Glue pla 3d prints together

How to glue PLA? 5 ways to do it

In this article I’ll share my secrets and tricks to glue PLA. When I came up with the idea of writing this post I didn’t even know that there were so many ways to do it, but remembering different ideas, experiments and videos, I’ve managed to bring together 5 different ways to do it.

Are you curious to know what these 5 techniques are? Read on. 👇👇👇

📖 What do you want to read?

How to glue PLA with adhesive

The easiest way to glue PLA for most cases is to use an adhesive, so the question is, what kind of glue can I use? We have used several types of glue and we can recommend the ones that have worked for us: cyanoacrylate and special adhesives for plastics.

Cyanoacrylate glue is usually the best choice for bonding PLA parts. Any brand will do. I prefer it on small tubes so it won’t spoil if I don’t use it in a while.What adhesives to use for PLA?

- Cyanoacrylate.

Cyanoacrylate is the technical name of the adhesives we know as Super Glue, Loctite, extra-strong glue or instant glue. It is a glue that works for everything, including PLA; it allows to bond it in an easy and fast way with an adhesive that almost all of us have for our home or workshop.

- Plastic adhesives. Many brands of adhesives sell specific adhesives for plastics, because generally these are a little difficult to glue. I have personally tried UHU for hard plastics, but there is nothing to envy about bonding it with a more typical cyanoacrylate glue.

Glue PLA with epoxy

If you decide to glue the PLA pieces with epoxy you will have 3 extra advantages:

- You’ll get a stronger bond than with conventional adhesives and glues.

- You can fill small gaps if the two bonding surfaces are not flat enough or cracks remain.

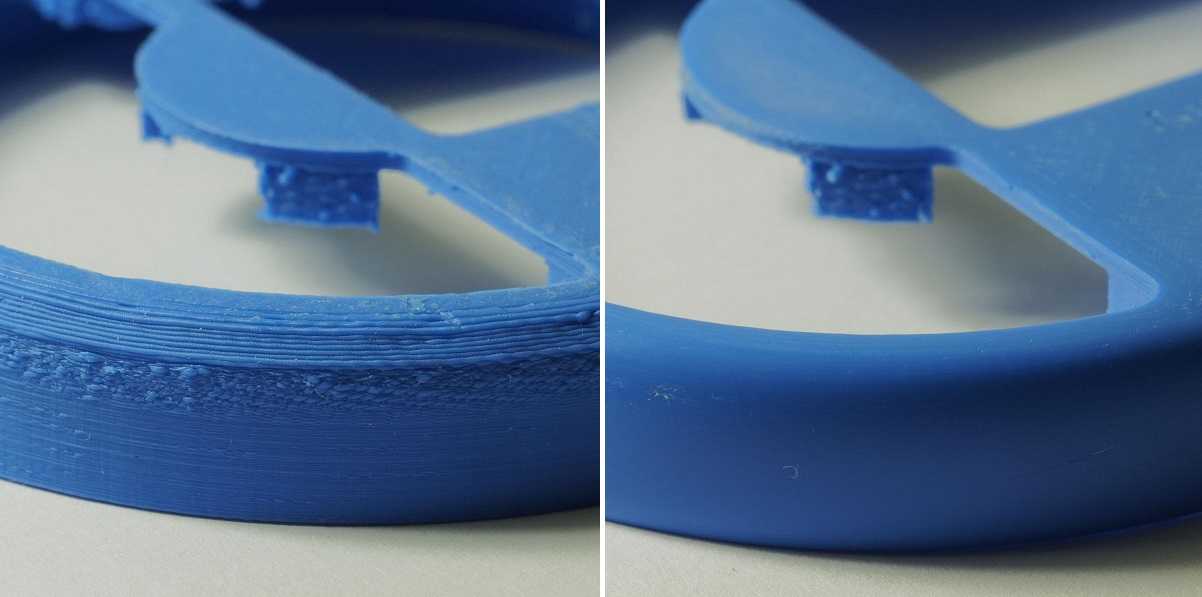

- You can also use epoxy to improve the surface finishing with the epoxy smoothing technique (apply an external layer to the part to remove 3D printing layer marks).

But you will have to endure the main disadvantage, which is that preparing, manipulating and applying epoxy is much more complicated and has to be done in a space that you don’t mind dirtying and well ventilated so as not to breathe the gases it gives off.

A lot of epoxy resins are sold to smooth 3D printing parts and any of them will help you to glue your pieces: you will kill two birds with one stone. The most famous product I have tried is SmoothOn’s XTC-30 resin. For both gluing and smoothing, you will be able to use any epoxy resin with the proper consistency (which allows you to apply it with a brush to work the piece for 10-15 minutes).

This is the XTC-30 epoxy, which is used for both gluing and smoothing PLA parts. As you can see, the packaging is terrible, but the product works wellUsing a hot glue gun

The hot-melt glue gun is an essential part of any workshop. It is suitable for making quick joints, covering gaps, gluing cardboard, insulating electronic components… You won’t get the prettiest bonds, but for prototypes and areas that are not seen, it’s the fastest choice.

PLA can be glued with hot-melt adhesive; the only thing we have to take into account is that from 60-70 ºC the plastic begins to soften, so we have to be careful not to melt the areas of the pieces that we are going to bond.

This is the hot-melt gun that I have, a Parkside gas model. You can use a gas or electric pistol, the only difference is that it warms up a little earlier and can be carried around the workshop without worrying about the cable.Glue PLA con acetone

Glueing PLA using acetone is an experimental technique that I discovered in the following video of Thomas Sanladerer, one of the most famous 3D printing youtubers.

As you’re going to see, the initial intention of the video was to smooth the PLA pieces with acetone, but the result is not very satisfactory. However, the surfaces of the pieces soften enough to allow them to stick to each other. You can use acetone to join large flat surfaces of ABS.

The Dremel’s technique for PLA welding

This technique doesn’t require glue or any other material: it consists of friction welding the PLA using a Dremel or any other rotary tool. A piece of filament is inserted into the Dremel’s mandrel and rotated in contact with the part so that the filament, melted by friction, fills the gaps and bonds the PLA parts.

I’ve been able to personally try this way of gluing PLA but it doesn’t quite convince me: it’s a bit messy to do (you have to stop and change the filament every time you spend it), I didn’t get a good bond or a good finish.

Perhaps for projects where you have to fill some cracks, it may be worth it, but I do not find sense to weld the pieces in this way instead of using any of the other methods.

Did you like the article?

You can’t say I haven’t given you options, you already have 5 different ways to glue your PLA parts!

If you’ve come this far, you’ve been interested in what I’ve told you. You can help me by leaving your opinion in the comments. I reply to everyone!

Read you later.

The Best Glue for PLA, PETG & ABS – Clever Creations

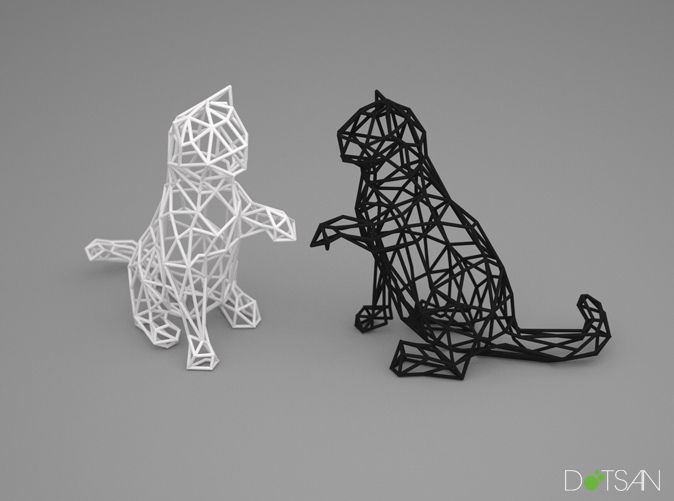

Gluing 3D printed parts together is something you will most likely have to do when you are starting to get into 3D printing. Maybe your printer’s build plate wasn’t large enough to print a model in one piece, or your print failed partway through and you are trying to fix it.

Whatever the reason for needing to glue 3D printed parts, there are a lot of things to consider before you get started. For example, choosing the right glue for your filament and project type. Gluing PLA, ABS, and PETG filament all prefer different adhesives.

Gluing PLA, ABS, and PETG filament all prefer different adhesives.

If you aren’t sure which glues work on which materials, when to use one type of glue over another, and what brands are the best choice for each type of glue, keep reading! We’ve covered all of that and more in the sections below.

What Makes a Good Adhesive for Gluing 3D Prints?

While there are dozens of adhesives on the market, very few are suitable for gluing 3D prints together. 3D printing is a versatile technology that uses different types of materials to create prints that are used for a variety of applications. Most adhesives aren’t formulated to work with some of these materials and lack the properties needed for the finished print’s intended purpose.

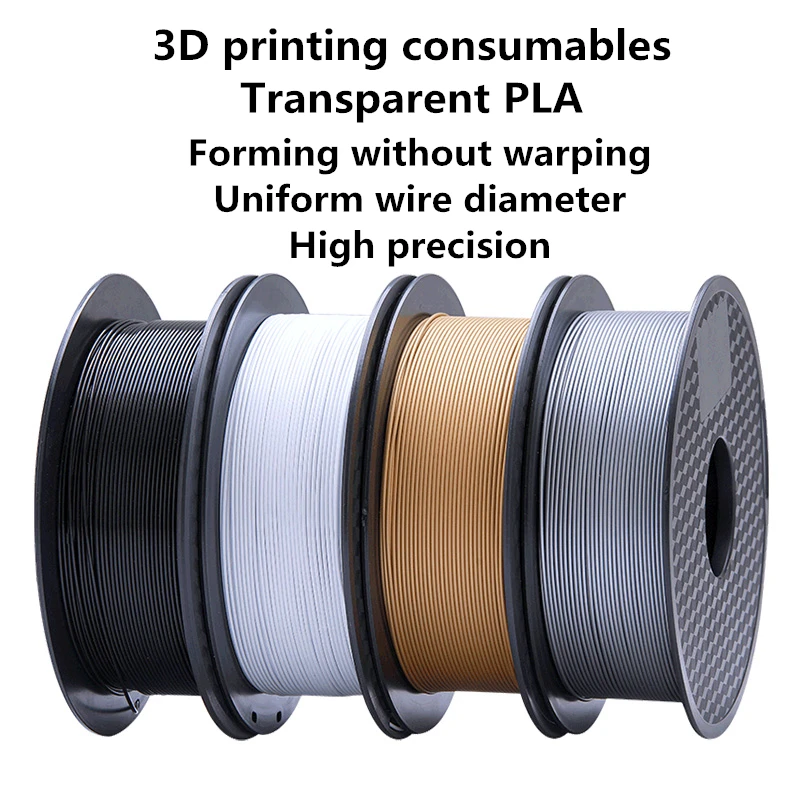

First and foremost, any adhesive used for gluing 3D printed parts together should be formulated to work with the type of plastic the 3D print is made from. Commonly used 3D printing filaments are PLA, ABS, PETG, and TPU. Some adhesives contain chemicals that react poorly or do not bond well with certain types of plastic.

A good adhesive for 3D prints will form a strong bond between the parts, leave as small of a seam between the two parts as possible, dry quickly, and not produce a lot of heat while curing.

What is the Best Glue for PLA?

Super Glue (Cyanoacrylate)

The best glue for PLA filament is standard super glue or cyanoacrylate glue. It’s widely available, forms a strong bond between printed parts within seconds, and dries clear.

Image: Proto3000 via Youtube

Cyanoacrylate superglue is one of the best glues for PLACapable of bonding surfaces with very thin layers of adhesive, super glue lets you create flush seams that are easy to hide. It also doesn’t produce any heat while bonding, so there is no worry about it warping low-temperature filaments like PLA.

One of the most common cyanoacrylate glue brands is Gorilla Glue, which is known for being one of the best glue products in its category. However, most super glue brands should suit your purposes just fine in this case.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,535 Reviews

Check Price3D Gloop

An adhesive specifically made for 3D printing, 3D Gloop is a versatile glue that can be used in several ways. 3D Gloop comes with a built-in brush in its cap to easily apply it to 3D printed parts. It creates an ultra-strong bond between parts that mostly cures within an hour (and fully cures in six hours).

While this brand offers separate formulas for PLA and ABS, you can use either on both materials. This allows you to bond different materials together with little to no visible difference in the bond. However, when bonding the same materials together, you should try to use the glue formula for that type of material for the best results.

You can also brush 3D Gloop onto glass and mirrored print beds to help with print adhesion and eliminate warping. They don’t recommend using it on coated or PEI beds since it can permanently bond to the surface.

One consideration that should be made with 3D Gloop is that it needs to be used carefully. It produces fumes when uncured (and on the print bed) that should not be breathed in, so use in a well-ventilated area and/or with a respirator is ideal.

It produces fumes when uncured (and on the print bed) that should not be breathed in, so use in a well-ventilated area and/or with a respirator is ideal.

3D Gloop can also be an irritant, so you should wear gloves and safety goggles when working with it and try to avoid getting it on your skin. Using it requires similar precautions as when working with 3D printing resin and dealing with 3D printer fumes, so you might already have some of the equipment you need available.

Urethane Glues

With similar bond strength to superglue but with added flexibility, urethane glue is a great option for gluing PLA 3D printed parts together. They take several days (sometimes up to a week) to fully cure, however, so they are not a great option for projects that need to be finished quickly.

Urethane glues are popular in the construction industry and are made for both indoor and outdoor use. This makes them more resilient than other glues to things like moisture, freezing, UV light, and so on. If your 3D prints will spend time out in the elements, urethane glue is a good choice for bonding any seams.

If your 3D prints will spend time out in the elements, urethane glue is a good choice for bonding any seams.

They also produce some heat during their curing process. While it doesn’t reach the temperature needed to warp PLA, it may still affect small or thin pieces. Despite the curing process, urethane glues form a very strong bond between glued PLA plastic and are a favorite of many 3D printing enthusiasts.

Gorilla Original Gorilla Glue, Waterproof Polyurethane Glue, 8...

Check PriceHot Glue Gun

If you’re in a pinch and need to glue PLA parts together, using a hot glue gun will technically do the trick. Hot glue doesn’t have the same bond strength as other adhesives mentioned so far in this article, so it shouldn’t be used on anything that is going to have a lot of mechanical stress on it.

Hot glue is also quite thick and stringy, so it is hard to apply an even, thin layer. It is equally difficult to get a close seam with it, and you can expect your joins to be messy. On the other hand, it dries incredibly fast, so you don’t need to wait around for long cure times.

On the other hand, it dries incredibly fast, so you don’t need to wait around for long cure times.

Recommended:

The Essential Guide to Hot Glue

The interesting thing about using a hot glue gun is that you can also melt PLA filament in it and use it as a rudimentary 3D pen. If you 3D print PLA cylinders in the diameter your hot glue gun uses, you can feed them through your gun like a regular glue stick for good results when gluing PLA parts together!

Image: Brodie via MyMiniFactory

3D printing a PLA glue stick let’s you glue with PLA!This will produce better results than traditional hot glue sticks, but the process can clog up your glue gun (especially cheaper ones) so don’t use it this way if you are concerned about switching back to plain glue after.

Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks

Check PriceEpoxy Resin

Epoxy resin is another great PLA glue that can be used to join PLA plastic pieces. Usually sold as a two-part kit (the resin and a hardener), the components need to be mixed to start the curing process. How long they take to cure depends on the brand and can vary from minutes to days.

How long they take to cure depends on the brand and can vary from minutes to days.

The Bob Smith Industries Quik-Cure Epoxy is a good choice for gluing PLA plastic since it starts to cure in five minutes, is mostly cured in 15 minutes, and reaches full cure within an hour. It is designed to be slightly flexible when cured, so like the urethane glues we looked at earlier, it is a good option for parts that need vibration dampening or impact resistance.

The bond strength on the epoxy resin is excellent, and it allows you to make very thin invisible seams. Most emit some heat during the curing process, so it is important to ensure it won’t reach the temperatures needed to melt your prints.

Bob Smith Industries BSI-201 Quik-Cure Epoxy (4.5 oz. Combined),Clear

Check Price3D Pen

A more sophisticated version of the process we outlined in the hot glue gun section, a 3D pen is a handheld device that melts and extrudes filaments. 3D pens can be used to pipe on melted PLA material and weld two parts together.

One big advantage to this method is that you can use the same filament as the prints, making the seam less noticeable. In terms of adhesion strength, however, a 3D pen is not the best glue for PLA.

The bonds created with this method will most likely hold under most light applications, but the strength won’t be as good as other methods outlined on the list. This technique should not be used for joining parts that will undergo mechanical stress or impacts.

While you can find several different 3D pens currently on the market, the 3Doodler Create+ is our favorite. It works with both PLA and ABS, so you have a lot of versatility in what you can use your pen for. It also has a dual extruder motor to push the filament through on both sides for more even feeding.

3Doodler Create+ 3D Printing Pen for Teens, Adults & Creators! -...

3,522 Reviews

Check PriceSoldering Iron

Image: ubcengphysprojectlab via Youtube

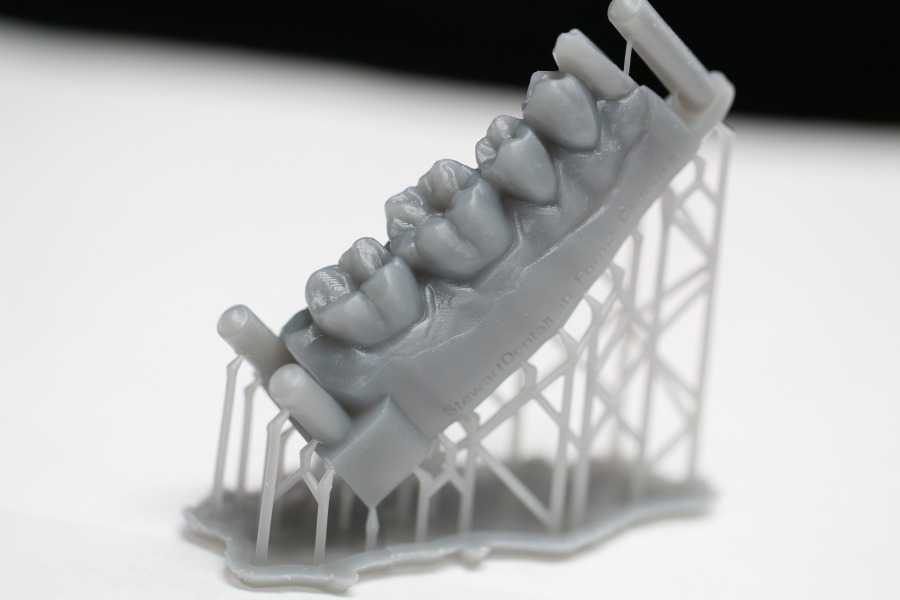

PLA welding with a soldering iron does not provide a lot of strengthAs a last resort, you can use a piece of PLA filament and a soldering iron to weld two PLA prints together. Using the tip of the soldering iron on the piece of PLA, you slowly melt the material along the line where the two parts meet. This process works better on something with a groove or curve to hold more PLA material, so this process is especially bad for adding two flat pieces together.

Using the tip of the soldering iron on the piece of PLA, you slowly melt the material along the line where the two parts meet. This process works better on something with a groove or curve to hold more PLA material, so this process is especially bad for adding two flat pieces together.

The most common use for PLA welding is trying to fix failed prints. Cracks, holes, and other issues can be somewhat resolved with PLA welding, so if you need to adhere split layers, this process is worth knowing.

However, for joining two separate 3D printed pieces, you are better off using one of the other solutions on this list. For this, a soldering iron is not optimal.

SOLDER STATION,40W,120V,W/ST3 TIP

Check PriceHow to Glue PLA 3D Printed Parts

- Sand down any rough or uneven edges with sandpaper until the edges of the two pieces are flat.

- Make sure both surfaces are clean and free of debris. If you need to wipe them with a wet cloth or wash them with soap and water, make sure to dry them thoroughly before gluing.

- Apply glue near the center of the printed parts. Don’t apply it too close to the edges to avoid it getting on the outside of the print.

- Spread the glue with a toothpick, the nozzle of the glue bottle, or some other small applicator until the part is evenly coated.

- Carefully press the parts together, making sure they are properly lined up. Hold them together with your hands or a clamp until a strong bond forms.

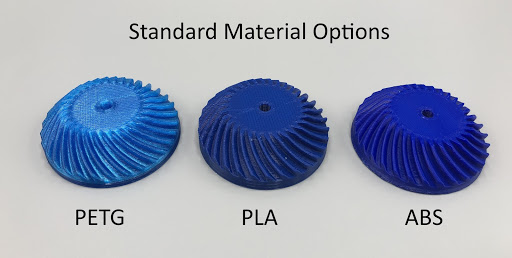

What is the Best Glue for ABS?

Acetone

The best way to glue ABS prints together is with acetone. ABS is acetone-soluble, meaning it breaks down when it comes into contact with it. Spreading a small amount of acetone on both surfaces being glued will break down the outer layers of ABS. When these layers are pressed together, the edges will reform as a single piece. This is called solvent welding.

Not only is the bond between the two printed parts very strong with this method, but it also eliminates the seam where the two parts meet. If done properly, they will look and act like they were printed as a single part. This is ideal if you want to 3D print cosplay armor or make a 3D printed helmet.

If done properly, they will look and act like they were printed as a single part. This is ideal if you want to 3D print cosplay armor or make a 3D printed helmet.

However, using too much acetone on the edges can damage them and leave an ugly or unstable join. It is therefore important to have some practice before potentially wasting your best ABS filament.

Acetone also poses some risks while using. It has strong fumes, so you should keep your workspace well ventilated. It is also highly flammable, so take care around open flames and high temperatures.

While acetone works well with ABS, it can’t be used with most other plastics the same way. PLA isn’t acetone soluble like ABS, so you can’t use it to glue PLA prints together.

Recommended:

PLA vs ABS: Which Filament is Better?

ABS Plumber’s Cement

ABS Plumber’s Cement is a thick paste-like adhesive that works extremely well with ABS. Since it is solvent-based glue, it works like acetone to form a solvent weld in the ABS. This creates a very strong bond between the parts, but it won’t be as clean as acetone welding since the putty is colored.

This creates a very strong bond between the parts, but it won’t be as clean as acetone welding since the putty is colored.

While it is best used with ABS, a plumber’s cement can also work to glue PLA parts together. Since you can find it in most hardware and general stores, it’s an easy solution if you are in a pinch. However, it doesn’t work well with PETG plastic.

Oatey 30889 Medium Bodied Solvent Cement, 8 Oz, Can, Liquid, Black

Check PriceABS Juice / Glue / Slurry

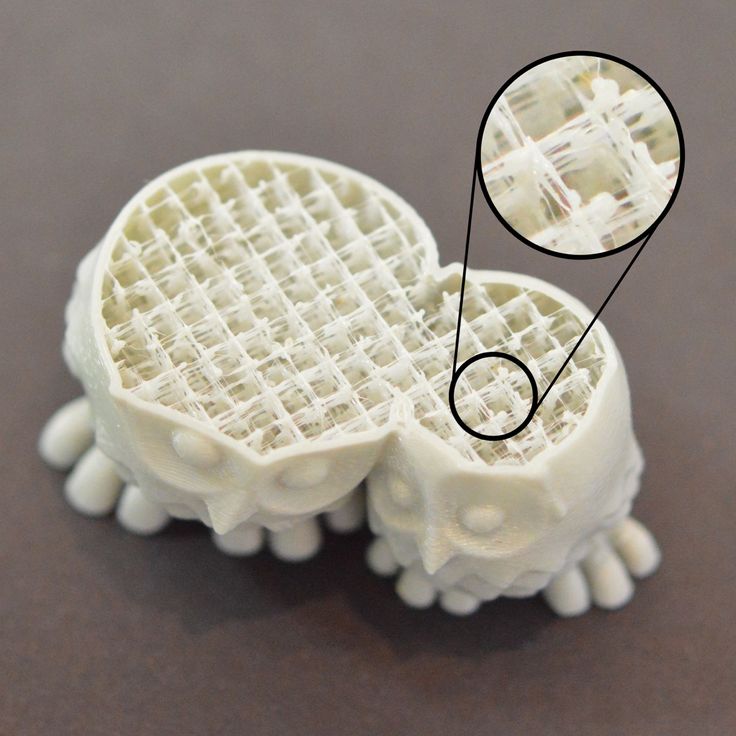

Easy to make yourself from ABS scraps (supports, failed 3D prints, etc.), ABS juice, glue, and slurry are the byproducts of ABS dissolving in acetone. All three of these products are great for forming bonds between two printed parts.

ABS juice is a thin milky substance that is brushed onto build plates for better print adhesions. ABS glue is a bit thicker and is ideal for joining parts together. The ABS slurry is the thickest in consistency and is used to fill in gaps, cracks, and holes in 3D prints.

You can make ABS juice, glue, or slurry by adding scrap ABS to a container of acetone and letting it dissolve (eventually the acetone used for ABS smoothing turns into a slurry as well). The more scrap you add, the thicker the resulting adhesive becomes.

Since these glues are made from acetone and ABS plastic, they are solvent-based. They will work well on ABS and similar plastics using solvent welding, but they aren’t the best glue for PLA and PETG.

Other Glues

The other adhesives listed above for PLA will also work with ABS. Superglue, urethane glue, and epoxy resin all work just as well with ABS as they do PLA. The 3D Gloop brand even has a formula specifically for ABS.

While all of these products technically can be used for ABS, solvent welding with acetone will almost always produce the best results.

What is the Best Glue for PETG?

PETG is one of the harder plastics to post-process. Paints, glues, and other materials don’t bond well with even the best PETG filament, but some work better than others. Superglue, Gorilla glue, silicone glue, and epoxy resin all work relatively well with PETG. 3D Gloop’s PETG formula is also worth trying, as it is one of the few products specifically formulated for the material.

Superglue, Gorilla glue, silicone glue, and epoxy resin all work relatively well with PETG. 3D Gloop’s PETG formula is also worth trying, as it is one of the few products specifically formulated for the material.

Frequently Asked Questions

Can you superglue PLA?

Superglue is the best option for gluing PLA together. It bonds quickly and forms a strong, lasting bond. However, it won’t work as well with other 3D printing filament types like ABS. For those plastics, solvent welding tends to be a better option.

Does Gorilla Glue Gel work on PLA?

Yes. Gorilla Glue Gel is a water-based contact adhesive that is specifically designed to work on both porous and non-porous materials. It forms an instant, permanent bond on contact and can be used on a wide range of materials, including wood, metal, plastic, rubber, glass, and more.

PLA (polylactic acid) is a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane. It is often used for 3D printing because it has a low melting point and does not release any harmful fumes when melted. Gorilla Glue Gel can be used to adhere PLA prints together or to attach them to a surface.

Gorilla Glue Gel can be used to adhere PLA prints together or to attach them to a surface.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,535 Reviews

Check PriceAre there special glues for 3D printing?

Yes, there are some adhesives specifically designed for gluing 3D prints. The 3D Gloop products we mentioned above are some of the most popular options, but your glue doesn’t necessarily need to be formulated for 3D printing. Many standard glues and adhesives work just as well (if not better) on printed plastics.

What glues work with all filaments?

Basic adhesives like superglue, Gorilla glue, epoxy resin, urethane glue, silicone glue, etc. all work with most of the common filament types. While some will work better with certain filaments than others, you can use any of them for finishing your 3D printing projects if they are all you have available.

The most effective way to use them is to focus on the best in each category rather than to try to find a one-size-fits-all product. The best glue for PLA and PETG is super glue, while solvent welding is the best glue for ABS.

The best glue for PLA and PETG is super glue, while solvent welding is the best glue for ABS.

How do you bond 3D printed parts together?

The most common way to bond 3D printed parts together is with adhesives. Many different types of adhesives can be used, but the most effective ones usually contain cyanoacrylate (CA) molecules. These adhesives are fast-acting and can be used to bond parts together in a matter of seconds.

Another popular way to bond 3D printed parts together is through the use of screws and bolts. This approach is often used when assembling large or complex structures. By using screws and bolts, it’s possible to create assemblies that are much stronger than those that can be created with adhesive bonding alone.

Will plastic glue work on PLA?

It depends on the type of plastic glue you’re using. Some glues will work better than others on PLA, so it’s worth doing some research to find the right one for your needs. If you’re looking for a strong bond, we recommend using an epoxy or cyanoacrylate adhesive.

Final Thoughts

When you need to bond 3D printed parts together, there are several options to choose from. While your standard super glue and epoxies work well for most types of 3D printing filament, things like homemade ABS glues, PLA welding, and friction welding are just a few of the other ways you can join 3D prints.

Whether you need to piece together a large model, fix a failed print, or join two different materials together, understanding how each glue works with the different plastics will make sure your bonded 3D prints are as strong as possible. The best glue for PLA is Cyanoacrylate super glue.

Do you still have questions about how to glue PLA or other filaments? Let us know in the comments!

(There is a solution) SLA resin post-processing: glue parts together

I recently bought an Elegoo Mars Pro 3D printer, and I was wondering when large pieces are printed that need to be printed in different steps: is there any post-processing, to make it more suitable for gluing?

I know about joints and so on, but sometimes the pieces are big but not thick enough to put a joint somewhere, so I think the only solution would be to glue them together. nine0003

nine0003

Should I use a specific adhesive to get the best results with resins? Is there any process (post-processing, reducing the layer height when printing, leaving the resin longer...) to improve the adhesion of different parts? Or can we go with any kind of "strong multilayer adhesive" without any further post-processing steps and the results should be the same in terms of quality?

Thank you!

▲ 1

As I found out after asking about the chemistry of 3D printing resin, the material uses radical polymerization to make a well bonded, branched copolymer. It is comparable to cast resin material, but more brittle. So let's see, akin to a PLA adhesive question, what can we do! nine0003

Step 0: Safety first!

Some of these methods work with chemicals that can irritate the skin (resins, cyanoacrylate) or have irritating or flammable fumes (heated cyanoacrylate).

Use proper protection when working with them! If necessary, use eye and respiratory protection, as well as gloves. Read the manual for the products you work with!

Read the manual for the products you work with!

Preparation

For most adhesives, it is desirable to prepare the surface: sand it very lightly to increase the surface area, do not touch the prints with bare hands to prevent fingerprints, etc. Follow the instructions!

Adhesives

As a result of chemistry, I would suggest the following adhesives:

- Resin itself! Carefully apply a thin layer of printing resin to the cured parts and then press them together before letting them cure again and you will have a good bond that may not even be visible since you have exactly the same material. However, please note that you can assemble the part between rinsing and curing for the absolute minimum visibility of the bonding surface and maximum bonding. Also note that for an opaque resin (completely opaque to 400nm light) it is better to look for another bonding system as the bond will be much weaker if it can only cure at the edge. nine0032

- Cyanoacrylate, aka Superglue.

This adhesive is pretty much an all-purpose adhesive, though it may fog up your surface. Also, not all superglues are the same, and some may work better than others or store differently.

This adhesive is pretty much an all-purpose adhesive, though it may fog up your surface. Also, not all superglues are the same, and some may work better than others or store differently. - Together with talcum powder, CA glue can easily fill gaps.

- CA is not stable when heated and when heated too much, if it decomposes into quite poisonous smoke!

- 2-phase epoxy or polyurethane. Other 9The 0042 category glues everything together, which should work pretty well. Epoxy bonds are stronger, polyurethane bonds are slightly more flexible, but both bond very well to the cured resin. Because resin prints don't actually deform when heated, you can go for even faster curing types.

- 2-Phase Putty - In the same vein, 2-Phase Putties like Green Stuff or Miliputt, which harden after mixing. Their heat dissipation is not too great, and they make it easy to fill gaps. However, my favorite material is not expensive model putty, but material from home depot: things like Pattex Repair sorry no english website for this or UHU Repair All Powerkitt cures in an hour, amazingly cheap and gets a smooth finish.

Other methods?

Unlike PLA, we cannot use thermal methods to add inserts, friction welding, or welding/soldering two parts together as resin prints are generally not thermoplastic.

, @ Trish

▲ 3

You can definitely use glue - however you can also smear some liquid resin around the edges of the two pieces, push them together and cure, this will hold them together.

You don't need much and you need to be careful not to let the drop drip out during curing (don't dip your fingers in it).

, @ Veegore

(There is a solution) What adhesives for PLA?

PLA is good, and bonding has been a topic on some of our most favorite maker channels. For example, Stefan from the CNC kitchen (this video) and Joel 3DPrinting Nerd (this video). Here is some information from them along with my own experience. By the way, most of these adhesives are not exactly specific to PLA and work for many other materials as well. However, be careful with PLA containing infilt, as this can seriously change its properties. nine0003

Here is some information from them along with my own experience. By the way, most of these adhesives are not exactly specific to PLA and work for many other materials as well. However, be careful with PLA containing infilt, as this can seriously change its properties. nine0003

Step 0: Safety first!

Some of these methods work with chemicals that can irritate the skin (resin, cyanoacrylate), have irritating fumes (acetone), or are flammable (acetone). Others (cyanoacrylate) are not heat resistant and break down into their components when exposed to heat.

Use proper protection when handling adhesive! If necessary, use eye and respiratory protection, as well as gloves. Read the manual for the products you work with! nine0084

Preparation

For most adhesives it is desirable to prepare the surface: sand it to increase surface area, remove grease from fingerprints, etc. Follow instructions!

Adhesives

- Cyanoacrylate - yes, one-size-fits-all is also the solution for PLA: Superglue.

However, be careful what type you get! Some are clearly better than others, and the use of an accelerator can change the properties of the adhesive.

However, be careful what type you get! Some are clearly better than others, and the use of an accelerator can change the properties of the adhesive. - Together with talcum powder, CA glue can easily fill gaps. nine0032

- CA is not heat stable and decomposes into quite poisonous smoke if heated too much! This can be handy for breaking metal-CA-metal bonds when machining small parts, but keep this in mind if you want to use inserts or plastic soles in the same areas! Do not contact CA in these cases.

- Epoxy is a favorite for very hard bonding, a few drops can stick a car to the roof... and it gets warm when cured. If you use a slow curing resin, you can safely use it to bond PLA without deforming the part. nine0030

- Uncured resins and their hardeners are highly irritating to the skin.

While they often stick to PLA, I personally don't like their adhesive power and often find them rather messy to work with.

While they often stick to PLA, I personally don't like their adhesive power and often find them rather messy to work with. Adhesive? Why glue?!

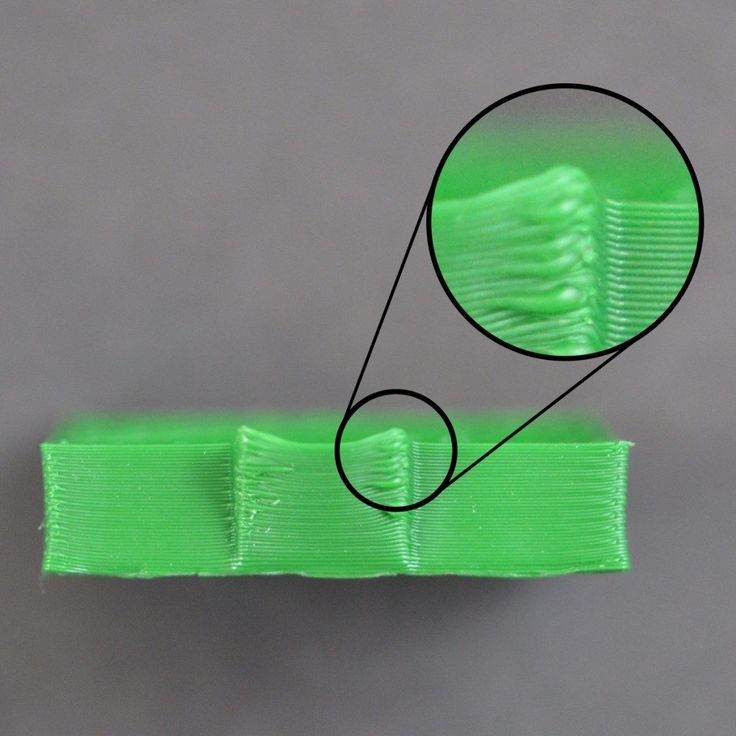

"Solder"

What better way to join parts than welding or soldering?! Often, none. My personal favorite is PLA glue - PLA itself, using it as PLA solder. This method also works for most other types of filaments, but is not recommended for ABS and other plastics that emit fumes without the use of respiratory protection!

- Take the pieces and make sure there is a cavity on both sides that can be filled. nine0032

- Take a soldering iron and set it to about 200°C.

- Take the length of the PLA filament.

- Melt the thread with a soldering iron and use it as solder when joining the two parts. Make sure at least some filament gets into the cavities and gets stuck there - it can help to stick the soldering iron into the goop there to get it to fuse with the filler/walls and press the hot pieces of PLA goop together against the iron before pulling it out by pressing pieces together.

- As the PLA cools and solidifies, the joint typically becomes more rigid than the actual layer boundaries. nine0032

Pen

Instead of using a soldering iron, you can also use the 3D printing pen , which eats filament, not PCL or some kind of gel! , but personally I don't like them.

Inserts!

On the other hand, a soldering iron is also a very good solution for making PLA inserts - heat a metal insert (like a nut) and press it against a smaller hole and it will mold the plastic around itself into a perfect fit without glue.