Iqube 3d scanner

iQube - 3D Foot scanning solution

iQube & iQube Mini

Our iQube 3D scanners capture accurate data of your client's foot to create custom insoles that fit perfectly first time. Improve your customer experience by capturing their foot data quickly and mess free in your practice, at their home or in a retail environment.

Overview

Digital Foot scanner

The iQube & iQube Mini foot scanners can produce high quality 3D scans of your client’s foot, a cast or a foam box impression in seconds and ready to import into your CAD solution to design accurate custom insoles. Here are some of the Features & Benefits:

Heel Capture

When scanning your client's foot, the iQube will capture the back of the heel as well as the plantar surface.

Foot Data

iQube allows you to capture your client's foot data with weight-on, weight-off and semi-weight bearing scans.

Portable

iQube and iQube mini are portable, allowing you to capture your client’s foot data wherever it is needed.

Time Saving

Reduce the lead time of producing custom insoles by capturing accurate data at the outset

iQube Mini Foot Scanner

The iQube Mini E100 is a fast, portable & accurate 3D plantar scanner with 1 camera, whether you need to scan a foot, cast or foam box, iQube mini is able to produce high-quality 3D images in seconds saving you time whilst improving the quality of the orthotic.

- Accuracy: +/- 1mm

- Scanning speed: 3 seconds

- Weight: 6 kg.

- Dimensions: 540 x 290 x 80 mm

- Maximum load: 200 kg.

- Software: RSscan Footscan Essentials

- Connection: USB 2.0

Scanning

- Foot length & width

- Arch height & length

- Estimated shoe size

- Output format: STL & picture

iQube Foot Scanner

The iQube E500 is a fast, portable & accurate 3D plantar scanner with 5 cameras, whether you need to scan a foot, a cast or a foam box, iQube is able to produce high-quality 3D images in seconds saving you time whilst improving the quality of the orthotics.

- Accuracy: +/- 0.4mm

- Scanning speed: 6 seconds

- Weight: 17 kg.

- Dimensions: 70 x 38 x 20 cm

- Maximum load: 200 kg.

- Software: RSscan Footscan Essentials

- Connection: USB 2.0

Scanning

- Foot length & width

- Arch height & length

- Estimated shoe size

- Output format: STL & picture

Full Weight bearing Foot Scan

A typical full weight scan of the patient’s foot is simple and in a matter of seconds you have a digital 3D model of your patient on which to design. The iQube remains flat on the ground.

Semi Weight bearing Foot scan

A semi weight bearing scan position is advantageous for certain diagnosis of conditions and is easily adaptable for the iQube. This is simply done by extending out one of the support legs on the lid whilst the other is closed creating the angle. The iQube then locates on top of the lid with the incline ready for use.

Non weight bearing foot scan

A non weight scan when manipulating the foot requires both hands and so activating the time delayed button is ideal for when the patient is on a lying on a bed or sitting in a chair to give you time to position the foot.

Cast Scan

Clever positioning allows the iQube to reach inside the cavity of a cast to give you a true 3D scan of a patient’s foot and converting your pre-existing records to digital.

Foam Scan

With the right positioning, even deep foam boxes are possible to scan using the iQube again digitising your records and reduce complications with physical storage.

Portability

The mobile podiatrists need to be able to make home visits and the iQube can do just that. Simply secure on the lid and carry it away like a suitcase.

Full Foot 3D scanner

The tiger scan 3d full foot scanner is a high-quality 3D scanning solution designed for orthotics, footwear manufacturers and designers. The foot scanner uses 9 cameras and is suitable for scanning lasts, feet, foam boxes, hands & insoles.

- Accuracy: +/- 0.5 mm

- Scanning speed: 5-15 seconds

- Weight: 26 kg.

- Dimensions: 730 x 430 x 320 mm

- Dimensions with handle and step: 755 x 832 x 1216 cm

- Maximum load: 200 kg.

- Software: RSscan Footscan Essentials

- Connection: 1x USB 2.0

Scanning

- Scan height above the ankle

- 3D view and automatic calculation of the height, length & width of the foot.

- Scan modes available from fast to high-quality.

- Bearing, half-bearing and non-bearing scanning.

- Output format: STL & picture.

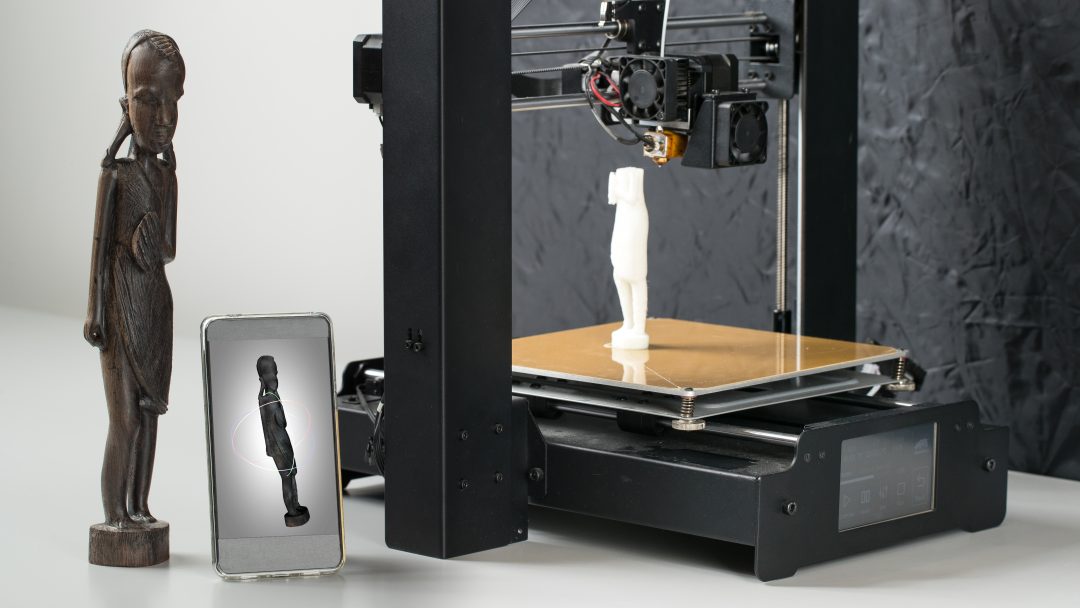

3D scanners for insoles, lasts and shoes.

Our plantar and full foot 3D scanners captures accurate data of your clients foot to create custom insoles or shoes that fit perfectly at first time. Improve your customer experience by capturing their foot data quickly and mess free in your practice, at their home or in a retail environment. Our scanners are perfect tools for doctors, orthopedists, shoes designers and makers.

| iQube mini | iQube (E500) | S3DT | |

|---|---|---|---|

| Dimensions (L x W x H) | 540 x 290 x 80 mm | 700 x 380 x 150 mm | 720 x 430 x 320 mm |

| Weight | 6 kg | 17 kg | 23 kg |

| Accuracy | 1 mm | 0.5 mm | 0.5 mm |

| Scanning area (L x W x H) | 340x160x80 ±5 mm | 340x180x150 mm ±5 mm | 400 x 200 x 180 mm ±5 mm |

| Scan time | 5-7 seconds | 5-9 seconds | 5-15 seconds |

| Elinvision software formats | STL, PLY, OBJ, JPEG | STL, PLY, OBJ, JPEG | STL, PLY, OBJ, JPEG |

| Scan objects | Foot, foam box, cast | Foot, foam box, cast | Foot, last, foam box, cast |

| Scanning abilities: | |||

| Foot bottom | |||

| Foot side | |||

| Full foot | |||

| Scanning 2D image | |||

| 3D points in color | |||

| Foot scanning in vertical position | |||

| I/O | 1x USB 2. 0 (1,8m USB cable A–B) 0 (1,8m USB cable A–B)1 x Foot switch (2,5m 6,3mm jack) | 1x USB 2.0 (1,8m USB cable A–B) 1 x Foot switch (2,5m 6,3mm jack) | 1x USB 2.0 (1,8m USB cable A–B) |

| More details | Brochure (download) | Brochure (download) | link |

eyJpZCI6IjEwIiwibGFiZWwiOiJTYWxlcyIsImFjdGl2ZSI6IjEiLCJvcmlnaW5hbF9pZCI6IjEiLCJ1bmlxdWVfaWQiOiJ3ZWZqMiIsInBhcmFtcyI6eyJlbmFibGVGb3JNZW1iZXJzaGlwIjoiMCIsInRwbCI6eyJ3aWR0aCI6IjEwMCIsIndpZHRoX21lYXN1cmUiOiIlIiwiYmdfdHlwZV8wIjoibm9uZSIsImJnX2ltZ18wIjoiIiwiYmdfY29sb3JfMCI6IiM4MWQ3NDIiLCJiZ190eXBlXzEiOiJjb2xvciIsImJnX2ltZ18xIjoiIiwiYmdfY29sb3JfMSI6IiMzMzMzMzMiLCJiZ190eXBlXzIiOiJjb2xvciIsImJnX2ltZ18yIjoiIiwiYmdfY29sb3JfMiI6IiMzMzMzMzMiLCJiZ190eXBlXzMiOiJjb2xvciIsImJnX2ltZ18zIjoiIiwiYmdfY29sb3JfMyI6IiMzMzMzMzMiLCJmaWVsZF9lcnJvcl9pbnZhbGlkIjoiIiwiZm9ybV9zZW50X21zZyI6IlRoYW5rIHlvdSBmb3IgY29udGFjdGluZyB1cyEiLCJmb3JtX3NlbnRfbXNnX2NvbG9yIjoiIzRhZThlYSIsImhpZGVfb25fc3VibWl0IjoiMSIsInJlZGlyZWN0X29uX3N1Ym1pdCI6IiIsInRlc3RfZW1haWwiOiJ0b21hcy56dWthdXNrYXNAZWxpbnZpc2lvbi5jb20iLCJzYXZlX2NvbnRhY3RzIjoiMSIsImV4cF9kZWxpbSI6IjsiLCJmYl9jb252ZXJ0X2Jhc2UiOiIiLCJmaWVsZF93cmFwcGVyIjoiPGRpdiBbZmllbGRfc2hlbGxfY2xhc3Nlc10gW2ZpZWxkX3NoZWxsX3N0eWxlc10+W2ZpZWxkXTxcL2Rpdj4ifSwiZmllbGRzIjpbeyJic19jbGFzc19pZCI6IjYiLCJuYW1lIjoiZmlyc3RfbmFtZSIsImxhYmVsIjoiIiwicGxhY2Vob2xkZXIiOiJGaXJzdCBOYW1lIiwidmFsdWUiOiIiLCJodG1sIjoidGV4dCIsIm1hbmRhdG9yeSI6IjEiLCJtaW5fc2l6ZSI6IiIsIm1heF9zaXplIjoiIiwiYWRkX2NsYXNzZXMiOiIiLCJhZGRfc3R5bGVzIjoiIiwiYWRkX2F0dHIiOiIiLCJ2bl9vbmx5X251bWJlciI6IjAiLCJ2bl9vbmx5X2xldHRlcnMiOiIwIiwidm5fcGF0dGVybiI6IjAifSx7ImJzX2NsYXNzX2lkIjoiNiIsIm5hbWUiOiJsYXN0X25hbWUiLCJsYWJlbCI6IiIsInBsYWNlaG9sZGVyIjoiTGFzdCBOYW1lIiwidmFsdWUiOiIiLCJodG1sIjoidGV4dCIsIm1hbmRhdG9yeSI6IjAiLCJtaW5fc2l6ZSI6IiIsIm1heF9zaXplIjoiIiwiYWRkX2NsYXNzZXMiOiIiLCJhZGRfc3R5bGVzIjoiIiwiYWRkX2F0dHIiOiIiLCJ2bl9vbmx5X251bWJlciI6IjAiLCJ2bl9vbmx5X2xldHRlcnMiOiIwIiwidm5fcGF0dGVybiI6IjAifSx7ImJzX2NsYXNzX2lkIjoiMTIiLCJuYW1lIjoiZW1haWwiLCJsYWJlbCI6IiIsInBsYWNlaG9sZGVyIjoiRW1haWwiLCJ2YWx1ZSI6IiIsImh0bWwiOiJlbWFpbCIsIm1hbmRhdG9yeSI6IjEiLCJtaW5fc2l6ZSI6IiIsIm1heF9zaXplIjoiIiwiYWRkX2NsYXNzZXMiOiIiLCJhZGRfc3R5bGVzIjoiIiwiYWRkX2F0dHIiOiIiLCJ2bl9vbmx5X251bWJlciI6IjAiLCJ2bl9vbmx5X2xldHRlcnMiOiIwIiwidm5fcGF0dGVybiI6IjAifSx7ImJzX2NsYXNzX2lkIjoiMTIiLCJuYW1lIjoiUHJvZHVjdHMiLCJsYWJlbCI6IkNob29zZSBwcm9kdWN0XC8tcyIsInZhbHVlIjoiIiwidmFsdWVfcHJlc2V0IjoiIiwiaHRtbCI6ImNoZWNrYm94bGlzdCIsIm1hbmRhdG9yeSI6IjEiLCJsYWJlbF9kZWxpbSI6IiIsImRpc3BsYXkiOiJyb3ciLCJhZGRfY2xhc3NlcyI6IiIsImFkZF9zdHlsZXMiOiIiLCJhZGRfYXR0ciI6IiIsImljb25fY2xhc3MiOiIiLCJpY29uX3NpemUiOiIiLCJpY29uX2NvbG9yIjoiIiwidGVybXMiOiIiLCJvcHRpb25zIjpbeyJuYW1lIjoiaVF1YmUgRTUwMCIsImxhYmVsIjoiaVF1YmUgRTUwMCJ9LHsibmFtZSI6ImlRdWJlIE1pbmkiLCJsYWJlbCI6ImlRdWJlIE1pbmkifSx7Im5hbWUiOiJTM0RUIiwibGFiZWwiOiJTM0RUIn1dfSx7ImJzX2NsYXNzX2lkIjoiMTIiLCJuYW1lIjoibWVzc2FnZSIsImxhYmVsIjoiIiwicGxhY2Vob2xkZXIiOiJDb21tZW50IiwidmFsdWUiOiIiLCJ2YWx1ZV9wcmVzZXQiOiIiLCJodG1sIjoidGV4dGFyZWEiLCJtYW5kYXRvcnkiOiIwIiwibWluX3NpemUiOiIiLCJtYXhfc2l6ZSI6IiIsImFkZF9jbGFzc2VzIjoiIiwiYWRkX3N0eWxlcyI6IiIsImFkZF9hdHRyIjoiIiwidm5fb25seV9udW1iZXIiOiIwIiwidm5fb25seV9sZXR0ZXJzIjoiMCIsInZuX3BhdHRlcm4iOiIwIn0seyJic19jbGFzc19pZCI6IjYiLCJuYW1lIjoic2VuZCIsImxhYmVsIjoiU2VuZCIsImh0bWwiOiJzdWJtaXQiLCJhZGRfY2xhc3NlcyI6IiIsImFkZF9zdHlsZXMiOiIiLCJhZGRfYXR0ciI6IiJ9LHsiYnNfY2xhc3NfaWQiOiI2IiwibmFtZSI6InJlc2V0IiwibGFiZWwiOiJSZXNldCIsImh0bWwiOiJyZXNldCIsImFkZF9jbGFzc2VzIjoiIiwiYWRkX3N0eWxlcyI6IiIsImFkZF9hdHRyIjoiIn1dLCJvcHRzX2F0dHJzIjp7ImJnX251bWJlciI6IjQifX0sImltZ19wcmV2aWV3IjoiYmFzZS1jb250YWN0LmpwZyIsInZpZXdzIjoiMTg1MjYiLCJ1bmlxdWVfdmlld3MiOiI0OTgzIiwiYWN0aW9ucyI6IjE2NCIsInNvcnRfb3JkZXIiOiIwIiwiaXNfcHJvIjoiMCIsImFiX2lkIjoiMCIsImRhdGVfY3JlYXRlZCI6IjIwMTYtMDUtMDMgMTg6MDE6MDMiLCJpbWdfcHJldmlld191cmwiOiJodHRwczpcL1wvc3Vwc3lzdGljLTQyZDcua3hjZG4uY29tXC9fYXNzZXRzXC9mb3Jtc1wvaW1nXC9wcmV2aWV3XC9iYXNlLWNvbnRhY3QuanBnIiwidmlld19pZCI6IjEwXzE0MjY0NSIsInZpZXdfaHRtbF9pZCI6ImNzcEZvcm1TaGVsbF8xMF8xNDI2NDUiLCJjb25uZWN0X2hhc2giOiI5ZmI4ZDkwODNkMGY4MjNjYTJhM2FiNjA0ZGUwNzJjMSJ9

Delcam plc - NTUU "KPI"

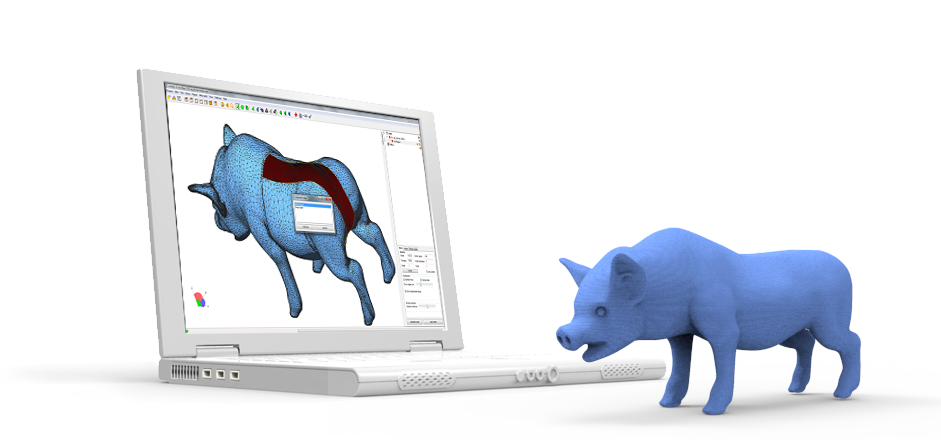

For almost five years, the Department of Integrated Engineering Technologies of MMI (head of the department - Doctor of Technical Sciences V. A. Pasichnik) has been operating the training center Delcam plc - NTUU "KPI" (supervisor - Doctor of Technical Sciences, prof. N.S. Ravskaya). Modern software Delcam plc allows you to design and create control programs in an automated mode for the manufacture of technical objects of complex spatial shape, taking into account the influence of geometry on the characteristics of these objects. The computer class of the ITM department is equipped with Power Solution software, on the basis of which laboratory work is carried out, term papers, bachelor's and master's works, etc. are carried out. Every year the software is updated, and students have the opportunity to study on the latest software, which is widely used at leading enterprises in Ukraine and the world.

A. Pasichnik) has been operating the training center Delcam plc - NTUU "KPI" (supervisor - Doctor of Technical Sciences, prof. N.S. Ravskaya). Modern software Delcam plc allows you to design and create control programs in an automated mode for the manufacture of technical objects of complex spatial shape, taking into account the influence of geometry on the characteristics of these objects. The computer class of the ITM department is equipped with Power Solution software, on the basis of which laboratory work is carried out, term papers, bachelor's and master's works, etc. are carried out. Every year the software is updated, and students have the opportunity to study on the latest software, which is widely used at leading enterprises in Ukraine and the world.

Students of the department annually take part in the international competition of student works by Delcam plc, for the third year in a row, the work of NTUU "KPI" takes prizes and is highly appreciated by Delcam plc. This year, the student work "Using CAD / CAM technologies to create a logo for the department of tool production of NTUU "KPI" (authors - students Vyacheslav Kozik and Dmitry Silchin, leaders - as. Alexander Anatolyevich Plivak and as. Sergey Vladimirovich Maydanyuk) won 2nd place In accordance with the cooperation agreement between NTUU "KPI" and Delcam plc and within the framework of the Delcam plc program of NTUU "KPI" specialists, employees of our university undergo training on the main software products of Delcam plc, such as PowerShape, PowerMill, CopyCad, ArtCam, PowerInspect and other Power Solution modules

Alexander Anatolyevich Plivak and as. Sergey Vladimirovich Maydanyuk) won 2nd place In accordance with the cooperation agreement between NTUU "KPI" and Delcam plc and within the framework of the Delcam plc program of NTUU "KPI" specialists, employees of our university undergo training on the main software products of Delcam plc, such as PowerShape, PowerMill, CopyCad, ArtCam, PowerInspect and other Power Solution modules

Today, one of the promising areas of development of the training center Delcam plc - NTUU "KPI" is the development and use of technologies for medical engineering. The complex software of Delcam plc company allows solving problems in dentistry (Dental-Cad, DentalMill), orthopedics (Delcam Crispin Orthopedic Solution), prosthetic parts of the face (Delcam FaceMaker).

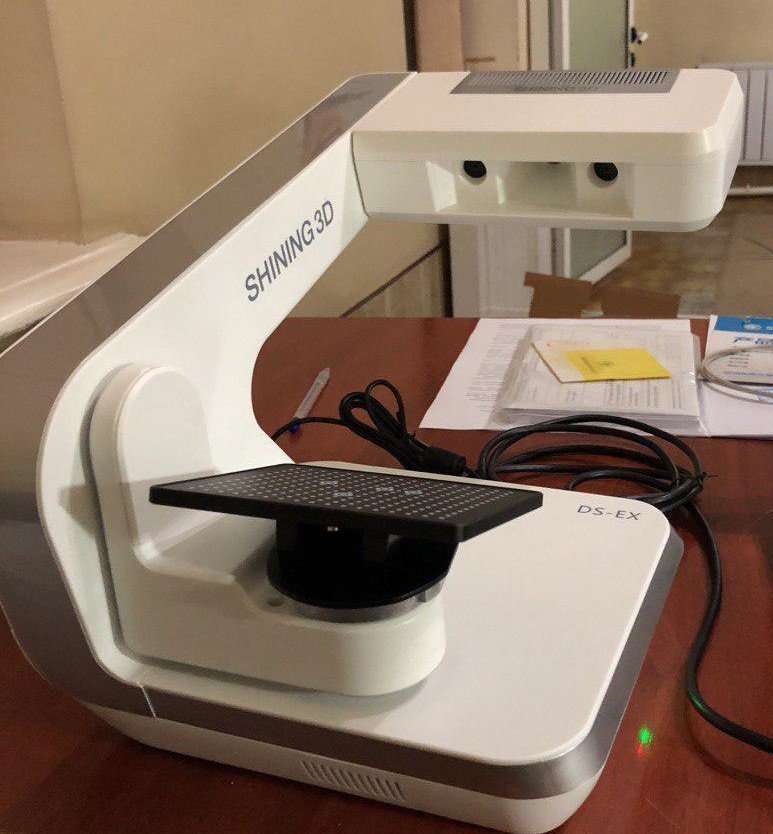

One of the first stages was the direction of orthopedic production. The key to success in this direction should be the special software Delcam Ortho-Model and OrthoMilll, the hardware - the orthopedic 3D scanner Delcam IQube and the qualified use of all modules.

In April 2010 Alexander Ivanov, engineer of the Department of Engineering and Technology, completed an internship at the training center of Delcam plc in Birmingham (Great Britain). He got acquainted with the activities of the company, its divisions, new achievements in the field of software development and application, acquired the skills to work with the company's new line of scanning equipment software in the field of medical engineering (Healthcare Solutions). OrthoModel opens up new possibilities for 3D modeling of orthopedic insoles, based on scanned data on a special Delcam IQube scanner.

Strong ties with one of the world leaders in software development - Delcam plc company allow applying the latest developments and technologies in the educational process and scientific research at NTUU "KPI" and have great prospects for further development.

Info. Department of Engineering and Technology

ММІ

Delcam

KKM

Primary Center

Kyiv Polytechnic

Training news

Ravska N. S.

News & Events | feetinform GmbH

from FET | Dec 7, 2021 | News & Events

NEW - FIF Mobile FIF Mobile is a simple and mobile solution for 3D scanning of the foot, footprint in foam and insoles. You can import measurement results directly from the application to the software...from FET | Jun 11, 2021 | News & Events

New FIFpro 21.0 Software Released! The new FIFpro 21.0 software version is available for download now. Key innovations: Integration of the new 3D scanner "Cobra". Extension of RAW functions processing of measurement heights by grid points...from FET | May 11, 2021 | News & Events

feetinform-YouTube channel Welcome to our feetinform-YouTube channel. (https://www.youtube.com/channel/UCaN7BuXhjzBicItc1ObOHWw). Here we present our latest developments, introduce you to our products and offer a platform for sharing tips and...from FET | Apr 22, 2021 | News & Events

New - Kobra 3D Scanner New - Kobra 3D Scanner Today we present you our new development: Kobra. Kobra is a versatile 3D infrared scanner for measuring a foot or footprint in foam. Install Kobra on your desktop for...

Kobra is a versatile 3D infrared scanner for measuring a foot or footprint in foam. Install Kobra on your desktop for... from FET | Feb 15, 2020 | News & Events

Gerne präsentieren wir Ihnen ab dem 03/01/2020 unsere neue Software FIF 3.0. • Neue Funktionen bei Adaptiven Modellvorlagen, Schnittstellen und Bibliotheken • Schneller navigieren mit Tastatur Kürzel, Voransicht in der Produktion • Auf dem neuesten Stand der Technik...from FET | Oct 9, 2019 | News & Events

OST Messe in Köln – Halle 4.2 / Stand F-029 Besuchen Sie uns vom 18. bis 19. Oktober 2019 auf der ORTHOPÄDIE SCHUH TECHNIK – Internationale Fachmesse und Kongress in Köln an unserem Stand F-029 / Halle 4.2. System zur Herstellung individueller orthopädischen...from FET | Mar 25, 2019 | News & Events

Anwendertreffen & Präsentation „Einlagen 3D-Drucker“Am 10.05.2019 um 14:00 bis 18:00 UhrGastgeberFUSS ArT GbRMoltkestraße 30-32D-77654 Offenburgwww.fussart.deAgendaEinlassü 13:30 UhrStart 14:30 UhrStart fehrstart 14 Kundenfeedback.

:quality(80)/images.vogel.de/vogelonline/bdb/1696600/1696673/original.jpg)