M1911 3d printer

M1911 best 3D printing files・Cults

Colt Delta Elite 10mm Auto

€15.02

Colt M45A1

€12.23

Remington R1 (classic)

€7.58

Kimber Warrior (John Wick 2)

€14.73

Ambi-Cut 1911 Full Frame Grips

Free

COLT 1911 MODERN SHAPE GRIPS UNIQUE NIGHTHAWK CUSTOM

€4

Pistol Colt M1911 Prop removable magazine practice fake training gun

€4

M1911 Rubber Band Gun Remix

Free

Airsoft TDC fixed outer barrel M1911/Hi Capa 5.1 TM

€5

TM Gas router m1911 magazine shim Airsoft

€2

AMT 1911 Hardballer 45 ACP (GAME/MOVIE MODEL PROP GUN)

€21. 82

Ww2 US Items and Equipment Pack1

€15

PISTOL Colt M1911 keychain

€2

Gas Route Shim For WE M1911A1 Airsoft GBB Mags

€0.57

Colt M1911

€4

M1911 pistol

€5

Pistol Colt M1911 Prop practice fake training gun

€4

IPSC Magwell for M1911 (CO2 & Lanyard Compatible)

€8.35

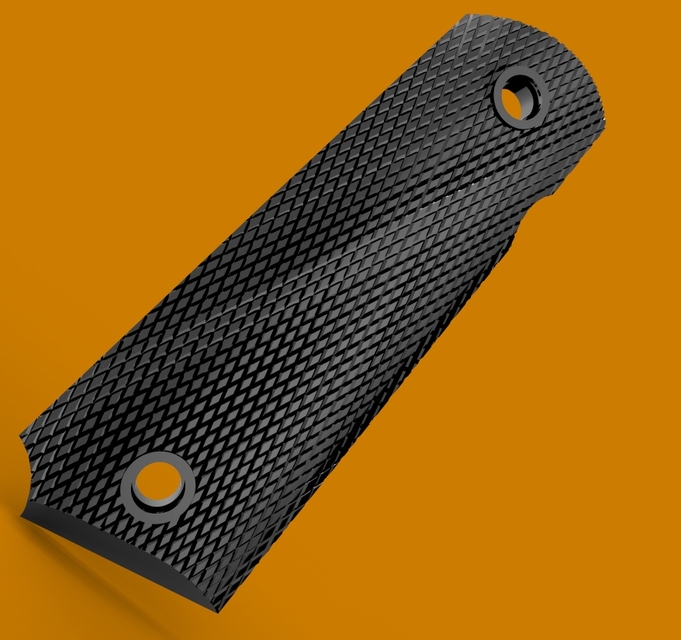

Checkered Grip for M1911 (CO2 Compatible)

€9

Colt M1911

€14.66

1911 Barrel Bushing Wrench

Free

1911 Barrel Bushing Tool Keychain

Free

M1911 Airsoft Adapters

Free

Colt Defender 45 acp (Prop gun)

€2. 87

87

KSC KWA HK45 USP USP Compact USP Tactical MK23 P226 M1911 VZ61 CZ75 PISTON RUBBER

€1.50

Blood Captain with Boomer Bolter

Free

1:12 Scale M1911

€6

WE 1911 Slide Stop

Free

Silencer Adapter for Colt 1911 Softair

€1.50

M1911/A1 FRAME

Free

M1911/A1 SLIDE

Free

M1911/A1 KITS

Free

colt m1911 1944

€3

COLT M1911 M1911 Co2 SOFTAIR GUN BRACKET SOFTAIR

€0.50

Colt M1911 with suppressor

€1

M700 Sniper Supressor

€4. 50

50

M1911 Colt Airsoft Supressor- barrel extender.

€3.50

Cybergun 1911 Magazine Cap Latch

Free

Correct WE 1911 Airsoft magazine follower

Free

1911 best STL files for 3D printer・Cults

Toy Colt 1911 49 pieces

€10

stand airsoft colt 1911 deadpool

€5

COLT 1911 AND CLONES MODERN SHAPE Skull theme

€4

Colt Delta Elite 10mm Auto

€14.88

1911 suppressor (airgun .177/ 4.5mm)

Free

Colt M45A1

€12.11

MIDATECH Adjustable Angular Grip (AAG)

€2

Airsoft Compact Holster Amomax Crytac

€5

Remington R1 (classic)

€7. 51

51

Kimber Warrior (John Wick 2)

€14.58

COLT1911

€3

Ambi-Cut 1911 Full Frame Grips

Free

COLT 1911 GRIP PANELS WITH SEPARATED PART FOR TPU RUBBER EXTRA DESIGN

€4

COLT 1911 MODERN SHAPE GRIPS UNIQUE NIGHTHAWK CUSTOM

€4

Holster pistol universal airsoft

€16

Pistol Colt M1911 Prop removable magazine practice fake training gun

€4

2011 BOLTSHOT (6-SHOT ARROW PISTOL)

€4.72

+4 BBs KWC / Elite Force 1911 Magazine Baseplate Extension

€0.75

Alternative Grip for Artemis / Airmax CP400 or Ram Maverick

€5

Colt stock 1911 Johnny Hallyday

€1

KWC/Elite Force 1911 Replacement Orange Tip

Free

1911 Cutaway model (3D printable)

€2. 52

52

BF.G - 1911 SKIN

€2.82

Mud-Claw 1911 Skin

€2.82

Colt 1911 Grip COBWEB aranha spider

€5.48

Cold 1911 Grip

€7.31

Colt 1911 grip panels with separated part for TPU rubber

€4

FLC 1911 Grips

Free

AMT 1911 Hardballer 45 ACP (GAME/MOVIE MODEL PROP GUN)

€21.61

STD 1911 Gel Blaster Punisher Compensator Muzzle Brake

Free

PISTOL Colt M1911 keychain

€2

M4 HPA Monk adapter extractor button

€6

Gas Route Shim For WE M1911A1 Airsoft GBB Mags

€0. 57

57

COLT 1911 and clones MODERN SHAPE GRIPS EGYPT theme

€4

COLT 1911 NEW 2022! ERGONOMIC GRIP PANEL GIGER THEME

€5

Pistol Colt M1911 Prop practice fake training gun

€4

Stand Colt 1911 for Airsoft Gun

€2

Stand Colt 1911 100th Anniversary for Airsoft Gun

€2

Stand Colt 1911 Auto Ordonance for Airsoft Gun

€2

1911 pin fix for eliteforce 1911 tactical

Free

KWC / Elite Force 1911 Magazine CO2 Puncture Set Screw

€0.61

1911 gun holder with lanyard loop

€0.94

1911 pistol holder without lanyard loop

€0. 94

94

COLT 1911 CLASSIC SHAPE GRIPS 1911 A1 handgun theme

€4

Colt 1911 Gun Display Stand

€4

1911 22lr v4

€300

1911 22lr v3

€180

1911 .22lr v2

€160

Krasnye Sovetov — 3D metal printing and Colt M1911 — Krasnye Sovetov

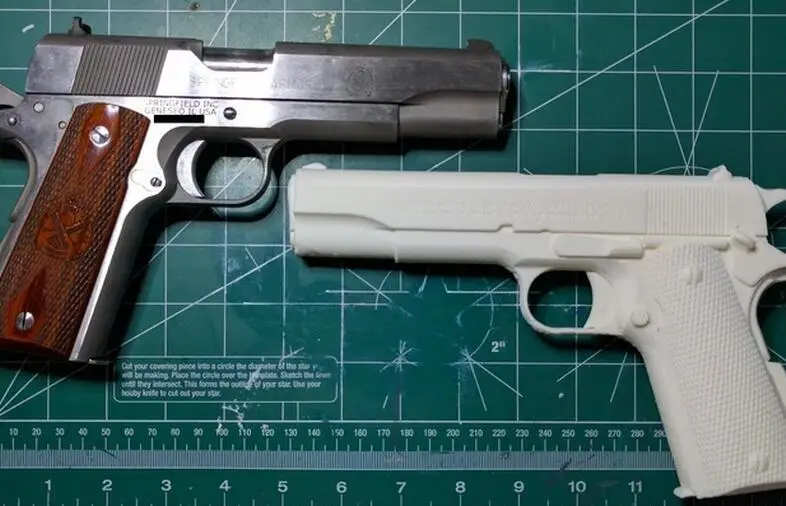

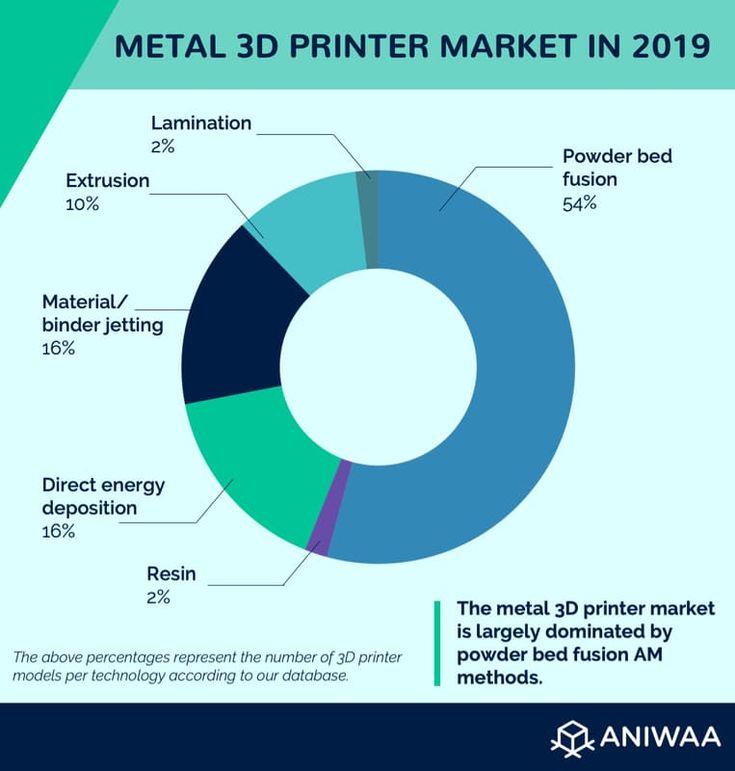

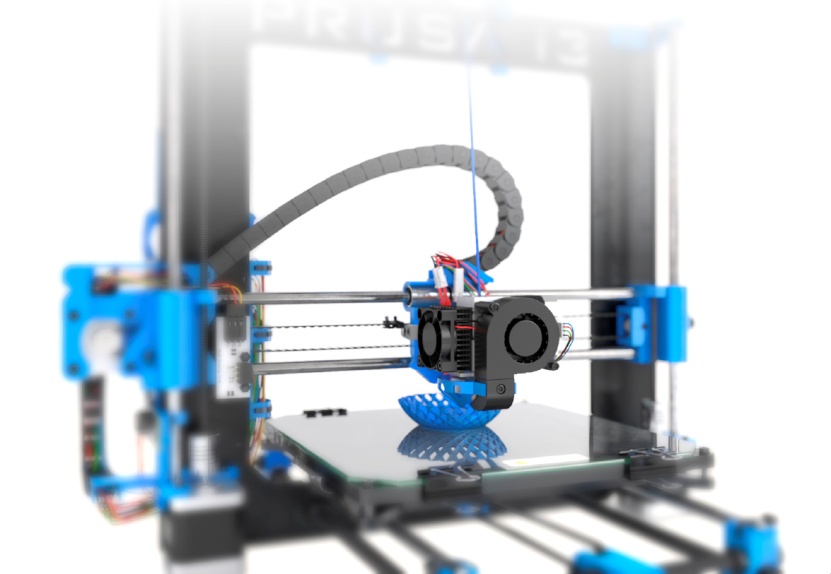

Just a couple of weeks ago, we posted the news that in 2013 the transition of 3D printing to the Iron Age was announced, that is, the creation of the first projects and samples of 3D printers that print Not plastic, but metal. We are glad to move from theory to practice and show you, dear readers, the first projects in this area. Namely: an aluminum 3D printer - Veder and more complex and energy-intensive printers from Solid Concepts, which printed the Colt M1911.

Well, first things first.

3D-printed army pistol

For the first time, a metal copy of an army pistol has been 3D printed. The printed pistol fires live ammunition and outwardly differs little from the factory "Colt" M1911, made on conventional machines.

Printed gun enthusiasts at Solid Concepts have printed the first metal firearm. Until now, such experiments have been limited to plastic parts or clumsy-looking and primitive in design plastic pistols chambered for small-caliber cartridges. The new printed pistol is a radical departure from these "crafts" - it is a fully functional combat weapon that fires a powerful .45ACP caliber cartridge. nine0012

The developers explain that they created the gun in order to demonstrate what durable and high-precision parts can be made using 3D printing. The testers have already fired dozens of rounds from the new pistol without any problems, while the plastic ones can withstand only a few shots.

Metal gun printing requires a whole new level of 3D printing technology. Solid Concepts used a technology known as direct metal laser sintering (DMLS or SLM), similar to the technology that NASA uses to produce experimental parts for the SLS launch vehicle engine. The essence of DMLS is that a laser running over a thin layer of metal powder gradually "grows" the part. Due to the high precision of the beam, which fuses tiny grains of metal, parts of the most complex shapes can be made in this way. nine0012

Solid Concepts used a technology known as direct metal laser sintering (DMLS or SLM), similar to the technology that NASA uses to produce experimental parts for the SLS launch vehicle engine. The essence of DMLS is that a laser running over a thin layer of metal powder gradually "grows" the part. Due to the high precision of the beam, which fuses tiny grains of metal, parts of the most complex shapes can be made in this way. nine0012

Factory drawings were used to make the pistol. The printer printed all the details of the gun, after which it could be assembled by only slightly grinding individual parts with a file. Interestingly, the printer even printed rifling in the bore, and these rifling, like all other parts, successfully withstood test firing.

It should be noted that the pistol was printed on a printer to demonstrate the promise of 3D printing technology, including in the production of weapons, especially highly specialized ones, which are very expensive to produce in mass series. It makes no sense for attackers to use DMLS technology: it is easier to buy a gun on the black market. DMLS printers are very expensive and not everyone can afford to rent them. In addition, the gun itself is not yet a weapon if there are no cartridges for it. Of course, bullets and cartridge cases can still be printed, but gunpowder and primers will have to be purchased separately, and they are sold only under license. So concerned parents should not be afraid that their offspring will order a “cupboard” (compact models weigh more than 500 kg) of a DMLS printer worth hundreds of thousands of dollars over the Internet and start printing pistols for themselves and their friends. nine0012

It makes no sense for attackers to use DMLS technology: it is easier to buy a gun on the black market. DMLS printers are very expensive and not everyone can afford to rent them. In addition, the gun itself is not yet a weapon if there are no cartridges for it. Of course, bullets and cartridge cases can still be printed, but gunpowder and primers will have to be purchased separately, and they are sold only under license. So concerned parents should not be afraid that their offspring will order a “cupboard” (compact models weigh more than 500 kg) of a DMLS printer worth hundreds of thousands of dollars over the Internet and start printing pistols for themselves and their friends. nine0012

Source - Scientific News

As the developers themselves noted, this, of course, is not a mass development. The printer on which this gun was printed is very large, heavy, overall, it has terrible energy consumption and all the other disadvantages associated with printing from metal. Which, of course, will be eliminated in the future, the only question is how far.

Which, of course, will be eliminated in the future, the only question is how far.

But speaking about such a model, we can safely say that such equipment is an unconditional step forward, since this is a new word in the issue of waste-free production and recycling of materials. This is definitely a more environmentally friendly way of production. nine0003

Vader 3D - the first 3D printer capable of printing with molten metal

Inventors Scott and Zachary Vader, father and son, have designed and prototyped a new Vader 3D printer that could revolutionize metal 3D printing. The Vader 3D printer uses molten aluminum as its "ink" instead of ordinary plastic, which makes it easy, simple and quick to create all-metal objects of any complexity without the need for lasers and complex anodizing processes. nine0012

Until recently, the only way to 3D print metal objects was laser fusion. In this method, a high-power laser beam heated the metal powder particles in the right places until they melted, as a result of which they were fused into a single whole. There was another method, developed by Shapeways, in which refractory metal powder was “glued together” at high temperature using ceramic binders and low-melting bronze, but this method was never widely used. nine0012

There was another method, developed by Shapeways, in which refractory metal powder was “glued together” at high temperature using ceramic binders and low-melting bronze, but this method was never widely used. nine0012

The Vader 3D printer has a thermal chamber in which the aluminum melting process takes place. Then, with the help of forces arising from the phenomena of an electromagnetic nature, the molten metal is forced out of the chamber onto the base. The metal leaves the thermal chamber of the printer in the form of droplets or thin streams moving at high speed, which allows it not to cool to the solidification stage until the very moment of contact with the base or surface of the partially printed object. The whole process of printing with molten metal is very similar to the process when printing on paper using a conventional inkjet printer. nine0012

The printer has very modest dimensions, it is a cube with a side length of 25 centimeters. Despite its small dimensions, the design of the printer is very massive, because it uses heavy metal and ceramic parts. It stands on a granite base that can withstand high temperatures, and a hexagonal metal plate is used as a printing base, which has sufficient thickness and large weight.

It stands on a granite base that can withstand high temperatures, and a hexagonal metal plate is used as a printing base, which has sufficient thickness and large weight.

Vader Systems was formed to commercialize 3D molten metal printing technology and has been in existence for seven months, with the final product, the Vader 3D 3D printer, to be on the market in 2014. The cost of this printer will be about 10 thousand dollars, which is not very much, given the capabilities of this device. nine0012

Source - Daily Tech

Aluminum is, of course, not the solution we are all waiting for, it has a low melting point, and therefore low energy consumption for the operation of such a unit. However, this is a sure step in the development of 3D printing with metals, and we can expect that we will soon see a 3D printer printing not with aluminum, but with cast iron.

Although an aluminum 3D printer can open up broader horizons than plastic ones. The main thing in this matter is the development trend in this area, and it is extremely positive. nine0003

The main thing in this matter is the development trend in this area, and it is extremely positive. nine0003

First 3D printed metal gun introduced // Watch

-

Profile

3D printers and 3D printing November 11, 2013, 14:15 November 11, 2013, 15:15 November 11, 2013, 04:15 PM November 11, 2013, 17:15 November 11, 2013, 18:15 November 11, 2013, 19:fifteen November 11, 2013, 20:15 November 11, 2013, 21:15 November 11, 2013, 22:15 November 11, 2013, 23:15 November 12, 2013, 00:15

- Asya Gorina

-

All metal parts of the M1911 pistol were 3D printed

nine0002 (photo by Solid Concepts).

-

This is what a fully functional 3D printed M1911 pistol looks like

(photo by Solid Concepts). nine0003

-

(photo by Solid Concepts).

-

All metal parts of the M19 pistol11 were printed on the

3D printer(photo by Solid Concepts).

-

This is what a fully functional 3D printed M1911 pistol looks like

nine0002 (photo by Solid Concepts). -

(photo by Solid Concepts).

nine0083

3D printing is moving in a new direction. Texas-based Solid Concepts has released the first 3D printed metal handgun. As a prototype, the engineers chose the popular M1911 model.

As a prototype, the engineers chose the popular M1911 model.

After the European Space Agency announced that 3D printing has entered the Iron Age, additive manufacturing specialists began to develop new concepts for 3D printing. Texas-based Solid Concepts has released the first 3D printed metal handgun. To create a fully functional firearm, the Model 19 Automatic Pistol11, the engineers used "laser sintering technology".

3D printed weapons have been introduced before, but all previous models were made of plastic, not metal.

The model, now 3D printed, is codenamed M1911. Created back in 1911 by John Moses Browning, this automatic pistol was widely used by the US Armed Forces until 1985, and is now the most popular model among shooting enthusiasts and Hollywood filmmakers. nine0003

Interestingly, when John Browning created the first model of his pistol, he made a model of its working parts from cardboard, drawing a two-dimensional drawing and cutting it out along the contour. Therefore, we can say that the M1911 model has moved into a new dimension.

Therefore, we can say that the M1911 model has moved into a new dimension.

More than 30 of the gun's components were made by laser sintering, in which powdered metals are melted by a laser beam and joined layer by layer according to a computer model, according to the company. After melting the metal powder, the 3D printer lays down the next layer on top and repeats this process until the computer program redirects the nozzle. At the final stage, excess powder is removed, and the printed structure is cooled and hardened. nine0003

The M1911 pistol consists of 33 components made of stainless steel and Inconel 625 nickel-chromium heat-resistant alloy. Even the nylon-coated carbon fiber grip was completely 3D printed.

Unlike most printed plastic pistols, the M1911 barrel was rifled. Representatives of Solid Concepts emphasize that some of the final stages of production had to be carried out manually, the new pistol was not machined. The whole assembly process took about 7 minutes. nine0003

nine0003

According to a press release from the company, the aim of creating a gun using additive manufacturing was not to reduce the cost of the process. Engineers have tried to show that 3D printed metal objects can be much higher quality and easier to manufacture than those created by traditional methods by now.

For example, 3D printing provides less porosity than conventional casting. Therefore, "printed" designs are the most durable and durable, if, of course, no mistakes were made during production. nine0003

"The concept of using laser sintering technology in the manufacture of metal weapons proves the reliability, accuracy and usability of metal in 3D printing of both functional prototypes and end-use products. We wanted to dispel the common misconception that 3D printing is an unreliable manufacturing method" , says Kent Firestone, VP of Additive Manufacturing at Solid Concepts.

The barrel of the new pistol can withstand a pressure of 14 thousand kilograms per square centimeter for each shot.