal binder jetting as options. These processes are suitable for creating metal prototypes, tooling, and production parts on demand. However, each metal 3D printing process uses different metals and fusing methods, resulting in parts with different mechanical properties, prices, and lead times.

Overview of Direct Metal Laser Sintering

DMLS, also known as selective laser melting (SLM), uses a laser to selectively fuse sections of fine metallic powder from the ground up. DMLS is advantageous because it can produce fully dense parts for fluid transfer applications. DMLS can use aluminum AlSi10Mg, stainless steel, maraging steel, tool steel, cobalt chrome, and Inconel. It is more expensive than binder jetting but has superior mechanical properties for high-precision applications. Learn more about DMLS materials, post-processing, tolerances, and applications →

Overview of Binder Jet 3D Printing

Metal binder jet is a multi-step process that first selectively deposits a binding agent onto a metal powder bed, layer by layer, to hold the metal powder in a 3-dimensional shape. This resulting shape is left to cure, then put into a furnace to sinter or be infiltrated with bronze. Binder jet parts with overhanging features are supported by loose powder on all sides of the part, which usually eliminates the need for post-processing.

Binder jetting is a popular metal 3D printing choice because parts are cheap and fast, which allows for higher volume, cost-effective production. Binder jetting metal parts are excellent for functional prototypes or end-use parts with a density of ~95% or greater. Metal binder jetting is also frequently used by artists and hobbyists because of its ability to create complex features at a fraction of the cost of DMLS or machining. Unlike DMLS, binder jet parts are prone to shrinkage so engineers should design parts with design-for-manufacturing principles in mind. This could include scaling their CAD model size by 1-2% and enlarging holes. Learn more about binder jetting materials, post-processing, tolerances, and applications →

Direct Metal Laser Sintering Material Properties

- Aluminum AlSi10Mg

- Stainless Steel 17-4

- Stainless Steel 316/L

New!

Metal Binder Jetting Material Properties

- X1 Metal 420i (420 stainless infiltrated with bronze)

- Six finishes available

Applications of Metal 3D Printing in Various Industries

Metal 3D printing can be used for rapid industrial tooling, where the metal 3D print can be used for parts with complex curvatures and small, thin-walled parts like conformal jigs and fixtures, stamps, dies, and cutting inserts.

For other industries like consumer products, robotics, aerospace, and defense, metal 3D printing can be used for integrated fastening features, end-effectors, and metal lattice structures. Since metal 3D printed parts have excellent durability and strength, they can be used in fully functional late-stage prototypes or end-use parts for any of the above applications.

Read about how this global distributor uses DMLS for custom shading systems, including high-strength coupling brackets and zipper assemblies.

Ready to get started on your custom metal 3D printing quote?

Free shipping on all 3D printing

Why Choose Xometry for 3D Metal Printing Service?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Only the top shops that apply to become Suppliers make it through our qualification process.

Get the Binder Jetting Design Guide

Get the DMLS Design Guide

Metal 3D Printing - The Essential Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

Metal 3D printing at home

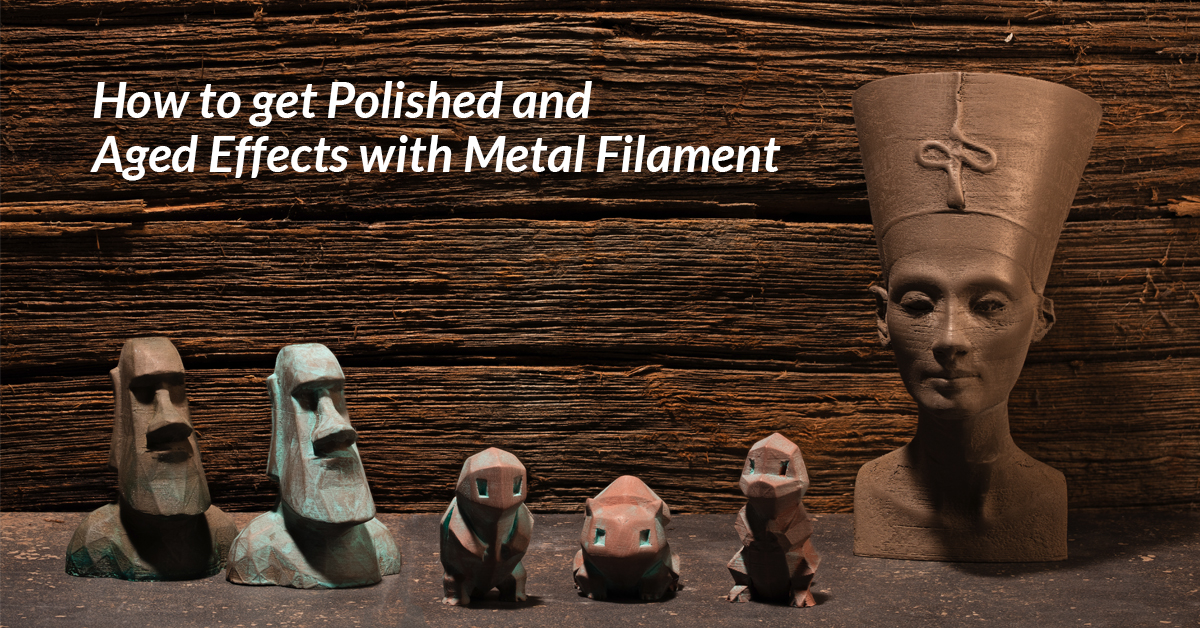

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

Where to start if you want to print metal objects at home ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metallic 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams of

Industrial metal 3D printing

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is best to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045". formed layer)

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

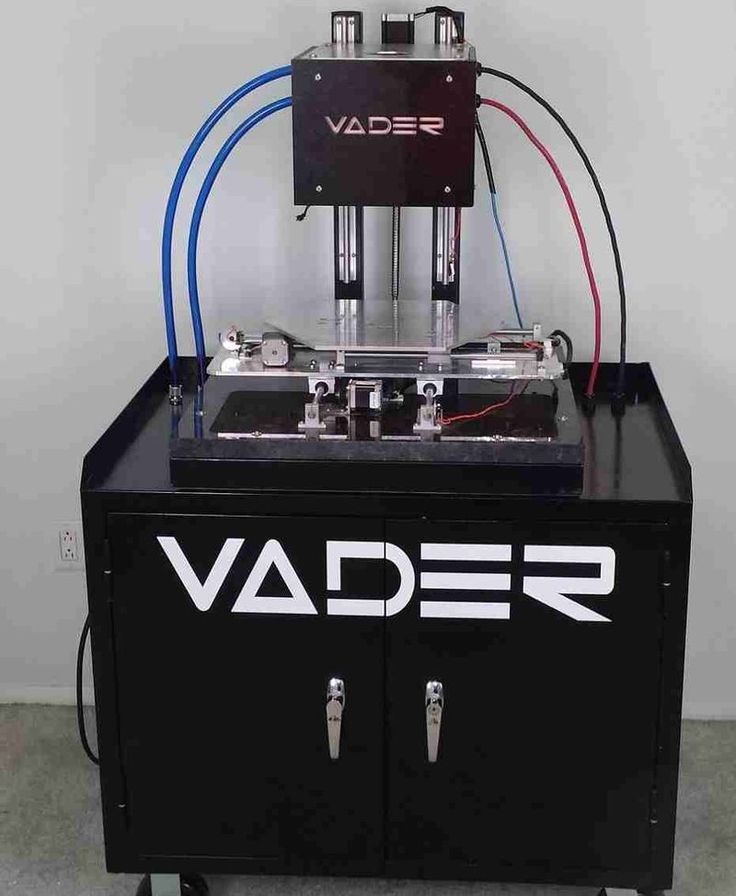

Metal 3D-printing process No. 2:

Binder Jetting (spraying the binder)

under 3DP technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metallic 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation and is a registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With some exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metallic 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

Metals for 3D printing: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial customers to prototyp 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

3D printing metals: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

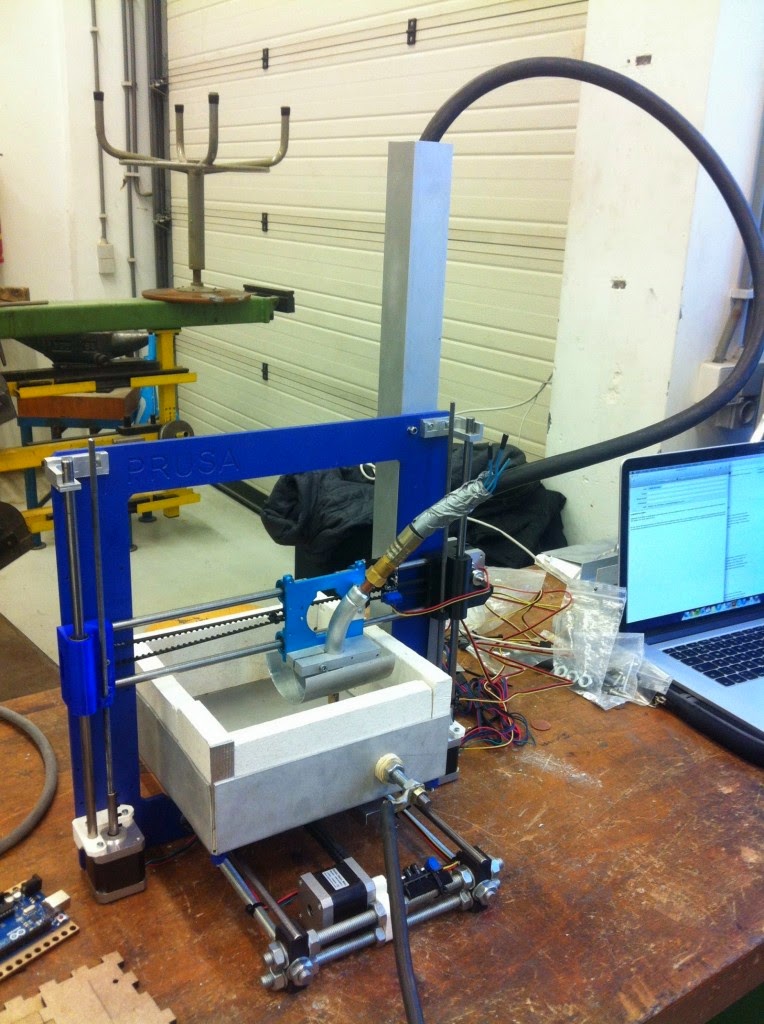

first complete metal 3D printing system for office or design office

In October 2021, Raise3D announced the release of the MetalFuse metal 3D printing system as the best solution for complex metal fabrication in small batches. In February 2022, the Russian distributor of the company, Tsvetnoy Mir, brought the system to Russia and is ready to share detailed information about it.

MetalFuse is a turnkey complex consisting of three pieces of equipment for 3D printing, cleaning and sintering of polymer-metal blanks into solid metal products.

From left to right, the components of the complex are shown:

- Forge 1 desktop 3D printer that prints with metal-filled filament.

- D200-E Station for catalytic resin debinding.

- Oven S200-C for vacuum sintering blanks into all-metal products.

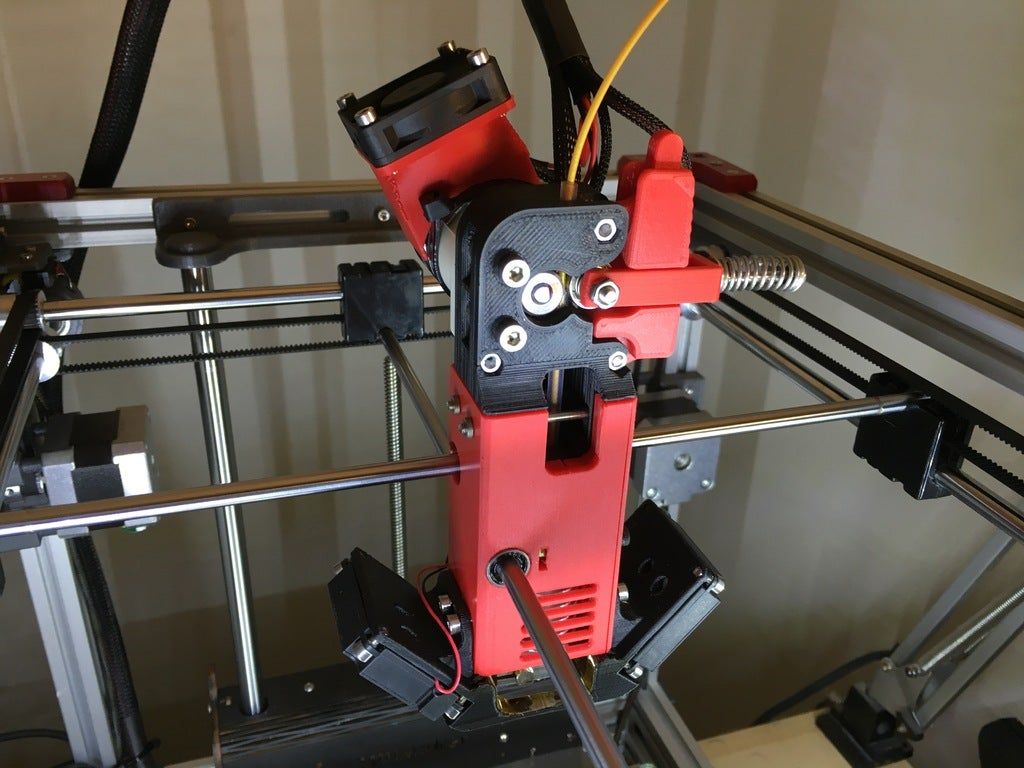

The first stage of fabrication on MetalFuse is the actual printing of the necessary part on the Forge 1 3D printer. The printer is quite easy to use and similar to other FDM/FFF 3D printers. However, it has significant differences. It has two extruders specially designed for metal-filled filament printing, an optimized hot end and extrusion system, automatic first layer control and accurate calibration. Forge 1 prints BASF Ultrafuse 316L and Ultrafuse 17-4 PH metal-filled filament with a diameter of 2.85 mm. The thread consists of particles of pure metal (steel) and a binder polymer.

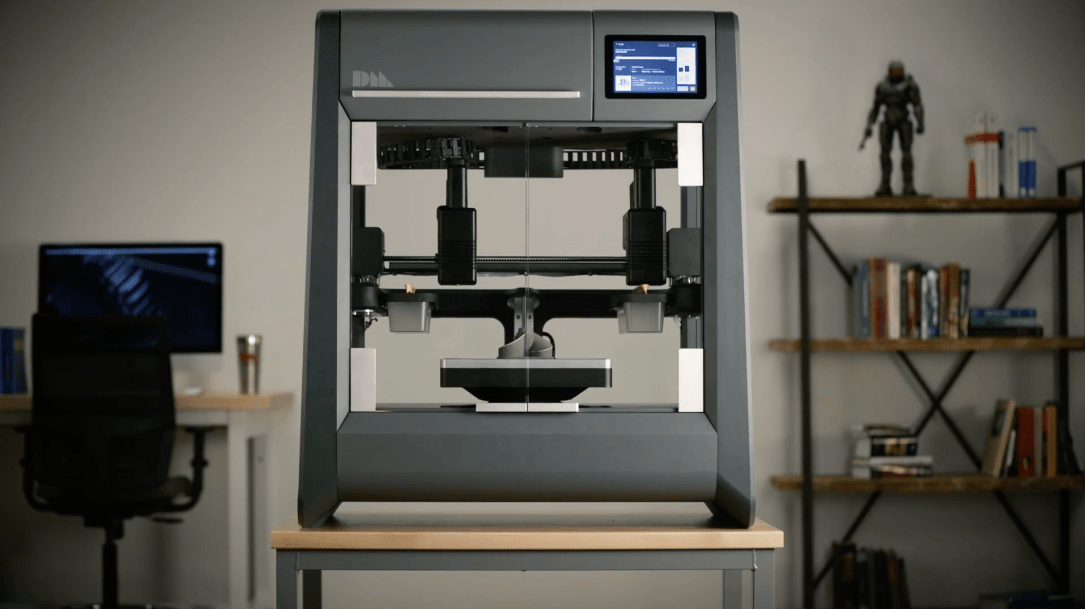

in the photo: 3D printer Forge 1

Characteristics of the 3D printer Forge 1:

Printer size: 620 × 626 × 760 mm

Building area: 300 × 300 × 300 mm

Technology Technology Technology Technology Technologies Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technology Technologies press: FFF

Extruder: 2 extruders with electronic lifting system

XYZ positioning accuracy: 0. 78125, 0.78125, 0.078125 microns

78125, 0.78125, 0.078125 microns

Print head speed: 30-150 mm/s

Max. platform heating temperature: 120 ºC

Supported materials: Ultrafuse 316L, Ultrafuse17-4 PH

Head diameter: 2.85 mm (Direct feed)

Max. extruder temperature: 300℃

Software: ideaMaker metal

Supported file types: STL, OBJ, 3MF, OLTP

OS: Windows/ macOS/ Linux

Pictured: printing process on Forge 1

Next device - station D200-E designed to remove the binder polymer . The D200-E uses a catalytic oxalic acid cleaning process. The process is safe and environmentally friendly. Cleaning with oxalic acid is easier than nitric acid treatment and faster than solvent and thermal treatment. It can even be used for titanium and copper.

When comparing the catalytic cleaning method with the solvent extraction method, one can see the clear advantages of the first: the cleaning cycle takes much less time (4-12 hours versus 12-72), the layer height is not limited, the residual rate of the polymer is lower. The second method leads to swelling and cracking, while there are no such defects after catalytic purification.

The second method leads to swelling and cracking, while there are no such defects after catalytic purification.

The use of a catalyst can reduce time costs by 60% and at the same time obtain products with a density of up to 97% of the level of wrought iron, increasing strength by 52% compared to products obtained by removing the binder with solvents.

D200-E features:

Station size: 806×806×1545 mm

Working load area: 200×200×200 mm

Tray Type: Adjustable Tier Tray (6 Tier)

Type of shielding gas: argon or nitrogen

Maximum volume of catalyst in the storage tank: 2 liters

Maximum gas flow: 5 l/min

Maximum cleaning speed: 1.55 mm/h

Power: 220-230 VAC, 50Hz, single-phase, 16 A/3.5 kW

Exhaust gas treatment: activated carbon adsorption unit

In the photo: the process of installing the model in the D200-E

The third device of the complex - furnace S200-C for vacuum sintering of blanks into all-metal products .

In the photo: the process of loading products into the S200-C sintering oven

S200-C oven features:

Oven size: 1304×1058×1950 mm

Working area: 200×200×200 mm

Sintering time: approx. 20 hours

Tray Type: Adjustable Tier Tray (6 Tier)

Type of shielding gas: argon or nitrogen

Maximum heat load: 12.5 kW

Maximum operating temperature: 1450℃

Power input: 380-400 VAC, 50Hz, three-phase, 40A/27kW

Pre-emergency stop: yes

Overheat protection: 1500℃

The S200-C oven from Raise3D uses vacuum sintering, does not require consumables, its cycle is 2 times shorter than other furnaces (10-24 hours compared to 17-31), it has a low gas consumption.

As already mentioned, Forge 1 prints with metal-filled plastic BASF Ultrafuse 316L and Ultrafuse 17-4 PH . These are innovative materials for the production of metal parts, developed by the largest German chemical concern BASF. The thread consists of 80-90% stainless steel and 10-20% polymer. The polymer contained in these materials acts as a link. Parts printed with Ultrafuse acquire their final properties, including hardness and strength, through a process of catalytic debinding and sintering.

The thread consists of 80-90% stainless steel and 10-20% polymer. The polymer contained in these materials acts as a link. Parts printed with Ultrafuse acquire their final properties, including hardness and strength, through a process of catalytic debinding and sintering.

The picture above shows what an Ultrafuse part looks like at each stage of production. After printing, it consists of metal and plastic and has a greenish tint. The model is still fragile and requires careful handling. Further, after cleaning from the polymer in D-200-E, it acquires a brown tint and consists of particles of pure metal and residual binder. Finally, after sintering at high temperatures, the secondary binder is removed, the metal particles are fused, and we get the part of the metallic color we are used to. The model reaches its final strength and hardness properties. Then it can be polished, processed in other familiar ways, or left as is.

In the photo: from left to right the product after printing on the printer, the product after cleaning and sintering, the product after polishing.

Photo: models made with MetalFuse

The table below compares the properties of MIM and MetalFuse parts:

| 0634 | Vickers hardness HV | ≤ 200 | 121 |

From the software for this system Raise3D introduced a new slicer - ideaMaker Metal . It has built-in templates for metal printing, it takes into account catalytic cleaning and sintering, supports mixed-type models (printing with multiple nozzles, with multiple templates, different layer thicknesses). ideaMaker is ultra-fast 64-bit and works with large models. Also, owners of the Forge 1 printer can use the web platform RaiseCloud , with which you can remotely control the print command. It monitors and reports on all printing processes.

The whole complex is environmentally friendly. The equipment is equipped with filters that remove harmful substances and reduce environmental pollution.

Pictured: filters installed in MetlaFuse

MetalFuse enables easy, fast, safe, economical and environmentally friendly in-house production of high quality metal parts in small batches.