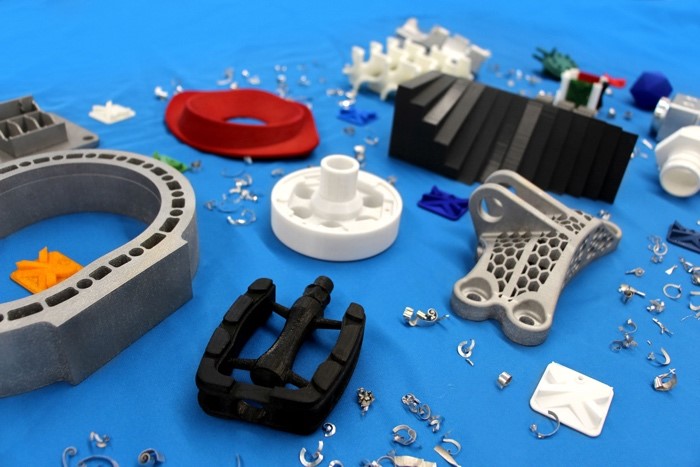

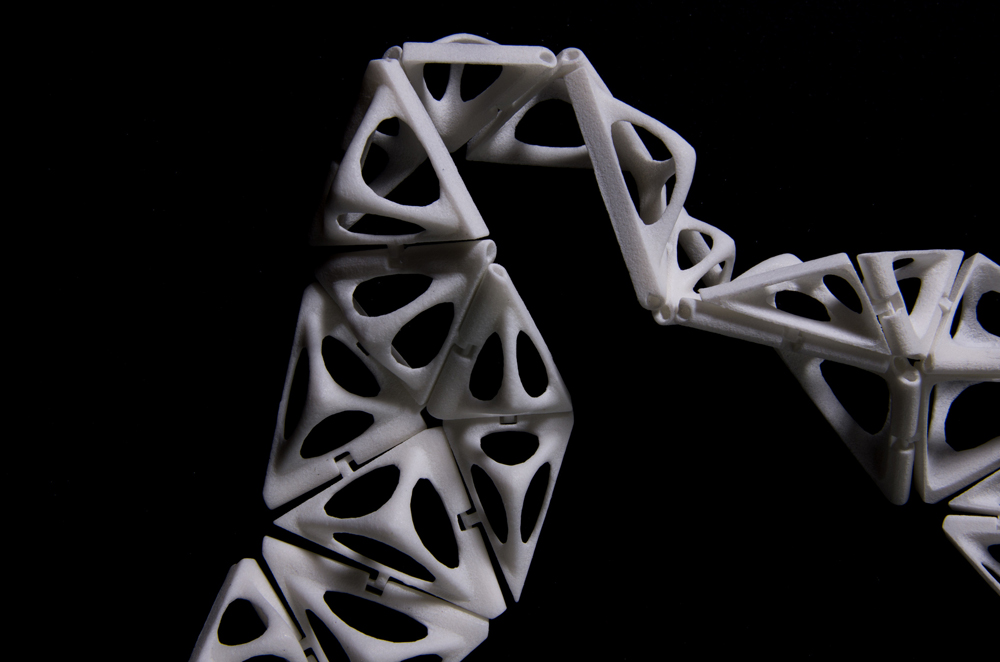

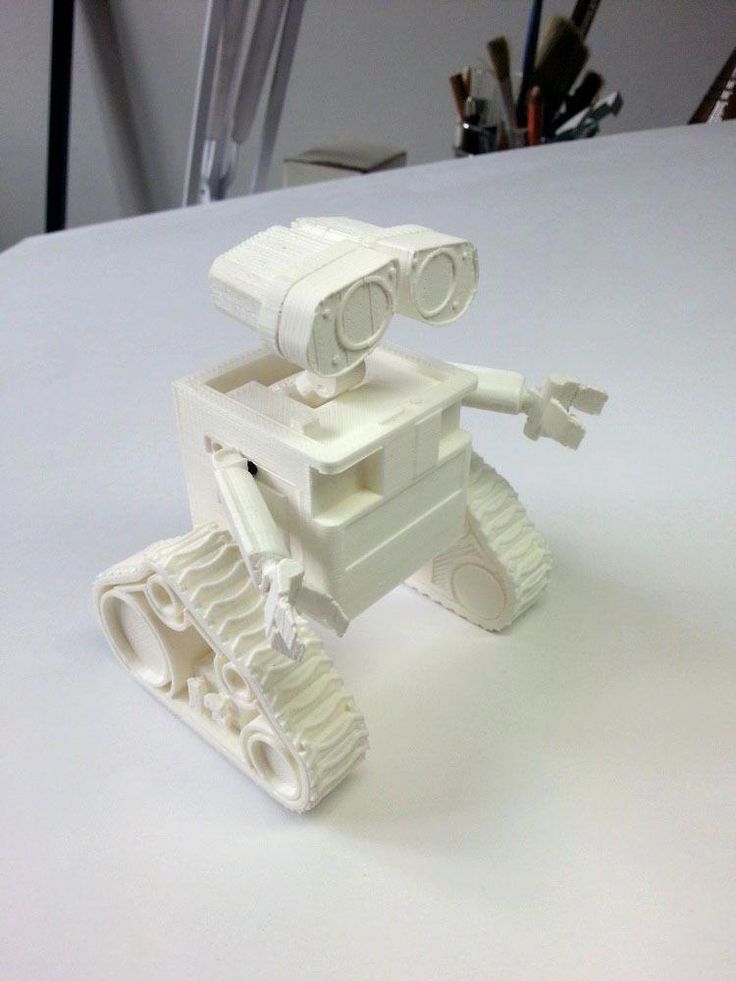

Complex 3d print

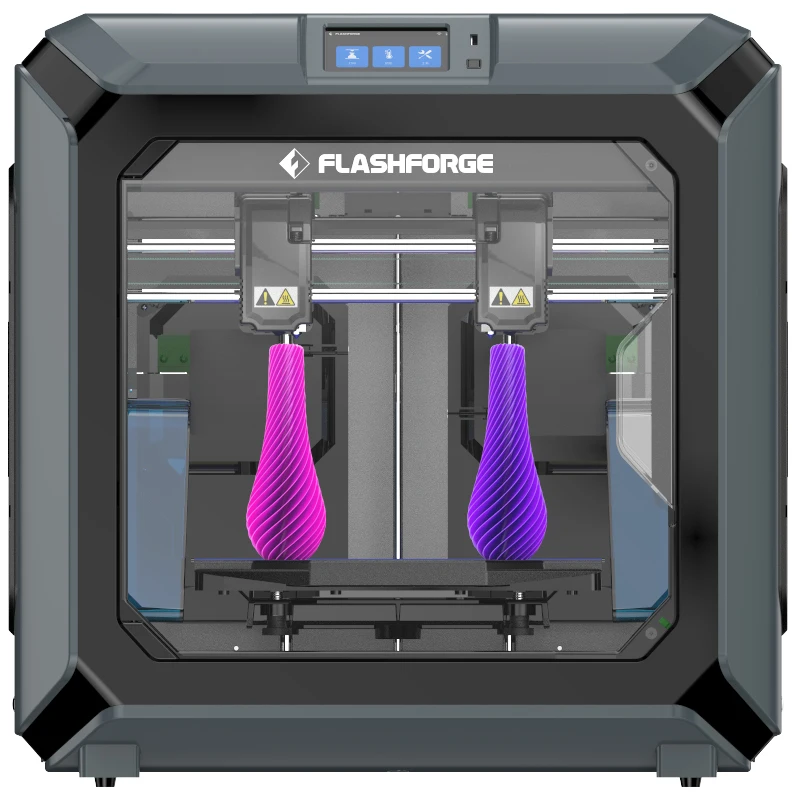

7 Complex Designs Achieved With 3D Printing

24 July 2019

By taking advantage of the design flexibility afforded by 3D printing, engineers can bring even the most challenging ideas to life.

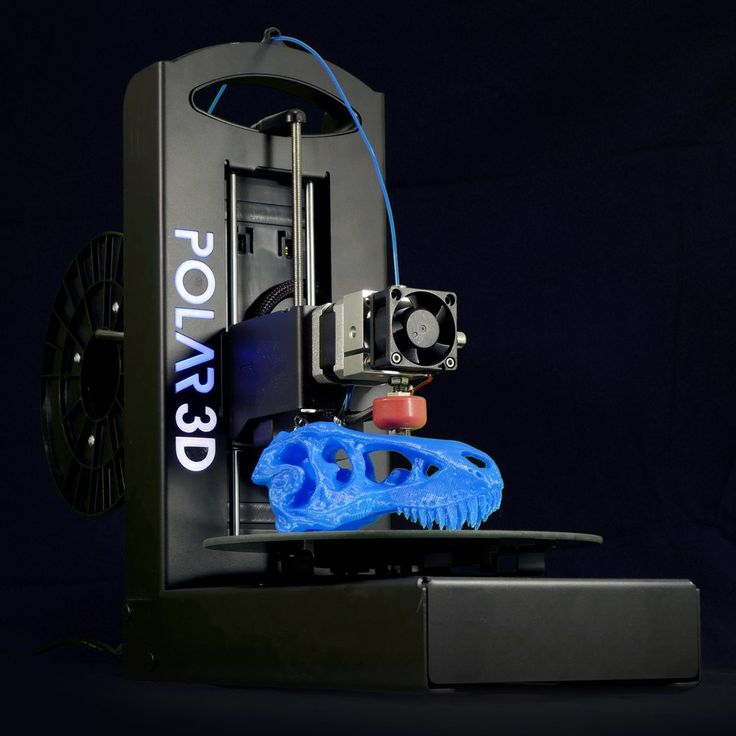

3D printing is a technology that can produce shapes and features unachievable with conventional manufacturing methods. To showcase the power of the technology, we explore 7 examples of impressive designs that were achieved only with 3D printing.

Application: Automotive

Benefits: Lightweighting, greater strength

French automaker, Bugatti, leveraged the design freedom of 3D printing for its latest Chiron supercar, producing what is said to be the world’s most powerful brake caliper — 3D printed in titanium.

While the brake caliper functions just like a normal caliper, the combination of 3D printing and titanium means that it is much stronger and roughly 40% lighter than the aluminium part currently in use.

Using a metal 3D printing process called Selective Laser Melting, the Bugatti team was able to experiment with a variety of geometries and wall thicknesses unattainable with traditional manufacturing techniques.

The result: an intricately-shaped brake caliper with wall thicknesses between 1 mm and 4 mm.

The end of 2018 saw Bugatti successfully testing the caliper at high loads, and the company is now preparing to take the component into production.

However, Bugatti is not the only company revolutionising the design of brake calipers. British automotive technology company, Carbon Performance, is also using 3D printing to ‘generate sustainable designs’ for 3D-printed automotive parts, including calipers.

To achieve this, Carbon Performance is using its new, AI-powered software platform. The platform helps to design components that can, for example, improve the fuel efficiency of a car.

The platform helps to design components that can, for example, improve the fuel efficiency of a car.

Using its design software and 3D printing, Carbon Performance is able to produce brake calipers that are more robust and environmentally friendly thanks, in part, to their lighter weight. Being able to create lightweight metal parts with 3D printing means less material is required and the production process incurs less material waste than with subtractive manufacturing.

Creating lightweight designs is one of the key benefits of 3D printing. As the trend towards electric and more efficient vehicles continues to grow, we’ll see more automakers exploring 3D printing in their efforts to create better-performing, lightweight car components.

Application: Automotive

Benefit: Significant weight savings

General Motors (GM) has recently created a 3D-printed version of an existing seat bracket using generative design tools.

Generative design software uses advanced algorithms to automatically generate multiple design variants based on specific parameters such as weight, material, size, strength and manufacturing methods. The subsequent designs feature complex, organic shapes which often can only be brought to life with the help of 3D printing.

This was exactly the case with GM’s seat bracket. Using Autodesk’s Fusion 360 generative design software, 150 design iterations were produced. GM then selected the design that offered the best trade-off between weight, performance and manufacturability.

The final design barely resembles the original bracket. 3D printed in metal, the new seat bracket is 40% lighter and 20% stronger than the original. It has also been manufactured as a one component, unlike the original part which has to be assembled from 8 separate parts.

The ability of 3D printing to create complex parts more quickly and with more flexibility makes the technology a natural choice for producing the redesigned component. The benefit shown in this example is part consolidation — the ability to print multiple parts as a one component, and thereby reduce assembly times and costs.

The benefit shown in this example is part consolidation — the ability to print multiple parts as a one component, and thereby reduce assembly times and costs.

Although GM’s seat bracket remains a proof-of-concept, the company sees huge potential in combining 3D printing and generative design software. Both technologies will certainly a key role in the future of vehicle manufacturing by facilitating faster design and product development, as well as the production of complex automotive parts.

Application: Medical

Benefit: Material optimisation

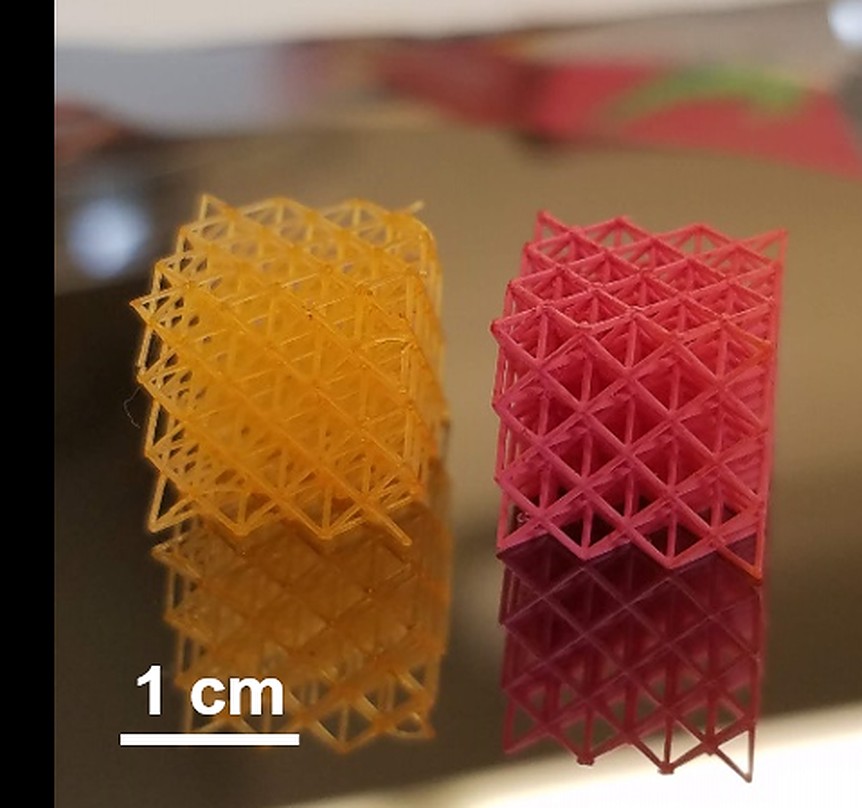

Topology optimisation is a generative design technique that enables designers to apply advanced algorithms to optimise the geometry of a part. Using the technology, the material distribution of a part can be optimised to remove any unnecessary material from the design.

One company leveraging topology optimisation is IT company, Altair, which combined 3D printing with topology optimisation to create an improved hip stem implant.

3D printing offers a range of benefits for hip implants, including the ability to customise an implant for the specific loads it is required to bear. Topology optimisation software facilitates this by allowing engineers to factor in the various load cases a hip implant might see during its life cycle.

By inputting parameters such as load cases and design constraints, the software optimises the material distribution within a defined material volume. This process results in a design showing where material can be removed to create the best-performing hip implant.

The Altair team used this approach to determine the solid and semi-dense areas of the implant before filling the semi-dense regions with lattice structures to make the implant lighter.

Compared to an intact femur or a femur with an off-the-shelf implant, the team found that the new design helps increase an endurance limit to about 10 million cycles. This means that the hip implant could endure jogging from Los Angeles to New York and back — twice.

The new design also helps to reduce stress shielding by 57%. Stress shielding refers to the reduction in bone density caused by placing a titanium implant inside a patient, and can ultimately lead to fractures and dislocation. For this reason, designing an implant as close to the original bone tissue as possible is key to reducing stress shielding and eliminating these unwanted effects.

Using 3D printing as a manufacturing technology is the only way to bring such designs to life. Not only does it make complex shapes like lattices possible, but it also can produce them more cost-effectively than conventional methods.

As of today, topologically-optimised 3D-printed implants are only starting to make their way into real-life use cases. It will take some time for healthcare regulators to develop new standardisation methods for these new implant designs. However, looking in the future, it’s clear that 3D printing will become a key technology for creating better-fitting, longer-lasting and higher-performing hip implants for a specific patient.

Application: Construction

Benefit: Innovative design

Unveiled at Dutch Design Week in 2018, MX3D’s stainless steel 3D-printed pedestrian bridge is one of the most exciting design projects in the 3D printing space.

By fitting welding machines onto robotic arms, the MX3D team was able to 3D print a bridge 12 metres long, achieving a unique look and shape. For instance, the design of the bridge is organic and fabric-like, with lots of curves and intricate features. The surface of the bridge has been left unsmoothed, leaving the layers of deposited steel visible that give the bridge a rough, unusual finish.

Interestingly, 3D printing wasn’t the only cutting-edge technology used for this project. To ensure both the safety and optimised performance of the bridge, the 3D-printed steel structure is equipped with a network of sensors to monitor the state of the bridge, recording the number of people walking across it and taking measurements of things like weight dispersion and air quality.

The whole project took nearly four years to execute and now the completed bridge is set to be installed in Amsterdam later this year.

Application: Energy

Benefit: Enhanced performance

GE Research is developing an ultra-efficient, low-emission heat exchanger for power generation equipment like gas turbines. Surprisingly, to achieve this, the team came up with an innovative design inspired by human lungs.

Human lungs are one of the most efficient and compact heat exchangers. The organ performs its heat-exchange function with a network of capillaries, which split the flow of blood into small streams. This network warms up the cooler air that we inhale, while also regulating the body’s temperature.

GE’s heat exchanger works in a similar way, but at much higher temperatures and pressures. The component features a trifurcating network of channels, which takes hot air coming out of a gas turbine. This network is intertwined with another network of channels filled with colder working fluid running in the opposite direction. The hot air and cool fluid do not mix with each other, but their close proximity allows the hot air to be cooled down, improving the thermal efficiency of a gas turbine.

This network is intertwined with another network of channels filled with colder working fluid running in the opposite direction. The hot air and cool fluid do not mix with each other, but their close proximity allows the hot air to be cooled down, improving the thermal efficiency of a gas turbine.

Crucially, 3D printing was the only technology capable of producing such a complex design.

Once the development process is complete, GE will be able to 3D print a heat exchanger that can operate cost-effectively at 250°C (450°F) degrees higher than today’s heat exchangers. With a significantly increased operating temperature, the 3D-printed component represents a new generation of high-performance heat exchangers.

Application: Automotive

Benefit: Weight savings

In 2018, BMW released its iconic i8 Roadster car, featuring an award-winning 3D-printed metal roof bracket.

The roof bracket, a small component that helps to fold and unfold the top of the car, required a new design to maximise the performance of the roof-folding mechanism. To achieve this goal, engineers at BMW turned to topology optimisation software.

By using this software, engineers were able to input parameters like the weight, the size of the component and the load it will take. The software then generated a design that optimised the material distribution of the part.

The design achieved by the engineering team was impossible to cast. The team found that the only way to make this design possible was through metal 3D printing.

Thanks to Selective Laser Melting (SLM) technology, engineers created a metal roof bracket that is 10 times stiffer and 44% lighter than the conventional alternative.

The part, which is now produced in small series, showcases a huge lightweight potential for vehicle designs when combined with the power of topology optimisation techniques.

Application: Energy

Benefit: Complex internal features

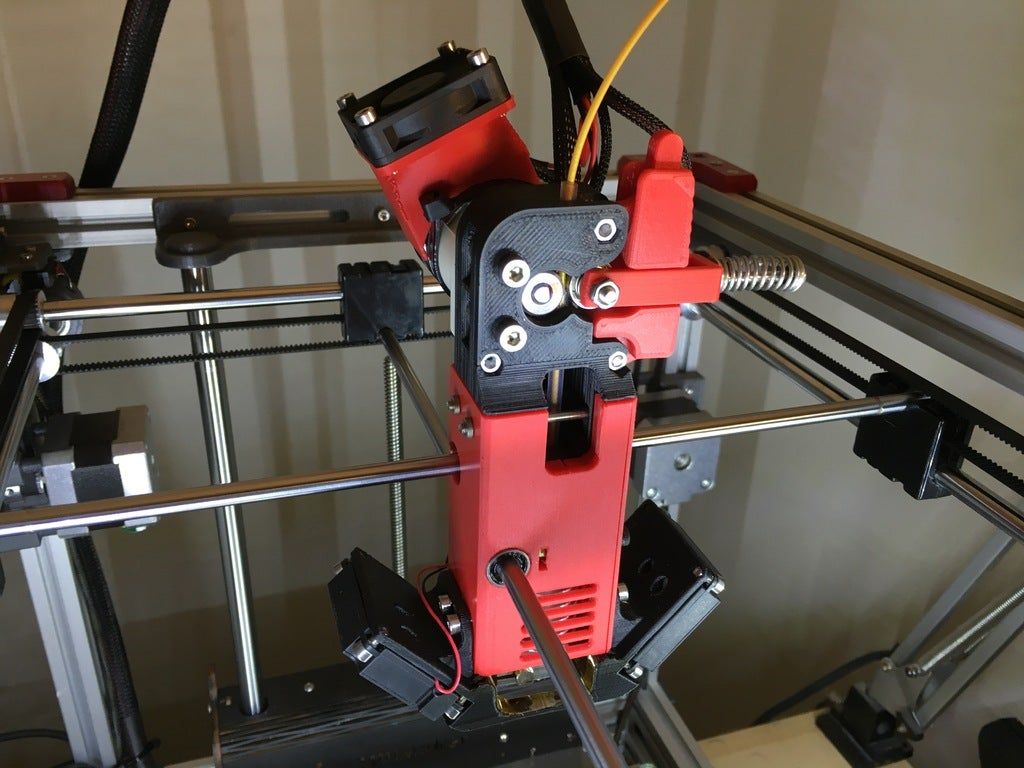

For a few years, engineering company, KW Micro Power, has been working on a design of a microturbine generator but faced challenges with taking this design to production. A key challenge lay in the production of one of the device’s components.

The component in question is a titanium disc featuring complex internal channels that help to manage exhaust gases more efficiently. When 3D-printed in metal, this component requires support structures to prevent drooping or warping during the printing process.

However, the complexity of internal features of the component made it impossible to remove the supports following production.

To overcome this challenge, the company collaborated with VELO3D, a 3D printer manufacturer that has developed its proprietary metal 3D printing technology, Intelligent Fusion. This technology enables VELO3D’s Sapphire 3D printer to print parts with minimal support structures and reduced residual stresses, which are often the cause of warping.

This technology enables VELO3D’s Sapphire 3D printer to print parts with minimal support structures and reduced residual stresses, which are often the cause of warping.

This is achieved due to a patented non-contact recoater, which is used to deliver a fresh layer of powder to be melted and fused with a laser. In powder-based metal 3D printing, when powder is laid on top of another layer, a recoater could dislodge the part if it’s not fixed to a build plate.

In VELO3D’s Sapphire System, the re-coating blade is not in contact with the powder bed. Once the powder is deposited, a scraper blade and vacuum process are applied to the top of the powder to make sure that it is absolutely level.

With a recoater not contacting the previous layer of powder, a part doesn’t need any support anchor it to a metal build plate. In the meantime, simulation and a closed-loop control system powering the printer enable complex internal features to be printed without supports.

To leverage the full power of the Sapphire 3D printer, VELO3D’s team helped KW Micro Power to further improve the design of the generator component. The finished part is 37% lighter than the original design and is said to perform better thanks to reduced stresses. But more importantly, the design which was previously deemed non manufacturable, was made possible thanks to a new generation of metal 3D printing technologies.

3D printing offers tremendous design flexibility, enabling designers and engineers to experiment with new forms and features, including topologically-optimised shapes, lattice structures and lightweight designs.

With so many opportunities unlocked by 3D printing, the technology allows manufacturers to produce innovative products with optimised an customised designs, which would be impossible with traditional manufacturing.

However, to unlock this potential it’s crucial to follow design principles unique to additive manufacturing. Only when armed with understanding about both possibilities and limitations of 3D printing, can companies use the technology to fulfill their most creative ideas.

Only when armed with understanding about both possibilities and limitations of 3D printing, can companies use the technology to fulfill their most creative ideas.

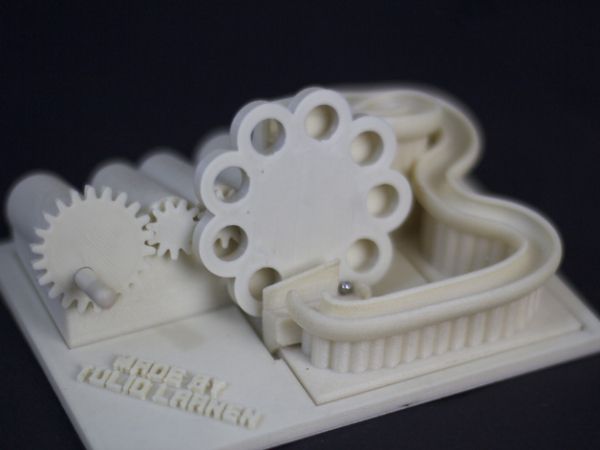

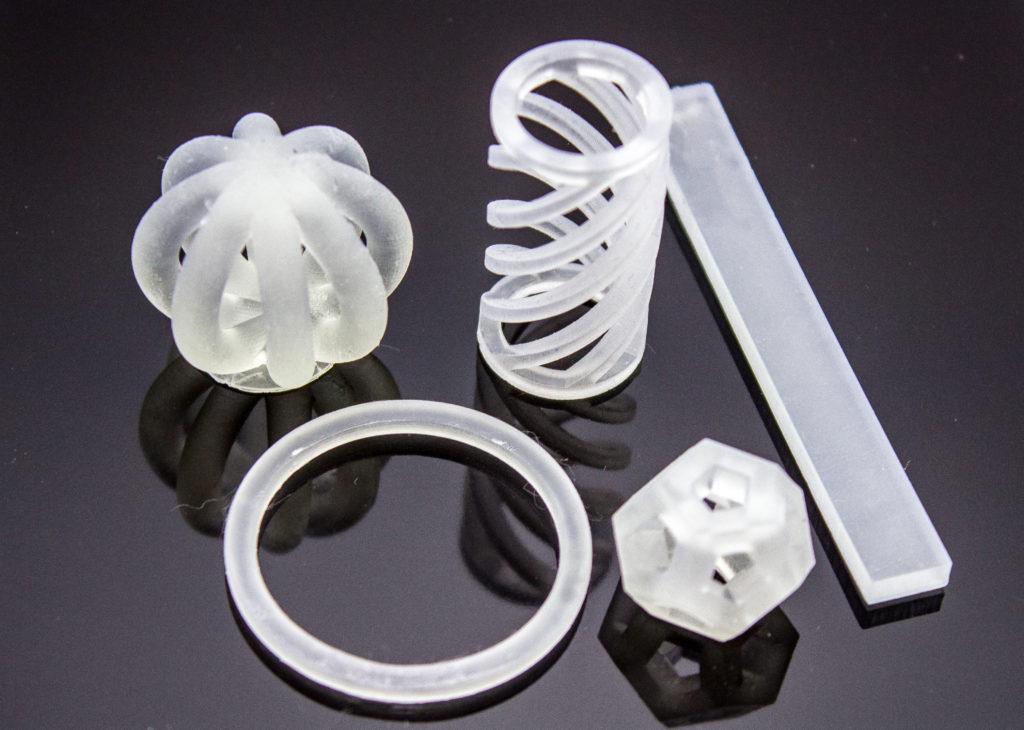

Complex geometries are possible with 3D printing

Industrial 3D printing means that the manufacturing process no longer determines the complexity of a component, but rather the product’s desired functionality and design. Complex geometries, such as three-dimensional structures with undercuts or cavities, are typically impossible to manufacture with conventional technologies like milling, turning or casting, or are only possible at disproportionately high costs.

Now, any shape that can be constructed in a 3D CAD program can be produced with additive manufacturing technology. There are almost no restrictions – even when manufacturing hollow structures. This works because the material is only added where it needs to go. Additive manufacturing gives developers maximum geometric design freedom, and complexity only plays a minor role in the production costs. The costs can often even be significantly reduced due to lower material consumption.

The costs can often even be significantly reduced due to lower material consumption.

EOS technology was a logical choice for us because we manufacture small series productions with complex shapes. We acquired the high-temperature system EOS P 800 at an early stage and were able to rapidly make progress in the development cycle of OsteoFab™ technology. EOS accompanied us throughout the entire process.

Scott DeFelice | President and CEO | OPM

Multiple structures in the same part

Thanks to 3D printing, the hip cup implant was significantly optimized. The artificial hip cup consists of solid sections that provide stability and porous elements on the surface. The differently sized pores help to anchor the implant firmly: Large pores are helpful for pressure transmission - smaller pores support the initial fixation. In this way, the complex surface structure simplifies osseointegration, or the growth between the living bone tissue and the surface of the implant.

Flexible structural adjustment possible

The full implant is manufactured in a single production step by the 3D printer and would be extremely difficult to make with conventional manufacturing methods. At the same time, the high flexibility of additive manufacturing enables the structure, surface roughness and pore size to be determined individually for each patient. Together with the Additive Minds Team at EOS and the established 3D metal printing system EOS M 290, Permedica succeeded in realizing a completely new product.

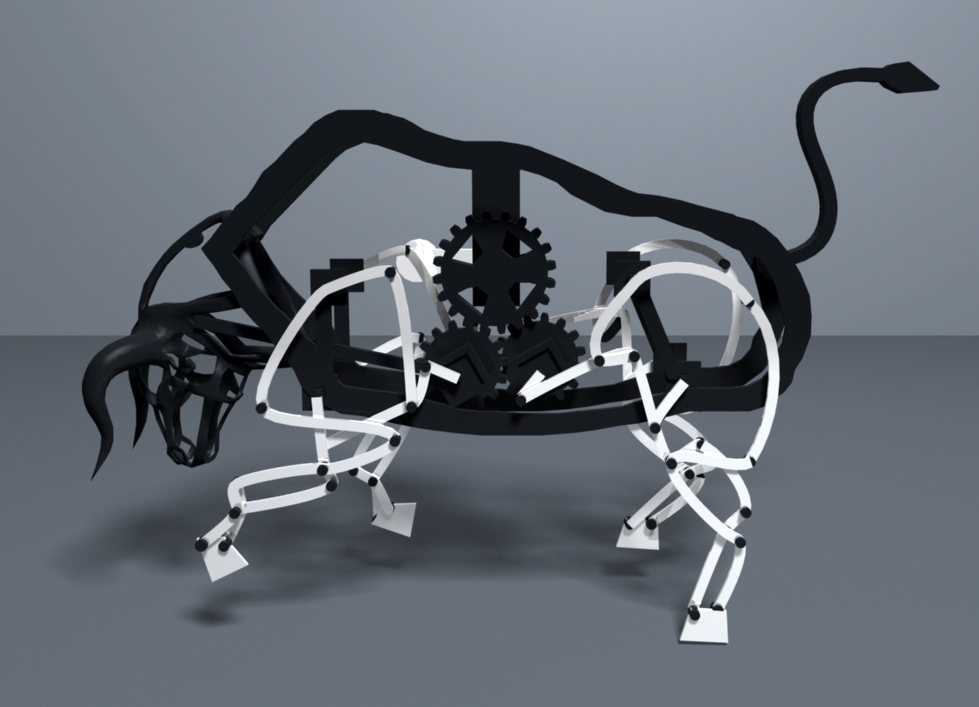

Evolutionary processes have created biological structures in great abundance and diversity: today, we know of more than 1 million species of animals and around 500,000 species of plants. These systems often have shapes and structures that are optimally adapted to their environment and are created with minimal use of materials and energy. The interdisciplinary research field of bionics aims to exploit this massive potential by adapting natural blueprints to technical applications.

This is where conventional manufacturing processes encounter their limits. By contrast, additive manufacturing achieves maximum design freedom. With our technology, you have the opportunity to build, discard, re-engineer and continuously optimize your prototypes during development. The tool-free production saves time and money - while offering enormous opportunities. As a result, there have been disruptive innovations in medicine, ergonomics and aviation, for example, especially in connection with aerodynamics.

Success Story Festo

Bionic Gripper

The additively manufactured Festo gripper DHDG is a bionic gripping device that can grip objects gently and flexibly but powerfully, and set them down safely. Its shape and function were inspired by nature. With the FORMIGA P 100 by EOS, the automation specialists Festo were able to produce the parts they needed quickly and cost-efficiently in small series production.

The results are impressive.

Thanks to the superior design freedom, the production can be flexibly guided by the design. By integration functionality into the part during production, Festo succeeded in significantly reducing the number of individual parts and the assembly cost. The resulting gripper is lightweight and durable. And even the price is right: Festo saved time and money with tool-free production.

By integration functionality into the part during production, Festo succeeded in significantly reducing the number of individual parts and the assembly cost. The resulting gripper is lightweight and durable. And even the price is right: Festo saved time and money with tool-free production.

Thinking in new ways is worth it: you can’t drill around corners, but you can easily print holes. The geometric freedom of design granted by industrial 3D printing opens new possibilities for designers. This requires know-how and a new approach to design.

We're here to help you take full advantage of additive manufacturing.

There are many upsides to 3D printing. EOS technology allows highly complex parts featuring functional integration and maximum product customization to be developed and manufactured quickly.

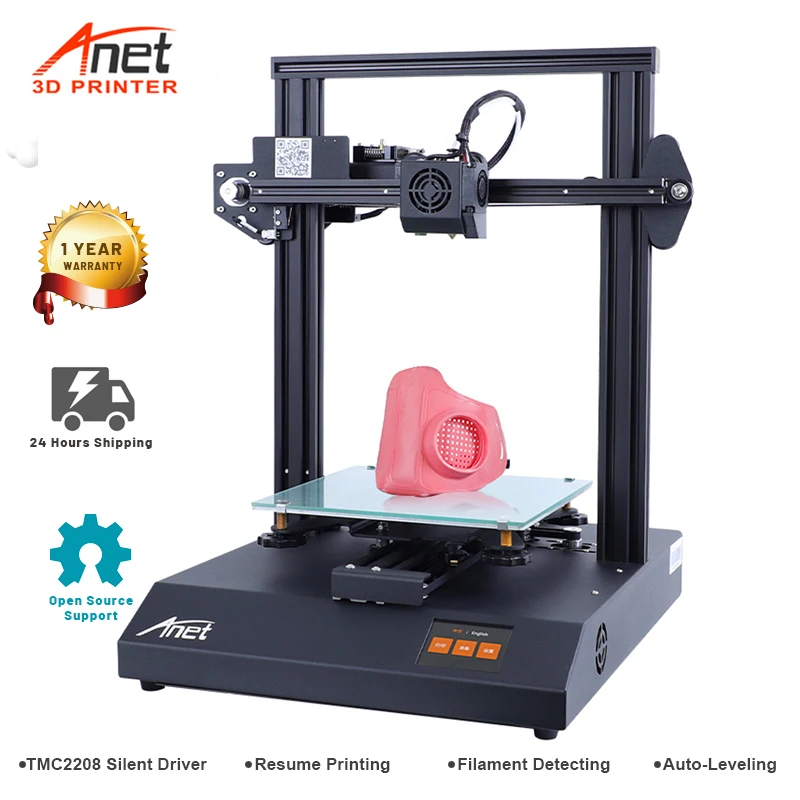

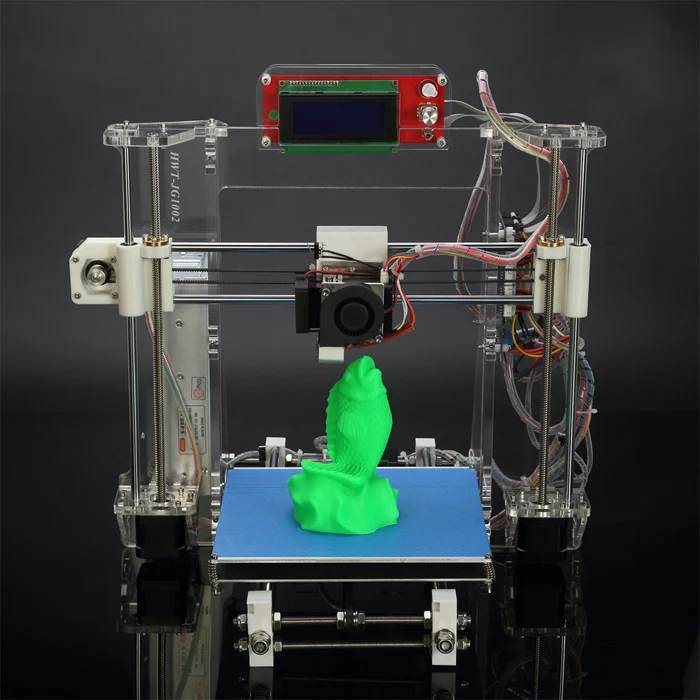

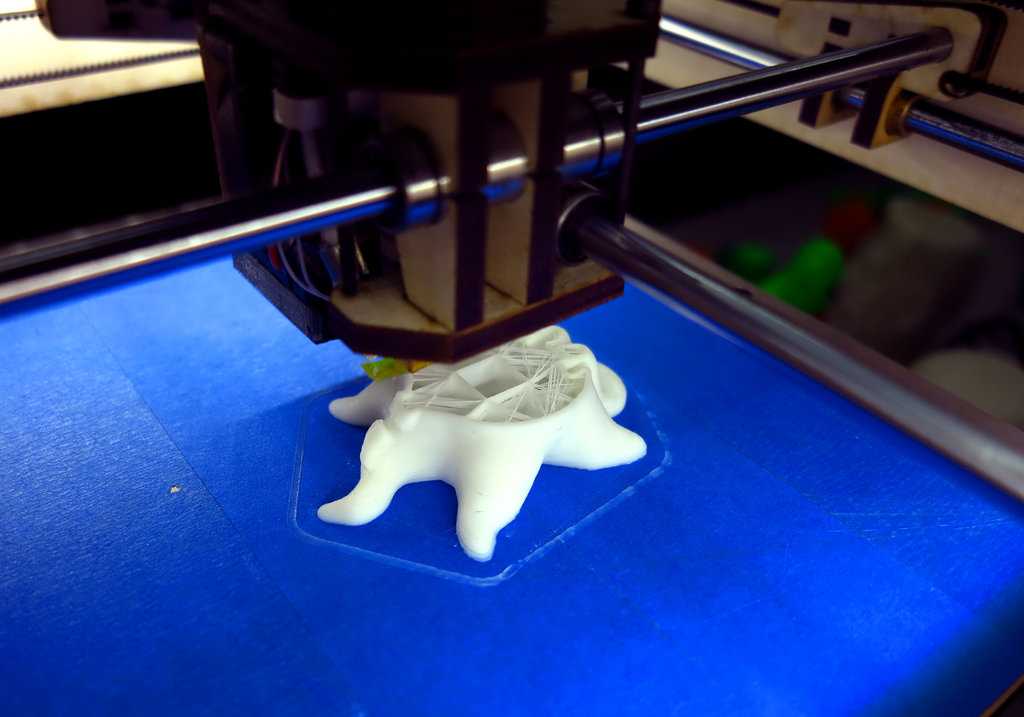

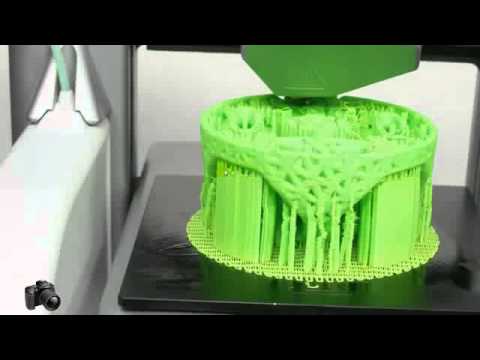

3D printing of complex ABS and PLA plastic parts with a lot of support / Sudo Null IT News Often there are situations when it is necessary to print a geometrically complex part on a 3D printer with a single extruder, for example, Hercules Strong, which, no matter how you twist it, cannot be printed without supports.

The option - to cut into pieces and glue in the context of this post will not be considered.

The option - to cut into pieces and glue in the context of this post will not be considered. One of our customers had difficulty preparing, printing and post-processing a part (see below). Above in the picture is the front side, the inner side (second picture) is printed with supports.

The complexity of 3D printing lies in the fact that it is almost impossible to remove supports from the rough side of the part, they are either removed with pieces of the part, or the first layers of the part sag over the supports and are not printed evenly.

Loading the part into Slic3r.

We arrange the part in such a way that the upper part of the panel is in good quality. We also care about the quality of the side outer walls. The inside of the panel is a draft, so we build supports in the inside.

Go to Print settings → Support materials and enable support.

It turns out that the whole part rests on supports, and it will be very difficult to remove them. The photo shows the result of our customer's print. It was he who gave us this interesting task. Print time 4.5 hours.

The photo shows the result of our customer's print. It was he who gave us this interesting task. Print time 4.5 hours.

It was possible to separate the supports with great difficulty with pliers. The inner surface is in very poor quality, it is impossible to process it.

Standard settings did not cope with the task in this case. Therefore, we will configure Slic3r manually.

In order for the supports to be easily removed and the inside of the panel to be of acceptable quality, you need to change some parameters:

Go to the Support Material section

1. Reduce the extrusion width on the supports. The support mesh will be printed with thin filaments similar to cobwebs. They are easy to remove by hand and at the same time their strength is enough to hold the first layers of the part.

Change the settings in Advanced → Extrusion width → Support material–0.35 mm.

2. In order for the threads of the first layer of the part that will be printed over the support not to sag, we need the support mesh to be dense, i. e. the step must be made at least 1 mm. This setting is called Pattern Spacing. This is the distance in millimeters between the support threads. If we specify a small distance there, it will take a very long time to print the supports. Therefore, we will do it this way: we will print the support in 3 mm increments, and print the last 2 support layers with the 1 mm increment we need, these layers will support the first layers of the part and the 1 mm increment will prevent the threads from sagging. This will save a lot of time. Change settings:

e. the step must be made at least 1 mm. This setting is called Pattern Spacing. This is the distance in millimeters between the support threads. If we specify a small distance there, it will take a very long time to print the supports. Therefore, we will do it this way: we will print the support in 3 mm increments, and print the last 2 support layers with the 1 mm increment we need, these layers will support the first layers of the part and the 1 mm increment will prevent the threads from sagging. This will save a lot of time. Change settings:

Pattern spacing –3 mm - print support in 3 mm increments

Interface layers –2, Interface pattern spacing–1 mm – set the two layers between the part and the support to print lines in 1 mm increments.

3. Contact Z distance set to 0. The first layer of the part will print close to the support, so it will be smoother. And reducing the width of the extrusion will allow us to easily remove the support from the surface of the part.

4. Go to the Speed section. In order for the support threads not to break due to reduced extrusion, we reduce the speed for Support material to 40 mm/s and Interface support material to 30 mm/s.

The speed for solid layers, the ones that will be printed on top of the support, is reduced to 50%. We do this so that the layers on the support lie more evenly and the thread does not break.

Speed → Solid Infill – 50%

Save the G-code and print.

Look at the result.

Esun PLA Green and Esun Cream ABS. Printed on Hercules Strong nozzle 0.5 mm, layer height 0.2 mm. Print time 6.5 hours PLA and almost 7 hours ABS.

The main part of the support was easily separated by hand, we removed the threads of the two layers between the part and the support with a clerical knife and a thin flat screwdriver. The surfaces above the supports turned out to be smooth, without breaks and sagging threads.

This method allows you to print complex parts with lots of support. The print time will increase depending on the Slic3r settings, which in turn will depend on the complexity of the part, the type of plastic and the desired result. In our case, the print time increased by almost 40%.

The print time will increase depending on the Slic3r settings, which in turn will depend on the complexity of the part, the type of plastic and the desired result. In our case, the print time increased by almost 40%.

As experiments have shown, it is possible to reduce the width of the extrusion on the support up to 40% of the nozzle diameter, the smaller this value, the easier it will be to separate the support, but the more likely it is that the extrusion will fail and the first layers of the part will lie unevenly or not stay on the support . Also, do not forget about the physical properties of the plastic: for ABS plastic, we reduced the support print speed to 30 mm / s, otherwise the extrusion failed. PLA plastic stretches well, unlike ABS, and was printed at a speed of 40mm / s without interruption. Therefore, all the listed parameters may vary in each specific case.

3D printer catalog

Don't forget to subscribe to our YouTube channel (new videos are released every week).

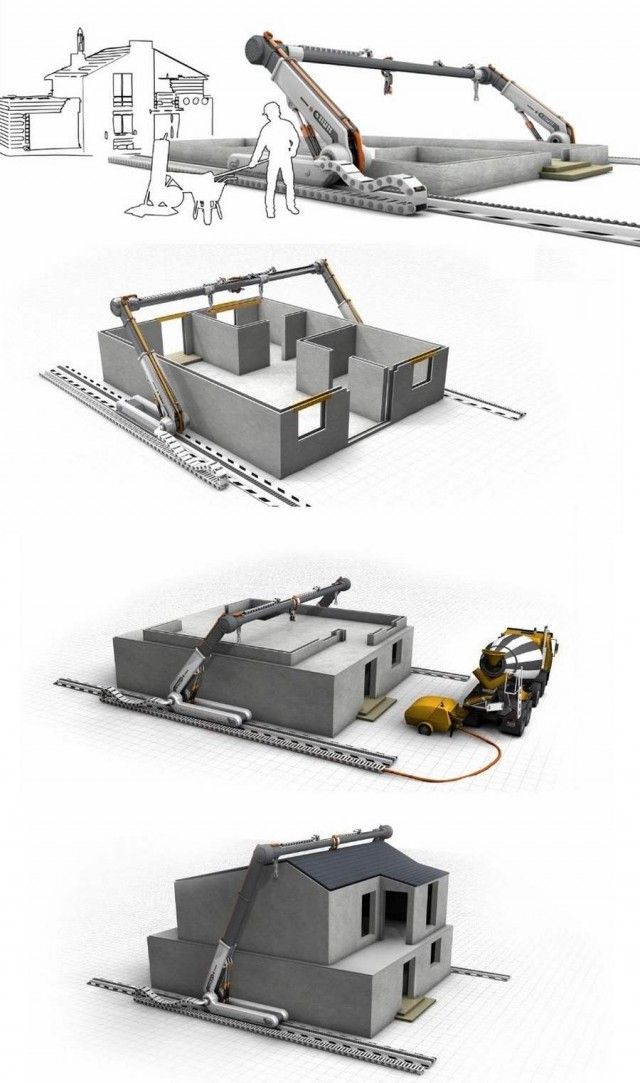

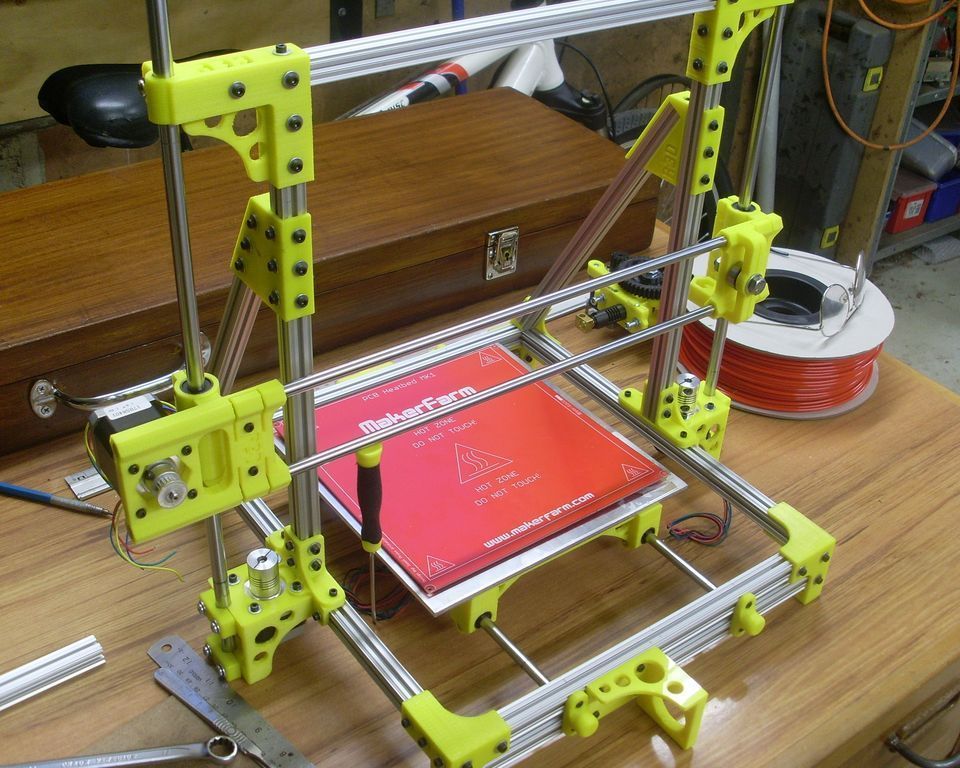

Concrete 3D printing: still ahead

Back to Concrete Issues main pageAdditive manufacturing, more commonly known as 3D printing, has been around since the 1980s. 3D printers have long been available for home use, so it's not surprising that industrial companies have begun to explore the possibility of using them in construction.

The use of 3D technology is widely and frequently discussed in the construction industry. Almost every week there is news of plans to 3D print structures ranging from bridges to houses that developers say can be built in one day. However, the initial enthusiasm in the media is quickly fading as there is less and less news of successful projects in this area. To shed some light on this topic, we asked a few experts for their opinions on the current state of 3D printing in construction.

One of the approaches to automation

There is a lot of hype in the construction industry around 3D printing technology, which, however, is still at an early stage of development. Concrete is a difficult material for 3D. A construction 3D printer works by applying concrete, layer by layer, through a nozzle, and in order to flow out of it, the concrete must be liquid. After printing, on the contrary, the material must quickly lose most of its fluidity in order to retain the printed form. However, at the same time, it should not harden too quickly to give the layers time to stick to each other. If layers are simply applied on top of others, without any connection between them, this will result in a weak structure, with no tensile strength. All this means that we cannot use ordinary concrete in 3D printing, and each structure needs a special type - always with different impurities.

Concrete is a difficult material for 3D. A construction 3D printer works by applying concrete, layer by layer, through a nozzle, and in order to flow out of it, the concrete must be liquid. After printing, on the contrary, the material must quickly lose most of its fluidity in order to retain the printed form. However, at the same time, it should not harden too quickly to give the layers time to stick to each other. If layers are simply applied on top of others, without any connection between them, this will result in a weak structure, with no tensile strength. All this means that we cannot use ordinary concrete in 3D printing, and each structure needs a special type - always with different impurities.

We must also take into account the complexity of the frame of the building that is being built. 3D printing is best for simple designs. Wall structures in Northern Europe, for example, are quite complex, and using 3D printing in them is quite problematic. The structure of the sandwich panel itself is a challenge for 3D printing: it has three layers - internal concrete, insulation, and external concrete. In addition, there are usually various wiring components inside the wall structure. Printing a three-layer structure and assembling electrical components during the printing process is not an easy task. The entire wall structure needs to be redesigned for 3D printing.

In addition, there are usually various wiring components inside the wall structure. Printing a three-layer structure and assembling electrical components during the printing process is not an easy task. The entire wall structure needs to be redesigned for 3D printing.

The current speed of 3D printers is incomparable with modern precast concrete factories. In addition, the quality of products from factories is much better than that obtained using additive technologies. 3D printing makes it possible to produce complex shapes, but in the case of typical concrete structures such as wall panels, its efficiency is far from that achieved by modern precast concrete technology.

Despite the limitations, we must be open to the possibilities that 3D printing brings. It can be considered as one of the approaches to increase the level of construction automation. If you look objectively, the future of 3D printing in construction is not clear. It may be one of the tools to help develop automation in construction, but certainly not the only one.

We must keep in mind that one of the main advantages of concrete is that it can be cast into shapes, create images and structures of varying complexity. Various types of concrete surface treatment are also currently available. Concrete construction is based, as a rule, precisely on its flexibility. With the help of 3D printing, we will completely change this. 3D printing certainly gives us new opportunities, but at the same time we lose some of the benefits of using concrete.

Jouni Punkki

Professor of Practice (Concrete Technology)

Aalto University, Helsinki, Finland

Jouni Punkki

Professor of Practice (Concrete Technology)

Helsinki Aalto University3 Finland

Financial viability is a big issue in the use of 3D printing in construction

We should consider 3D printing in construction as a very interesting technology that has some potential in the future. From a safety point of view, there are rules governing construction of any kind, and of course there are requirements for adding reinforced bars as supports in 3D framing. Since this technology is new and regulatory practices are constantly changing, these rules can be difficult to comply with. But I don't think there is any reason to be concerned about the safety of 3D printed structures.

Since this technology is new and regulatory practices are constantly changing, these rules can be difficult to comply with. But I don't think there is any reason to be concerned about the safety of 3D printed structures.

Concrete 3D printing faces the same challenges as other industries embracing this technology. Using molds to make components by casting will be much faster because with 3D printing you need extra time to make sure the previous layer can support the structure before adding the next one.

One of the advantages that 3D printed structures can provide over conventional building methods is that they are much easier to incorporate smart technologies such as sensors, making them easier to integrate into the smart city concept. From this point of view, it is much more difficult to modernize existing houses built using traditional building technologies.

Developing new technologies takes time. It's about testing, learning, and trying to figure out all the different variables. 3D printing of concrete structures is likely to become more commonplace. However, what role it will take in the construction industry, we cannot yet predict.

3D printing of concrete structures is likely to become more commonplace. However, what role it will take in the construction industry, we cannot yet predict.

The important question, of course, is can we make it financially viable? Is this technology something that customers will pay for? Will the cost of acquiring special 3D technologies be competitive, or at least comparable to what is on the market? There are other ways to achieve similar results, and these options are cheaper and more readily available to the construction industry.

Jouni Partanen

Head of Department (Advanced Manufacturing)

Faculty of Mechanical Engineering

Aalto University, Helsinki, Finland

CONCRETE EXPERIMENT 01 Design: Ashish Mohite, Michal Trpak Concrete Printing done by: Hyperion robotics Photographer: Umění ve městě 2019CONCRETE EXPERIMENTS Design: Ashish Mohite, Kunal Chadha Concrete Printing done by: Hyperion robotics Photographer: Ashish MohiteLots of claims, but not much evidence yet

There are several companies in the US and Europe that claim to be 3D printing concrete, but in the last two to three years they have only completed small projects such as private homes. One Russian company was erecting a three-story building in Dubai, and another company, already in Estonia, is now building a house using 3D printing. We help them make it a reality, but the project is still far from being completed.

One Russian company was erecting a three-story building in Dubai, and another company, already in Estonia, is now building a house using 3D printing. We help them make it a reality, but the project is still far from being completed.

Construction is a highly regulated industry, and one of the reasons why 3D printed concrete is no longer commercially available is the time it takes to get permits. In addition, the concrete used for 3D printing is more expensive than traditional concrete materials due to the admixtures needed to ensure the correct composition.

However, this technology continues to evolve. When a wall is 3D printed, it looks like a sandwich with two sublayers to make room for pipes and ventilation. In Zurich, it was possible to build a three-story house using various technologies. They invented a "smart stove" that had all the heating elements inside, however very expensive 3D printed molds were used for this. It was a pilot project to prove that the concept could be implemented.

Most of the 3D printing companies in construction, of course, say that this technology is better than precast concrete, but in reality this has not yet been proven.

Ashish mohit

Doctor

Mechanical Engineering Faculty

Aalto University, Helsinki, Finland

Ashish Mohita

Doctor

Mechanical Engineering

University of Aalo, Helsinki, Helsinki, Finlandia 9000

3D printing: promising, but it has a long way to go

The current technology used in construction is pouring concrete. To make it financially viable, you must keep the structure simple and standardized. If you don't, the price will go up as you have to make and customize different molds. In addition, simple products are not only visually unattractive, but also require a large amount of concrete in the manufacture. With 3D printing, we can reduce the amount of concrete used by about 50% by focusing, for example, on where the wall bears the load. We can print lines to make a slab and only use materials where we really need them. However, this means that we must also develop new design methods to benefit from the technology. Unfortunately, this takes time.

We can print lines to make a slab and only use materials where we really need them. However, this means that we must also develop new design methods to benefit from the technology. Unfortunately, this takes time.

The industry is focused on using currently available material. I think if you're going to change something, you'd better look at it from a social perspective and from a sustainability perspective. I saw an opportunity when working with digital concrete: everyone supports changing the composition of concrete because 3D printing is not perceived as a threat to the traditional construction industry.

I think 3D printing opens up a lot of possibilities for making smart materials. Why not tie the conductive materials directly into the concrete so that you no longer have to insert wires into concrete structures after they are made? With 3D printing, you can add inches, make material changes, make electrical connections in the right place, make concrete transparent where you want. It's about combining 3D printed concrete with smart technology to ultimately benefit us as a society.

It's about combining 3D printed concrete with smart technology to ultimately benefit us as a society.

One of the barriers is economic viability. A technology such as 3D printing will not be widely adopted unless there is a visible economic benefit at some point. Thus, manufacturers could consider expanding their business model so that construction is valued not only by the price of the house or structure being built, but also by the impact it has on our ecosystem and its sustainability.

However, there is a big difference between 3D printing a bridge and a house. We announced a 3D printed house project in Eindhoven two and a half years ago, and the first house has yet to be built. The complexity becomes apparent already when compared with the first printing bridge, which was opened within half a year after the start of the project.

We realized that this is terribly difficult because building a house involves complex systems - HVAC, electricity, internet connection - that you have to consider. It took us a long time to figure out how to do this, and I think it will be many more years before we can print houses or buildings on a larger scale. Bridges are much easier to build using 3D printing, as they have fewer details.

It took us a long time to figure out how to do this, and I think it will be many more years before we can print houses or buildings on a larger scale. Bridges are much easier to build using 3D printing, as they have fewer details.

Theo Sale

Dean of the Faculty of Built Environments

Professor of Structural / Concrete Design

Technical University of Eindhoven, The Netherlands

Theo Sale

Dean of the Faculty of Built Environments

Professor of Structural / Concrete Design

Technical University of Eindhoven, The Netherlands

Ideal for decorative elements, but not yet for structures

3D printing is a very interesting manufacturing system that we are following closely. It is already used in many industries such as steel and plastics, as well as in aeronautics, and especially in the production of aircraft parts. However, it is not widely used in the construction industry.

According to experts, there are still many barriers that need to be removed before 3D printing will leave its mark on construction, but I believe that it is the future of our business - it's just a matter of time. Now 3D printing is mainly used to create decorative items. Some cruise ships, for example, use 3D printed plastic and cellulose fibers as part of their interior design.

Now 3D printing is mainly used to create decorative items. Some cruise ships, for example, use 3D printed plastic and cellulose fibers as part of their interior design.

Although concrete is not yet widely used in 3D printing, it offers many advantages: fire resistance, strength, and the ability to support heavy structural elements. This is what makes it an ideal material for 3D printing items such as statues or columns, especially since each of us needs something beyond the usual box-like prefabricated structures.

Decorative elements, of course, can also be molded from concrete, but this requires workers - craftsmen to equip the molds. One of the practical applications of 3D printing in construction is mold making. In complex precast concrete projects, mold tooling is always a challenge as it requires a lot of manpower and precision. If the molds were 3D printed, the process would be easier and less labor intensive.

Tested to 3D print entire frames using concrete for projects such as small single-family cottages.